One of the most basic jobs you can perform for your customers is a cooling system service. While the procedures are simple and are often overlooked as a profitable portion of the business, proper techniques and materials can turn this around and give your customers cooling system protection for years to come.

Ask anyone what a “cooling system service” is and you will probably get the tried-and-true answer of draining and refilling the cooling system. This is commonly reduced to draining the radiator and refilling it. But what is the purpose of servicing the cooling system? Was the vehicle overheating? Will the engine overheat in the future? These days, coolant has become much more than the “green stuff.” Phosphates, organic acid compounds and other additives add to the confusion: Can I mix this with that? Do I have to flush the whole system? What color should the coolant be? This may sound silly, but when you perform some service work (replacing a thermostat) you will lose some coolant. You need to know what coolant is compatible with what you already have in there. Will you pick one of the aftermarket so-called all-purpose solutions? Will the coolant you use breach the customer’s existing warranty? Understanding the requirements of Mercedes-Benz vehicles will make the decision-making process easier.

The Mercedes-Benz coolant is a cost-competitive option that many of us do not think about. It contains the

necessary corrosion additives and is ethylene glycol-based, so we can use a regular hydrometer and refractor to test it. It is also clear, which make contamination easier to spot.

Why We Do What We Do

Put any two different materials together and chances are they are going to react with one another. Some reactions will happen quicker than others, but eventually something is going to happen. The same dynamic happens within the cooling system of any engine. In modern engines, aluminum alloys make up the blocks and cylinder heads. These aluminum alloys are more reactive than their iron or steel alloy counterparts. Coolants that run through these aluminum components often react with them, breaking down both the coolant and the aluminum. The debris from this reaction gets circulated throughout the cooling system. It often builds up in small cavities found in places like the radiator and/or heater core. Eventually, the passages become blocked and circulation is reduced. These contaminants can also build up on thermostats, possibly causing them to stick closed. We all know a closed thermostat will restrict coolant flow to the engine and result in overheating.

To prevent this corrosion effect on cooling system components, we replace the coolant. It removes the corrosion contaminants and restores higher boiling points and lower freezing points within the cooling system. Mercedes-Benz maintenance schedules have you replace the coolant at 147,000 miles or 15 years. These maintenance schedules are dependent on use of approved anti-corrosion/anti-freeze coolants and you are required to check the cooling system at each service. Mercedes-Benz factory coolant (Part # Q 1 03 0002) meets all the requirements to achieve these low-maintenance intervals. Money saved putting in a less expensive coolant is often lost in the long run with clogged and corroded components requiring replacement, as well and additional coolant flushes. We should all agree that the minimal money saved on coolant does not come close to the cost of a cooling system repair. The labor time on a cooling system services varies from 1.0 to 1.5 hours depending on the model. Let’s go over how we are going to test to see if the coolant is up to the task.

A Few Minutes Testing

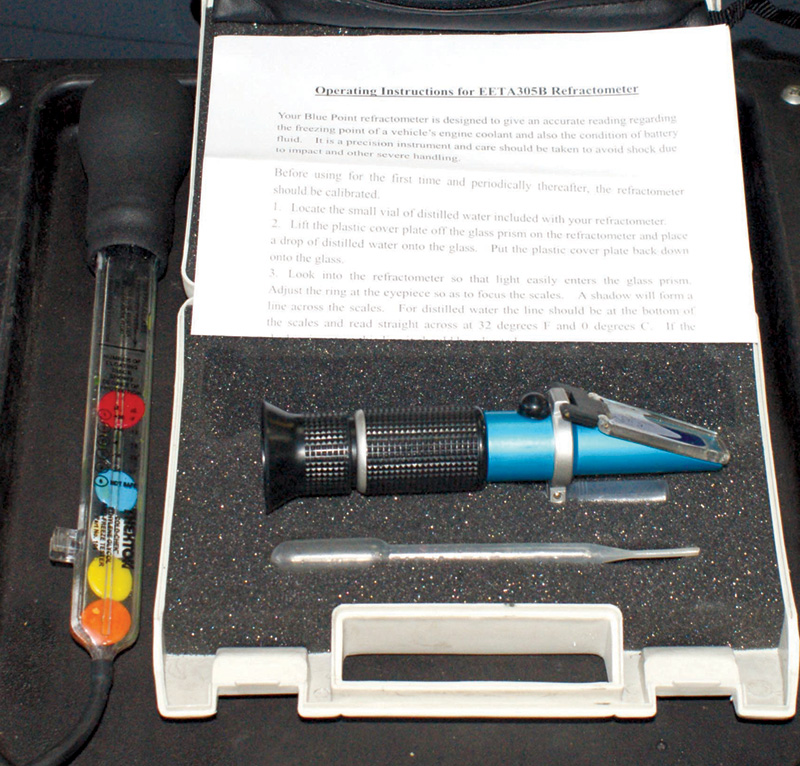

Here are the tools of the trade. Mercedes-Benz factory coolant is

ethylene glycol-based, so a coolant hydrometer will work fine. Hydrometers are not the most precise method of measuring concentration. The refractometer is much more accurate. Remember, coolant temperature affects the specific gravity of the sample. Know what you gauge is calibrated for.

