It’s cold out, but Mercedes-Benz owners have single, dual and multiple zone climate control systems that keep them comfortable

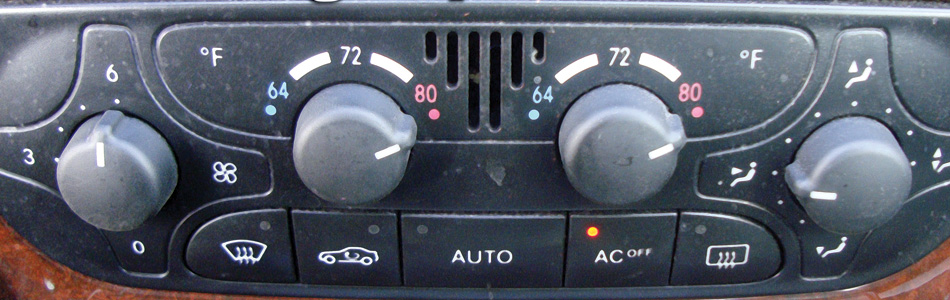

A quick look at the heater control panel reveals that this is a manual dual-zone system. This means the vehicle has a duo-valve, which controls coolant flow to two different heater cores.

While Mercedes-Benz vehicles are known for all their other creature comforts, the heating function is an absolute necessity. Problems in this area don’t only make the passengers uncomfortable, they can also be dangerous because the lack of a defroster may allow the windshield and front windows to ice up blocking the driver’s view. If a customer comes in with a no-heat complaint, your first step should be to find out if the problem is in the mechanical heat supply portion of the system or in the electronic controls. Since Mercedes-Benz offers single-, dual-, and multiple-zone HVAC systems, you also need to know which zone is missing heat, if not all of them.

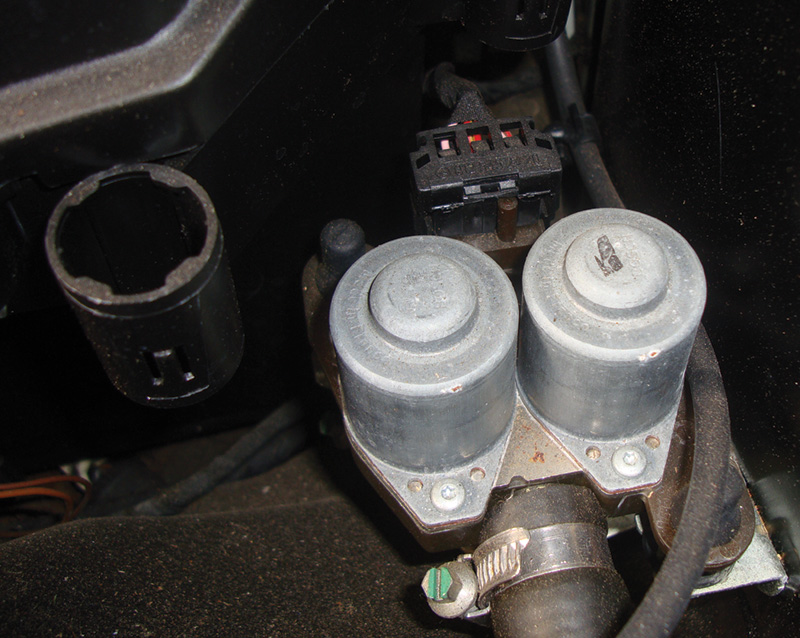

This 124 chassis has the older mono-valve. The heater control valve and the auxiliary coolant pump are integrated into one housing, which is replaced as a unit. Notice the coolant leak from the valve.

All heating systems available in the United States rely on engine coolant to supply the necessary heat for the cabin, so the water pump is an integral part of the system. Low water pump output can lead to insufficient heating, but it can be difficult to diagnose this situation. One strategy is to read the coolant temperature sensor signal voltage either through directly measuring the signal voltage with a DMM, or by using your SDS tool. See how long it takes to get the engine up to normal operating temperature. The PCM monitors the CTS to determine if engine temperature is increasing fast enough to enable closed loop operation within the allotted time. If this takes too long, the PCM should flag Code P0128. Another sign you need to check the water pump is if heat is lost at idle, but returns as engine rpm is increased.

Newer auxiliary coolant pumps have good accessibility. You can easily measure the amp draw while you set the controls to maximum heat. This reading of over one amp is good.

We all know a thermostat remains closed while the engine is cold to direct coolant back into the water pump instead of passing it through the radiator. If the thermostat is stuck open, or has been removed in a misguided attempt to make the engine run cooler, you can also expect Code P0128 because the coolant will take too long to reach normal operating temperature. Of course, this will also reduce heat in the cabin, particularly when the vehicle reaches cruising speeds. If you are accustomed to working on other manufacturers’ vehicles, you may think you can remove the thermostat and see what happens. But with Mercedes-Benz engines doing this is likely to cause overheating. Checking the temperature of the heater hoses is a good way to determine if you have sufficient coolant flow.

