Are you taking it for granted that you have a solid understanding of the system that keeps the battery up? Keep reading, or risk damaging expensive components and arriving at faulty diagnoses

Once upon a time, any technician with even a little experience knew almost everything there was to know about automotive starting and charging systems. There was a battery, alternator (or, if we go back far enough, a D.C. generator), starter and an ignition switch and solenoid set-up, and that was about it. Five minutes with a test light and a screwdriver would get you to the root of the problem, and everyone lived in harmony.

While the basics haven’t changed much, the details sure have. Dual-battery systems, 220-amp alternators, AGM batteries and intelligent load management have all been introduced since the last time you studied the topic, so we’ll present a refresher course to bring everyone up to speed.

We don’t have the space to deal with starting systems today. With the advent of electronic starting systems like Keyless Go, to cover the topic adequately would take a whole article in itself. StarTuned will do that, but in a future issue.

Without all these parts working together to produce the amperage a modern vehicle requires, driving trips would have to be short indeed.

Square one

Let’s start with the most basic basics. You need a battery to store power, so it can supply power while the engine is not running (and power to get it running). You also need an energy source to keep the battery topped up and to supply power to the vehicle while the engine is running, usually in the form of an alternator.

Although we all know that cars run on a 12 volt system, that’s a “nominal” voltage. A fully-charged lead-acid battery has a terminal voltage of about 12.65 volts. To charge this battery, we’d need a voltage around 13.8 to 14.2 volts depending upon temperature – high enough to charge the battery fairly quickly, but not so high that it reaches the “gassing voltage”, which is about 14.4 volts. Exceed that voltage, and the water breaks down into free oxygen and hydrogen very rapidly, and the battery “boils” dry. In addition, the released H2 is explosive.

Charging a battery at high current also hurts it. Ideally, you should never charge at more than five amps, but to maintain realistic charging times we commonly bump that up to 20 amps.

Soaked up

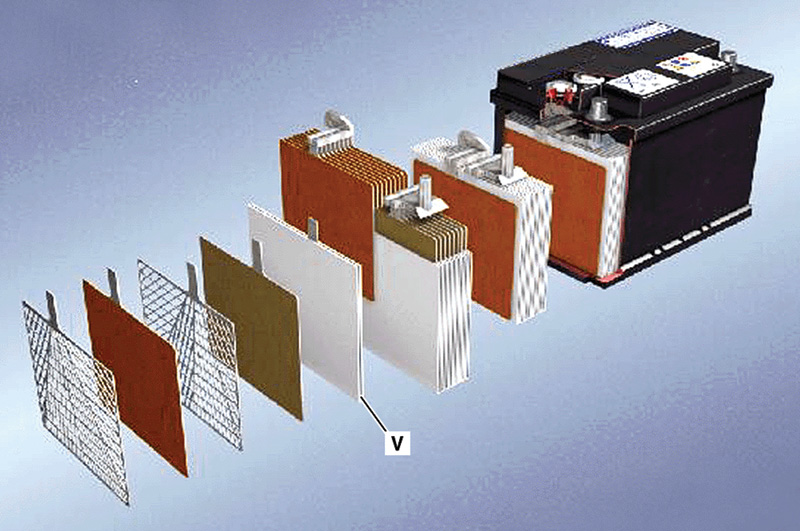

The latest thing on the market is the Absorbed Glass Mat (AGM) battery. This adds glass matting, or ‘fleece’ (think attic insulation), to the inside of the battery. The fleece absorbs all of the sulfuric acid like a paper towel while allowing it to circulate enough for the chemical activity necessary. The advantages of an AGM battery are increased service life, ability to withstand a deep discharge, and – most importantly – they are non-spillable.

In this cutaway of an AGM battery, you can see the fine white fiberglass mats (V) that hold the electrolyte.

By non-spillable, we mean that the normally liquid acid is captured inside the battery. One of the tests for the ‘non-spillable’ rating is to drill a series of 6 mm holes in the bottom of the battery case – yes, with the acid in there – and to place it onto a sheet of blotter paper for 15 minutes. If any acid leaks out, the test is failed.

Don’t confuse AGM batteries with the older gelled-electrolyte batteries commonly used for low current applications. This type of battery is not suited to supplying the high currents for, say, starting an engine, while the AGM will happily act as the source of hundreds of amperes.

