As testament to how integrated today’s BMW models are, you can actually get data on clutch operation from a GT1.

The worst thing that can happen with a clutch job is that it fails to resolve the customer’scomplaint. Before dropping a transmission, what can the service writer and tech do to ensure that clutch removal and replacement will actually resolve the complaint? First, adequate time must be invested in fully understanding the customer’s concerns. Second, diagnosis should rule out all possible external causes of clutch complaints before the transmission comes down. These practices will not only save the shop time, but may also save the customer unnecessary expenses, and prevent some very unpleasant comebacks.

Clutch diagnosis begins by confirming the customer’s complaint. These generally come in four manifestations: noises, pedal Feel, clutch actuation, and engaged operation. No two clutches feel exactly the same. Pedal height, pressure and speed of release that are acceptable to one customer may be unacceptable to another. Riding along with the customer to fully understand his or her perception of the problem is especially worthwhile on these high-ticket repairs.

Defining Clutch Feel

The feel of a clutch is determined by a number of factors, including the spring rate on the pressure plate, pedal leverage, the pedal over-center or return spring, free play and so forth. Several items particularly affect the engagement feel on a BMW. One is the Clutch Delay Valve (CDV), or “lock” valve, which limits the rate of clutch engagement by restricting the flow of hydraulic fluid. Self-adjusting clutch features attempt to maintain a constant pedal height. These noticeably affect feel, in a manner not all drivers are accustomed to. Lastly, a dual mass flywheel, because of its greater mass, and increased torsional dampening, will affect engagement feel. Ideally, the hydraulic system itself is neutral in terms of feel. However, a sticking master or clutch cylinder can further slow down clutch travel, thereby affecting engagement. Binding of the release bearing on the splines, fork, or input shaft sleeve can similarly affect feel.

No matter how well designed and manufactured, the release bearing is sometimes the cause of noise when the clutch pedal is depressed.

The most frequent complaint regarding engaged clutch operation is slippage. When you have a clutch that slips under high-torque situations, the usual suspects are, “Friction surfaces on the disc worn down to the rivets” or “Oil contamination.” But that’s not necessarily the case. What if the clutch simply isn’t disengaging fully? Something as simple as a lack of free play on the clutch pedal can cause slippage. Adjusting a pedal, or clutch linkage is a lot faster and less expensive than replacing a clutch disc, only to find the problem is still there. Or, does this model have automatic adjustment? Could it have failed?

Release mechanism

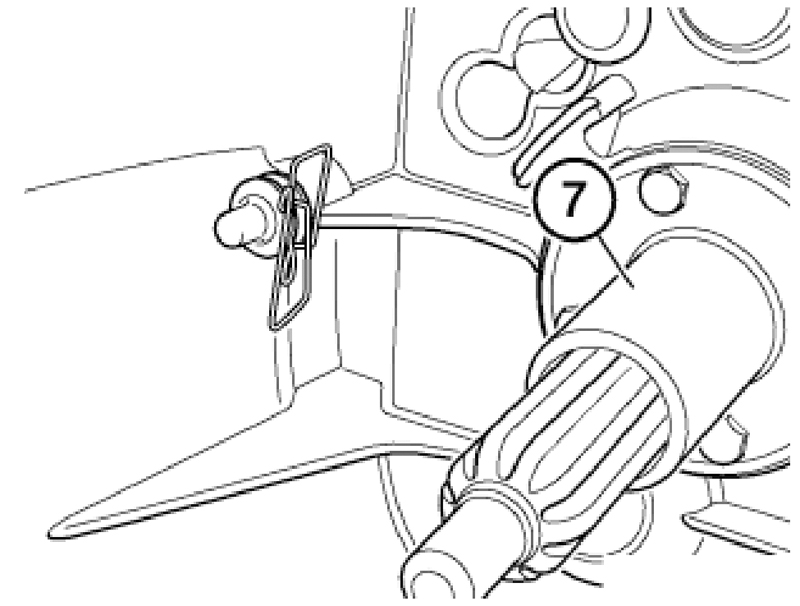

Contrary to popular belief, you should never grease the release bearing guide sleeve as it may cause sticking.

