Mercedes-Benz has always been synonymous with agile handling, a stable feel, and compliant suspensions. Active Body Control is one way the company brings these attributes into modern times.

Think of Mercedes-Benz and you may envision a full-size S-Class. Its compliant ride makes easy work of long trips. The driver would want to feel the feedback of a taut suspension, but not so stiff that her or she feels every bump. Or, you may picture the SL-Class. An SL owner may want a stiffer suspension for carving through winding roads. In either case, handling was one reason they purchased a Mercedes-Benz. The ABC suspension system provides the best of both worlds. With it, the driver is in greater control of the vehicle’s ride than was ever before possible, and, where necessary, the ABC control unit reacts to conditions and makes adjustments accordingly. ABC is optional on the S-Class, but standard on some other models.

Active Body Control is aptly named because it is “active.” Like any computer-managed system, it has sensors that read the environment around it and pass this information on to a control unit. This is processed with digital logic and decisions are made on how to best to control the vehicle, commands are sent to accomplish that, and this all occurs within milliseconds of input changes.

Even if the driver is unaware of changes in road conditions, or the level of cornering power that’s necessary for the way the car is being driven, ABC assists in maintaining stability. It is an electro-hydraulic system that directs pressurized fluid to individual strut assemblies to control adjust vehicle level and suspension compliance.