Although the sulfuric acid is said to be diluted, it’s still plenty powerful, and therefore dangerous. Ask anyone who has spilled some on his or her skin, or, heaven forbid, splashed some into his or her eyes. Acid contacting you anywhere is a medical emergency, calling for lots and lots of water and, in many cases, a precautionary trip to the Emergency Room. Don’t discount the seriousness of battery acid — it keeps on eating away at your flesh for hours after exposure.

Considering the sobering nature of battery acid, you can easily understand how much safer an AGM battery can be for all involved. In modern vehicles, where tight spaces have moved batteries into the trunk and passenger compartments, it becomes absolutely critical to replace the battery with the proper type.

This MB-approved electronic battery tester takes you way beyond the traditional means of diagnosis, and it gives you a definitive answer in a minute or so without applying a load.

Suitable equipment

It’s very important to adhere to the 20 Amp limit with AGM batteries, since they’re more easily damaged by rapid charging. A special 20-ampere fully-automatic charger is the only Mercedes-Benz approved way to recharge an AGM battery (Part Number 110-9420).

Battery diagnosis has gone beyond the hydrometers and carbon piles of the past. Today, Mercedes-Benz recommends the use of a no-load battery tester, specifically the Midtronics MCR717, available as a special tool through MBUSA (Part number W900 589 09 21 00). It provides a definitive answer on battery condition in about a minute – Good, Bad, or Charge & Retest. Of course, a load test can still be performed, but the new AGM batteries do not lend themselves to a specific gravity measurement, making an accurate diagnosis difficult with a traditional VAT.

If you find that the battery is marginal or dead, the best bet for both you and your customer is a Genuine Mercedes-Benz replacement. You may be surprised to learn that the prices are competitive with the local parts store, and the quality and warrantee are top notch. Not to mention that it will always fit.

Before installing that new battery, you need to find out why the old one died. Did it just fail because of age? Is excessive rest current draining the battery? Did the customer leave the lights on? Is the alternator doing its job? Is the accessory drive belt slipping? Does the car get driven enough to keep the battery charged? Is there something else causing the problem? Finding the answer isn’t always easy, but it’s the right way to fix the complaint. Remember, if it happens again, you can be sure the customer will be right back in your shop, and a lot less happy.

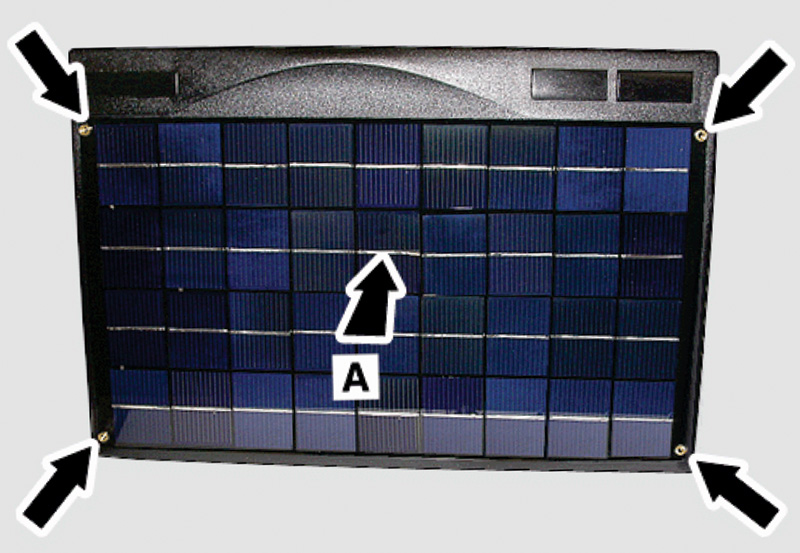

Attach this solar panel to a south-facing window to maintain the battery of a car that’s not driven often. The arrows indicate the location of the suction cups.

Two batteries, no waiting

Now let’s have a look at some of the new things under the sun. The first is a dual-battery system, introduced with the SL-Class (230 chassis) in model year 2003, and also installed in the E-Class (211 chassis) and subsequent models. This system uses a relatively large starting battery, located in the trunk, coupled with a small battery for lighter electrical loads. These two batteries are connected through a Battery Control Module, which regulates the charging and discharging of the two batteries, as well as handling load management.

