Serpentine belts have changed the dynamics of powering a wide variety of engine accessories. Dealing with apparent “belt noise” is often the first step in recognizing that a belt and possibly other system components are worn out, or operating under duress — it might be only a matter of time before a breakdown on the road.

Jumping into his pristine Mercedes-Benz, the driver fires it up, backs out of his driveway, and quickly heads out for an appointment. Proudly wearing its three-pointed star, the vehicle continues to run perfectly and is a constant pleasure to drive and own.

But there’s that noise. As he accelerates, an annoying squeal sounds off again from under the hood.

“Would probably have been one of the fan belts slipping in an old car, but I’ve heard that now there’s a single belt that powers everything, and there is no traditional fan belt,” he thinks. “This isn’t getting any better and could be most anything. Better have it looked at.” Good idea.

Depending on the age of the vehicle, myriad noises that make you suspect a belt could be from the:

- Radiator fan

- Air conditioning compressor

- Water pump

- Power steering

- Alternator

- Serpentine belt, which replaces all of those accessory belts in modern cars

You need to evaluate the entire accessory drive system when tracking down noises that sound like a misbehaving belt, including belt, tensioner, and pulley condition, vehicle mileage, the state of the belt-driven components including the power steering pump, air conditioning compressor, water pump, and alternator. Unsteady or sporadic alternator performance, for instance, can not only interfere with the smooth running of the belt, but might even turn on the MIL (Malfunction Indicator Lamp).

Serpentine saves power and space

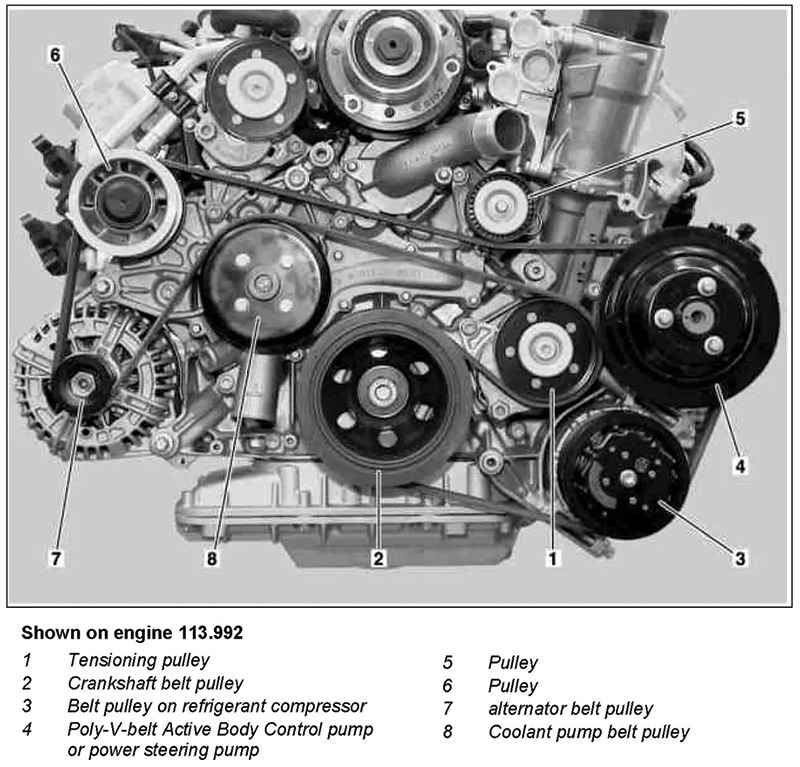

The serp on this Mercedes-Benz W211 E55 AMG engine engages eight pulleys. Ten is the most we’ve seen.