Pedal and hydraulic system issues often masquerade as clutch issues. The first diagnostic step should be measuring the “throw” of the slave cylinder, and comparing it to specifications. When a clutch won’t fully disengage, it makes it difficult to put the transmission into first gear at a stop. Try pressing the pedal repeatedly to see if it “pumps up” and gets firmer, easing engagement. If so, air in the hydraulic system is indicated. Either air or a fluid leak can cause a loss of “throw,” causing the gears to grind. Another often-missed cause of lost throw can be loose bolts between the bell housing and the engine.

Fluid contamination can “melt” seals inside the master and slave cylinder. A non-release situation as well as lack of throw can be caused by damaged master cylinder seals. Inspect the reservoir cap, sometimes shared with the brake system. Is it abnormally clean, indicating that it has been removed recently? How’s the level? Does it appear that fluid has been lost? Look at the fluid, and smell it. If something’s not right, get suspicious, and find out if the owner has perhaps added the wrong fluid. Motor oil, of course, will destroy seals, but we’ve also heard of people using ATF, antifreeze, and even windshield washer fluid.

Loose hardware securing either the slave or master cylinder can likewise cause a loss of throw. Similarly, check for pedal problems caused by loose or bent brackets, a bent pedal, worn-out pivots, missing or deformed springs.

Noises

Noisy pedal operation is typically caused by worn-out bushings on the lever pin, which are replaceable. Installation of aftermarket pedal bushings and other pedal components can sometimes lead to binding, or other problems. Make sure everything is O.E., and well lubricated. Before diagnosing a stiff pedal as broken tabs on a release bearing, check the pedal assembly itself for binding or wear, including the over-center spring.

Some pilot bearing noise may be audible when the clutch is depressed and the transmission input shaft stops turning. With the engine running and the transmission in neutral, any noise is most likely coming from the transmission’s front bearing, and a small amount is usually acceptable. Release bearings can make different noises at different stages of their demise. A slave cylinder with inadequate free play can cause a release bearing to continuously rub against the fingers of the pressure plate, causing a high pitched squeal. Later on, a release bearing approaching the final stage of seizing up can make quite a howl whenever the pedal is pressed. In this case the cure will still require a clutch job, but preventing the problem from recurring is what’s gained by diagnosing a lack of free play that may have CAUSED the release bearing to fail. Again, this is something that can be done before pulling the bell housing.

Examine the bottom of the bell housing. If oil is present the rear main seal of the engine or the front seal of the transmission may need to be replaced. Smell the fluid and see if you can determine whether it’s engine oil, ATF or gear lube. Some dual mass flywheels are hydraulically damped, and can also leak fluid when they fail. If the customer complaint included slippage and/or a bad smell, oil contamination of the clutch could easily be the cause. Some bell housings provide an inspection port. This eases checking disc and pressure plate condition, looking for leaks, and hunting down clutch noises.

