Being some of the most sophisticated vehicles in the world, just about every aspect of BMWs is a technological marvel. Think about how these vehicles have evolved over the last couple of decades and you might put the engineering that went into them right up there with that of the space shuttle. Take their HVAC systems, for example. To say they’re extremely advanced is an understatement, which requires considerable discipline on your part if you want to understand how they work and interact with the rest of the vehicle. Never forget, however, that the basics still apply. You still need to check such things as the refrigerant charge, blower operation, blend door movement, coolant level and condition, etc.

Once you go beyond those essentials, you must learn a considerable amount of additional information about the various climate control systems BMW offers so you will be prepared when problems arise. Knowing the subtleties of how these systems function can make the difference between being profitable and struggling to break even. You need to know how the A/C compressor is controlled, how heat is provided, and what controls blower motor operation. This may sound simple enough, but there are three available options and all are electronically controlled to some extent, which takes this area of service onto another level.

In The Old Days

BMW has used several systems to control the interior temperature of its vehicles over the years, each with its own level of sophistication. For example, IHKS is a manual system typically found on 3-Series cars such as the 318ti, Z3 and Z8. The driver is in control of temperature settings, mode door position, and blower speed. Despite the fact that it’s basically manual, many of the components are electronically-controlled. For instance, the A/C compressor is ruled by the DME, which also handles fuel injection. It directly controls the compressor through a relay, and it can increase idle speed to handle the additional load. An input from the IHKS system tells the DME when to energize the clutch. Blower speed is handled by multiple resistors through a switch. Mode door control is by means of a manual cable except for the motor that handles fresh air recirculation. This motor receives a pulse width-modulated signal from the IHKS control unit and opens or closes the door accordingly.

The next level of sophistication is IHKR. This was an option on the 3-Series and standard on most 5-Series, and is considered semi-automatic. Blower speed is still controlled with multiple resistors, and mode door control is still by means of cable, but cabin temperature is regulated by the IHKR control unit. Sensors send interior and exterior temperature readings to the electronics, which use that data to make decisions about how best to control the compressor and blend door.

Both IHKS and IHKR have pressure switches that will only pass along the A/C request if there is enough refrigerant in the system. They also shut off the compressor if the pressure exceeds approximately 450 psi on the high side. Another sensor reading that can shut off compressor operation is that from the evaporator temperature sensor. This is mounted in the evaporator core and its resistance rises as it gets colder, which keeps the signal voltage high. If the signal voltage drops too low, the IHKS/R control unit will shut off the compressor. While IHKR automatically responds to temperature changes, it still can only provide the same temperature air to all of the vehicle’s occupants.

The Flagship of AC Systems

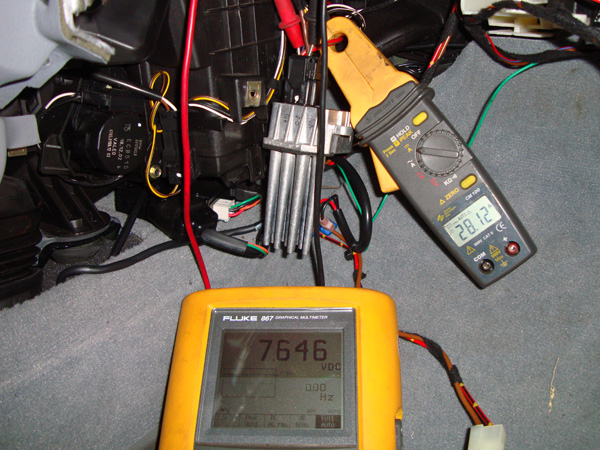

Here we are measuring the command signal from the IHKA control unit to the blower module, and the motor’s amp draw. With the highest blower speed selected, 7.5V is being sent to the blower module, which then grounds the motor. Draw is about 30 amps.

BMW’s most sophisticated HVAC is IHKA. It’s fully automatic, so it reacts to changes in temperature load by controlling blower speed, compressor operation, and mode door control. That’s right, the A/C compressor is now controlled by the IHKA control unit, not the DME. This information is passed along to the DME so it can adjust idle speed for the additional load. The IKHA control unit is integrated with the switch assembly, and blower speed control is computer-controlled. A final-stage blower module uses integrated circuitry (a power transistor) to vary the amperage on the ground side of the motor. An analog signal is sent from the IHKA control unit to this module. As the voltage increases, so does the blower speed. Usually, this voltage command varies from 0V to approximately 7V. This allows the control unit to regulate blower speed as temperature inputs change without any assistance from the driver. The mode doors are also controlled by the IHKA unit, which sends signals on a single wire to each servo motor. This is known as the MI-Bus. Specific pulse width-modulated signals command specific doors to open or close.

