These suggestions and solutions for technical problems come from service bulletins and other technical information published by Mercedes-Benz, selected and rewritten for independent repair shops.

E-Class engine performance problems/Check Engine Light with Code(s) P03xx

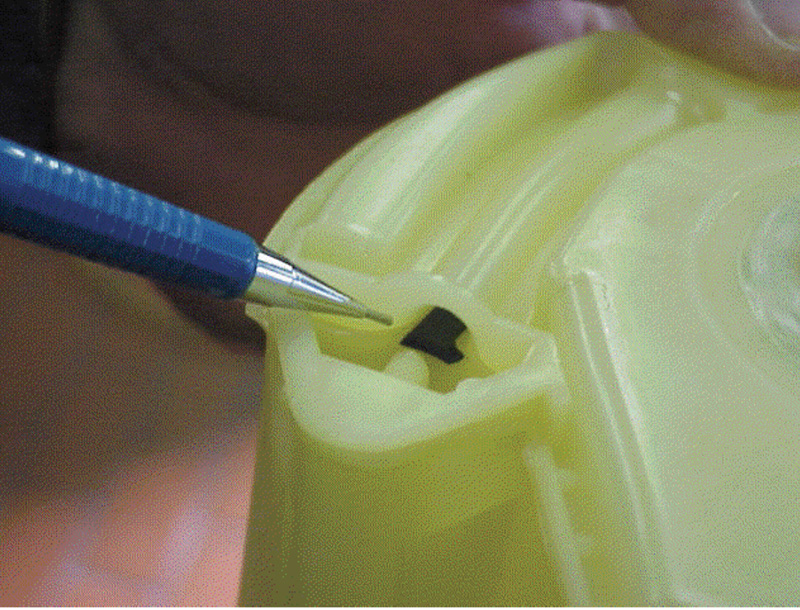

If you encounter an E-Class vehicle (W210) with a complaint of engine misfire/lack of performance with a low fuel level (below approximately one-quarter tank) and/or “Check Engine Light” (MIL) activated with code(s) P03XX (misfire detection), a possible cause is a lack of fuel supply due to an obstructed opening to the fuel pump in the splash bowl. If the tank level at the time of misfire was low, it is possible that the condition was caused by insufficient fuel entering the splash bowl, thus failing to feed the fuel pump. This is probably due to foreign material blocking the fuel supply hole. During a low fuel level condition, fuel enters only through the supply hole at the bottom of the splash bowl.

Perform the following procedure:

- Ensure all related systems are working and within specifications – repair as necessary.

- With your scan tool, check the freeze frame for “fuel tank level.” Write down the freeze frame data and clear OBD memory.

- Lower the fuel level in the tank to approximately the same level or lower than indicated in the freeze frame.

- Try to duplicate the condition as far as load and rpm are concerned as indicated on the freeze frame and see if the engine misfires and a code is set.

- Connect a fuel pressure gauge and drive the car with high load/rpm while monitoring the fuel pressure. It should remain constant.

Note: Make sure the codes are stored with fuel level at one-quarter tank or below (see freeze frame data) , i.e. below the top of the upper splash bowl rim, and that no fuel can enter the splash bowl from the top opening. If the misfire can be duplicated and/or misfire code(s) are set again during the procedure in Step 4 and 5, or fuel pressure starts to fluctuate during procedure in step 4, replace the fuel tank. If, on the other hand, during Step 4 no misfire is observed and/or no misfire code is set, and the fuel pressure remains stable during Step 5, the cause for the customer complaint is something other than described above and needs to be further diagnosed.

E420 Engine Does Not Reach Full Power in High Temperature Conditions

If a 119.985 engine is not producing full power when the ambient temperature is over 86 deg. F. (30 deg. C), the elbow from the air intake at the radiator grill may be partially collapsing during full acceleration from idle. Install improved intake elbow, part number A210 528 07 04.

Flywheel Sensor Problems on 1997 Models with M104 Engine

Hard starting, rough idle, lack of performance/misfire, and/or engine not revving higher than 2,500 rpm may be caused by corrosion or water in the plug of the flywheel sensor. This condition may set DTCs relating to flywheel sensor or misfire. Replace the flywheel sensor and plug.

Squeaking Steering Column in E320 and E430

If you encounter complaints of squeaking noises from the steering column, verify the noise with the engine off and the weight off the front wheels to eliminate any hydraulic noises from the pump and rack. Locate the source of the noise. If it is coming from the sealing boot between the firewall and the steering shaft, the boot should be replaced with Part Number A210 462 10 96 and be lubricated with the improved grease Part Number A001 989 84 51 10.

