It’s more than just an empty space to keep your gas when you’re not using it. The fuel tank is an integral part of engine performance, emissions control, and, most importantly, safety systems. Even still, it’s relatively simple. Problems are rare, but when they do happen they can be real head scratchers. Let’s take a look at some of the problems that can develop in fuel tanks and how to complete a successful repair in short order.

It’s a universal part of the internal combustion motor vehicle. To make combustion you must have fuel to combust. On the other side of that coin, the fuel is very combustible and in no way safe to just be carrying around. We have been using gasoline so long that the hazardous nature has been all but forgotten by the public.

Fortunately, Nissan engineers have been diligent and have designed some pretty good systems to keep the fuel safely tucked away. The system of pipes, hoses, valves and canisters attached to the fuel tank can seem daunting at first, but once you delve a little deeper you’ll find it’s really pretty simple.

Unfortunately, simple doesn’t mean failure-proof. This is especially true in the case of the fuel tank. Along with the problems that can develop with normal sensor failures, there is the very real possibility of failures caused by misuse. Here, that refers to topping off the tank, regularly driving in deep mud and water, or ignoring the Check Engine light because “it’s only an EVAP code.” Spend more than 5 minutes at any gas station and you’re sure to hear someone forcing fuel past the safety limit with that all too familiar, “click, click, click” as try to get it to the next even dollar. If only they knew the cost of the damage they could be causing.

When considering the fuel tank as your focus in a diagnostic procedure, you will typically be looking at a short list of very particular symptoms. For the purpose of this discussion, even though it’s in the fuel tank, we will be considering the fuel pump part of the fuel injection system. Fuel gauge inaccuracies, leaks, trouble filling the tank, and certain EVAP failures are known to be problematic for the diagnostic technician, mainly because they are so rare one typically doesn’t have the opportunity to learn from the experience of regularly seeing them in our shops.

One of the better safety features in fuel tank design is putting it in the center of the vehicle, tucked up behind the frame on trucks or in a nook, under the back seat, on cars and smaller SUVs. This is great in that it is unlikely that a collision will damage the tank.

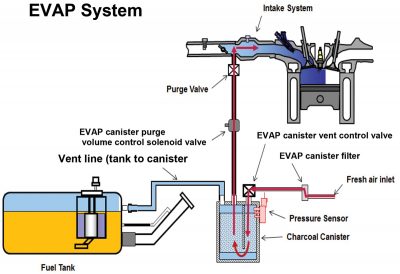

This safe location requires some plumbing to get fuel into the tank, typically two hoses — one larger and one smaller. The reason is simple, if you’re putting fuel into the tank, you’re displacing air. You need a second path to let the air out while fuel is going in. With vehicles made after 1996 this is accomplished with the EVAP system and canister vent valve.

The charcoal in the canister catches the hydrocarbons in the air venting out of the gas tank and later, when the engine is running, engine vacuum sucks them into the engine to be cleanly burned with the rest of the fuel. If significant restriction happens in the vent system, it will result in difficulty filling the fuel tank. The displaced air, during refueling, tries to vent through the filler neck causing a burp that is sensed as back pressure by the fuel filling handle, stopping the pump.

In most cases, restrictions happen in the charcoal canister or on the vent side of it. Typically, you’ll find liquid gas in the canister from repeated over filling of the fuel tank, or possibly from debris in the vent filter. This is tested for by the ECM as part of the required OBDII EVAP monitoring. Confirming the cause can be as simple as disconnecting the vent pipe at the canister and testing to see if the tank is easier to fill.

What happens if that vent pipe becomes completely plugged between the canister and the fuel tank? Re-fueling becomes near impossible and no EVAP codes are set. This is a known condition that is addressed in TSB NTB017-030A for most Nissan vehicles from as early as 2003 to 2017 and possibly beyond. This particular vent pipe has a tendency to get plugged. If, perhaps, physical damage, corrosion, charcoal from the canister, or some other debris gets into that pipe, filling the tank becomes a real chore.

Testing for a blocked vent pipe is half questioning the driver and half smoke testing the EVAP system. Since Nissan vehicles typically have the EVAP system pressure sensor outside of the fuel tank, it’s entirely possible to have this EVAP problem without setting any trouble codes. Your only symptom may be the customer’s complaint. Is it hard to fill the tank everywhere?

Difficult filling at one or two gas pumps and normal filling at others is not going to indicate a completely blocked vent. In this case it is more likely to be caused by a partially restricted vent filter, canister or a malfunctioning vent valve that doesn’t work well with overly sensitive or faster pumps at certain filling stations.

Is the tank less than ¼ full? The tank will need to be less than ¼ full to get a reliable result from the smoke test, and if the tank subsequently needs to be replaced, having it near empty will make your job that much easier.

Assuming you have a yes to the two questions, simply connect the smoke machine to the EVAP system and close the canister vent valve with the CONSULT III Plus. Unlike a normal EVAP test you will then remove the gas cap. The vent hose we’re inspecting serves as the connection between the gas tank and the charcoal canister. If the hoses are all clear, as they should be, the tank will fill with smoke. If the vent is plugged, you will see no smoke from the filler neck and the smoke machine will indicate no leak in the system even with the gas cap removed.

If you do see smoke from under the gas cap, the vent is not completely plugged. That’s not to say the plumbing to the tank is problem free. Liquid gasoline can collect in the charcoal canister from years of “topping off” the gas tank. In extreme cases this can lead to internal damage and the release of charcoal particles into the vent and purge sides of the system.

