Every so often we run into the problem of not having a problem to solve. What do we do when we have a vehicle that is not setting codes, but it is also not running OBD II monitors? They need to run so the car can pass our state inspection program. Well, this Honda gave us plenty not to solve, so how did we do it?

When we were young and learning how to diagnose fuel-injected engines, all the old timers would beg for a carbureted vehicle to diagnose. In later years as we all got more familiar with fuel injection, we would all complain, “Oh no, I have to diagnose a carbureted engine? Give me fuel injection!” Our biggest problem was that each manufacturer had its own ways of doing things. We had to learn many different systems both domestic and foreign. We had to know GM, Ford, and Chrysler, plus Asian and European engine management systems. Remember those days?

Then OBD II came along in the mid-nineties and that was going to fix everything. All the manufacturers were going to have their diagnostic software speak the same language. Didn’t that just work out great? We can’t wait for OBD III! (we hope you’re catching our drift). One of the great accomplishments of OBD II was the setting up of “monitors,” which would run or not according to the system’s whims.

Self-diagnostic ability was built into each engine management computer. It would monitor the input sensor values and output solenoid controls and make sure each component of each system was functioning properly. Some of these systems are monitored continuously (all the time), and others are not monitored continuously (non-continuous), but are tested as the vehicle completes a “drive cycle.”. Three monitors are continuous: the misfire monitor, the fuel system monitor, and the comprehensive component monitor. The PCM is always watching crankshaft speed for misfires. Misfires can lead to increased harmful emissions and destroy the cat. The fuel injection feedback system is also monitored to see if the vehicle is running too rich or too lean, which may also lead to an increase in air pollution. Finally, the comprehensive component monitor looks at input signal voltages to make sure they make sense, and at all of the output voltages to make sure the computer can control the system.

Non-continuous monitors are tests the PCM performs on a system while the vehicle is running and certain conditions are met. Although the EPA would probably like it if an engineer would test the O2 sensor while the engine is under the heavy load of acceleration while going up a hill, that wouldn’t be fair to the O2 sensor. A rich condition is required under load. However, most of us do not spend all our time driving uphill. On a flat and steady road, the engineer can have the PCM check its systems since all of the input sensor readings are stable as the vehicle cruises along. The PCM’s fuel control system can watch the O2 sensor signal voltage and make sure it is switching between rich and lean within a specific time frame. If it is, the O2 sensor passes the test and the monitor will indicate that it has run and passed. If not, then the monitor will indicate a failure, and after a second running flag a code.

Well, it’s one thing to have a vehicle come in with a flagged DTC. All we have to do is scan the PCM for DTCs and look up the code in our information system. We are often rewarded with a flow chart outlining test procedures we can follow, use our personal experience to test the system that has the fault and/or, dare I say, just wing it and replace something that’s likely to fix the problem. There are many ways we can approach the problem. Some are the long way and others are the short way, but we each have our own way. After the repair, we can retest the system and verify that it worked. Sometimes, particularly with intermittent problems, we have to wait to find out while our customers drive the vehicle we repaired. As the PCM runs its monitors, it will either pass or fail depending on the accuracy of our diagnosis and repair.

It’s another thing when we do not have any DTCs. There may not even be a drivability problem that our customer is complaining about. But if the car has to go to a motor vehicle inspection facility and these monitors have not run, the owner may get a “tsk, tsk, tsk . . .” from the inspector, who might believe someone has cleared the DTCs and tried to sneak the vehicle through inspection. The fact that the monitors have not run might make the inspector suspect that the owner is trying to hide some failure. The vehicle has to be driven and these monitors have to run to completion in order for the state to okay the emissions portion of the inspection program. If the monitors have not run, you have to keep driving until they do. Some states allow a grace period, which gives the owner enough time to drive the vehicle legally until the monitors run.

But what happens after “saying grace” and the monitors still haven’t run? That was the case with the 2001 Honda Accord with a 2.3L four that’s our subject here. It came in and some work needed to be done for it to pass inspection. After the work was done it still had a problem. It was not flagging any DTCs, but it was also not running its monitors to completion. None of the monitors ran — not one! So where were we going to start? We did not have a code and there was no drivability problem to diagnose. We may have a bad PCM, so can we trust the data we’re getting? We tried using the vehicle-specific software in our aftermarket scan tool, but we didn’t find any codes there, either. We could’ve started by looking at data to see if something seems unusual to us, but if nothing leapt out at us, what were we going to do?

We decided to do some simple testing of the engine management system. We like to start off with the basics and make sure we are not missing something obvious. Fuel pressure first, which is not easy. There are no pressure tap Schraders on the rail of this vehicle. With the proper adapters, we could have tapped into the banjo bolt that brings the fuel pressure into the rail, but we decided that since the vehicle was on the lift and we were going to change the fuel filter anyway, we would connect our Motor Vac machine to the fuel filter. Unfortunately, we had a perfectly reasonable 40 psi. After changing the filter, we moved on to a basic manifold vacuum test and found we had a very normal 20 in. Hg at idle with no load — nothing wrong here.