On more recent high-end chassis such as E66 and later 7-Series, FKA (rear climate control) has been implemented. This is a three-zone system where the two front passengers and the rear passengers can control temperature independently. On the E70, a true four-zone system is used wherein each individual passenger has control of the temperature in his or her own area. This is achieved with an HVAC unit mounted in the front of the trunk that handles the temperature control of the rear cabin. It has independent control of mode doors and blower speed, but shares the same A/C system otherwise. However, there are two separate refrigerant control valves for the front and rear evaporators. This requires some additional service procedures. You will need to use the iComm/ISTA diagnostic interface to put the dual system into a filling mode. This fully opens the refrigerant control valves so the system can be evacuated and refilled.

Bringing Up The Rear

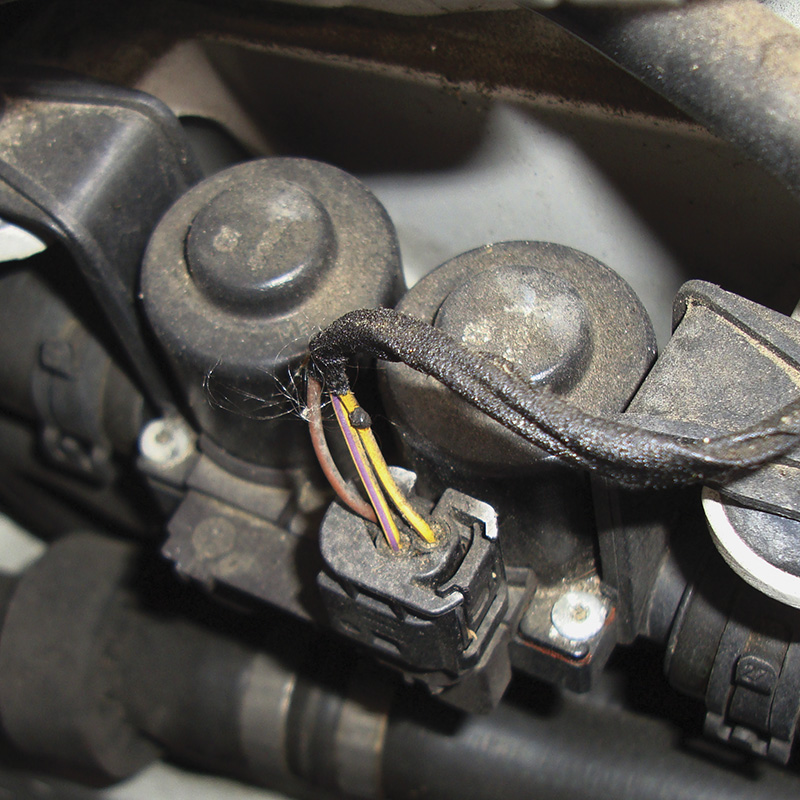

The duo-valve is a two-part heater valve that can independently control coolant flow to two separate heater cores. This is critical to the water-based control of interior temperatures. The valves are normally open, and are pulsed closed to reduce the heat supply.

Some specific service procedures are required if the rear system is to continue to function properly. There are two independent control panels, one for each side of the rear seats, but only the right-side panel has the intelligence to learn the stops for all the servo motors. The left side must be calibrated to the right side after service work is performed. You can find these procedures on www.bmwtechinfo.com. On 2007 and later X5s, there is an additional third-row heater option that is different from conventional heating systems. This new system is referred to as HB3SR, and uses a PTC (Positive Temperature Coefficient) heater element for the rearmost seats. This is an electrical system that is not part of IHKA. It is part of the vehicle’s electrical system and can be shut off, or heating output can be reduced by 50% through the LIN bus if the amperage load exceeds what is available from the charging system. A HB3SR control unit manages the 300-watt ceramic element, which is heated by electric coils. This is only activated when maximum heat is selected.