Hot judder

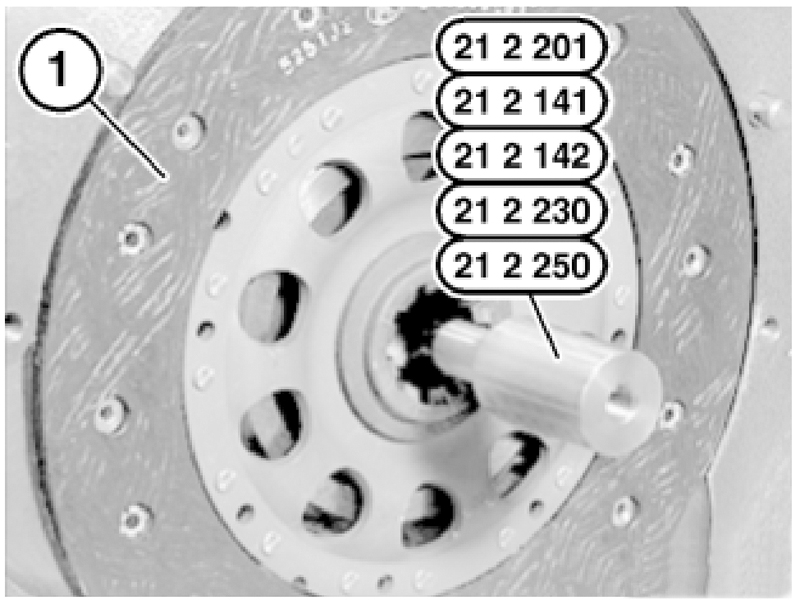

The best way to be sure of perfect disk and pilot hole alignment, thus easing transmission installation, is to use the special BMW tool for the model at hand.

Many 3-Series exhibit slight takeoff judder when they are hot, such as in summertime stop-and-go traffic. Typically, they’re fine once they cool down. Replacement of the friction disk with new genuine BMW parts will cure the problem. Before diving into any more serious clutch judder (on takeoff) problems, carefully examine the engine, transmission, and differential mounts. This may require removing them for a thorough inspection since cracks often can’t be seen in place, especially when the mount is dirty.

Care must be taken to avoid damage when re-installing the transmission. Using the bolts to pull in an out-of-line transmission can destroy a disk or pilot bearing. Instead, readjust your transmission hoist to the proper angle that allows it to slide in easily. When plastic alignment tools don’t fit, or don’t fit snugly enough, consider purchasing the appropriate BMW special tool.

BMW has adopted dual-disk clutches for certain late models to provide better performance and pedal feel.

DMF Concerns

The issue of dual mass flywheels, their diagnosis, pattern failures, and replacement will be the subject of a future article. Needless to say, when diagnosing any clutch complaint today, you must consider the possible role of the DMF in causing certain problems. Excessive gear chatter at idle is a warning sign. Unusual engine vibration at low-to mid rpm is another, and will occur whether the vehicle is moving or not. Normally, DMFs should last the life of the car. Racetrack or other “hard” driving may shorten their life to 50K miles or less.

Dual-disk clutches are being fitted to the latest M5 sedans, and are forthcoming on future models. Information on servicing these may be found on TIS.

The bottom line on clutch work is that it’s an expensive nightmare when you replace a clutch, but the problem doesn’t go away. Instead of asking yourself then, “Well, what else could be causing this problem,” always ask that question before you start the clutch job. Now and then you will save yourself a big headache and the customer a pile of money.

Writing Clutch Service

Ride-alongs give the tech or service writer the opportunity to see how skillfully customers use the clutch. Ask them to accelerate quickly from a stop, and see how high they rev the engine before engaging the clutch. Ask non-threateningly how often they use an SMG’s “launch” feature, and record their answers – which you can later compare to GT1.

Sneak a peek and see if the driver continually “rides” the clutch. Does the driver shift into neutral at stoplights, or hold the clutch down interminably? Get the driver to perform an uphill start if you can. Does he or she cheat and use the clutch as a hill-holder? Ask the person to shift down a gear to slow the vehicle and see if he or she does so smoothly, or violently crunches the transmission into a lower gear and backdrives the engine to high rpm. Ask young drivers, “Are you hard on the clutch?” in a non-threatening manner. “Do you chirp the tires? How often?”

When components of the clutch system must be replaced, even a little knowledge of the customer’s clutch skills can provide you with the confidence to make an accurate diagnosis and address the issue.

Without sufficient detail of the customer complaint recorded on the RO, during a test drive a tech will compare the clutch’s operation to what the tech him or herself believes the clutch should feel like, instead of how the customer believes it should behave – or how it “used” to feel. The result is all too often an expensive repair that doesn’t alleviate the customer complaint.A simple note of “bad clutch” or “needs new clutch” is insufficient. What is needed by the tech is a FULL description of when and where the clutch misbehaves, along with what it sounds or feels like. Write down the customer’s own words whenever possible. The customer should be asked, “Has the clutch always felt like this, has it changed recently, or just gotten steadily worse over time?”

