I was called in to a shop for a complaint of erratic engine operation on a 2007 Jeep Grand Cherokee with a 5.7L engine (Figure #1). The engine would run fine with no problems for a while, but at any given moment it would begin to abruptly surge up and down and cut out. The engine could be immediately restarted and would run perfectly again until the next episode. The shop had installed high-performance spark plugs and ignition coils a few weeks earlier, but there were no drivability complaints at the time. The shop even put the old ignition coils back into the engine, but the problem still remained. There were no codes stored in the PCM memory, and the shop did not want to start playing Russian roulette with auto parts, so they called me in for tech assistance.

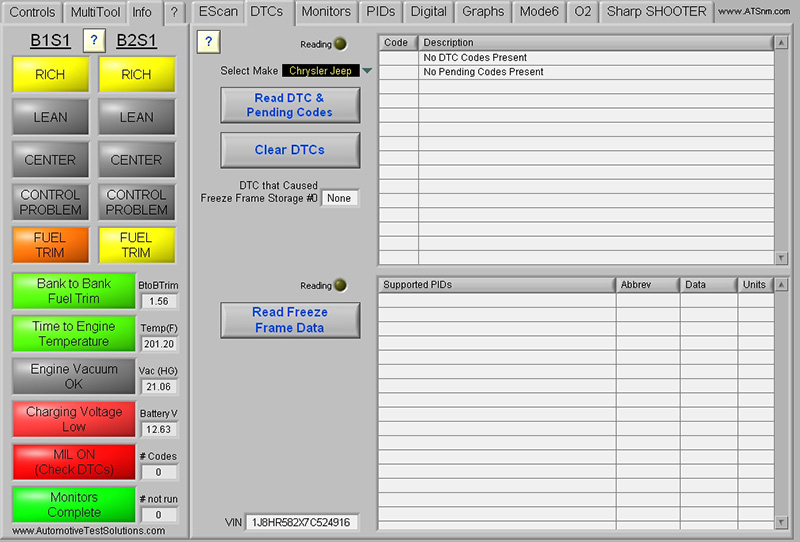

When I arrived, I attached my Escan generic OBD II scan tool to the vehicle to check for codes — none were recorded in memory (Figure #2). I started the vehicle and it seemed to run okay, but then it suddenly started to run erratically with a bouncing tachometer. The engine seemed to dip in and out with a near-stall condition. After a few seconds of this, the engine just cut out as if the ignition key had been turned off. I immediately restarted the engine and the problem was gone. I ran it again for quite a while and could not reproduce the problem. It was as if the crank or cam sensor was giving an erratic signal, or the PCM had an internal board issue. I could no longer reproduce the problem, so I offered the garage a free opinion: Try a new crank sensor due to their high failure rate. It would be a cheap fix if it worked.

The shop called back the next day and told me that the crank sensor did not fix the problem and that they had rechecked all the PCM power and ground feeds. The shop was willing to try a new PCM since the problem was so intermittent and everything seemed to lead to an erratic computer. I agreed to program the new PCM for them in hopes that the problem would go away. I could not think of anything else that could cause such an erratic problem. I went there the next day after the new PCM was delivered to program it with new software and configure it to match the vehicle. I started the Jeep and it ran fine for the first 15 minutes, but then it went back into its dance. At this point I got that feeling we all get when we realize that there is an expensive unneeded part installed that someone has to take the blame for. At this point, the shop I were both now married to the vehicle, and we had to find the problem or this PCM was going to be this evening’s meal.

