In this day of ever advancing automotive technology, most technicians look forward to getting a repair order that says something like “Check brakes” instead of something like “Check intermittent (fill in the blank) on Tuesdays going down the freeway backwards at 86.2 miles per hour.”

Of course that’s an extreme example, but a good old brake job can be a relief for some technicians, especially those that do a lot of diagnostics.

We all know that Volvo’s mantra has always been safety. That’s why Volvo has always been on the cutting edge of brake system technology.

In August of 1966 Volvo introduced a new car model to the world. It was called the Volvo 144. In terms of safety, this car was extremely advanced. It had disc brakes all round, a safety steering column and a new lock on the three-point safety belts. The body had energy-absorbing crumple zones at the front and rear. Even the door locks had a safety design.

With Volvo’s introduction of the 144 they also introduced a new brake system — the triangle-split dual-circuit brake system. The car had two brake circuits and, if one of them failed, 80 percent of braking effect was still available.

The Volvo 144 was a huge success in Sweden and also abroad. In the USA, the Volvo 144 complied with the new safety regulations before they had even been made public.

In the automotive world, everything changes. So whether you have been working on Volvos for 30 years or 3 months, you need to pay attention and keep up with the changes The fact that you are reading this is a good sign.

With systems like Advanced Driver Assistance Systems (ADAS) and semi-autonomous braking systems becoming standard equipment on a lot of newer cars and trucks on the road, you will need to learn how these new systems work and, when they don’t work, how to go about repairing them.

Having the right tools and training is critical to the diagnosis, repair and service of these modern braking systems.

A lot of this training you can source for free. Online videos and trade publications (like this one!) are out there for you to access whenever you want.

Volvo Brake Technical Journals (TJs)

When you talk about repair information, among the most valuable resources are the Technical Journals (TJs) issued by the auto manufacturers.

Volvo periodically issues new Technical Journals to fix problems that come up on Volvos that are already on the road. There are several dealing with brake issues on all different years and models.

The most up to date Technical Journals can be found on Volvotechinfo.com and if you have an active subscription to VIDA you can find them there.

Do I need the Factory Volvo Software (VIDA) to Work on Volvo Brake Systems?

The answer is YES in a lot of cases, especially on newer Volvo models 2010 and up.

Let’s face it, these days your shop needs to have access to the OEM scan tools. The generic all in one scanner just won’t cut it in a lot of cases, especially when dealing with newer cars with integrated driver assist capabilities.

Systems like Advanced Driver Assistance Systems (ADAS) or, in the case of Volvo, City Safe, are becoming standard equipment on most cars these days and when it comes to testing and calibrating these systems you will need the factory tool to do it right.

Yes there are some aftermarket scan tools that can get codes and some live data, even some that have bi-directional command abilities.

But Volvo’s VIDA is the only system that has it all in one place and the only system that can download software to Volvos’ network modules.

A lot of shops think that they can’t afford VIDA, but they are wrong. Your shop can have VIDA for the cost of a laptop and Volvo’s DICE tool.

Once you have that your shop can purchase use of the VIDA software for as little as $64 for a three day subscription (price subject to change without notice).

Compared to the price of some generic scan tools, VIDA is a real bargain.

Here are a few examples of brake work where you would have to use VIDA software.

On Volvos equipped with electronic parking brakes you will need VIDA to put the rear calipers into “SERVICE MODE.” This retracts the screw type caliper pistons so you can replace the rear pads.

|

Conditions:

|

|

| Parameter | Value |

| PBM – Neutral | Yes |

| PBM – Maintenance Mode | No |

| PBM – Left brake pad applied | No |

| PBM – Right brake pad applied | No |

| PBM – Left brake pad released | Yes |

| PBM – Right brake pad released | Yes |

| PBM – Left brake pad extended release, service mode | No |

| PBM – Right brake pad extended release, service mode | No |

If you install a Brake Control Module (BCM) in a 1999 or newer Volvo you will need to load a software package in order for the car’s network to recognize the new part.

There are software updates for all modules on Volvos, including the BCM, and only VIDA can load these important software updates.

Software updates include this one which is covered in Technical Journal TJ21247:

Retailer Technical Journal 21247

Electrically operatetd Parking Brake (EPB)

Drive away function delayed

Date 06-24-2009

Reference: VIDA, VSTG

| Model | Type | Model Year | Chasis Range |

| S80 | 124 | 2007-2010 | 000850-113001 |

| V70 | 135 | 2008-2010 | 000395-118001 |

| XC70 | 136 | 2008-2010 | 000400-074001 |

| XC60 | 156 | 2010-2010 | 000212-050001 |

| The drive away function which releases the EPB upon take off may be delayed if the customer enters the car and drives away within 1 – 1.5 seconds. | |||

The Parking Brake Module (PBM) needs to receive data from other control modules before it will release the EPB. Service software has been developed to prevent this delay.

SERVICE: Download PBM Upgrade software using VIDA.

Brake System Replacement Parts

They are All the same, right?

Have you ever had a customer think or say that? Not very often. That’s because, unless your customer is 16 and just got their license and is that rare species of teenager that has to pay for the repairs themselves, they have probably had a brake job done on their car before.

If your customer has had a cheap brake job done before, they probably know that there is a vast difference in the quality of replacement parts out there.

Most technicians that have been doing this for a while have seen the effects of poor quality brake parts.

There are high quality replacement brake parts available to you these days and some are made right alongside the factory replacement parts, so what’s the difference?

Well there are a few.