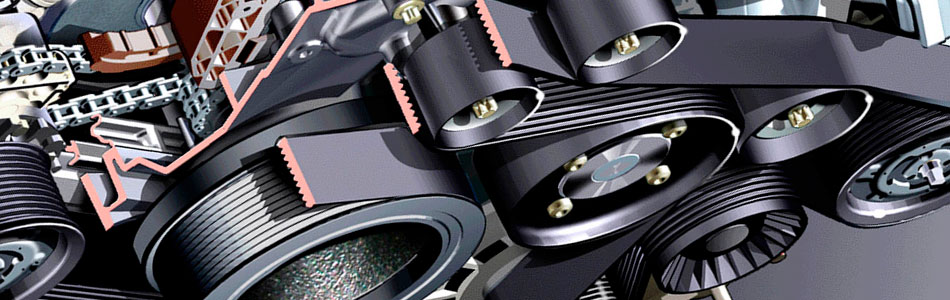

The flat multi-”V” belt (also known as poly “V,” multi groove, or multi ribbed) with all its advantages was first adopted in the late 1970s, and its applications have evolved from fixed centers and manual tension adjustments to the hugely-successful full-serpentine with its automatic tensioner we have today.

Ever since Mercedes-Benz began using the full-serpentine two decades ago, it’s been the Lord of the Belts. It’s more energy-efficient and saves space in the engine compartment when compared to traditional “V” belts. When all is right with a “serp,” it works like a charm, and R&R no longer involves bloody knuckles. If some condition should cause it to slip, or, worse yet, snap, virtually every system vital to the car’s mobility will be adversely affected. Belt failure is dangerous, so much so that the A/C compressor clutch circuit interrupter was created to keep the belt from burning up if the compressor should seize.

The serpentine concept of a single, all-encompassing power take-off handling multiple accessories, rather than an individual belt for every application, was originally intended primarily as a packaging efficiency. By eliminating a stack of “V” belts, the engine package could be made considerably shorter, and accessories could be powered off both the front and back faces of the belt. Other compelling serpentine strengths are its heat-dissipating qualities, its ability to spin fast without lifting off and losing its grip (a function of its light weight), and the flexibility to bend around the small diameter pulleys needed for high drive ratios.

Keeping the belt engaged and on track requires relatively low tension due to even loading across its full width, and this tension is provided automatically by a spring loaded idler, which eliminates the need for periodic manual adjustments.

A squeal, or a chirp?

But let’s get back to the driver with the noise.

There are two quite different common belt noises — “chirp” and “squeal” — with unique causes and solutions to whatever problem is causing the noise. A “squeal” is a high-pitched sound that continues for a matter of seconds, or remains constant. It will usually get louder with increased engine speed and is normally caused by chronic slippage between the belt and pulleys. A “chirp” is a sharp, short-duration noise, also high-pitched, that is commonly present at low engine speeds or idle. As belt speed increases, the chirp may diminish and disappear. Most chirps happen as a short belt span goes into a grooved pulley after leaving a pulley on the back side.

Chirping is normally from a misaligned pulley where the belt ridges initially contact the sides of the pulley’s grooves, then slide downward along the groove’s sides as the ridges seat. This could mean:

- Pulley misaligned or improperly installed

- Belt ribs extremely worn

- Worn pulley bearings causing the pulley to wobble and rock

- Contamination from oil, power steering fluid, antifreeze, belt dressing, or other substances

A squeal that occurs only when the vehicle is accelerating, or only when the engine is started cold, is probably due to a slipping belt. Causes of slip and squeal include:

- Low belt tension

- Substantial belt wear, stretched belt, degraded tensioner spring, or an excessively long belt

- Accessory or idler pulley drag, seized bearings, or accessory lock-up

- Contamination, especially from automotive fluids, but perhaps from the unconscionable use of belt dressing — that outmoded sticky stuff has always been verboten on multi-”V” belts.

- Water splashing onto the belt causing hydroplaning and loss of “traction,” as you might say of a tire.

This old chloroprene/neoprene belt shows the cracking that outmoded material commonly developed. It was still driving those accessories at 120,000 miles, which is testament to the serpentine concept’s basic durability, but failure was imminent.

Serpentine belt issues are commonly the result of a weak belt tensioner spring, damaged or dry tensioner or idler pulley bearings, misalignment of a pulley, or bad bearings causing wobble or drag in one of the accessories the belt drives.