Jumping to the conclusion that a driver (especially a young one) is responsible for clutch problems, even a prematurely worn clutch, is a mistake that immediately erodes customer satisfaction and distracts the tech from searching for the real cause of a problem. Never excuse a clutch complaint with “All of those models feel like that.”

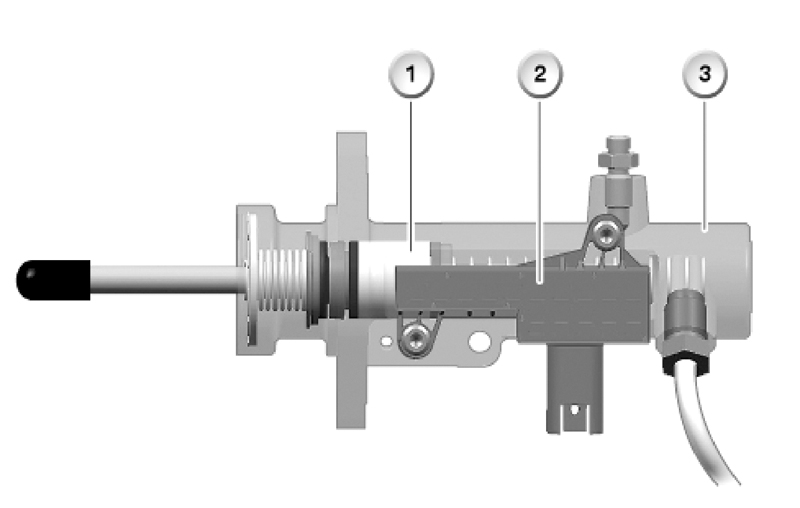

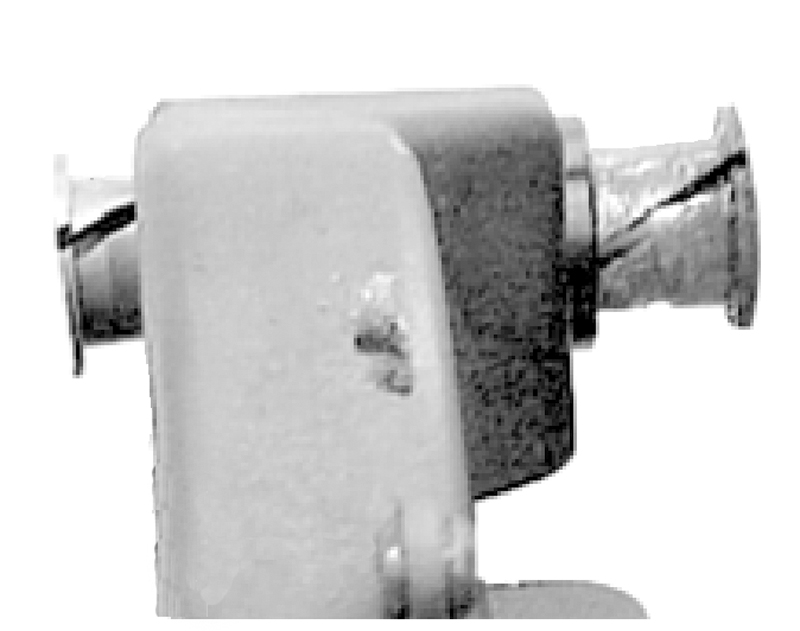

Here’s the SMG clutch actuator slave cylinder (3), showing the permanent magnet (1) and the clutch travel sensor (2).

Clutch Diagnostic Tables

http://www.lukclutch.com/support/diagnostics_pre_teardown.phtml http://www.exedy.co.uk/

[EDIT: ]

Dual Mass Flywheel Diagnostics

http://www.standardtransmission.com/dmf.html

0 Comments