We moved on to sensor readings. We compared the MAP sensor voltage to the MAP sensor we were seeing. Typically, a good MAP sensor will read 2.9V with the key on and the engine off and .9 to 1.0V idling with 20 in. HG in the manifold. This reading may vary depending on your altitude, but for us these were normal numbers. We looked at the coolant sensor to make sure the engine was getting up to temperature, and it was. Just idling, it went up to 205 deg. F., so we knew the thermostat was closing properly and keeping the engine up to temperature. We checked the TPS signal voltage and saw that it read about .75V closed. We did not know if this was normal, but the PCM was not flagging a TPS code or an idle too high or too low code. We needed to find some answers.

We did have a unique tool just for situations like this. It is called PH2 Solutions. It is a software program and special OBD II cable that connects to the USB port of your PC. It is also available already installed on a laptop computer. This tool has some unique features. It is not a manufacturer-specific scan tool. It communicates with the PCM using one of the generic OBD II protocols of the car it is plugged into. It can work well as a generic scan tool. It can pull codes and pending codes and clear them. It can also tell you which monitors have run and which ones have not. Its most important task is to tell you what “conditions” the PCM is looking at while it is deciding which monitors to run to completion and which ones it will not.

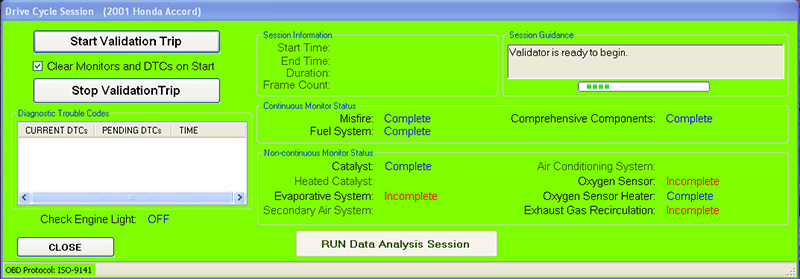

With nothing else to go on, we decided to try out our new tool. There are two applications. The first is the Drive Cycle Validator. Using this function you are instructed to drive the vehicle on a 15-minute road test with the Drive Cycle software running. An ideal road test would be about 7 ½ minutes at 45 mph, then increase speed to 55mph for another 7 ½ minutes. In the Drive Cycle software is a clock that lets you know how long the session is running. Some vehicles may require more driving, but the Drive cycle software will let you know right away which monitors have already run and if there are pending or hard codes that have set in the PCM. The drive cycle is also a good way to verify a repair right away instead of returning the vehicle to the customer and seeing if the code comes back.

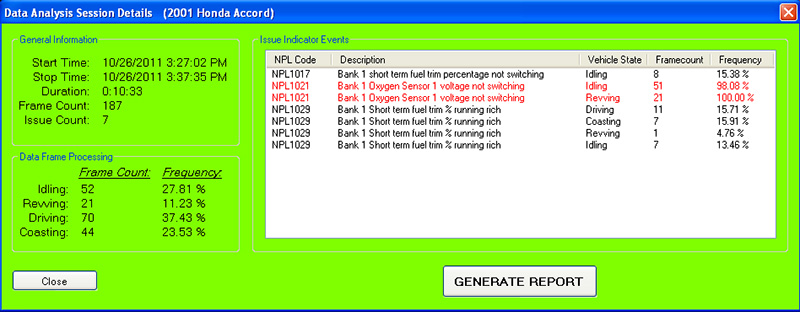

The second part of the PH2 Solutions program is called the Data Analysis Session. This actually provides feedback while you are driving the vehicle. Once you start the analysis, the software starts analyzing frames of data. These frames are broken down into Idling, Revving (acceleration), Driving (steady cruising speed), and Coasting. This helps you isolate when the problem is occurring. If your problem is at idle, you only need to test the vehicle at idle. In the lower “Issue Indicator Event” field, you are informed of the condition that is interfering with the running of the monitors. This is a tremendous help when dealing with a vehicle that will not run monitors. The PH2 software is not going to run the monitor for you as you can on Audis and Volkswagens, for example, but it does tell you the conditions that are interfering with running the monitors. These conditions may not be so severe that they flag a code.

We started a data analysis session and went for a road test. We immediately saw what we thought was the problem. The first messages we received indicated that the coolant temperature and air temperature were too low to run any monitors. We have heard in the past of thermostats sticking open and allowing the engine temperature to drop while driving down the road. We called their technical support specialist and found that the vehicle needs to be properly warmed up before you can start the analysis. We then allowed the vehicle to idle for 15 minutes to get the engine to full operating temperature. Once we did this and ran the session again the coolant and air temperature messages went away, but at least we knew the software was working. We now went on another road test and started to see the real cause of the problem — we were rewarded with usable results.

