Don’t be afraid to tackle service on the Nissan Altima Hybrid. Beyond the high-voltage electrical system, it’s really just like any other Altima. But, there are a few special facts you should know.

You can do it

There’s no reason for qualified independent shops to turn away hybrid work. Obviously, technicians must take the time to educate themselves before working on unfamiliar systems, and shops must be properly equipped. Nissan makes all of this possible by providing independent repair shops the same information and tooling available to Nissan and Infiniti dealerships. You can find technical information and self-guided training courses at www.nissan-techinfo.com, and dealer level equipment at www.nissantechmate.com.

If you are up to the challenge, maintenance work is a great place to start. Not only is it relatively easy to learn, it’s also all that a two-year-old Nissan is likely to need.

Do no harm

The Altima Hybrid has proven extremely reliable, and it will continue to be reliable for years to come if it is properly maintained. However, maintenance can be detrimental when incorrect procedures, parts, or fluids are used during service. When servicing the Altima Hybrid, it’s best to adopt an axiom from the medical profession: “First, do no harm”. If any ingredient is missing, whether it be knowledge, tooling, fluids, or parts, it’s much better to simply do nothing until everything is in place and the job can be done correctly.

Read, then do

You wouldn’t want to drain the inverter coolant only to find you’ll need a special tool you don’t own to fill it, would you? The best place to start is in the Maintenance section of the online manual. The Maintenance section has all of the information you are likely to need, such as service schedules, procedures, fluid types and quantities, torque specifications, etc. It might even be a good idea to give the Maintenance section a quick read before the car arrives, so you’ll be fully prepared once it does.

Torque it!

A torque wrench should not sit buried in a toolbox until an engine repair rolls into the bay! Drain plugs, spark plugs, and lug nuts all have specified torque values. Many experienced technicians believe they have “the touch”, and can get it just right every time. However, if you use a torque wrench daily, you may notice that some days 18 ft. lbs. “seems tighter” than other days.

Inspections

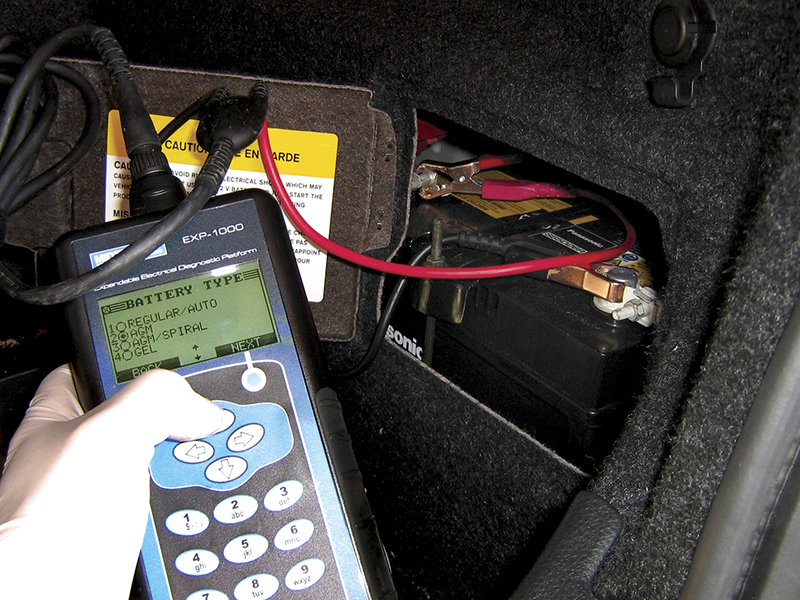

Test the 12V glass mat battery using an internal resistance tester such as the Midtronics EXP-1000 or EXP-1200.

Inspecting the vehicle is arguably one of the most important aspects of a maintenance service. Vehicle owners rely on their technician to alert them to any problems that might be dangerous or potentially costly if not addressed. For the most part, the inspection on the Altima Hybrid is the same as any other car. However, there are a few additional items that should be checked.

It’s not a bad idea to check the High Voltage (HV) cables for looseness or damage. If a HV cable is open or shorted, a trouble code will set. However, it is possible for undercar collisions to tug the cables loose and leave them more vulnerable to further damage.

The inverter cooling system should be inspected just like the ICE (Internal Combustion Engine) cooling system.

