BMW’s newer modular engines are quite complex, both in construction and operational theory, especially in the case of Gasoline Direct Injected (GDI) engines. The industry is now acutely aware of the carbon issues plaguing these GDI vehicles.

This year’s live, hands-on training event at the BIMRS conference introduces the strategy of baseline scan data diagnosis combined with mechanical testing with a lab scope and pressure transducer to identify the root causes of common GDI driveability issues quickly and effectively. Read on for the overview discussion of this unique diagnostic approach.

Another year at the BIMRS conference is upon us. This is an event where we can all get together from shops and dealerships located all over the planet, to network with owners, service advisers, technicians, instructors and vendors, all of us operating with one common purpose, which is the accurate and profitable diagnosis, maintenance and repair of BMW vehicles.

And hopefully, we all come together to improve our ability to satisfy our customers with a heart of service, good workmanship, improved diagnostic accuracy, professionalism and pride in our work.

Being able to network with other technicians that work exclusively on BMW vehicles is sometimes just as important as the training classes themselves. Networking time with other technicians is invaluable for learning new “tricks of the trade,” figuring out how that tech has been getting that diagnosis done more accurately, learning new work-arounds for problems, and learning from both the old school guys, as well as the sharp young crowd too…

But when we return to our shops after the event, how do we actually make hands-on use of all of this great subject matter training?

Enter the concept of targeted physical testing of the vehicle.

In addition to learning theory and information on new technology, we must get better at putting physical testing into practice in our actual diagnostics. Failure to do so can be costly to the shop, the technician, and the customer.

These classes follow a similar theme; how do we accurately flow a diagnosis in a reasonable amount of time on a coding or no-code driveability problem, specifically on a GDI vehicle, more importantly, without firing the parts cannon at the car based on guesswork via scan data or parts swapping?

This is where becoming a diagnostic wizard requires some learning, a solid, dependable physical testing regimen, some study of chemistry, and some adjustable-on-the-fly testing methodology.

What if we could develop a basic strategy of approach and a set of generic tests that could be applied to all vehicles and pretty much all diagnostic problems, regardless of vehicle manufacturer, model year, or complexity? Could that help to improve diagnostic speed and accuracy?

You bet.

There is one big thing we typically don’t know during an average scanner diagnosis, which is the bane of the technician’s existence – what is REALLY going on down in that engine or transmission… mechanically? That, folks, has always been the one thing that we cannot “see” in conjunction with – and in confirmation of — the electronic scan data we rely on during these tricky diagnoses. Until now.

The ability to answer the mechanical AND carbon interference question quickly and accurately without disassembly of the engine or component is the challenge.

This is the basis of what our live classes show at the event — how to put these diagnostic concepts and testing strategies together in a controlled process without getting bogged down in the technology. Theory to testing. Keep it simple.

We can easily out-tech ourselves, or we can be out-teched by the sheer complexity of the technology when diagnosing one of these vehicles. We approach with a scanner, get a code or multiple codes, and we make decisions about where to start. This is how we have been trained over the years.

Most experienced techs have a pretty good flow for this kind of approach, but due to the actual technical complexity of how these circuits work, we can quickly get lost in data, schematics, testing, re-testing and theory. And we can go down the wrong path quickly, causing hours of needless work.

None of us, including factory/OEM field engineers, are immune from this. The car always acts differently in real-time service with time, mileage, mechanical wear, and deposit buildup, than it does for an engineer on a test bench at the factory with a brand new vehicle in his hands while writing a diagnostic procedure. Any experienced tech knows that!

Deposit removal chemistry or shell blasting flat out have been known to resolve a driveability issue that had been otherwise unresolved with a lot of electrical diagnosis and parts replacement.

Is chemistry magic?

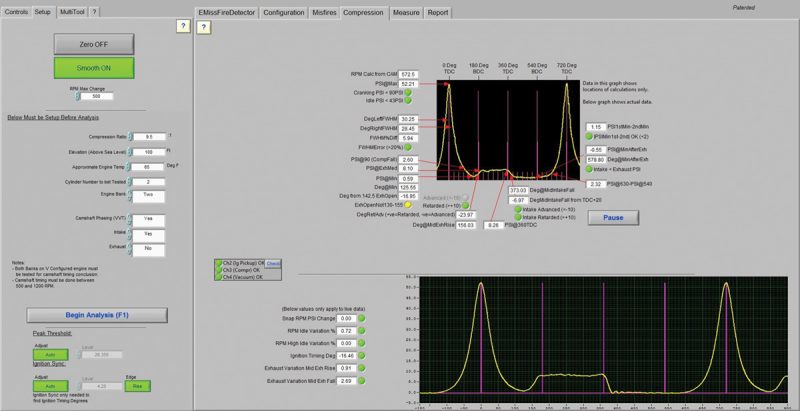

No, but it is necessary, and it needs to be in the mix always with the diagnosis of driveability problems in GDI vehicles. Baseline theory using scan data allows us to identify these carbon issues very effectively.