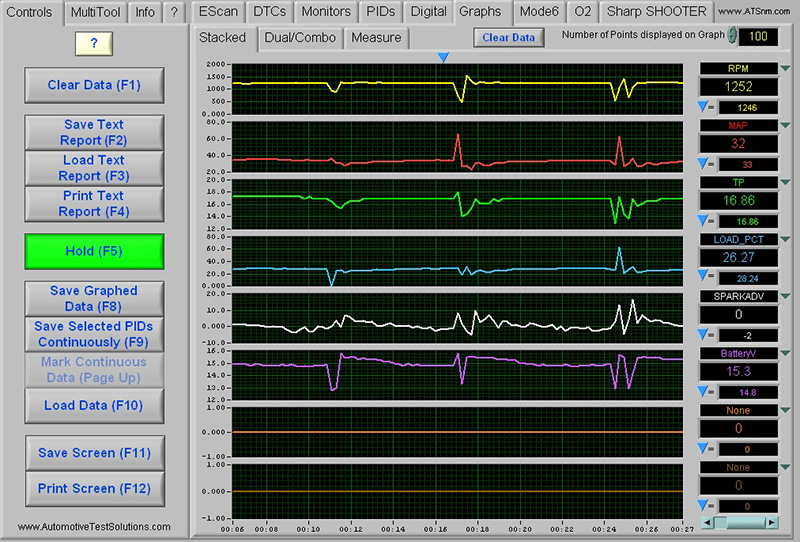

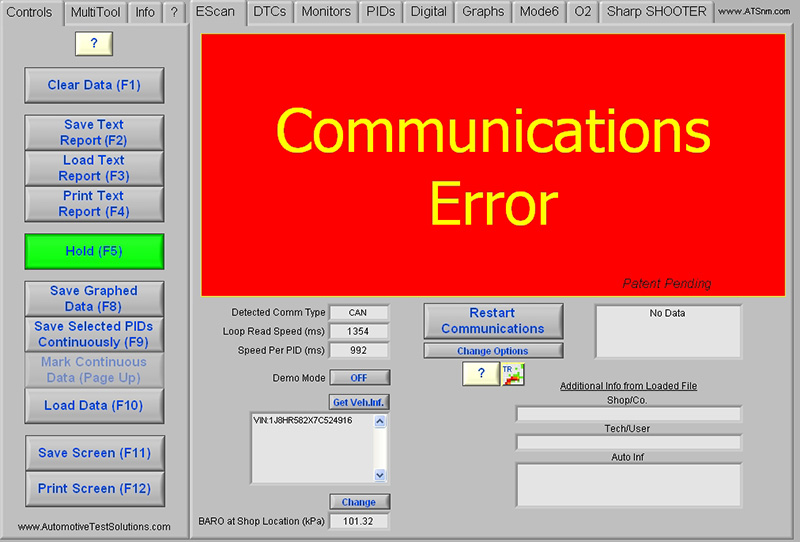

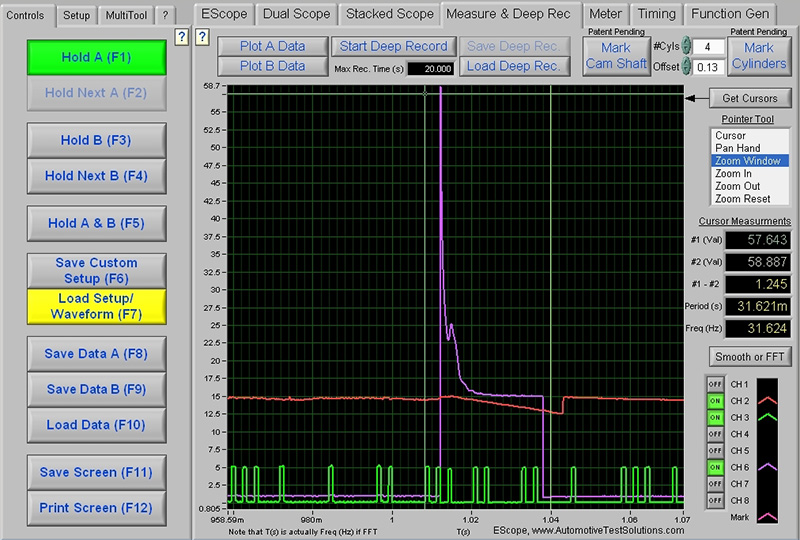

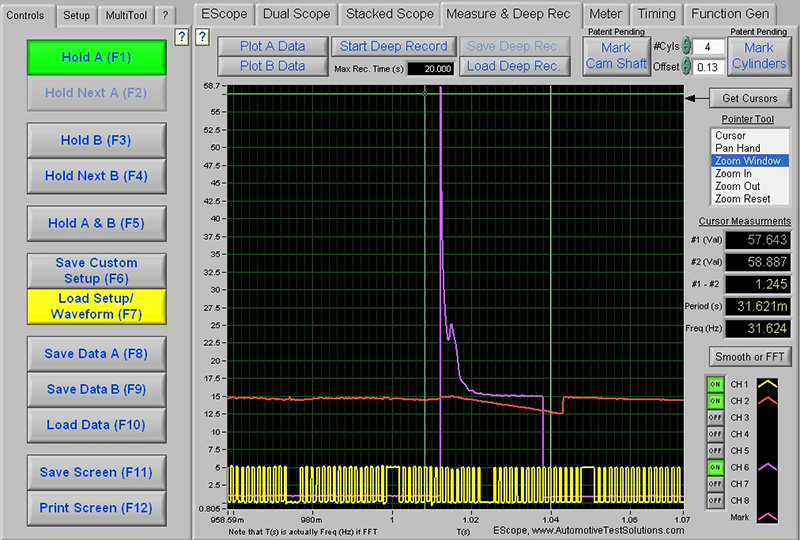

I knew my timeframe was short for finding the culprit because I had no idea how long the problem was going to stick around. I quickly placed my Escan tool on the vehicle and graphed some PCM parameters to see if anything looked unusual or out of range (Figure #3). I was monitoring the rpm, MAP and TPS sensors and could see the engine rpm going into an idle roll. But then something unusual happened — I lost communication with the PCM as the problem got worse (Figure #4), then the engine cut out. This had to be a loss of power or ground to the PCM, or possibly a reference voltage feed momentarily shorting to ground because the PCM was shutting down operations at the same time as it decided to no longer communicate with my scan tool. The only way I was going to nail this problem would be with a multi-trace scope to watch as many signals as I could before this problem decided to go away.