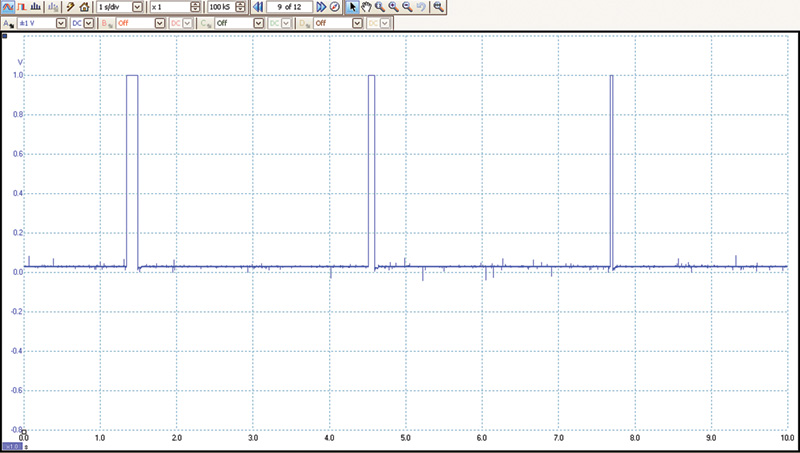

If the duo-valve is accessible, you can check the electrical signals on the two outsde pins of the three-pin connector. This C43 has power on the center pin, and the two outer pins are grounded to close the valve.

For years, Mercedes-Benz vehicles have used auxiliary coolant pumps to assist the flow of hot coolant into and out of the cabin. This is necessary for high-demand situations because dual- and multiple-zone systems have increased the amount of plumbing involved. You should also be aware that electrically-controlled heater valves block coolant flow when the A/C is on. These valves are allowed to open only when heat is selected. On dual- and multiple-zone systems, a duo-valve is used to control coolant flow to the two heater cores underneath the dash and also for the core in the rear of the cabin. The duo-valve is actually two heater control valves in one unit controlled via three wires. The center pin is the common power or ground supply, depending on the application. The two outer wires control the positioning of the two valves. The valves are normally open, so if they fail they should default to full heat.

The outer wires are either supplied power or ground to close the valve and reduce coolant flow. By unplugging the connector, you should get full heat. If not, either the valve is stuck closed or the heater core is clogged. Look at the wiring diagram to determine if the valve is fed power or ground on the center pin. If it is supplied power, the valve would need to be grounded to close, and you will see lower voltage on the outer pin. If the center pin is grounded, then voltage would need to be increased to close the valve. Once you have determined that the duo-valve is functioning, you can start testing the auxiliary coolant pump motor. These motors are not always commanded on when heat is selected. Instead, they are turned on only when high heater temperatures are selected. They are simple two-wire DC motors that have a power and ground supply, and they usually draw about one amp. If you see any less than that, the pump impeller may be loose on its shaft and not be spinning. A higher reading than that means the pump may be starting to seize.

Here is the electrical signal that controls the valve. Unplug the valve’s electrical connector and you should get full heat out of the vents.

Genuine Mercedes-Benz coolant should be used with distilled water to fill the cooling system, which will help reduce corrosion. On almost all models, the recommended change interval for coolant is at 143,000 miles, or 15 years, believe it or not. That incredibly long life is due to the excellent qualities of the OEM antifreeze and a silicate additive packet in the reservoir. Still, nobody will accuse you of doing unnecessary work if you put your customers on a more frequent schedule. This will head off the possibility of clogging in the radiator, thermostat, heater cores, heater control valves, and auxiliary coolant pump.

If you have a water cooler at work, chances are your supplier can provide distilled water. Even clean tap water has additives that may not be compatible with surfaces inside the vehicle’s cooling system. Have a talk with your customers and you will find that most Mercedes-Benz owners will invest in using OEM coolant as opposed to a cheaper brand. When servicing the cooling system, you need to do more than just drain the radiator and refill it. You should also drain the block so that you can replace more than just 50% of the coolant. Refer to WIS for proper procedures and equipment. A coolant exchange machine is an excellent way to more completely (and profitably) replace the contents of the cooling system. After tapping into a cooling hose, old coolant is drawn out of the system. This generates a vacuum, which is used to draw the fresh coolant mixture out of an additional tank to fill the system completely (typically, Mercedes-Benz engines are engineered to self-bleed, but this speeds up the process). Make sure to command full heat from the climate control system to allow coolant to flow more easily in and out of the heater cores. By properly maintaining your customers’ cooling systems with OEM parts and coolant, you can provide years of trouble-free service. If there is ever a problem with the heating system, following the testing procedures explained above for auxiliary coolant pump motors, heater control valves, and water pumps should allow you to arrive at a diagnosis quickly, then offer a cost-effective solution. Your reputation is why your customers bring their vehicles to you, and we want to help keep it that way.

0 Comments