Note: For all other E models, do not replace the boot. Simply lubricate the existing boot with the improved grease on both sealing surfaces inside and outside the front bulkhead.

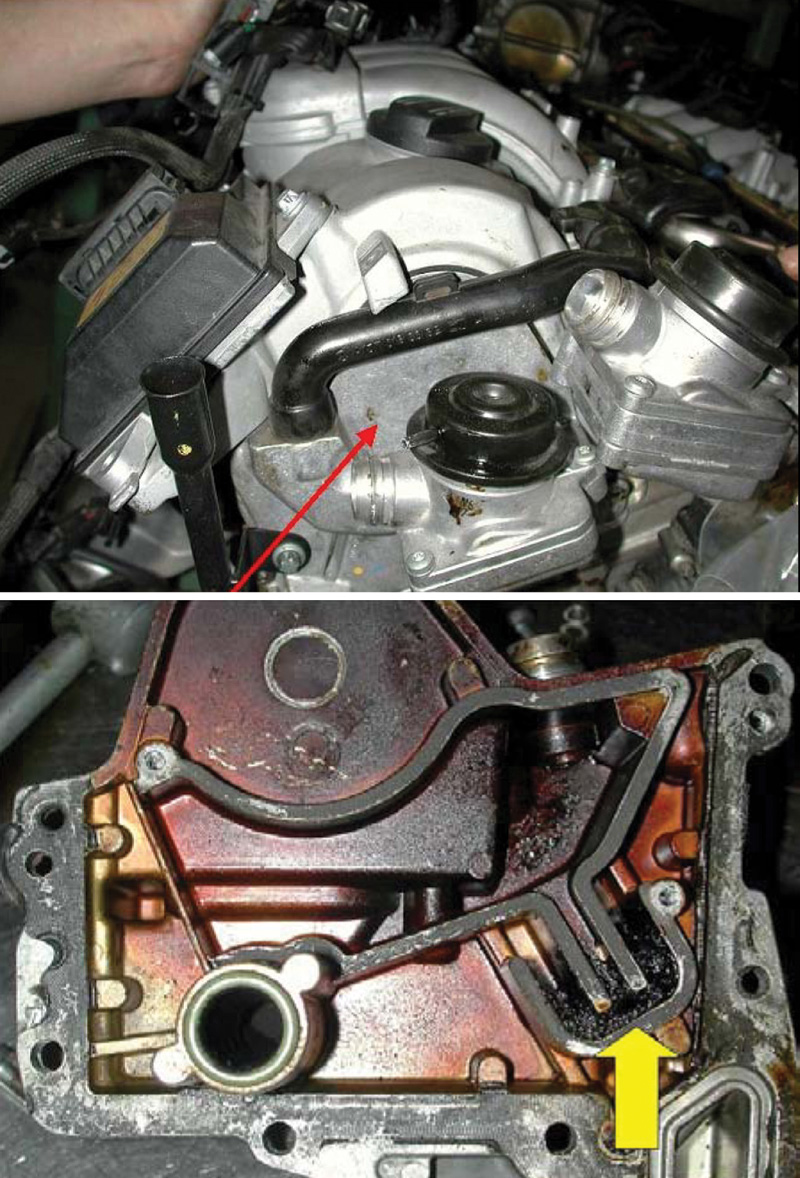

M137 Engine Running Complaints With Blue Smoke and/or Hydrocarbon Odors During First Start Up

M137 Engine Running Complaints With Blue Smoke and/or Hydrocarbon Odors During First Start Up

Engine running complaints/misfire in conjunction with blue smoke and hydrocarbon odors for several seconds during first start-up, and/or an excessive amount of standing oil in the intake manifold with an M137 engine may be due to a PCV (positive crankcase ventilation) System intake assembly (front cover, right cylinder head) oil condensation drain that is clogged with oil sludge.

Remove and disassemble the front cover assembly of the right cylinder head (refer to WIS document AR01.30-P-5700L, up to and including step number 14). Inspect the oil condensation drain for clogging and clean out the oil sludge blocking the drain. Reassemble and reinstall the front cover assembly of the right cylinder head.

Note: When performing oil and filter change, be sure not to overfill the crankcase. Refer to the Approved Service Products Booklet for approved engine oils.