The 12V battery should be tested at least every 15,000 miles. The 12V battery has no role in “cranking” the ICE, so there will not be the typical slow cranking associated with a weak battery. Because of this, owners usually do not notice a bad 12V battery until the car suddenly fails to start.

Tires

Tires should be rotated every 7,500 miles (every other oil change). Nissan recommends front to rear rotation with no crossover on the Altima Hybrid. Lug nuts should be tightened to 83 ft. lbs.

Tire pressure should be set to 35 psi at 70 deg. F, before driving. Please keep in mind that tire pressure will increase or decrease about 1 psi for every 10 deg. F above or below 70 deg. F. With the advent of TPMS (Tire Pressure Monitoring System), accuracy in temperature compensation will be put to the test. For instance: if tire pressure is set to 35 psi after a freeway road test, the TPMS warning icon will probably be on the next cold morning.

Don’t forget about the spare tire. There is no TPMS sensor on the spare, so be sure to check the pressure on the spare when servicing.

Filters

Cut an old coolant bottle to make an oil deflector. It will save you clean-up time and avoids customer complaints.

The ICE air filter should be replaced every 30,000 miles, or sooner if the vehicle is driven though dusty or otherwise polluted air.

The service interval for the cabin filter is every 15,000 miles. However, cabin filter life will vary depending on a number of factors: such as how often the blower is used, the level of local air pollution, and whether the car is parked under trees. Be sure to clean any leaves or other debris from the fresh air duct located at the bottom of the windshield.

Always lubricate the oil filter gasket with clean motor oil so it won’t become stuck in place. The “next guy” may be you!

The Altima Hybrid does not have a serviceable fuel filter.

The oil filter should be replaced every 3,750 miles when the motor oil is changed. The oil filter gasket should be lubricated with fresh motor oil and the filter should be tightened to 13 ft. lbs. or 2/3 turn after the gasket makes contact.

When the ICE restarts after idle stop or EV mode driving, it will be cranked at a speed four times faster than an engine in a normal car. Oil filter quality is critical. Nissan oil filters use a high quality anti-drainback valve, and will perform as they should. Installing an aftermarket filter is a gamble with any Nissan, but it’s even riskier with this hybrid.

FLUIDS

ICE oil

The ICE oil should be replaced every 3,750 miles along with the filter. The drain plug torque is 25 ft. lbs. and a new crush washer should be used every time.

The Altima Hybrid uses 0W-20 synthetic motor oil. Using an incorrect grade can cause accelerated engine wear as well as performance issues. 0W-20 synthetic oil is not commonly available from wholesale lubricant vendors, but Nissan dealers will have it in stock. In warmer climates, 5W-20 oil can be used in a pinch, but 0W-20 is preferable.

Transaxle oil

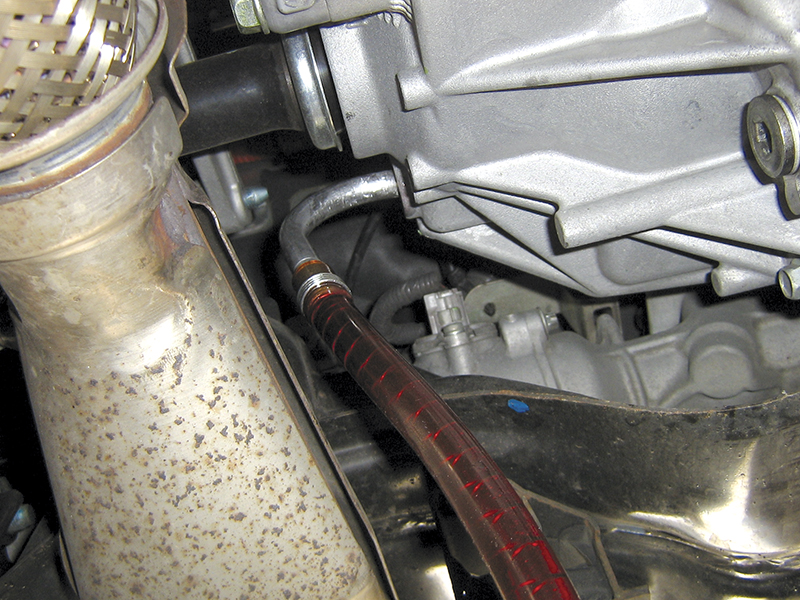

The transaxle fluid should be inspected and its condition evaluated every 15,000 miles. If the vehicle is driven under harsh conditions – towing a trailer for instance – it should be automatically replaced every 30,000 miles.