The battery control module measures the load capacity of the main battery, actual current flow to loads, and can take active measures to stabilize the electrical system. These measures include bumping up idle speed, connecting the auxiliary battery to the system via a relay, or shutting off non-essential consumers through the CAN Bus.

This means that, under certain electrical conditions, some electrical features may not work, while at other times they function normally. While it is beyond the scope of this article to get into the gory details for each model, just remember that all of this and more is available 24/7 in the MB Workshop Information System (WIS), online at www.startekinfo.com.

Jump-starting a dual battery system must be performed exactly as described in the owner’s manual, or damage to the battery control module or other components could result. Connecting jumper cables to the wrong battery might turn into an expensive lesson.

Trickle-down theory

If the car sits around a lot – not unusual for an older vehicle, particularly a sports car that isn’t a daily driver – the battery might need more charge than the alternator is able to provide in the abbreviated opportunities it has. This is especially true if the vehicle is driven mainly on short trips, where the battery has to start the engine frequently, without enough running time for recharging.

MB sells a fully-automatic trickle charger exactly suited for cases like this (Part Number B67542024). Connected either by means of alligator clips directly to the battery, or through a socket that you install in a convenient location for the customer, the trickle charger is left connected the whole time the car is parked. Priced around $100, it’ll ensure the battery is kept in tip-top condition. As a bonus, it can also be used to keep the motorcycle or lawn tractor battery happy.

If the car is kept outside, another possibility is the solar panel (Special Tool Number W900 589 02 6300) that you mount on a suitable window with suction cups. While its ability to produce current is small, it should be enough to prevent the battery from running down even if the car isn’t driven for long periods.

Draw poker

Testing the rest current draw in a dual-battery system is different from what’s done with ordinary systems. As a matter of fact, testing the rest current draw in cars equipped with a Controller Area Network (CAN) bus (most MB models from 1998) is fairly complex – you have to wait for the bus to go to sleep (usually 15 minutes, but sometimes up to 65 minutes) before the rest current drops to normal.

Normal rest current should be under 60 mA (0.060 Amps) — with older cars, far below that. You’ll always have some rest current – for the clock, the alarm system, and a few other always-on systems – but locating a larger draw can get frustrating. Although it’s beyond the scope of this article to provide specifics, the general procedure is to isolate and measure. Once the CAN bus goes to sleep, start removing fuses to locate the general area of the excessive current draw. Keep reducing the search area until you find a promising candidate. Then, restore the whole system and work down the path just identified.

