While most systems in late-model Mercedes-Benz vehicles are lasting longer than ever before, this is one area that still needs at least as much attention as it did in the past

Winter is probably not the time when you’re thinking about overheated engines, but this condition is more common than you might think in any season of the year. Summertime is when you might get more customers reporting that their cars are running hot — hardly surprising, since it’s hotter outside and you have the added load of the A/C condenser. But you need to think about the cooling system in the winter as well — they don’t call it anti-freeze for nothing.

To the layman, the engine cooling system is a simple undertaking: Just pump water through the engine to extract excess heat. But good technicians know better. There’s nothing simple about it, especially when there’s a problem to be located. The layman isn’t far off, however. It really is just a liquid used to move heat around. But, as we all know, the devil’s in the details.

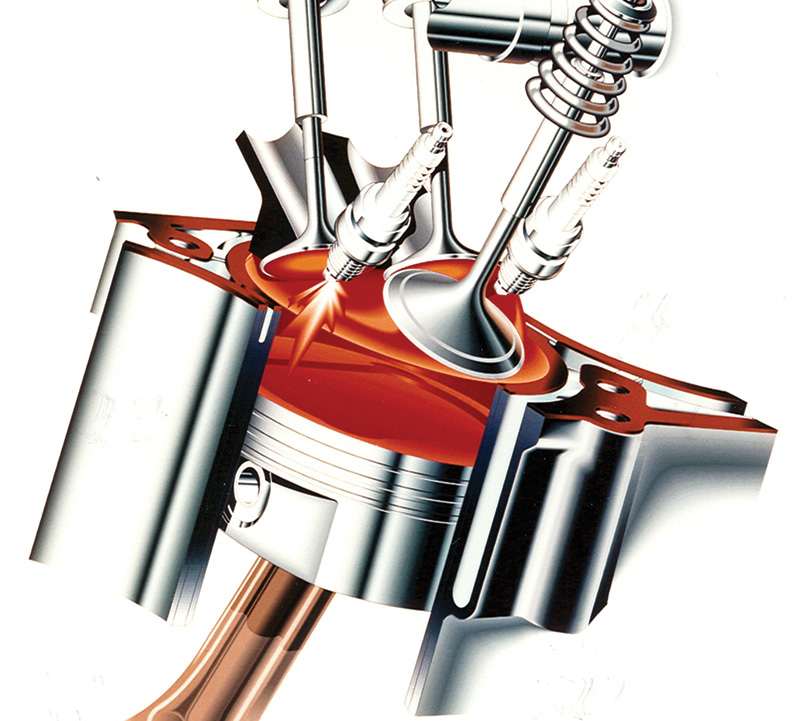

Although modern engines are much more efficient at converting the heat released in the combustion chamber into useful work than their predecessors were, there would still be plenty of waste heat left to destroy the inner workings if it were not carried away by the cooling system.

