Nitrous oxide is not for everyone. Still, those who do use it as a power adder are not only intimately involved with their cars or trucks, but are also likely to be sought out by others as the neighborhood expert when it comes to service and repair advice. When asked for a recommendation for even basic maintenance, these experts—often amateur racers—frequently send customers to shops they know and trust. A shop that has a reputation for top-notch performance work will be expected to handle other tasks easily, quickly and expertly. Offering nitrous oxide installation and bottle refills is an excellent way to develop that reputation and also attract performance enthusiasts who may purchase other goods or services as a byproduct of their visits.

Inert to seriously reactive

Nitrous oxide is an inert gas whose molecule comprises two nitrogen atoms bonded to one oxygen atom. When injected into the combustion chamber along with a sufficient quantity of additional fuel, nitrous can add significant horsepower at minimal cost. As the piston squeezes the nitrous and the air/fuel mixture, the molecular bonds break down, releasing the oxygen atoms at a temperature of about 570 to 580 deg. F.

“The oxygen released from the nitrous allows extra fuel to burn, and the nitrogen acts as a buffering component that helps dampen the increased cylinder pressures,” explains Matt Held, media and PR manager for Holley Performance Products, which manufactures the Nitrous Oxide Systems product line. “At the same time, the nitrous oxide helps cool the air temperature coming into the cylinder by 60 to 80 degrees. That helps alleviate detonation, which can harm the pistons.”

The buffering effect of the nitrogen atoms is crucial. Pure oxygen acts almost like a torch in the intake manifold or combustion chamber and could be ignited by any sufficient source, including a hot spot or even static electricity. Because nitrous oxide adds about 14% more oxygen than normal air, it increases the burn rate of any fuel. That requires the ignition timing to be retarded slightly to ensure peak cylinder pressure at 10 to 15 degrees after top dead center.

Diesels, too

While nitrous is most often associated with gasoline-powered engines, any type of internal combustion powerplant can benefit from it.

“We’ve done kits for everything from ¼-scale dragsters running weed-eater engines to big diesel trucks,” says Mike Flynn, head of the technical department for Nitrous Supply. “That being says, any engine will have a limit as to what it can handle. Most engines can handle about 40% to 50% more total power—including all power adders—but the makeup of the engine must be considered. I have told folks that they should not install nitrous on some engines based on the power they were already making or the inherent weakness of some components.”

As diesel applications have become more prevalent, both on and off the pavement and in racing, nitrous has also found a market there.

“Diesel engines use nitrous differently than gas-powered engines,” says Mike DeFord, marketing manager for diesel specialist Bully Dog Technologies. “On a diesel engine, nitrous oxide creates a cleaner and more thorough burn within the engine. The engine uses more of the previously unused fuel, thus making more horsepower. In many cases, increased fuel mileage can also be obtained.”

Dry or wet

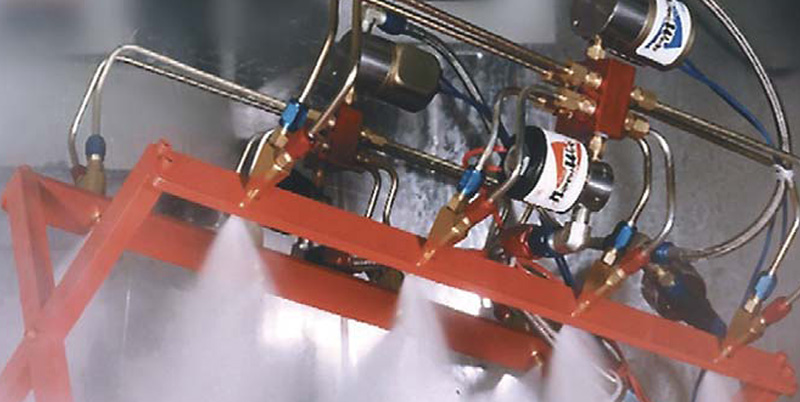

Basic nitrous oxide injection systems consist of an aluminum canister (bottle) that contains the nitrous supply as well as plumbing lines, one or more solenoids that control the flow of the nitrous and/or fuel, and either a plate with spray bars or direct port injectors. A plate system may spray nitrous only (a “dry” system) and derive additional fuel from the stock fuel system or spray a combination of nitrous and fuel (a “wet” system) through either a plate or a single nozzle.

“A plate system uses an actual spacer plate that bolts directly under a carburetor or a throttle body,” says Adam Campbell, a sales representative for the Nitrous Works division of Barry Grant Inc. “The direct-port system will have an individual nozzle in each runner of the intake manifold to supply the nitrous and fuel.”

A direct-port system obviously requires a little more technical expertise to install and tune, and it will cost a bit more due to the greater complexity and number of parts, according to Arty Feles of Edelbrock Corporation.

“A plate system on an eight-cylinder engine generally has only two jets—one nitrous and one fuel— and it is typically used due to the ease of installation and good power gains,” Feles says. “You can bolt it on in just a couple of hours and be ready to use the kit. On the other hand, a direct-port system typically has 16 jets you can adjust—one nitrous and one fuel per nozzle, with each runner getting one dedicated nozzle. It’s a more tunable kit with higher horsepower potential.”

Cheapest big boost

In either case, however, the dollar-per-horsepower gains can be remarkable, and nitrous systems have the advantage of selective use.

“Nitrous is invisible to the engine and operator until it is actually needed,” says Mike Wood, CEO of Nitrous Express Inc. “It does not affect drivability, fuel mileage, resale value, is easily adjustable and is the cheapest per horsepower investment you can make.”

In fact, a properly installed and correctly used nitrous injection system may cost as little as an eighth or even a tenth of the price to build an equally powerful high-performance engine using other methods.