Standard industry belt diagnostics and maintenance once centered on replacing a serpentine belt if it had three cracks in a three-inch section. This was a good rule for older chloroprene/neoprene belts, but inappropriate for today’s EPDM belts. EPDM (ethylene propylene diene monomer), which began to appear in the late 1990s, is much more resistant to cracking and “chunking,” so cracks are no longer a good indicator of a belt’s condition. Wear is the main problem since they are expected to survive for over 100,000 miles. So, you should be looking for material loss on the sides of the “V”s, and inexpensive plastic gauges are available to help you detect it.

More on EPDM

In the late 1990s, Mercedes-Benz replaced chloroprene/neoprene serpentine belts with those made of ethylene propylene diene monomer (EPDM). You can’t tell these materials apart visually, but there’s a huge difference in durability. Belts made with the older stuff have a life expectancy of 60,000 miles or so, and typically display deterioration as cracks and chunk-outs.

EPDM belts usually don’t give you these visible signs even at more than 100,000 miles, but they are still suffering from a gradual loss of rubber — think tire wear. An EPDM belt with 100,000 miles on it may have lost more than 10% of its rib material, and it only takes 5% to lessen performance. Wear obviously widens the space between the ribs so that it bottoms out in the valleys of the pulleys — the crucial wedging force is reduced.

All belt drives, serpentines or otherwise, are exposed to dirt, dust, road salt and sand, water, and engine fluids, and these contaminants along with any misalignment will cause accelerated wear of the rubber rib surface. When serpentine belts lose rib material, the profile of the ribs changes, thus how the belt fits around the pulleys, and this reduces tension and allows the slippage that can cause overheating and failure. Also, belts are designed to have clearance between the ribs and the pulley grooves (valleys), and material loss reduces that clearance impeding the flow of water and debris through the pulley. Belt slip from hydroplaning is often the result.

One means of identifying the noise and determining its cause is spraying the rib side of the belt with water at idle. If the noise gets louder, it’s a squeal. If it goes away, it’s a chirp. Another method is to remove the belt, and reverse it so that it travels backwards. If the noise disappears or gets quieter, the problem is almost certainly a misaligned pulley. If reversing the belt does not temporarily eliminate or soften the noise, the problem is something else.

Finding and curing misalignment and belt noise

The tensioner pulley should turn freely without binding, and the tensioner arm should move smoothly through its entire range. Obviously, adequate tension to keep the belt engaged is essential. Make sure you take a close look at the gauge marks on the tensioner. If the pointer is far to the loose side, you’ve found excessive wear.

We should mention that on older models without automatic tensioners, proper installation includes re-tightening after five minutes of run-in. If this is not done, the belt may sound off right away, suffer damage, and need replacement again prematurely.

With misalignment one of the primary causes of belt noise, identifying and correcting it is crucial:

- Check the alignment of all pulleys, either with a straight edge or laser alignment device

- Make sure accessory pulleys and brackets are snugly tightened to mounting surfaces

- Replace tensioner or idler pulleys and any accessories that feel rough and are difficult to rotate by hand, or that wobble

- Closely check power steering pulleys, a major cause of misalignment

As we say often in StarTuned®, taking the time to ask the customer some questions can save you from going down diagnostic dead-ends. Did the sound develop gradually, or start suddenly? When, exactly, does he or she hear it? Did anybody else do any repairs lately that involved the front of the engine (perhaps leaving out spacers or washers)?

Unusual signs

Studying the belt for unusual signs can help identify problems. Glazing at the edges, on its ridges, or in the grooves indicates that the belt is slipping and friction has caused overheating. Fraying at the belt edge is a good indicator of a misaligned pulley. If something appears to have attacked the surface of the belt, it’s probably fluid contamination from oil, power steering fluid, or coolant, and this will transfer to the pulley groove surfaces, making them slippery and attracting dirt that grinds away at everything.