Waste heat

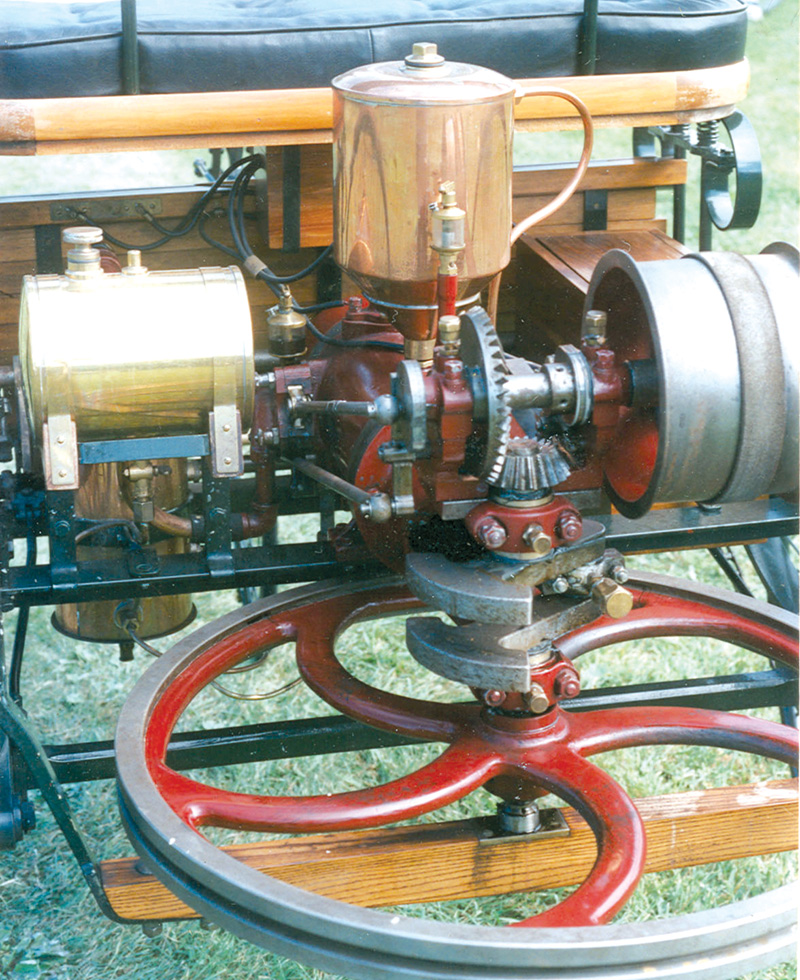

Even modern, fuel-efficient engines generate large amounts of waste heat — better than half the energy put into the internal combustion engine comes out as heat, not work. Left to itself, the metal of the engine would eventually melt if all that heat wasn’t managed. Air cooling just isn’t enough for a large engine, so, like the iron horizontal single in the very first automobile (the Benz Patent Motorwagen of 1886), we use water, or at least a mixture of water and some helpful chemicals. Bertha Benz, on that famous first car trip, used more than ten times as much water in keeping the engine cool as she did gasoline to make it run.

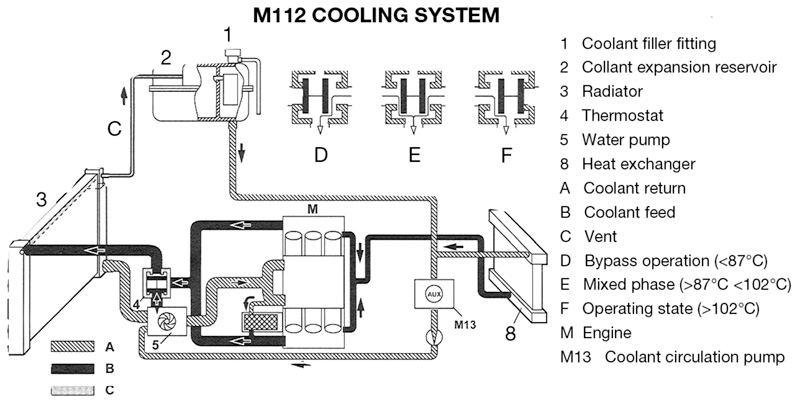

Engineers carefully create passages within the engine to allow liquid coolant to flow, extracting the excess heat both quickly and evenly. Heat always flows from hotter areas to cooler areas, which is actually the second law of thermodynamics, so the exact rate of heat transfer depends on the temperature difference. A greater difference means faster heat flow. If you don’t like your coffee too hot, delay adding the milk, which would cool it down, since the hotter black coffee loses its heat to the environment faster than the cooler milk-laden brew would. Engine designers know this, too, so the coolest water is introduced into the engine where the greatest amount of heat needs to be extracted.

The engine of the 1886 Benz Patent Motorwagen was water cooled, and that copper jug on top served as the heat exchanger. It wasn’t pressurized, however — the water just boiled off.