The first message we saw was “Bank 1 Oxygen Sensor 1 voltage not switching.” We did not have O2 sensor codes, but our PH2 was telling us the oxygen sensor voltage was not switching between rich and lean. The problem was happening at idle. We needed to continue the road test to see if the problem also occurred during acceleration, cruising, and on deceleration. During the road test there were no messages telling us about any problems with driving conditions, but when the vehicle returned to idle the message “voltage not switching” returned. So, we at least knew the problem was only at idle. We now had something we could start looking for. We did not think we had a mixture problem at idle, but apparently we did. We kept the engine at idle and started looking at O2 sensor activity and fuel trim readings. We were surprised with what we found.

The next step was to look at scan data. We would normally put an oscilloscope on the O2 sensor signal wire, but this was an F23A4 motor so it has an Air Fuel Ratio (AFR) sensor. These sensors use milliamps to signal a rich or lean condition and are very difficult to scope. We did find two technical service bulletins from Honda, but both dealt with the tremendous cost of replacing the Air Fuel Ratio sensor, PCM and, in one case, all four injectors. This could have been a costly repair for our customer, so we decided to look at little deeper and see if we could do something else first. A quick look at the fuel trims showed us something we didn’t expect.

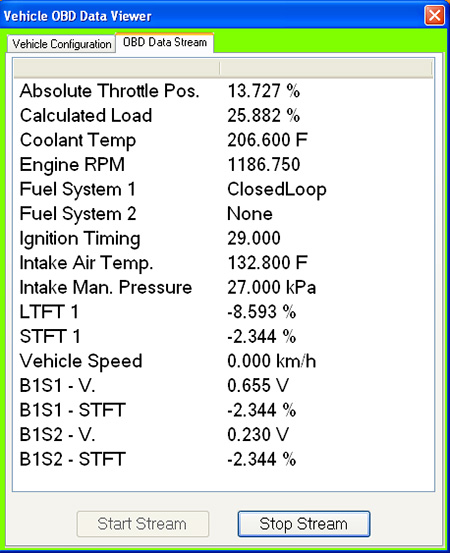

We found we could use the PH2 Solutions software as a generic scan tool. Looking under Tools in the Menu bar, you can view a live OBD II data stream. At idle, the fuel trims were unusual. After idling for five minutes, we noticed the long-term fuel trim was about -8% and the short term fuel trim was about -2%. Now we knew why this did not flag any codes. Typically, fuel trims have to shift over 10% +/- to set a code. We were under the limit, but very close to setting a code for an O2 sensor rich condition. We still had to find out what was causing the richness. The TSB having us replacing the injectors was looking like the fix for this one. We could have performed a fuel contribution test for each injector, but what if they all flowed the same?

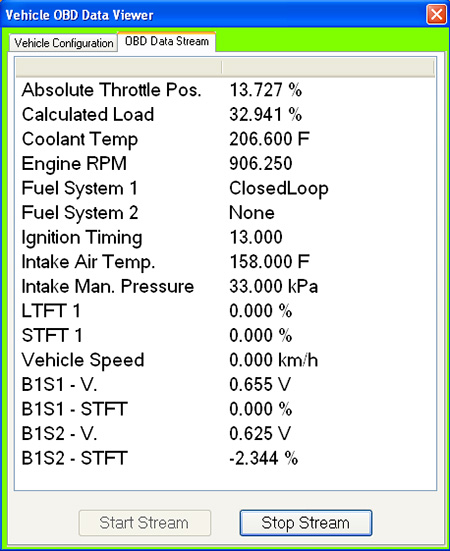

We went back over our sensor readings and the only one we were not sure of was the TPS. We looked up the DTC for the TPS and Honda specifications told us the voltage should be about .5V, but we were at .75V. Now, you cannot change the TPS on a Honda. They sell the TPS with the whole throttle body. The TPS is riveted and the mounting holes are not slotted, so you cannot adjust it. I don’t recommend this as a repair, but as a simple, quick way to test the system after making a change. We bent the throttle tab until the TPS voltage indicated .5V. We then disconnected the battery to reset the fuel trims to 0%. After an extended idle both fuel trims remained at 0% at a normal idle speed of 900 rpm.

Admittedly, we had never noticed the abnormally high idle speed of 1,100rpm. But remember, the PCM did not flag a P0506/P0507, either. They did not even show up as pending codes! We found that our new tool, the PH2 Solutions, pointed us in the right direction when we did not have any direction. It caused us to take a closer look at what conditions were not being met to run the all-important O2 sensor monitor. Once the TPS voltage was corrected, the idle speed returned to normal and so did the fuel trims. In the state of New Jersey, 2001 and later vehicles need to have all but one monitor run to pass the state inspection process. This Honda finally passed with flying colors once the throttle body was replaced and the TPS voltage was back within specifications. Now who would have thought of that?

by Kerry Jonsson

0 Comments