Typical problem causes and symptoms include:

- Belt slipping — squealing sound, polished belt edges, glazed belt grooves

- Misalignment of an accessory drive pulley — chirping sound, frayed belt edge

- Fluid contamination — oil, power steering, or coolant leak

- Defective tensioner, other than severe old age — excessive cracking

- Defective bearing in tensioner pulley or idler pulley — whirring sound

- Delaminating belt backing, chunking of belt ridges, or foreign object embedded in belt groove— rhythmic noises occurring at engine speed

- Damaged bearings in driven accessory — grinding sound (use your stethoscope)

- Belt coming off — pulley or belt misalignment (faulty assembly during service?), defective tensioner, or bearing wear in the tensioner, idler, or accessories

Because of their internal reinforcement, serpentine belts don’t actually stretch with use, but they wear, which has the same effect of increasing their operating diameter. While the tensioner is spring-loaded to continuously take up the slack, is it working properly? If a belt starts slipping, take it off, inspect the tensioner for cracks or signs of metal-to-metal contact between its arm and the spring case, make sure the arm exerts firm pressure throughout its travel, and spin the pulley by hand. You should feel no binding, resistance, or roughness, and hear no clicking or grinding.

Push the pulley side-to-side and in and out on its shaft to make sure there is no wobble or end play, and do the same on idler pulleys. Push the tensioner arm against the spring as far as it will move. You should feel firm and even spring pressure with no binding.

By the way, be aware that tensioner and idler pulley bolts often have left-hand threads.

Straightedge and laser

An accessory drive pulley can be misaligned either as “parallel misalignment,” also referred to as “offset misalignment,” or “angular misalignment.” Parallel misalignment is when the pulley is not in line with the other pulleys because it is too far or not far enough onto its shaft, often due to faulty service procedures. Angular misalignment is where the pulley is at an angle to the other pulleys, normally caused by worn accessory bearings — you’ll feel wobble.

Lay a straightedge across two pulley faces. If it doesn’t lie flat, one of the pulleys is misaligned. Check each against others until you isolate the one that’s out of line. Special laser tools are available to accomplish the same thing, and they may work where a straightedge won’t fit.

Accessory drive pulleys are often pressed onto their shafts, so when the accessory is replaced, the pulley is replaced with it. Even pulleys that must be transferred from an old component to a new one are often press-fitted. If the pulley is not installed to the exact original depth so that it is in line with the others, it must be moved in or out as necessary.