Even the flow rate is calculated for greatest effect. Mercedes engineers validate their designs every August in Death Valley, CA by driving in some of the hottest weather imaginable, with the A/C on, of course, to see if their calculations of thermal capacity pass the real-world test. Disturb any part of that carefully-designed system, and on a cool day you might not notice. But let it get a bit warm out, or start towing a load and you’ll see the needle pegging in no time, which can lead to catastrophic (and expensive!) damage.

Exchange and efficiency

Once you pick up all the heat, you have to dump it somewhere. While a little bit is useful in heating the passenger cabin, the bulk of the heat is transferred to the local environment by air flowing (forced by the fan and the forward movement of the car, and aided by convection) over the radiator. Again, heat transfer is proportional to temperature difference (called the “delta”), so the idea is to get the coolest air to flow over the hottest possible coolant. You see, the actual temperature of the system doesn’t matter much (as long as it’s within the limits of the materials involved), just the absolute amount of heat transferred in a certain time.

In other words, there’s a good reason why modern engines run hotter than those of just a generation ago: Efficiency. Hotter engines burn fuel better, and hotter coolant moves heat more efficiently. Everyone wins.

This diagram of an M-Class V6 cooling system shows that the coolest water is introduced into the engine where the greatest amount of heat needs to be extracted. Also, note the auxiliary coolant pump (M13).

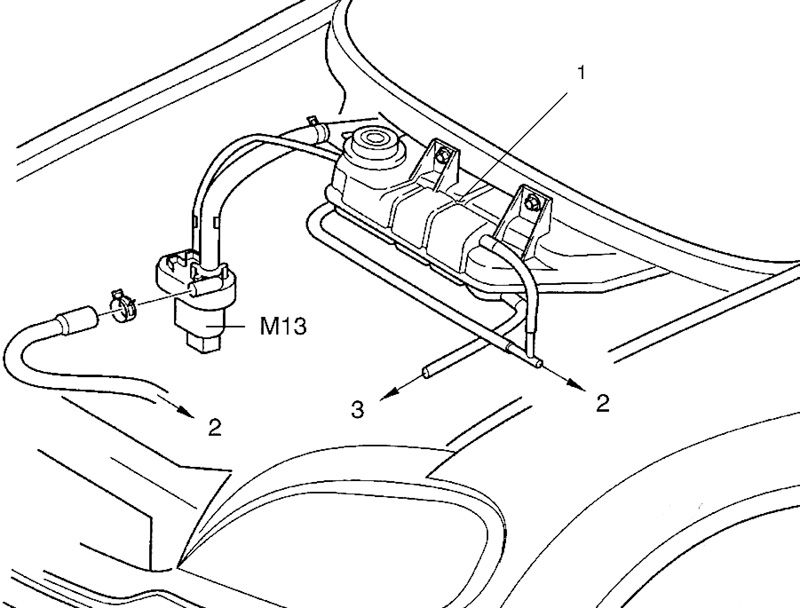

Some Mercedes models use an electrically-powered auxiliary coolant pump. Controlled by the All Activity Module, or AC push button unit, it maintains a consistent flow at low speeds, helps get heat to the cabin, and runs after the engine is shut off to prevent hot spots and heat soak problems.

Water vs. glycol

The ability of a material to absorb and release heat is known as its specific heat. Water has a very high specific heat, which means that it would be an ideal fluid for the movement of heat. The only problem is that it doesn’t have a great temperature range for that task — it boils and freezes under fairly ordinary conditions. Nonetheless, a cooling system running pure water would run the coolest. We had a neighbor who insisted on running 100% anti-freeze in his pickup truck. Despite our scientific explanations of specific heat and viscosity, he stated, “It runs hot already — if I added water, it’d really be boiling over, so I’m sticking with the pure stuff.” He never did understand why it ran hot in the first place.