The transaxle fluid will degrade at different rates depending on how the car is used. The fluid in a typical Altima Hybrid will usually look “like new” at the first 15K inspection, “somewhat discolored” at the 30K inspection, and “very discolored” at the 45K inspection.

HybridTransaxle fluid replacement is similar to manual transaxle fluid replacement: the fluid is drained and filled from the underside of the car, and the fluid level should be adjusted to be even with or just below the bottom edge of the fill port.

Be sure not to overfill the transaxle. The transaxle is sealed to protect the fluid from moisture; you may even notice a hissing as you loosen the fill plug due to the pressure differential. Overfilling the fluid may cause over-pressurization and leaks, as well as excessive drag and loss of fuel economy.

The transaxle houses both the MG1 (Motor/Generator 1) and MG2 (Motor/Generator 2) and is quite different from typical automatic transmissions, including other CVTs (Continuously Variable Transmissions) found in Nissan products. This very special transaxle requires a very specific transaxle fluid: Nissan Type W. Don’t let salesmen talk you into using any of the “multi-vehicle” fluids, as they will cause transaxle damage and void the warranty.

Type W has a few special handling requirements. First, it’s moisture sensitive, so care for it as you would brake fluid – store it in a sealed container and only open the container just before use. Also, Type W should not be mixed with any other fluid, so it’s best to use a dedicated filling pump if possible. If not, the pump should be thoroughly drained and cleaned before filling with Type W.

The transaxle drain and fill plugs should be tightened to 29 ft. lbs. with new crush washers installed.

Coolant / Antifreeze

Coolant should be replaced for the first time at 60,000 miles or four years from the production date, whichever comes first. However, after the first coolant service, the coolant replacement interval is shortened to every 30,000 miles or two years.

The Altima Hybrid has two separate cooling systems: one for the ICE and one for the inverter and transaxle. It is important to read the service manual procedures before attempting to replace coolant. Improper procedures can lead to damage.

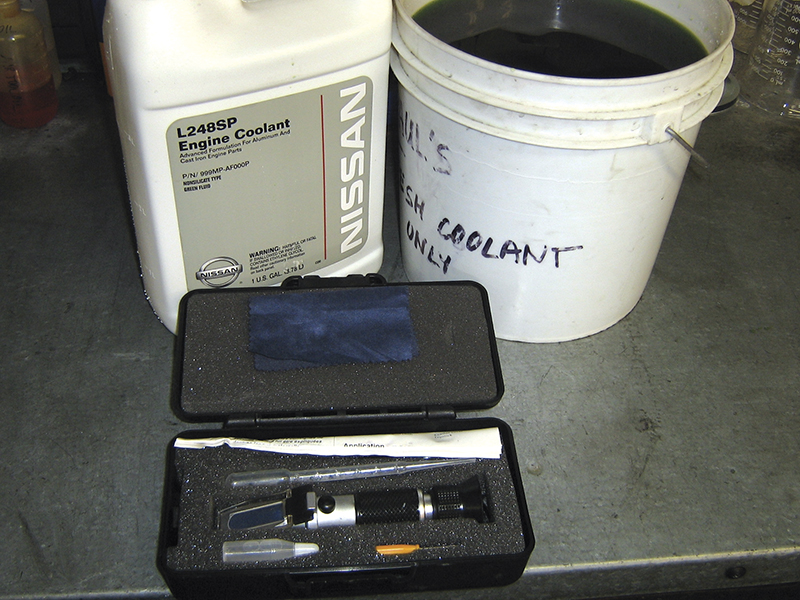

The Altima Hybrid uses Nissan Long Life Antifreeze for both the ICE cooling system and the inverter cooling system.