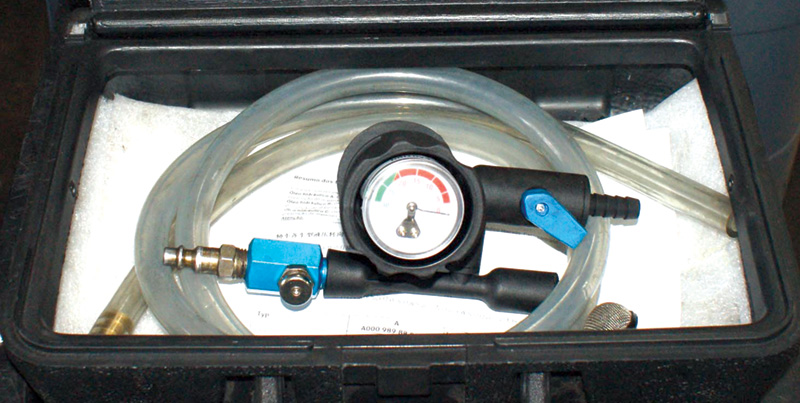

The first thing we are taught about testing cooling systems is a visual check. Looking at the coolant level and the coolant itself is the first test we should perform. Cooling systems that are not up to level at some point had a problem. Either the coolant is leaking out somewhere, or it’s being used by the engine. At this point a cooling system pressure test is called for. Commercial testers are available from your tool supplier along with the necessary cooling system adaptors. Simply pump up the system to the rated pressure capacity of the radiator cap and see if the pressure drops. If it does, look for external leaks. You may also want to attach an additional adaptor and check the cap. If you cannot find any external leaks, it’s time to look at the possibility of an internal leak. In the last issue of Star Tuned, testing for head gasket problems was covered, so look there for those answers.

If the cooling system passes the pressure test, it’s time to test the coolant itself. Mercedes-Benz recommends testing the coolant at every service (i.e. oil change). This can be done one of two ways. The first method involves a cooling system hydrometer. This tool measures the specific gravity of the coolant, specifically ethylene glycol. This specific gravity is a measurement of coolant concentration. The ideal mixture should be 50% coolant and 50% water. This ethylene glycol mixture’s specific gravity will be affected by the temperature of the fluid, therefore a coolant hydrometer’s scale needs to be calibrated to a specific temperature. You can use your infrared temperature gun to determine the liquid’s temperature and have it match the temperature of the hydrometer scale. Remember, specific gravity changes with temperature. A 50/50 mix of ethylene glycol will have a specific gravity reading of 1.057 at about 100 deg. F. If the vehicle came in and the coolant was 150 deg. F., the same good mixture would yield a reading of 1.037. If your tool is calibrated to 100 deg. F. you would think the concentration was 35%, so make sure you know what temperature your hydrometer is calibrated to.

A vacuum-assist tool can save a lot of time in bleeding the system. Generally, Mercedes-Benz engines do not have a problem with bleeding out air, but this helps eliminate the possibility. Shop air often powers up the vacuum pump. Once the cooling system is in a vacuum, a valve is switched and fresh coolant is drawn in to fill the vacuum.

This tool draws coolant into a clear plastic tube with either weighted balls of varying density, or a single float pivoting on a pin. See how many balls float or how far the single float rises and that will indicate the specific gravity of the coolant. Air bubbles in the sample affect the buoyancy of the float as well. Even expensive hydrometers have the same problems. Believe it or not, this tool is often not precise enough to give you a reading you can depend on. Also, the hydrometer cannot be used on propylene glycol-based coolants since two different concentrations can yield the same specific gravity readings. Mercedes-Benz brand coolant is based on ethylene glycol, so you can use a hydrometer to test it. Remember, temperature variations still have to be taken into consideration. Could there be a better way?

It is more expensive than a simple hydrometer, but the refractometer is very capable of precise measurements of coolant concentration. The principle is simple. As light passes through a liquid, it will bend a different amount for a different liquid, in our case a different coolant concentration. By using a refractometer, you send light through tje coolant sample and see how the light bends on the refractometer scale. You then compare that sample to water. Either ethylene glycol- or propylene glycol-based coolants can be measured with a refractometer. The temperature of the coolant mixture still affects the reading, but since the sample is so small (only a drop) the liquid quickly assumes the temperature of the tool.

Simply put a drop on the lens, close the clear cover and point the refractometer into a light source. A meter of good quality will have you calibrate it by first sampling distilled water. Once calibrated, you can sample your coolant and check the concentration.

How We Do What We Do

For maintenance or service work, you may need to replace the coolant. How can you do this quickly and be profitable?