Checking for this condition is pretty straightforward. Simply pull the canister down and see if any gas pours out. Also check the vent filter on the canister vent valve for blockage. Pathfinder, Xterra and Frontier vehicles from the early 2000s have been known to collect mud, bugs or even water in the vent when used in recreational off-roading. Keeping the vent filter free of debris is necessary in order to allow proper EVAP function and trouble free fueling. If you’re working on a truck that you know has been playing in the mud, check the vent filter, even if they’re not having trouble filling yet.

Should the vent be found to be completely blocked, there is a chance the repair is covered under a warranty extension for this specific problem, out to 15 years 150,000 miles. The repair for most models is simply replacing the section of the hose with the restriction. Unfortunately, Nissan Maxima, Altima and Quest vehicles will require a fuel tank replacement as the vent can’t be changed separately. Check out TSB NTB17-030a for more information and a list of what parts might be needed for the particular Nissan you’re working on.

Although there are many reasons cars get towed into the shop, one of the most frustrating for drivers and technicians alike is running out of gas. If the customer is used to running low on fuel and “knows” how far they can go after the light comes on, that’s one thing. When the gauge still shows a quarter tank and you’ve just spent the past two hours figuring out the gauge was wrong, that’s an entirely different frustration. We are simply forced to consider that any sensor information received by the ECM can be in error.

It’s not very common, but that can include the fuel level readings. Sometimes it’s a known probability. 2006 and 2008 Frontier, Pathfinder, and Xterra vehicles are subject to a safety recall for the in-tank fuel level sensor as it can fail in such a way as to read ¼ tank and actually be out of fuel. Most of the time it’s a complete surprise. Fuel pump failures seem to be much more likely than simply running out of fuel, especially when the gauge doesn’t indicate empty.

So, do you automatically start each no-start diagnosis with a gallon of gas added to the tank? Only if it’s reading empty on the gauge or if it’s a model known to have fuel level sensor issues. Testing should always be done methodically. Testing for rare failures first will almost always lead you to massive amounts of wasted time. Empty fuel tanks have specific signs that will emerge in the normal course of testing. Most of the time, the engine will fire intermittently or start and die several times. The fuel pressure reading will often be sporadic, and sampling the fuel from the fuel rail will reveal pockets of air in the fuel stream, or maybe even just pressurized air in the fuel rail. You may even notice that the fuel pump is louder than you would have expected. The experienced technician will see these signs and know it is time for the gas can.

Gas gauges can be inaccurate. This is rare in modern vehicles, but it does still happen. Nissan vehicles after about 2010 use a diagnostic mode that tests the function of the gauges. This is the familiar sweeping of the gauges when the ignition is turned on. These gauges receive their information through the CAN/BUS system and the ECM. For vehicle models without the automatic diagnostic mode in the combination meter, testing for proper gauge function involves looking at the input signal to the combination meter.

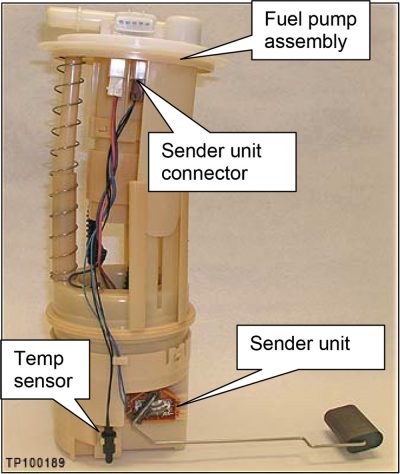

Although there will be some differences between the models, let’s take the example of a 2008 Rogue. Measuring voltage between terminal 34 at the combination meter and ground will indicate the signal the meter is receiving. About 3.5 volts is empty, 2 volts is half full, and full is near 0 volts. If the voltages match it’s time to look into the tank and measure the actual fuel sending unit.

The diagnostic procedure for a gas gauge reading incorrectly will then have you testing resistances on the wires going to the fuel tank. There is a trick that may save you some time. Use a known good fuel sending unit and temporarily connect it to the connector at the fuel pump module. It is almost always easier to access the electrical connection at the fuel pump module than pulling the dash apart to get to the back of the combination meter. By verifying with an external fuel gauge that the combination meter is reading correctly, you can eliminate all the wiring in the harness and the meter as possible causes. Since most Nissan vehicles have easy access to the fuel sending unit under the back seat or in the trunk, this is a much quicker and easier test.

This is a time to be patient. Fuel gauges do not move quickly. Position the senor in the full position then go and get a cup of coffee, come back and verify the gauge reads full. Position the sender in the middle then go and tell the service writer that new joke you just heard. If the combination meter reads correctly at full, half, and empty with the temporary sending unit, you know that the fuel sending unit in the tank is your likely cause. If it doesn’t read correctly you know that your problem is either the harness or the combination meter itself and it’s time to get that dash opened up for some in-depth testing.

Should the vehicle you’re testing not get repaired during the same visit you’re testing it, be sure to advise the owner to be aware of their fuel level. If you’re dealing with a re-fueling problem that might be a plugged vent pipe, the customer will need to get the fuel level below ¼ tank. If it’s a faulty fuel gauge, you will need to advise the customer to keep the tank above half full to make sure they don’t run out of fuel. If it’s in your shop for both, better to just keep working on it until it’s fixed.

Download PDF

0 Comments