Unfortunately, water also causes corrosion and deposit formation, which is a big problem in a cooling system since it clogs up the small passages in the radiator and engine and also interferes with heat transfer. While distilled water won’t cause mineral deposits and contains no harmful chemicals such as chlorine, it’s actually the worst for corrosion since it has a strong affinity for just about everything, which grows even stronger when it gets hot. To prevent this, we add at least a small amount of impurity, designed to satisfy the water’s thirst for metal.

Freezing

If the water temperature falls below the freezing point, it freezes. Seems obvious, but that’s the most important reason to add even more impurities to the cooling water, to prevent it from freezing. Frozen water does not circulate, and it cannot carry the excess heat away. Although the heat of the engine will quickly melt what’s in the block, that heat will never reach the radiator. If that weren’t bad enough, water has a very nasty surprise for us when it freezes.

Most materials shrink when they get cold, and expand when they get hot. A mercury thermometer is proof of this, and the effect is very linear across a wide temperature range. Water, though, is different: Cool it down and it contracts, all right, until about 38 deg. F. Then, it starts to expand again. By the time the water freezes, it has expanded a few percent and, since it’s now a solid in a confined space, it has the power to crack open the strongest engine block. Freeze plugs are installed in the block to help relieve the pressure, but they are not always effective.

Modern anti-freeze uses ethylene glycol and other chemicals to lower the freezing point of the coolant to some range that’s determined by the percentage of water in the mix. A 50/50 mixture freezes around -34 deg. F., plenty of protection for most places. If you live where it gets colder than that, move.

Boiling hot

Similarly, the anti-freeze also raises the boiling point of the water slightly, but that effect is hardly worth mentioning. Not that it’s too small to be of notice, but it’s really not necessary — we can also raise the boiling point of water by increasing the pressure contained in the cooling system. At one atmosphere, pure water boils at 212 deg. F. Add 50% anti-freeze, and that goes up to 225 deg. F. Raise the pressure to 2.4 atmospheres (about 20 psi) and it now boils at 275 deg. F. Although the anti-freeze helps with boiling point, it’s the pressure cap that allows modern engines to run at 120 deg. C without overheating.

Neglected coolant maintenance, or the use of the wrong anti-freeze, will not only lead to clogging and inefficient heat transfer, but also to component erosion/corrosion and leaks at connections and joints.

Corrosion and goop

Even though adding anti-freeze to the cooling system actually reduces its efficiency (as we said, by reducing the specific heat of the fluid) and it’s not really necessary for boiling protection (that’s what the pressure cap is for), there’s still a good reason to use it: corrosion protection. Metal corrodes, rust for iron and steel, and white oxide for aluminum, and when that happens inside an engine, it can’t be good. Increase the temperature, and the chemical reaction speeds up. While most anti-freeze solutions provide reasonable protection against rust, not all work as well on aluminum. Mercedes-Benz has used aluminum blocks for a long time, and their anti-freeze solution is carefully formulated to prevent aluminum oxide.

In the shop, it’s always obvious which cars used the real stuff, and which the heavily advertised generic. Aside from color, the goop that forms with the generics is simply absent from the cars using the M-B anti-freeze. That goop, made of chemicals in the anti-freeze that react with the metal of the cooling system, turns into sludge and eventually gums up the whole works. Generic might be a little cheaper, and it’ll do in a pinch, but we always use the real stuff in our own cars.

The hydrometer has been the standard tool for gauging the percentage of anti-freeze in the coolant blend for decades, but a refractometer is far more accurate and dependable.

Reality check

With that review of essential cooling system theory out of the way, we can move on to applying the science for practical purposes. How many times have you had a customer come in and say, “It’s running a little hot. Can you have a look at it?” Hopefully, the driver actually understands the normal temperature for his car, and now sees the gauge registering higher than usual. In case you didn’t know, a Mercedes engine isn’t overheating until the gauge hits the red, usually around 120 deg. C. The point is, an engine that ran at 95 deg. C when it was new might regularly hit 105 deg. C after some miles, and that’s not a cause for major alarm.