The first step in a cooling system service is to drain the existing coolant from the radiator. There is usually a drain valve on the driver’s side or passenger’s side tank of the radiator. After removing the cap of the coolant system expansion tank (to allow air into the system), you can raise the vehicle. Then, open the drain plug on the radiator tank. This will only drain the radiator and some portion of the water pump and thermostat housing. The next step is to drain the block. This is often overlooked due to the lack of knowledge of where the drain plugs are and access to them. With a paid subscription to www.startekinfo.com, you can view service procedures to locate the drains. These plugs are located at the base of the water jacket on one or both sides. They will often be difficult to remove, so be careful not to round off the bolt head. This is probably the most time-consuming part of the process.

Refilling the system used to be simple. Add coolant to the expansion tank and let the engine run. If there were some problems in filling a system, an old trick was to prop the thermostat open with two pieces of aspirin while filling the system. This would give the air a chance to escape as the system filled up with coolant. Although we are not aware of aspirin causing any problems currently, with new coolant additives, radiator seals and gasket materials all sorts of reactions may take place. Mercedes-Benz cooling systems have the expansion tank at the highest point, so are self-bleeding.

These days with dual heater cores, auxiliary cooling pump motors and external cooling system plumbing, there is a multitude of places air can get trapped. This can lead to symptoms such as overheating and poor heater performance. You may have to run the engine for a while before you bleed all the air out. Check the service procedures and see if there is a bleed procedure for the articular vehicle you are working on.

There are tools available to assist you in the refill procedure. You have probably heard of “vacuum assist” cooling system fillers. These tools use your shop’s compressed air supply and a vacuum pump to generate a vacuum in the cooling system. Once the system is in a vacuum, a valve allows coolant from a pickup tube to fill the vacuum in the coolant passages. This can reduce and/or eliminate any air bound in the cooling system. There is no need to run the vehicle for an extended period of time to self-bleed the air out of the system. You can now move on to your next job.

If you would like to complete the task of draining the cooling system, you can flush out the heater core. Removing contaminants will improve heater function and prevent further blockages down the road. The great part here is the time saved. Most Mercedes-Benz vehicles use an auxiliary cooling pump motor. This motor can be activated through the use of your Compact III scan tool, or by just supplying power and ground to the pump motor directly. The motors draw only about .5 amps and will pump all of the coolant out of the heater core while you are refilling it with new coolant. Most pumps are on the output side of the cooling system. Disconnect the line on the pump returning the coolant to the water pump and run it into a container. Block the water pump side of the line you have just disconnected and run the pump until you see new coolant. We would not recommend using any aftermarket coolant flushing solutions as these may contain harsh chemicals that can attack seals and gaskets after a few thousand miles. If the cooling system is maintained in a timely manner these “cooling system repairs in a can” should not be necessary.

If You Want To Pull Out The Big Guns

Another tool investment that will save you time, ensure all of the coolant is being exchanged and reduce air in the system, there are coolant exchange machines. These no longer require that you put the vehicle on a lift and open drain plugs on the radiator and engine block. As long as you have access to a coolant hose, you can exchange the old coolant with a fresh supply with a minimum of mess.

These machines have external tanks you can pre-fill with your 50/50 distilled water and antifreeze coolant mix. The next step is to disconnect the upper radiator hose and connect the coolant line adaptors from the machine to the car. Most coolant exchange machines do not need the vehicle to be warmed up, or even running. A vacuum pump pumps out the old fluid into an empty tank and replaces it with the coolant prepared in the refill tank. You should know by now the type of anti-corrosion/anti-freeze we should be using in Mercedes-Benz vehicles, but this is only half the equation.

Here is a tool that might be a good investment providing you sell enough cooling system services. You can keep one tank with a 50/50 mixture of Mercedes-Benz coolant and distilled water and exchange it with the old coolant without even running the engine. You may still have to pump out the heater cores separately.

Water Quality

In this article, we discussed proper cooling system service procedures, anti-corrosion anti-freeze and tools to test and exchange the coolant. One more subject we need to discuss is something we very often take for granted. That is water supply. “City” water for drinking is treated. It contains fluoride or chloride salts due to the treatment, so it is not desirable to mix it with coolant. Do not use this, or hard water, in Mercedes-Benz cooling systems. In the odd chance you have a supply of spring water, either bottled or from a well, do not use this, either. Bottled water is not regulated and probably contains minerals that can react with engine components, and also acts as an abrasive when passing through the cooling system. Instead, use distilled water. It is the best to use since it contains no additives. The slight additional cost of distilled water should not significantly increase the cost of the overall cooling system service and eliminates harmful contaminants.

In Conclusion

Cooling system service is one of the simpler tasks you perform for your customers, but it is also one of the most important. Advancements in the chemical composition of coolants and cooling system plumbing make corrosion and air-bound systems real problems that need to be addressed. Using Mercedes-Benz antifreeze will insure corrosion protection and warranty claims will not be an issue. Draining the block, radiator and heater core will insure all expired coolant is removed. Finally, refilling the system without air pockets can be accomplished with a vacuum-assist tool, or a coolant exchanger. If customers notice your attention to detail on the cooling system, we are sure they will trust your judgment when it comes to more involved repairs, and that is good for all.

0 Comments