“You can have a very mild-mannered street car with a decent-duration camshaft, but the minute you want to go fast, all you’ve got to do is open your nitrous bottle, and you’ve got an instant 100, 200 or 300 extra horsepower,” says Matt Patrick, product manager for ZEX Performance Products. “If you weren’t using nitrous, you’d have to have either a high-rpm or a large-displacement engine suitably built for racing to get that sort of power level out of it. You can add 300 horsepower with an investment of about $600 or $700 [with nitrous]. To get that same kind of power increase from a supercharger or a turbo kit, you’re looking at $4,000 to $5,000.”

All that power comes with a few caveats, not the least of which is an admonishment from every manufacturer not to over-use system.

Beware skinny mixes

“People get greedy,” Held says. “They load up an engine with too much nitrous, and the engine can go lean. We have jetting charts for our kits that tell which ones to use for the right ratio of fuel to nitrous for optimum power. If you get too much oxygen and not enough fuel, the engine can go lean and end up burning the pistons. Several of our kits have fuel-pressure safety switches to prevent that. If a kit doesn’t have that, it’s an option that you can easily buy as an accessory item. It monitors the fuel pressure and doesn’t allow the nitrous system to fire if it doesn’t see the correct fuel pressure.”

Many manufacturers also offer other safety features such as blow-off pressure discs that allow the nitrous to be discharged if a specific bottle pressure is exceeded. Blow-down tubes are another safety item that should be used if a bottle is mounted in an area where it might affect the passengers—a hatchback, for instance. Blow-down tubes release the nitrous under the car so that it doesn’t enter the passenger compartment.

Additionally, there are laws and regulations in some states about using nitrous on the street. For instance, it might be legal to have the plumbing in place but have the bottle disconnected in some regions. Other areas require that a small sticker be visible in the vehicle window to denote that the car is carrying nitrous. Shops should check their local ordinances and make their customers aware of any such rules.

It is also wise for shop owners and technicians to consult with component or kit manufacturers when they begin work on an unfamiliar vehicle or product.

“Unless he has a lot of experience,” Campbell advises, “a technician should know as much as he can about his customer’s combination and the components that he has and then work with the manufacturer directly to determine what a safe nitrous oxide level would be and what else might be required.”

That level can vary dramatically depending upon the vehicle and engine type. Most manufacturers agree that the vast majority of systems are tuned for less than 200 horsepower for an average street car that sees a race track only two or three times a year.

“Most V8 engines on a stock fuel pump can very safely handle up to about 125 horsepower,” says Patrick, “and we generally recommend up to about 75 horsepower maximum on most four- and six-cylinder applications. Those are safe, practical numbers for your average, everyday customer. Most guys are not looking for a full-on direct-port-type Pro Mod system. They want a simple-to-install kit that is safe for the engine and that will pick them up anywhere from 75 to 100 horsepower.”

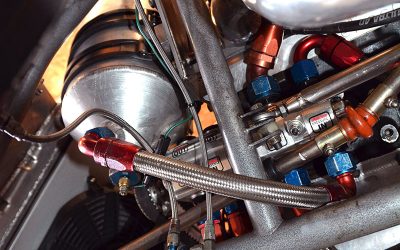

In addition, every manufacturer we spoke with recommended that shops interested in nitrous oxide installations add a nitrous fill station to their facilities. A fill station works in essentially the same way as a propane fill station, using a larger storage tank to load customer bottles. Larger quantities of nitrous are available from compressed gas dealers, such as welding supply houses.

“Repeat customers equal more profits,” Feles says. “Becoming a nitrous refill station is an excellent method of keeping your existing nitrous customers coming back to your store for more. You will also attract new customers as word of mouth spreads that your shop refills nitrous oxide.”

Many manufacturers provide materials to help market nitrous oxide. Some offer banners that advertise the fill station, but there are also point-of-purchase displays, counter brochures, plan-o-grams and catalogs available. And if the shop is located anywhere near a race track, signage and sponsorships there provide a considerable boost to sales.

Inventory is another important consideration. Sales of nitrous to new customers tend to be spontaneous, spur-of-the-moment decisions, so a shop should keep at least a few basic kits on hand.

“On the carbureted market, 95% are going to be the standard, square-flange-type kit,” Patrick says. “You can keep one or two of those on the shelves because virtually anyone who walks in with a carbureted performance V8 engine is going to use that type. On the EFI side, every manufacturer has standard four-cylinder, six-cylinder and V8 kits. Those are also pretty safe to put on the shelf.”

New cars?

Patrick also noted that more and more people are putting nitrous on newer vehicles such as ’05-’07 Mustangs, the new Charger Mangum and Hemi trucks as well as some sport compact models.

“People are putting nitrous on a lot of newer vehicles that aren’t even out of warranty,” he says. “Shops need to be aware that it’s not just second-hand cars; it’s brand-new cars. The problems with the newer vehicles is that they are going to what is known as a returnless as well as a sealed fuel system, and they’re using hard nylon fuel lines. In years past, you could just send out a universal kit, and it would have a barbed tee. You could cut the fuel line and set the fuel so that you would have a source for feeding the nitrous system. Because of the hard plastic lines and the sealed fuel systems on the newer cars, there is no easy way to tap fuel off the fuel system of the vehicle for the nitrous kit unless you build some custom adapters.”

To address that problem, Zex and other manufacturers have begun to develop a greater number of vehicle-specific kits with special adapters and hose kits. To service those newer vehicles, a shop should ensure that its WD keeps those types of kits in stock.

As a shop increases its proficiency with installations and service for the performance-enthusiast core, those customers will guide the decisions of others, and greater traffic always leads to increased sales.

by Steve Campbell

0 Comments