I was called to a shop to perform a program update on a 2006 Ford E250 van with a 6.0L engine (Figure 1). This is a task I am asked to do on a daily basis. There are many shops that do not make the investment to purchase a programming interface, or to subscribe to automotive manufacturer websites to download programming files. This may be due to the fact that they may not get enough calls for reprogramming to justify the cost, or they may not want to expose themselves to the liabilities involved in reprogramming.

There are many precautions that must be observed while programming a vehicle. The most important one is having the proper battery charger, such as the Fronius Power Supply (Figure 2). This device will maintain a uniform voltage in the battery under the different load conditions caused by power consumption changes during reprogramming, as when cooling fans or even headlights come on in the process. If system voltage falls out of range, the programming procedure could be aborted with a possible loss of a controller. The other dangers are the loss of the Internet connection, a scan tool running out of power, or vehicle cabling disconnections. Any of these malfunctions will result in the loss of a new control module that cannot be returned if it is corrupted in the reprogramming process.

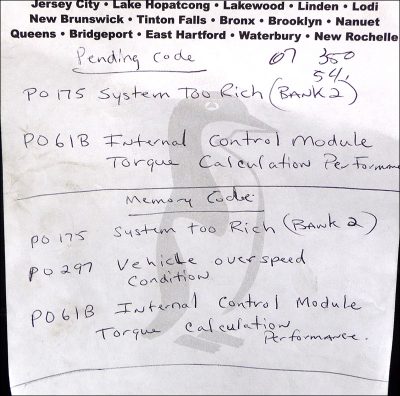

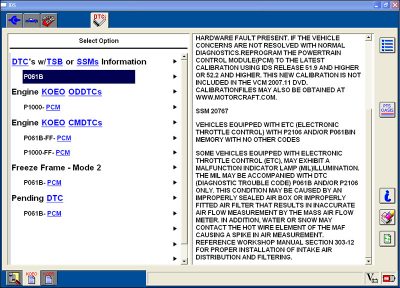

The tech at the shop provided me with a service bulletin he found to resolve a code P061B (Internal Control Module Torque Calculation Performance) and a drivability problem in the form of a throttle response issue. This is common practice today with all the resources that are now available to techs either through subscriptions from different aftermarket information companies, or directly from manufacturer websites. To verify the complaint, I hooked up the Ford factory IDS scan tool to view the codes stored in memory. There were no codes stored because the shop tech had erased them all. This is something many technicians do without realizing that if someone else were to get involved with the vehicle, there is no longer any information left behind to aid in the diagnostic process. When codes are erased, so is the freeze-frame information that can sometimes hold many valuable clues to what conditions were present when the problem occurred, thus aiding in the solving of code-related problems. Luckily, the tech at this shop was smart enough to write down all the information in detail (Figure 3). That was impressive!

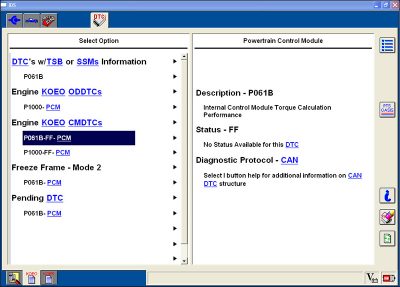

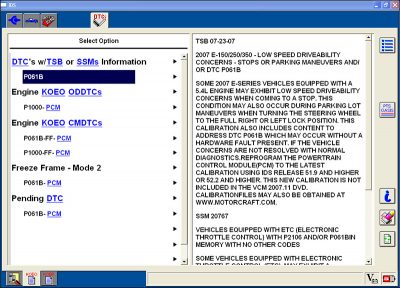

After reading the codes he wrote down, I proceeded with reprograming to provide him with the latest updates available from Ford for this vehicle. I followed the step-by-step procedure with the Ford IDS tool, and when the programming process was done the scan tool cleared codes. This is done to assure that any “U” codes that were created in the other controllers in the network when the PCM went to sleep during the reprogramming phase are removed. The final step was to shut off the key and then turn it back on to reboot the new PCM software. I then started the vehicle, but it did not run very well and the MIL/Check Engine light came back on. When I went back into the codes menu, the same code P061B had reappeared in memory (Figure 4). The software update I installed addressed this code (as you can read in the service bulletin link 07-23-07 for this situation) when I highlighted it at the upper left side of the IDS screen (Figure 5), but the software update did not resolve this vehicle’s issue.