ICE coolant service

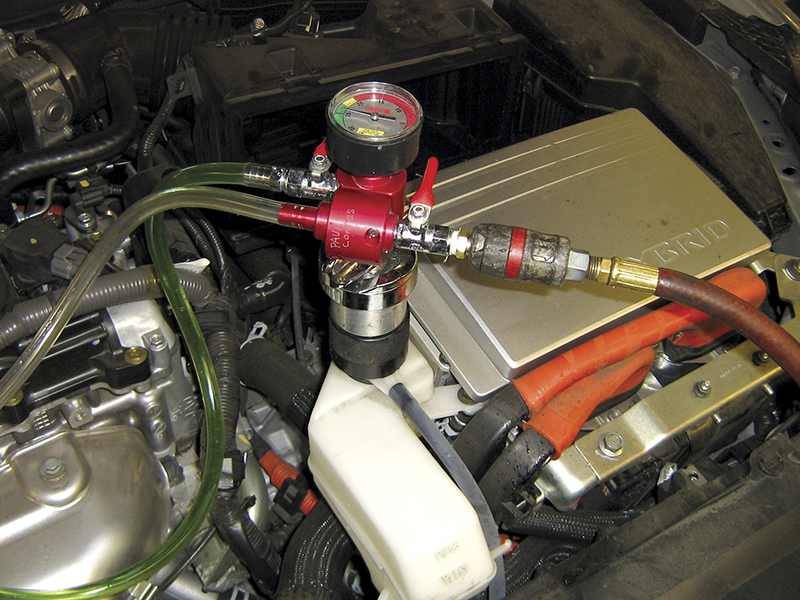

Using a coolant system vacuum filling tool helps to eliminate potentially harmful pockets of trapped air.

Using the Nissan cooling system filling tool, part number J-45695, will help ensure no air is trapped in the system. Drain coolant from the radiator drain plug and the engine drain plug. Use a new o-ring on the radiator plug and thread sealer on the engine drain plug.

The heater controls should be set to HOT while filling. Double click the Ready button without stepping on the brake. Then set the climate control to HOT. Read full instructions in the service manual before starting.

Inverter coolant service

Although not mentioned in the service manual, the cooling system filling tool makes bleeding the inverter system much easier. Use the Consult III INV WATER PUMP active test to run the inverter water pump while filling.

Drain coolant from the inverter radiator and the transaxle. Use a new o-ring for the inverter radiator and a new crush washer for the transaxle. Be sure to read full instructions in the service manual before starting.

Brake fluid

There is no set interval for bleeding the brake hydraulic system on the Altima Hybrid. However, it may become necessary to bleed the brake lines from time to time, so it bears mentioning here. For complete instructions, check the Maintenance section of the service manual.