Water Pump Leaking on All M- and G-Class Models with 112 or 113 Engine

If you receive a customer complaint of the water pump leaking on any vehicle with either the 112 or the 113 engine, replace the water pump only if it is clearly visible that coolant drips continuously from the vent hole.

Traces of coolant residue and wetness (formation of droplets) at the vent hole of the water pump are normal and therefore are not considered “leakage.” Water pump replacements under such conditions are therefore not justified.

A small amount of coolant in the groove of the pump seal is required for lubrication of the pump. Coolant droplets forming at the vent hole dry up and leave a distinct residue due to the high content of solid matter in the coolant (6g/100cc). This is particularly obvious on vehicles used for short distance driving with the engine being started and stopped frequently.

In a warranty situation, water pumps returned for leaking coolant will be checked very carefully and warranty claims might be debited if a pump is found to be in acceptable working order.

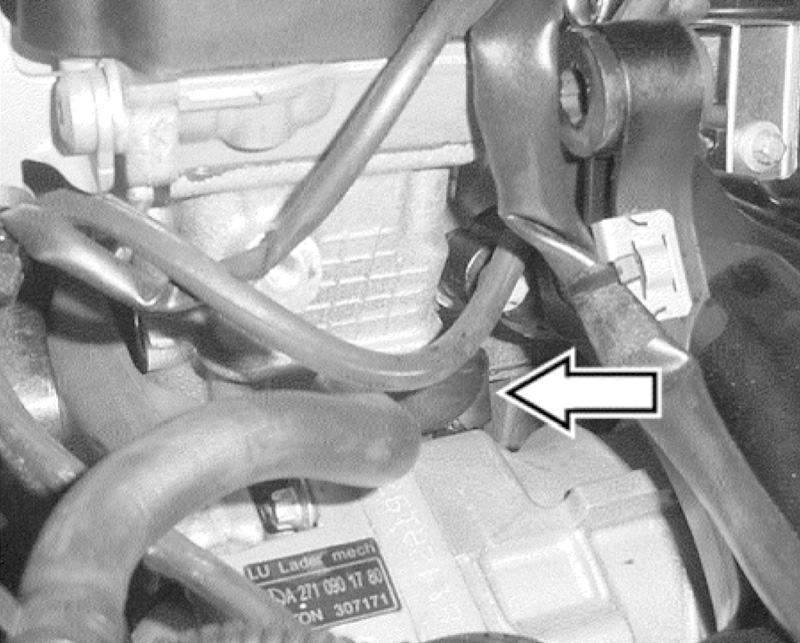

C230CL 1.8 Kompressor Engine Performance Complaint

Engine vibration, rpm fluctuations at idle, or poor accelerator response along with codes P2020 (P0172), P2046, P201C or P201A may be caused by a tear in the partial load vent hose at the connection to the crankcase. Air will bypass the mass air sensor — i.e. unmeasured air will enter the intake — causing the engine to run lean.

Engine vibration, rpm fluctuations at idle, or poor accelerator response along with codes P2020 (P0172), P2046, P201C or P201A may be caused by a tear in the partial load vent hose at the connection to the crankcase. Air will bypass the mass air sensor — i.e. unmeasured air will enter the intake — causing the engine to run lean.

The remedy:

- Remove the supercharger. Refer to WIS document AR09.50-P-4705QK.

- Remove and install partial load vent hose for crankcase ventilation.

- Install the supercharger according to the WIS document above.

Note: Use a “click clamp” as specified in parts information for securing hose. Ensure that the clamp is positioned as close to the end of the hose as possible and fastened tight.

Parts Information:

| Click Clamp | A005 997 49 90 |

| Partial Load Vent Hose | A271 018 04 82 |

A/C Compressor Switches On Frequently

Models C, E, CL, S, SL

If the air conditioning compressor as well as the mirror heaters switch on with an increased frequency, replace the multifunction sensor for the activated charcoal filter. The increased frequency of operation is a result of an incorrectly calibrated Convenience Automatic Air Conditioning multifunction sensor sending erroneous values over the CAN bus.

C Models with CODE (581b): Install AR83.40-P-6730P multifunction sensor.

CL and S Models: Install AR83.40-P-6730M multifunction sensor.

E Models with CODE (581a): InstallAR83.40-P-6730T Convenience Automatic Air Conditioning multifunction sensor.

SL Models: Install AR83.40-P-6730R multifunction sensor.

0 Comments