Changing duties

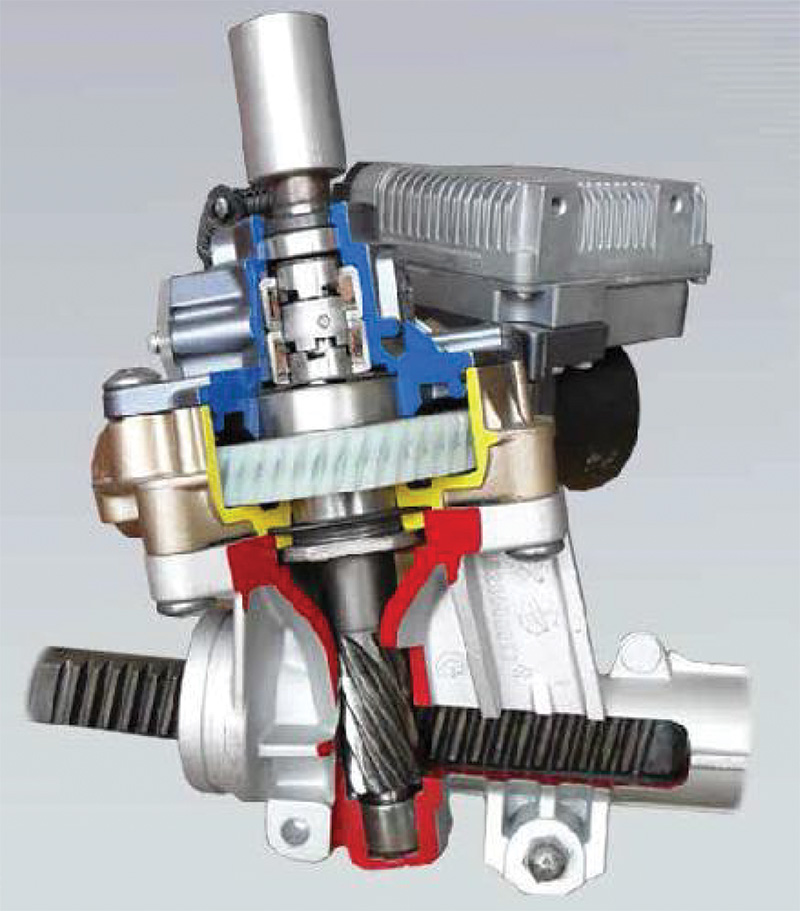

As we get more and more Mercedes-Benz models equipped with electrical power steering, it’ll represent one less accessory for serps to drive.

Conventional power steering is one of the major causes of belt distress. Add to that fluid leaks, the large amount of room the pump and its hoses take up, and its parasitic drag, and hydraulic p.s. isn’t really such a great system. What’s the alternative besides developing stronger biceps? Electrical power! Mercedes-Benz has been systematically adopting electric power steering (EPS) in late models — an electric motor assembly provides steering assistance, utilizing a ball-screw mechanism to provide the boost needed to steer the vehicle effortlessly. This results in one less accessory the belt has to drive, and one less point of potential trouble.

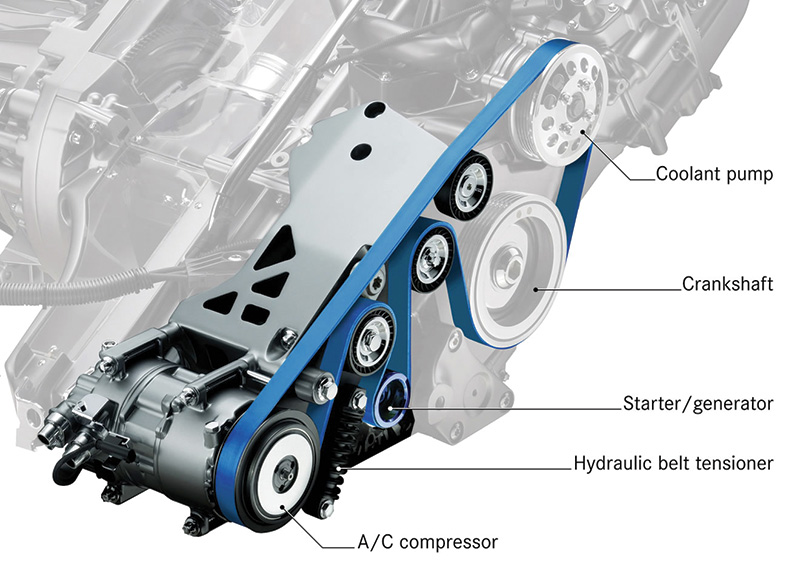

But that may be a wash because there’s another new system that adds stress to the belt’s life: ECO Start. A stop/start system saves fuel, but who wants to hear the regular starter engage every time a traffic light turns green? The answer is to use a starter/generator combination, which can give the crankshaft just enough of a spin by means of the accessory belt to start internal combustion. Time will tell how long serps will last in this kind of service.

The starter/generator of ECO Start gives the crankshaft a twist to get the engine started smoothly and silently. More work for the serpentine.

We’ll conclude with an interesting statistic: It’s estimated that 20% of the vehicles on the road are in need of a new serpentine belt. That represents a big opportunity for you to both help your customers avoid the inconvenience and even danger of a sudden breakdown and make a nice profit. If they complain about the high cost of modern belts when compared to the “V” type, explain that not only do serpentines take the place of several of the old-fashioned variety, but they typically last at least three times as long without giving any trouble. They’re a good deal for everybody involved.

0 Comments