The Heart

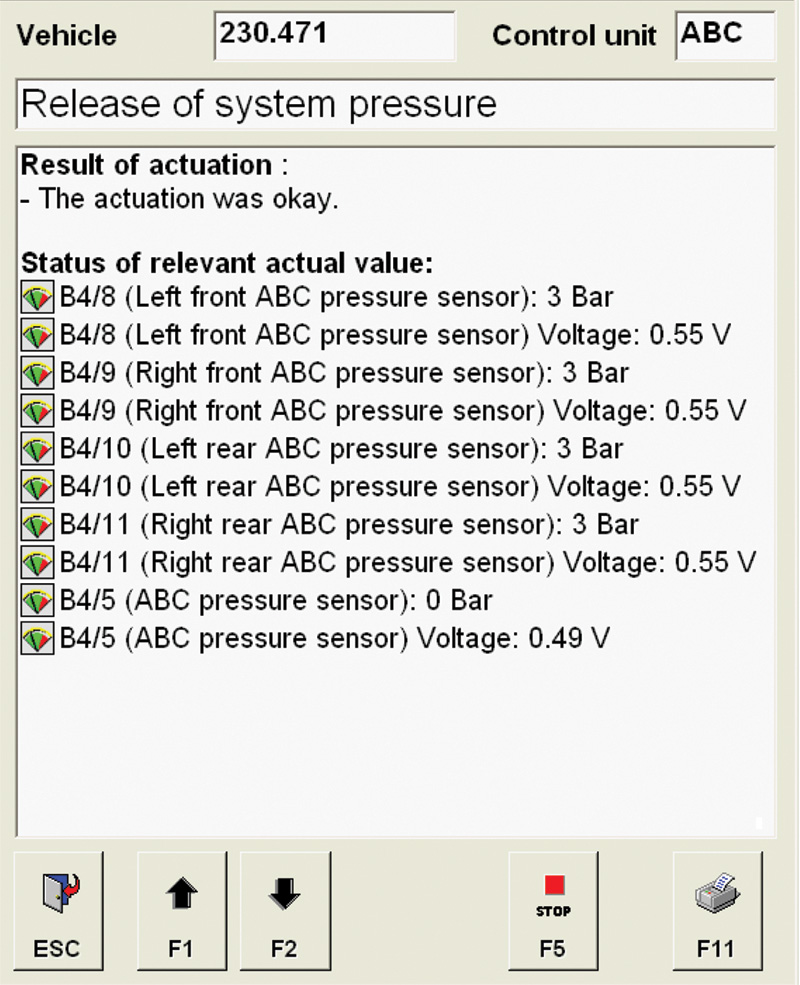

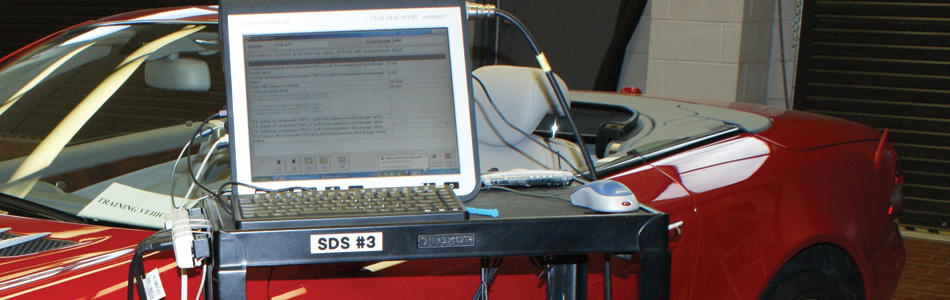

The hydraulic pump is the heart of this system. It is capable of generating over 3,000 psi of force to suspend the vehicle. This is an important factor to know during service. If you are going to be removing hydraulic lines or components, you will need to depressurize the accumulator first. You can perform this task with your SDS, available for purchase though Mercedes-Benz. Contact your dealer, or go to the Mercedes-Benz service information website www.startekinfo.com.

The power steering system shares the same fluid supply and pressure to operate, so when there’s a problem check there for leaks as well. These pumps should not be allowed to run dry. If they do for more than four seconds, internal damage may occur. Fill the reservoirs before starting the engine after servicing. There are filters in the reservoirs and they should be changed when the system is opened and the fluid is replaced.

Any time you are going to open the system, you must release the pressure. Over 200 bar (3,000 psi) may be present, which can be very dangerous to any technician. Through your SDS, you can drop the pressure to a safe level before you begin work.

The pump supplies pressure to a distribution manifold with an accumulator. The accumulator is has a nitrogen charge that bears on a on a diaphragm that separates it from the hydraulic fluid. This maintains the high pressure the system needs when demand exceeds what the pump can supply. This pressure is directed to the front and rear suspension control valves. Each of these has its own accumulator to help maintain pressure in its half of the system. The valves house the solenoids that direct fluid into and out of the strut assemblies. When the vehicle is raised on a lift, these valves are supposed to close to prevent the lines from losing pressure. However, if you have the key on at any time the electronics will depressurize the system to try to lower the now fully-extended suspension. This is not a safe way to depressurize the system for service as there will be some significant residual psi.

Strutting Along

Using your SDS, you can command a dynamic test (aka “Rodeo Mode”) where the system applies and releases pressure to all four corners of the vehicle. Follow the on-screen instructions and accelerate the engine to 3,000 rpm so the pump can supply enough pressure for the test.

Each strut assembly has two individual solenoids. One controls the vehicle level and the other controls the dampening stiffness of the strut. In the front valve assembly, there are two pairs of solenoids, one for the driver’s side and the other for the passenger’s side suspension. The same applies to the rear valve. There is an internal spring inside each strut assembly. Typically, the ABC control unit supplies power and ground for the solenoids. The level solenoid both allows higher fluid pressure to raise its strut, and releases excess pressure to lower the vehicle. The suspension control solenoid acts the same way. It opens and either lowers the pressure or increases it to change the dampening characteristics of the shock. The overall system pressure is generated by the pump and regulated by the ABC Suction Restrictor Valve. The pump makes pressure and the restrictor valve bleeds off the excess and returns it to the reservoir.