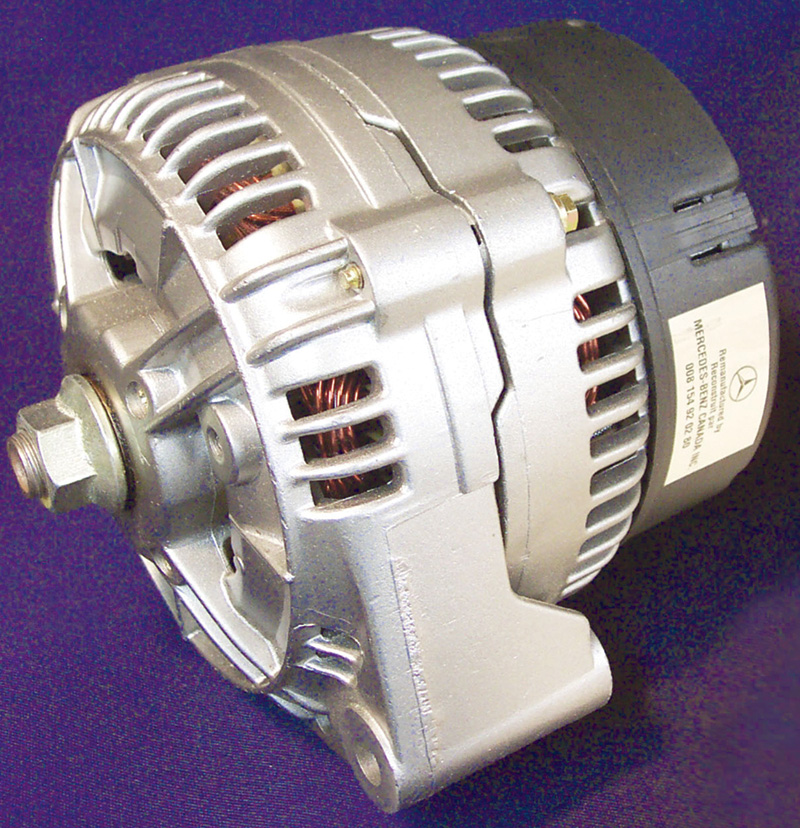

Is this an alternator or a generator? It’s all a matter of semantics, but we believe the term “alternator” makes a useful distinction.

Alt or Gen?

Alternators are also new and old. A basic alternator is a self-exciting AC generator, producing three-phase alternating current, which is converted to direct current (DC) and electronically regulated to a nominal 12 volts for supplying vehicle systems and keeping the battery charged.

Even though the terms generator and alternator are often used interchangeably, the difference is that a generator produces DC and an alternator produces AC. So, even though the car’s alternator produces AC, it gets converted to DC by means of diodes, so the technically correct term would be generator. At least, that’s what the Society of Automotive Engineers (SAE) has determined. But, we need to differentiate between actual generators, which use permanent magnets and a commutator to generate only DC (not seen on new cars for four decades), and the modern generators which use electromagnets to generate a magnetic field and convert their AC to DC. Many technicians call the modern version an alternator, a convention we will follow, although all automobile manufacturers are obligated to use the term “generator” since the EPA accepts the SAE definitions.

The old-style generators had heavy armatures, and because of that could not be allowed to spin as fast as an alternator, lest they fly apart. The lower speeds limited the amount of current they could deliver at idle. An alternator is much lighter, and can be spun at two to three times engine speed right up to redline. So, it has a much flatter charging curve, delivering a substantial amount of energy even at engine idle.

Field work

A self-exciting alternator has nothing to do with alleviating boredom; instead, it means that coils of wire are used to generate the magnetic field, through which other coils of wire are moved to generate electricity. But, an alternator cannot start producing electricity until it can build up a magnetic field, and it can’t build up a magnetic field until there is electricity – a Catch-22. The solution is to use the vehicle battery for the so-called bootstrap current.