FIT

Even though a replacement brake pad may be a copy of the OE Volvo pad, it’s just that, a copy. Due to patent laws the part won’t necessarily be the exact same size or design and may not perform as well as the OE part.

WARRANTY

Volvo offers a 2-year warranty on its brake pads and rotors (U.S. only).

Most aftermarket brake manufacturers only give you a one year limited warranty, or none at all.

PRICE

Have you compared the prices of OE Volvo brake parts to some aftermarket parts? You may be surprised. Yes you might save a couple of bucks in some cases, but if you have a comeback there goes any profit and your reputation.

VALUE

Most customers will appreciate that your shop installs Volvo OE parts on their car, even if it costs a bit more.

Here is a real world example of why OE Volvo brake pads are the best fit for your customers’ cars.

Case Study 2005 V70 R

This car came into the shop with a customer complaint of squealing from the front brakes at low speeds. The customer stated that they had just been to another local Volvo shop and had the front brake pads and rotors replaced only about 2,000 miles ago.

When the service writer interviewed the customer about why they had not taken the car back to the original shop for a possible warranty repair on the brakes, they stated that they did and the other shop told them that they needed to drive the car more to “break in“ the new parts.

This customer was not satisfied with this and decided to bring the car in for a second opinion.

The technician was able to readily reproduce the customer’s noise complaint on a short test drive.

The car was put up on a lift and the wheels were removed to inspect the brakes. The shop that had performed the brake job had a good reputation and was known for good work and using quality parts.

The tech noted that everything looked correctly installed and there was no missing or damaged hardware. The tech removed the brake pads from one of the calipers and noticed that the pads that were installed were a high quality aftermarket brand and looked to have no visible defects. The new brake discs were also very high quality aftermarket parts.

So why were these brakes making noise?

Since the service writer at this shop knew the service writer at the shop that first performed the brake job, he was able to call them and inquire about the work done on the car.

The other shop told the service writer that they had already replaced this customer’s brake parts under warranty and did not understand how they could still be squealing.

Volvo’s fix for the squeal is to install vibration dampers on the inside of the caliper, bolted on with the caliper mounting bolts. These dampers would counteract the vibration caused by the light weight caliper design that came on the S60/V70 R cars from 2004-2005.

The service writer decided to call their local Volvo dealership’s parts department and order an OE brake pad set for this car. When the parts arrived, the technician and service writer compared the OE Volvo pads to the high quality aftermarket pad set.

Right off the bat you could see the differences.

The aftermarket pads wear surfaces were all the same shape and size with bevels on both ends being cut at the same angle. However the factory Volvo set had friction material that was cut at different angles at each end and had arrows that indicated installation direction. This updated pad design was developed to help fix the R’s tendency to squeal at low speed braking, while the aftermarket pad set was just designed to stop the vehicle.

In many cases Volvo engineers have re-designed parts to fix problems that have arisen on cars that have been on the road for a few years. They base the need for a re-design on feedback from technicians in the field.

Volvo Electronic Parking Brake Systems (EPB)

Volvo started using an electronic parking brake system in some of its cars in 2007. This system is very reliable, but it pays to understand how these systems work in order to avoid misdiagnosis of EPB issues.

This is how they work:

The parking brake switch has three positions, of which two are counter sprung and the third is in the neutral position.

The parking switch consists of a number of smaller switches. The switch has six terminal pins. When the switch is activated the smaller switches open and close inside the switch. This creates a pattern for the six terminal pins. The Parking Brake Module (PBM) recognizes certain approved patterns for activating and deactivating the parking brake. If a faulty pattern occurs, the Parking Brake Module (PBM) indicates this by a diagnostic trouble code being set.

Background lighting/instrument lighting for the parking brake switches is supplied with voltage via the Central Electronic Module (CEM).

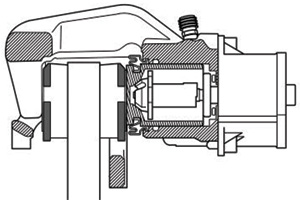

The brake caliper which is used together with the Parking Brake Module is a special design. The brake caliper consists of the normal components of a brake caliper, along with an electric motor, a gearbox and a shaft/spindle which presses on the brake pads. The electric motor is connected directly to the Parking Brake Module.

For vehicles equipped with Parking Brake Module there are brake calipers of this type located on the rear wheels. These brake calipers replace the normal brake calipers. The brake caliper has a connection for the hydraulics and functions as a normal brake caliper when the parking brake is not used.

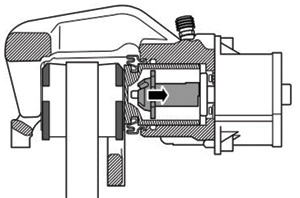

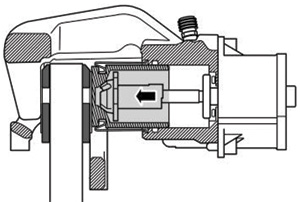

When the parking brake is activated, the electric motor provides torque which is transferred to pressure via a spindle. The spindle is located in the brake piston and presses on it so that the brake pads are applied. When the current to the electric motor is broken (the vehicle is parked), the self-locking thread on the shaft retains the brake pressure.

When the parking brake is released the spindle is wound back and the piston releases the pressure. The shaft remains in position.

The spindle follows the wear on the brake pads

The spindle on the shaft is screwed out continuously with the piston in order to follow the wear in the brake pads. The spindle applies the pressure in the same way each time.

0 Comments