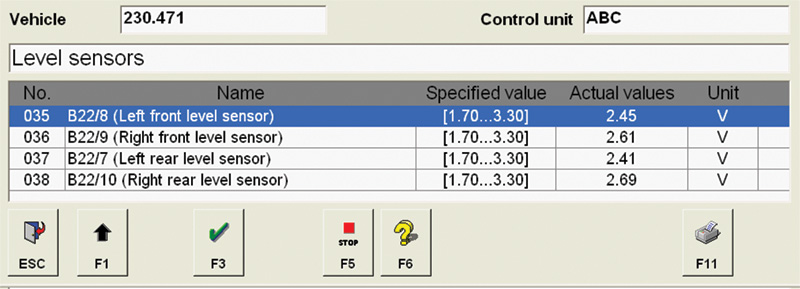

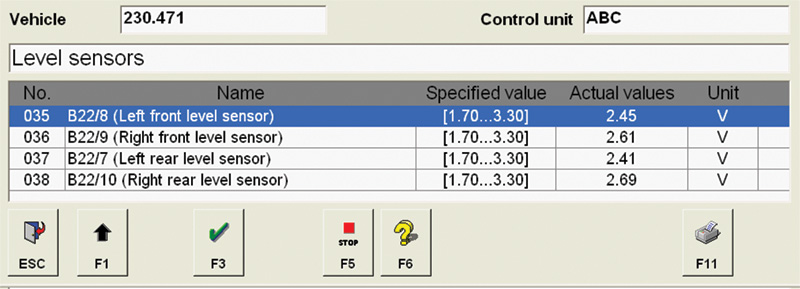

With your SDS, you can monitor the voltage of the level sensors to isolate a bad one. You can also monitor system pressures, plunger solenoid amp draw, and body acceleration sensor signal voltage.

The ABC control unit knows what the system pressure is by means of a sensor. Its location varies depending on the model you are working on. For instance, a 220 chassis has it mounted in the fluid distribution manifold under the sub-frame on the passenger’s side. A 230 chassis may have it in the front control valve, which is mounted in the front wheel house on the driver’s side, behind the bumper. It reads the main system pressure that is being fed to the front and rear control valves. It is a three-wire sensor with a five-volt reference, signal voltage, and a ground wire all going to the ABC control unit. You can monitor this voltage and get a corresponding pressure reading in Actual Values on your SDS (Star Diagnostic System). You can also read the pressure in each strut assembly with your SDS software.

A Symphony of Sensors

Above: In the static position on level ground the body acceleration sensors should read about 2.5V. As the vehicle moves, the signal voltage will increase or decrease depending on vehicle direction. If these sensors are off by more than a few tenths of a volt, the control unit will flag a code.

In order for an ABC system to accurately control each corner of the vehicle, it needs multiple sensors to read individual ride height, suspension events, and the overall direction and movement of the body. This is accomplished with a symphony of sensors mounted in both suspension components and the body. Each strut has one sensor that reads vehicle level and another that reports on the rate of the strut’s acceleration. The level sensor helps the ABC control unit set the ride height and the plunger travel sensor monitors suspension movements over bumps. The level control sensors are mounted on the body of the vehicle with a linkage attached to the lower control arm of each corner. The plunger travel sensors are mounted inside the strut assembly and are not serviceable separately. If one fails you will have to replace the strut itself.

With your SDS, you can monitor the voltage of the level sensors to isolate a bad one. You can also monitor system pressures, plunger solenoid amp draw, and body acceleration sensor signal voltage.

There are typically five additional sensors that help the ABC control unit determine direction, rotational speed, and rate of change the body. There are the front right and left body acceleration sensors, the rear left body acceleration sensor (the right rear’s movement is extrapolated from the signals generated by the other three), a lateral acceleration sensor, and longitudinal acceleration sensor. They have the job of telling the ABC control unit if the vehicle is accelerating or braking, and to what degree the vehicle is being turned to the left or the right. Normally, without the help of ABC, the suspension on the outside of the turn is compressed. The height, plunger travel, and acceleration sensors for that side tell the ABC unit that. If it feels it needs to, it can apply greater ABC system pressure to that side’s strut assemblies, extending them, much the way a cheetah extends its outside legs in a 60-mph turn. It’s simple physics, but the process is high-tech.