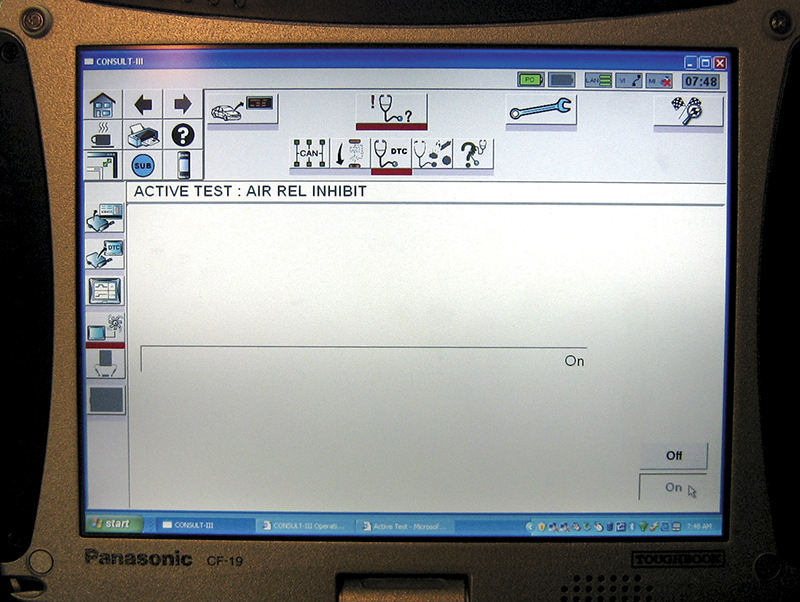

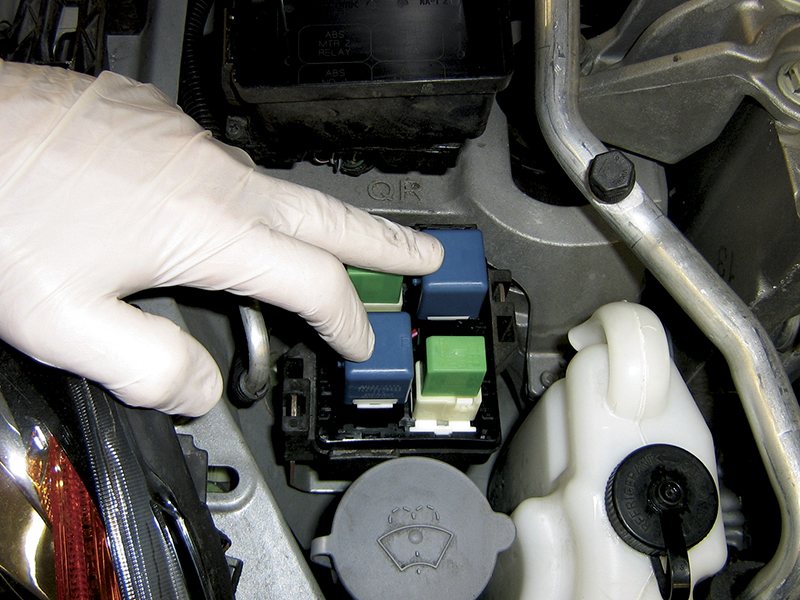

The Consult III must be used for functions like bleeding the brake lines and servicing the inverter cooling system.

It is impossible to bleed the brake hydraulic system without the Consult III, so bleeding should never be undertaken without a Consult III available. The procedures are far from intuitive, so be willing to spend time reading before beginning. Complete bleeding procedures would require an entire article to describe, but here are a few of the key points, which may make understanding the procedures a little easier:

Front brake lines

The section of the manual which describes bleeding the front lines is called AIR RELEASE OF STATIC PRESSURE SYSTEM (FRONT WHEEL).

Two ABS pump motor relays must be removed to bleed the front lines. If you ignore the instruction to set the parking brake, you will be locked out and will not be able to bleed the brakes. Follow the instructions exactly.

The active test AIR REL INHIBIT allows bleeding of the front brakes. It may not seem entirely clear in the manual, but once conditions are set, bleeding the front lines is the same as on a conventional car: press the pedal, open bleeder, close the bleeder, repeat. You may hear the brake warning buzzer sound during bleeding. It’s OK.

Rear brake lines

The two ABS pump motor relays must be installed. Use active test AIR REL INHIBIT to bleed the rear brakes. When bleeding the rear brake lines, accumulator pressure is used to push fluid through the lines. Just press and hold the brake pedal with the bleeder open to start the flow.

There are four additional ABS system bleeding procedures for sections other than the lines to the wheels:

- Suction drain system

- Power supply system

- Stroke simulator system

- High pressure line

Please read the manual for information on these procedures.

Spark plugs

Once a staple of vehicle maintenance, spark plugs now remain undisturbed for 105,000 miles; early replacement is seldom necessary. The quality of the installation should be commensurate with the expected service life. To that end:

- Use compressed air to clean any grit from coils and spark tubes before removing the plugs.

- Shine a light on the coil boots and check for carbon tracking or water intrusion

- Apply dielectric grease to the coil boots

- Don’t attempt to re-gap or clean spark plugs

- Use a dab of anti-seize on the plug threads

- Tighten spark plugs to 18 ft. lbs. using an accurate torque wrench

Valve clearance

There is no set interval for inspecting valve clearance. Valve clearance should be inspected whenever there is valve noise or an idle quality concern. It also makes sense to check valve clearance any time the valve cover is removed for gasket replacement.

Unlike many engines that use selective thickness buckets or shims, valve clearances on the QR25DE engine are checked hot. Valve clearance should be checked with engine temperature close to 176 deg. F. Nissan also provides cold clearance specs, for situations where the engine cannot be warmed. However, proper hot clearance should be verified later.

Valve clearance is adjusted by selecting a thicker or thinner lifter. There are 26 sizes available in increments of just under .001 inch. The camshafts must be removed in order to remove and replace the lifters, so measure twice, replace once.

Finishing touches

After maintenance work has been completed, be sure to reset the maintenance reminder, wipe off any finger prints and double check all of your work before returning the car to your customer.

0 Comments