The first step is to have a look at the coolant – with the engine cold, of course. Imagine the danger of suddenly releasing the pressure on a cooling system that’s above the boiling point. Because the pressure is released, everything in the entire system boils all at once, causing the scalding hot coolant to spew wildly about. Anyway, the coolant should be clean, clear and bright, not murky and clumpy. Using a hydrometer or refractometer (the better choice), check the percentage of anti-freeze. As we said, too much will cause an engine to run hotter.

If you can peer inside the radiator (maybe by removing a cap or hose, or perhaps by pressing a boroscope into service), that can give you some big clues on the system’s condition. Heavy whitish corrosion and/or colored jelly are signs of a system in trouble.

If a leak isn’t obvious, a pressure tester is still the first thing to use to locate it. Pump up the system, then look around under the hood with a good light and listen carefully for hissing.

Flushing

If the overheating is mild, and has built up gradually over time, then cleaning out the cooling system will probably do the trick. Mercedes sells powdered citric acid for this purpose, which you mix with water and run through the system (after draining it, of course) for a few minutes, and then flushing out the system again. Draining a Mercedes engine properly takes more than just opening the radiator petcock. Don’t forget the drain plugs in the block as well. In every case, there is a published procedure, and it’s always best to look it up or ask your local dealer about it.

A basic flush without the acid cleaning is also an item on the regular maintenance sheets, and should be done as a matter of course every few years, depending on the model. After a few years, the additives in the anti-freeze can turn acidic and slowly but surely cause permanent damage. A simple drain and refill, as with brake fluid, can prevent a lot of problems for little cost. We’ve never been fond of extended-life claims for coolants because this maintenance is relatively cheap compared to the repairs it might prevent.

Sometimes a flush helps, sometimes not. If there is a faulty component in the system, it needs to be replaced. While we most frequently find components whose only fault is a leak, these are rarely the cause of overheating. Coolant loss can be from a simple hose, connection or heat-exchange component leak, or from a more serious problem such as a blown head gasket. Pressurizing the system with a hand pump is still the primary method of locating leaks. Combine that with your boroscope inserted into the spark plug or glow plug holes to search for head gasket leaks. Of course, you know to look for telltale whitish residue.

In hard cases, nothing will work better than adding fluorescent dye, running the engine, then looking around with a UV light.

Note that a small drip from the weep hole at the bottom of the water pump housing is completely normal. The coolant helps lubricate the pump shaft seal, and a few drops will always get past.

After you get a basic understanding of heat flow from using a non-contact infrared pyrometer on normal systems, it can help you locate clogs and hot spots.

Clogs

If the overheating started suddenly and ferociously, then there’s probably something impeding the flow of coolant. A common suspect is the thermostat, but don’t just drop in a new one and call it a day. Personally, we’ve found chunks of rubber hose, cigarette butts, and a handful of leak-stop particles clogging up the works, sometimes in unexpected locations.

When you get a complaint of no heat, you need to check the heater core circuit for clogs. If a flush makes no difference, check water flow using a garden hose. Be sure to open the mono-valve by removing power from it, or opening the heat valve in older cars, or nothing will flow.