At this point, the tech knew he had made a bad decision to opt for reprogramming as a cure for the problem, but it is not uncommon for this to happen. There are many times when there are software updates intended to address particular issues on a vehicle, but this should be the last step to take after you have exhausted all other possible causes of the problem. Today, I had arrived as a software salesman only, but it was now the shop’s choice to allow me to take off my salesman’s hat and put on my diagnostician’s hat.

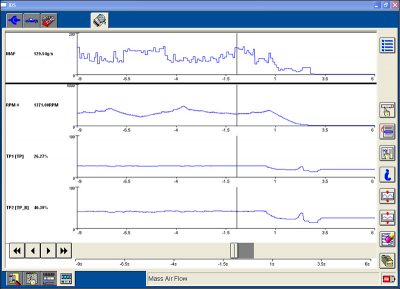

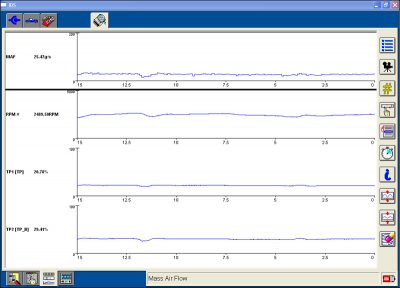

Code P061B deals with any correlation problem between the Throttle Position Sensor and the Mass Air Flow sensor. The engine had a hard time revving up, and it was blowing a lot of black smoke out of the tail pipe — it was being over-fueled. The most common cause of this condition would be a MAF sensor out of range. I needed to verify MAF operation by doing some simple data integrity checks. I placed the MAF, rpm, and TPS parameters in a graph mode to view what the PCM was seeing (Figure 6). Looking at data PID values changing in a digital format is not what I would prefer to do unless I were a number-crunching pro. Graphing signals is a major asset to diagnostics because it gives a technician the visual associations between PIDs over time to help better see what is happening. Viewing the graph you could see that the MAF was well out of range at 129 GPS at a given value of 1371 rpm with only a 26% throttle opening. It was a no brainer as to why the vehicle was running so rich that it was blowing black smoke. This vehicle had a MAF sensor that was out of range. Or, was it?

One of the cool features of the Ford IDS scan tool is that it will tie into service manual information on a code. By simply highlighting the code in the upper left-hand corner and scrolling down, the information window on the right-side screen displays the details of what can set this code (Figure7). Ford says that if you encounter a code P061B, you should inspect for an improperly-sealed air box or air filter, which can result in inaccurate measurement by the air flow sensor.

In addition, Ford claims that if water or snow contacts the hot wire element of the MAF sensor, it may cause a spike in air measurement. This is all good information, so at this point I needed to dig into the filter housing to check the integrity of the sensor assembly and its connector feed circuits prior to throwing a new MAF sensor at the problem. When I pulled the air cleaner cover off, I was surprised to see part of the air filter missing (Figure8) — the bullet-shaped cone. Then I inspected the MAF sensor and was shocked to see the missing air filter bullet jammed into the MAF inlet (Figure 9).

I removed it from the MAF housing (Figure 10) to clear the passage, put the air cleaner housing back in place to prevent any cross-flow air from passing over the sensor, and started the engine. Now, it ran like the powerful Triton it claimed to be. I re-checked my data graph, and could now see that the MAF sensor read a normal 25 GPS at a given value of 2,489 rpm at about a 20% throttle opening (Figure 11). This poor engine had had a serious air volume flow problem. This air filter speeding bullet had an adhesive failure (Figure 12), flipped over, got sucked through the filter element, and jammed itself into the MAF housing. This created a venturi effect and allowed a rush of air to flow past the MAF’s sensing device, which falsified the sensor signal. This is a rare thing to happen, but it teaches us two lessons: Beware of cheap, off-brand parts, and always check the basics before you move on to reprogramming, or any other high-tech procedure!

0 Comments