It is wise to never discount a fuel, oil, or carbon issue as the potential cause of a driveability problem, especially in GDI vehicles. You do so at your own flat rate peril. Nobody wants to become the Comeback King.

Years of experience suggest that a mechanical issue or a carbon deposit related issue that have caused a concern was missed, after the obvious parts had been replaced already.

The reason that technicians often miss these mechanical causes is that traditional compression tests, and worse, static cylinder leak-down tests, are not sufficient tests for tracking down these intermittent misfires and driveability issues in the GDI platforms. To explain this requires more space than is allotted here…

We also find that once that part has failed, for example the high pressure pump, injector, engine component, turbo, catalytic converter, etc… it was a deposit problem that started the slippery slope to failure. Should we, then, learn how to identify these issues before the component fails?

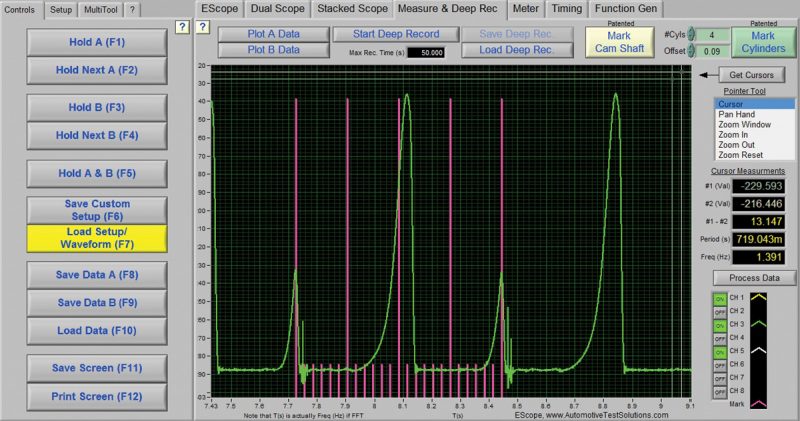

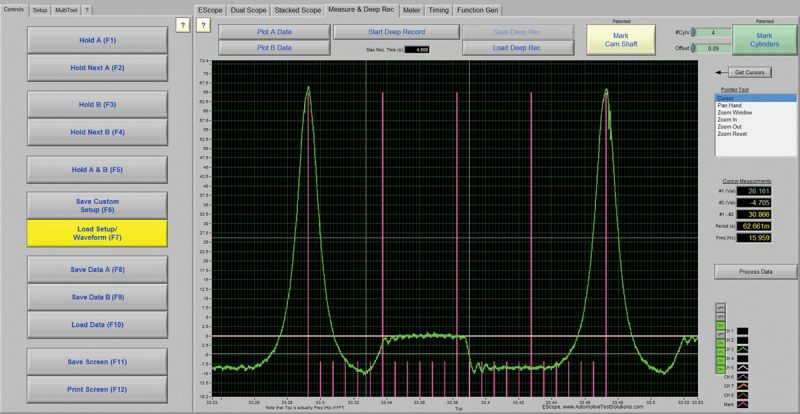

In the live classes, we demonstrate that, with the advent of pressure transducers and in-cylinder dynamic compression testing, we can use a lab scope to literally see, and accurately diagnose, the inside of the engine and carbon depositing issues most times without any engine disassembly.

As a result of baselining scan data strategy and scope testing combined, we have also learned and have recorded proof that cleaning carbon does restore good driveability, and lab scopes really are a great tool for finding faults of all kinds quickly.

The lab scope is the one tool in our arsenal that allows us to see the behavior of the electricity in any given circuit. This is the key to determining an accurate direction while diagnosing these difficult GDI driveability issues, especially those that are intermittent, without missing the causal issue or replacing unnecessary parts.

If we combine the scope with some physical transducers, where we can convert mechanical actions to electrical waveforms, and teach our technicians how to interpret and leverage this technology, we have pure magic, and the great unknown actually begins to reveal itself in the service bay.

Here is the real beauty of this diagnostic methodology: The tests we are teaching are the same tests, no matter the vehicle year, model or engine configuration.

This means a tech can take a set of repeatable test methods from vehicle to vehicle and be diagnostically productive without spending tons of time in researching and schematics. The procedures simplify the technology and focus the technician on what is really ailing the car.

In the live lab scope session, we cover testing methods using mechanical transducers for testing VANOS and ECU input/output behavior, cam timing codes, and carbon deposit diagnosis in the valve and combustion chamber areas.

We pay particular attention to the concept of signal rationality and combining both mechanical and electrically processed signals together, or signal overlay. This strategy answers a lot of unknowns in a traditional diagnostic process. Signal overlay allows us to confirm beyond a shadow of a doubt whether or not the ECU is receiving and processing a signal properly in relation to actual crankshaft rotation. This concept allows us to diagnose VANOS issues very quickly and accurately, and also allows us to identify carbon issues, deposits on rings, valves that intermittently aren’t seating, worn cam lobes, cam timing issues, even down to details like weak valve springs. We can see all of this without engine disassembly if we are willing to equip ourselves, study, and practice how to do it.

Download PDF

0 Comments