Components

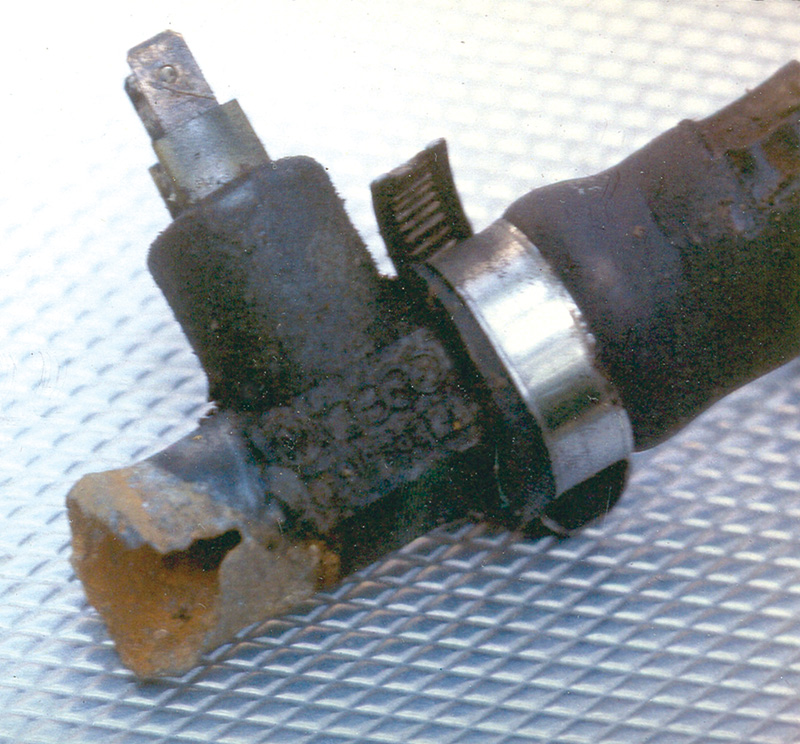

In difficult cases, you may have to remove components from the system and check them individually. Thermostats are checked in a pot of hot water with a thermometer. The radiator is checked for flow with a garden hose (with the engine cool as you don’t want to cause thermal shock). Try running the water through backwards, and any crud will get washed away. Anything less than full flow needs to be corrected. Hoses are inspected on the inside carefully by eye, finger and flashlight. If you find any deterioration or sponginess, replace it, even if chunks aren’t falling off it. They’re cheap parts compared to a ruined engine.

Check the water pump as well. Some aftermarket pumps have been known to have large clearances between the impeller and body, hurting pumping efficiency, and there have also been cases of loose impellers. Mercedes-Benz pumps are quite reasonable, and warranted, of course. And don’t forget to check the pressure cap because if it blows off at too few psi, there will be coolant loss, and if at too many psi it may cause some other component to start leaking.

One frequently underestimated component is the fan shroud. If missing or damaged, average operating temperature will increase by perhaps 10 deg. C. While you’re there, make sure the engine fan is working properly by seeing that it’s spinning well with the engine running, and reacts when you rev it up. Also, run the engine long enough to ensure the electric auxiliary fans kick in — run the A/C to speed up that process. Blown fuses and worn motors are not unheard of.

If the overheating complaint is not due to one of the removable components (thankfully, it usually is), then you have your work cut out for you. Most customers wouldn’t pay for an engine teardown for a mild overheat complaint, so you’re limited to inspecting what you can, making sure the system is clean, having the right anti-freeze mix in there, and being reasonable about what constitutes overheating. Having the gauge edging near the red when idling in beach traffic in July with the air conditioning on is not necessarily an indication of system trouble. Educate your customers on how to help the system cope with severe conditions — shifting to neutral to remove load, holding the throttle open a little when the car’s not moving to increase pumping speed and get that fan spinning, even shutting off the A/C, if necessary.

By the way, the possibility of overheating incidents is one reason for the trend at M-B toward synthetic motor oil. Sure, it costs more, but it can avoid incredibly expensive internal engine damage because its film strength holds up at far higher temperatures than does that of ordinary oil.

Although pure water carries the most heat, we need to treat it with anti-freeze to keep it from damaging the engine and cooling system components. A regular maintenance program of coolant replacement, along with inspections of hoses and other components, helps prevent catastrophes. When problems do occur, they need to be diagnosed just as carefully as those in any other system, and addressed. While the cooling system may seem simple, it is one of the more complex and critical mechanical systems in the vehicle.

0 Comments