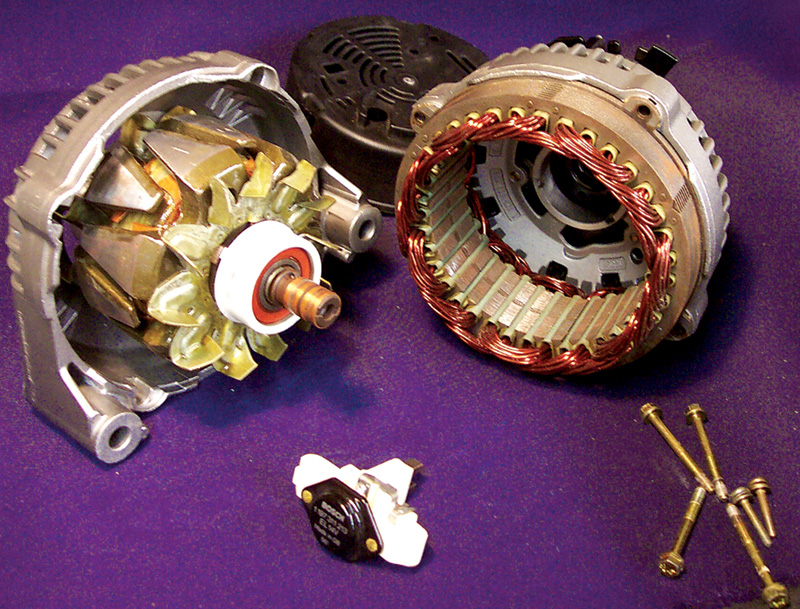

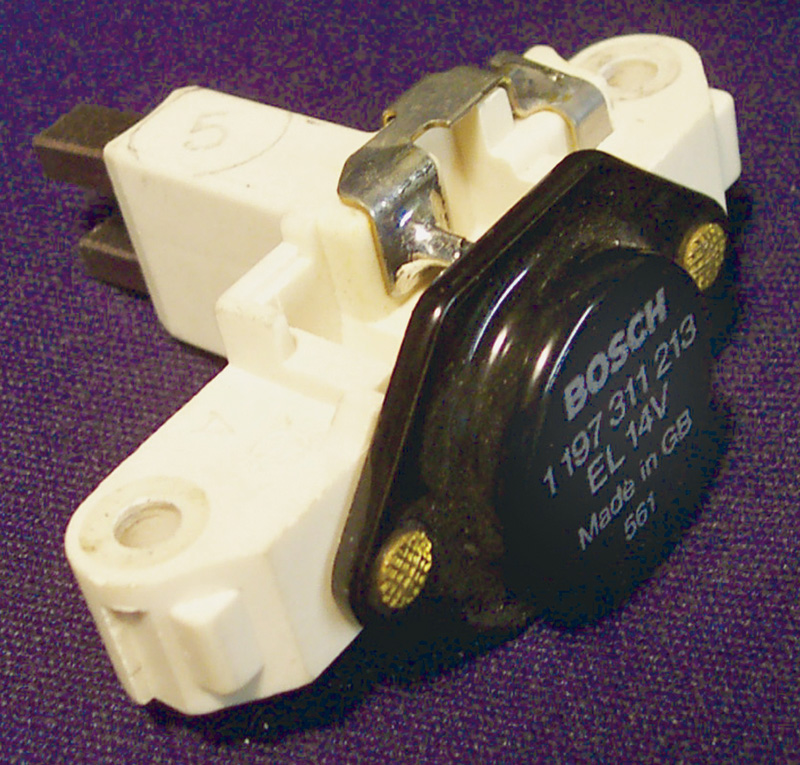

A small amount of electrical current is allowed to flow through the spinning electrical coils, which, once a certain shaft rpm is reached (about 1,400 or so), rapidly increases until the magnetic field builds up to full strength. Carbon brushes carry the current to the spinning coils, and these brushes are usually a part of the voltage regulator assembly. The voltage regulator works by limiting the current through the brushes to the coils, modulating the magnetic field to maintain a constant output voltage despite varying loads, speeds and temperatures. The regulator assembly is also available separately as a spare part – no need to replace the whole alternator.

Details

With the newer alternators, expect current capacities well in excess of 150 Amperes. This means that wiring and electrical connections become much more critical. For example, a tenth of an ohm (0.1) might not seem like much, but at 200 amps that means a power loss (into heat ) of 4,000 watts – enough to heat a room. Thankfully, modern wiring methods help avoid such cases of high resistance, but cleanliness (and tightness) still count.

Some newer alternators are water-cooled. It’s easy to spot the coolant lines, but if you’ve never heard of the concept, having anti-freeze pour out of an alternator may be disconcerting. While still not commonplace, it’s not unheard of, either.

As in the old days, a burned out charge lamp in the instrument cluster will prevent the alternator from self-exciting: The initial current we spoke about earlier flows backwards though the light bulb from the battery. In most cases, there is a resistor in parallel with the indicator lamp to ensure that enough current flows – a 1.2-watt light bulb just isn’t large enough. Suspect an issue with this circuit if the alternator never excites itself.

A very noisy alternator can be caused by a bad bearing – unlikely unless the car has high miles — or a blown diode. A shorted or open diode puts an unbalanced mechanical load on the alternator shaft, causing it to vibrate. Modern testers can identify a bad diode in a few seconds by picking up ripple voltage. You can’t test the diodes individually unless you open the alternator, which is not advised unless you have no other choice.

We’ll sum up with a list of tips:

- Good grounds are always important, and the central ground in any vehicle is the back half of the alternator.

- Replace batteries with the same size and type only. The wrong battery could fail prematurely, or become a safety hazard in a crash.

- Be sure to install the vent tube and vent plug from the old battery into the new battery. Battery gases are explosive, and must be vented properly. If unsure, consult a dealer.

- Follow all safety precautions when working with batteries. An exploding battery can ruin your day – or your life. If you’re not familiar with all of the many safety procedures necessary for working on and around batteries and charging systems, find experienced help.

- If the vehicle battery is discharged, find out why before you replace it, or you’ll just end up with a comeback.

0 Comments