The “Active” in ABC

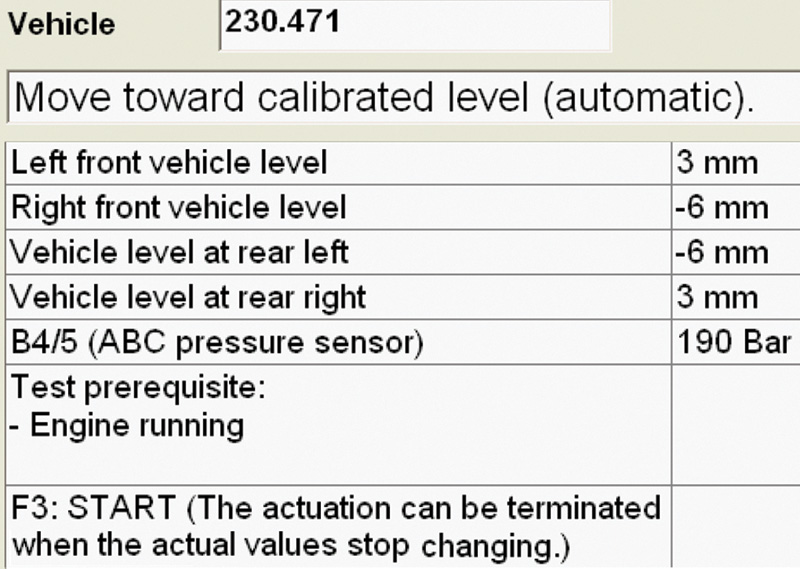

After completing an ABC repair, you should perform a level calibration under “Actuations” with your SDS to match the vehicle to the new components you have installed. This improves ride quality and helps determine if there are any other problems with the system.

ABC prevents the suspension from unsettling the vehicle or bottoming out if the driver goes over a large bump in the middle of a turn. All of the sensors mentioned are of the three-wire type with a five-volt reference, signal wire, and ground, all connected to the control unit. The body acceleration sensors have to be able to react differently in each situation. The signal voltage is close to 2.5 volts with the vehicle level and standing still, or while driving straight down the road at a steady speed. Under acceleration and deceleration, the longitudinal acceleration sensor will either increase or decrease its voltage from 2.5 volts. If you turn the steering wheel hard enough to the left, right and rear body acceleration sensors will also deviate from the 2.5 volt static position. You can monitor these voltages while someone else drives the vehicle, or you can observe these reading with your SDS.

Some of the functions of the ABC system can be adjusted manually. To improve the center of gravity at higher speeds, the ABC control unit automatically lowers the vehicle, but the driver has some control of the ride height via a switch on the control panel in case he or she wants to raise the car when entering a steep driveway, for example. On the 230 chassis, there is also a sport setting for stiffer damping.

Automatic functions may not work properly if the ABC system is not calibrated. If you have to service the system, there are several functions that will need to be performed with the SDS unit. We already discussed the importance of depressurizing before opening the hydraulics. Beyond that, you will have to perform a level calibration, plunger sensor calibration, and a load compensation calibration in that order before the system will work as it’s supposed to.

Using Your SDS

There are many dynamic tests you can perform with the SDS to verify that the ABC components are functioning properly. Under “Actual Values,” you can monitor the signal voltages of level sensor and plunger travel sensor, and the individual pressure readings for each strut. You can also monitor the current draw of each plunger solenoid that controls pressure to the strut assemblies. This will let you know if a solenoid is sticking, which may cause a corner to stay in the up or down position. Typically, they draw under 750ma when being operated. If you see a reading higher than that, suspect a sticking solenoid. Level sensor signals are given in voltages, which will, of course, vary with the ride-height setting. You can also read the ride heights by their deviation from the calibrated level.

Once you have replaced the defective hydraulic or electrical ABC component, you will have to perform some steps on a level surface before you can return the vehicle to the customer. First, you should reset the system to the calibrated level. You can find this under “Actuations” on your SDS. You will not notice the vehicle moving, but you will see the deviation in millimeters change. When the numbers stop changing the calibration is complete. Performing these last few steps will improve ride control.

Knowing how the system works and how to properly service it will keep your customers coming back to you. Original OEM parts from your Mercedes-Benz dealer will ensure the quality of your repairs. While you are at the dealer picking up parts, you should also remember the filters in the ABC reservoir and the CHF 11s fluid that Mercedes-Benz specifies for its hydraulic systems. Complete the repair by recalibrating the ABC and you will have serviced the vehicle just as the dealer would have.

0 Comments