BMW uses both water-based and air-based temperature control. This allows greater flexibility in individual temperature control of the separate passenger zones. For instance, the two front zones of a 745Li have separate heater cores. The air is cooled as is passes through the single evaporator core. It is then heated to the set temperature for that side of the cabin by the heater core for that zone. Two water valves or duo-valves control the quantity of heated coolant into each heater core. In an air-based system, either fresh or recirculated air is directed through the evaporator and the heater core. The position of the temperature blend door is controlled to combine heated and cooled air until the desired temperature is reached. BMW employs both single- and dual-zone air-based systems. These provide greater control over interior temperatures, but take up a larger volume of space inside the dashboard.

Sensing the Change

Engines with conventional belt-driven water pumps may have an auxiliary electric pump to increase the supply of heated coolant for the cabin (it draws about one amp). BMW engines with electric water pumps no longer use the auxiliary pump.

Either IHKA water- or air-based systems require sensors for feedback to work properly. The interior temperature sensor is mounted in the control panel of the IHKA unit. Very small voltage changes occur in this sensor since the temperature range is relatively small. There may be footwell temperature sensors as well to enhance the overall interior temperature reading. The outside temperature is also read by its own sensor, which is typically mounted in the front bumper area and is wired to the instrument cluster. This information is put on the CAN bus and distributed to all the control units that require it. The IHKA unit is one of them and uses the outside temperature signal to detect the overall load on the system. There are many other temperature sensors involved. An evaporator temperature sensor is still used to determine if the evaporator is freezing. Condensation build-up in the evaporator can freeze and block air flow, reducing the quantity of cool air.

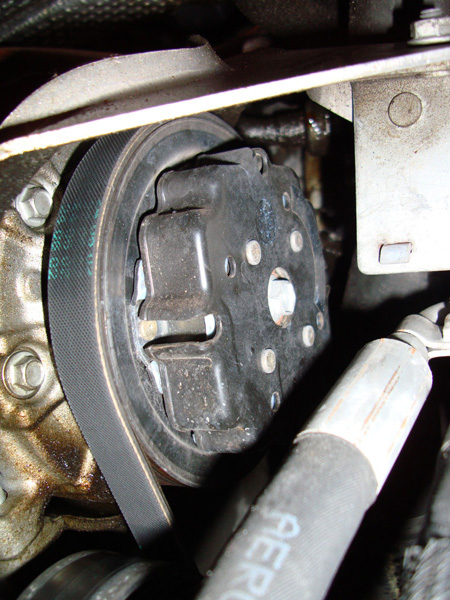

The A/C compressor shuts off if the evaporator starts to freeze up. On older models, the DME controls the compressor, but more modern BMWs use the IHKA control unit. This is no longer done by cycling the compressor on and off as BMW now uses variable-displacement compressors. In place of an electrical/magnetic clutch, a rubber coupling connects the outer pulley with the inner compressor drive shaft. So, if the compressor seizes the rubber decouples and allows the single serpentine belt to continue to spin other, more crucial components, such as the water pump. Compressor output is adjusted by means of a control valve that uses low-side pressure to position the swash plate inside the compressor and adjust the length of the pistons’ stroke. The plate can be positioned to produce a minimal stroke and offer little to no load on the engine. When A/C demand is high, the compressor displacement is increased by repositioning the swash plate to maximum stroke.

A Flexible Compressor

When you look at the pulley of a variable-displacement compressor, you’ll see a rubber coupling instead of a clutch. A control valve in the rear of the compressor adjusts the output according to commands from the IHKA control unit.

This changes the way you look at A/C pressure readings. Of course, you have to verify that you have the correct quantity of R-134 in the system. The specified charge can be found on a green sticker mounted under the hood. With modern evacuation and recovery equipment, you can easily verify a proper fill. On dual-zone systems, remember to use iComm/ISTA to engage the fill mode. While checking system pressures, you need to make sure the compressor is commanded fully open. This may require that you set the A/C system to MAX and open all the doors. The interior temperature sensors will read the warmer air and request greater cooling. The compressor will be commanded to maximum stroke and you can watch the high- and low-side pressures. As a guideline, the low-side pressure will ideally drop below 30 psi while under maximum load. The high-side will vary more with ambient temperature. On cool days, you may only see 150 psi or so, but on hot days it may go as high a 400 psi. You should have a large fan blowing through the condenser to simulate road speed for accurate performance information.

With hot weather approaching, your customers will want their air conditioning systems to work just as it did when the vehicle was new. Deep knowledge of BMW climate control systems we will enable to address their concerns with accurate diagnosis and genuine BMW parts. Utilize the three biggest tools in your arsenal: www.bmwtechinfo.com, iComm/ISTA, and your local BMW dealer’s parts department.

0 Comments