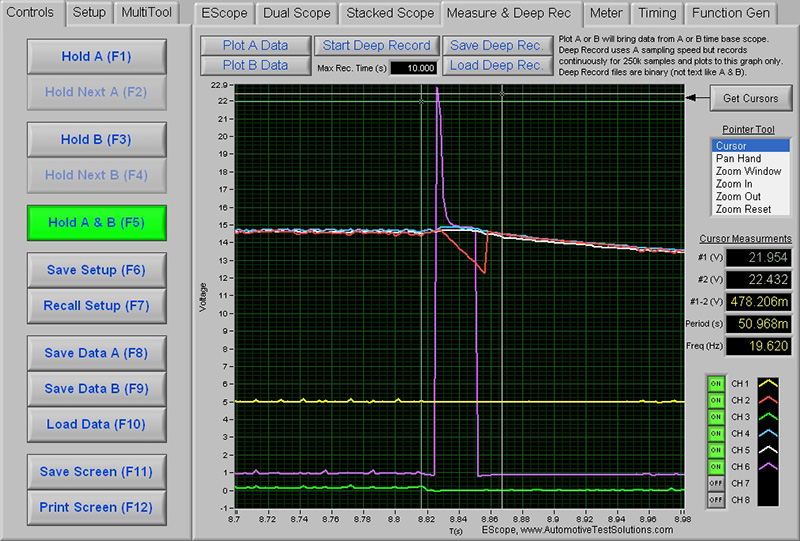

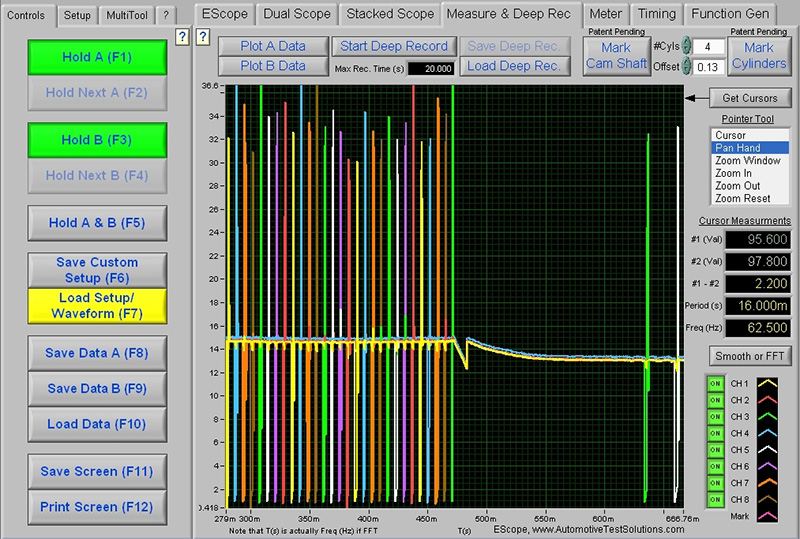

I used my eight-trace Escope and quickly selected six main items that would help me pinpoint the problem using my different colored leads as follows: white for PCM battery feed, blue for PCM ignition feed, red for PCM Auto Shutdown Down relay feed, purple for ASD relay coil driver, yellow for 5V reference, and green for PCM ground. As the engine started to run erratically, I captured my first event (Figure #5). I could see that the ASD relay driver momentarily was released by the PCM under 50ms, but I never lost my 5V reference, or my powers and grounds. It was as if something was telling the PCM to let go of the ASD relay coil, so I now had to dig a little deeper. I wanted to see if I was losing a cam or crank signal, so I captured two more events using my green lead for the cam signal (Figure #6) and my yellow lead for the crank signal (Figure #7). Neither waveform pattern showed a loss of cam or crank signal when the ASD relay was being released, but the tachometer was definitely following the cutting in and out of the engine.

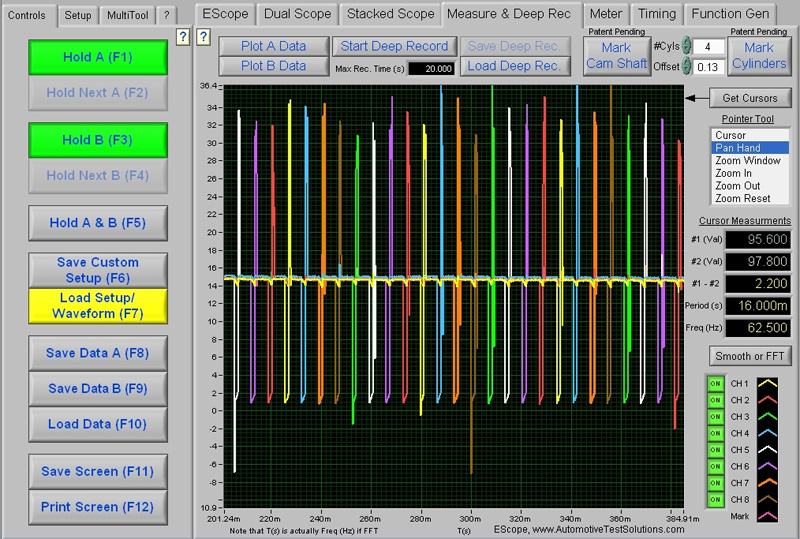

I had an eight-trace scope, so it was to my advantage to monitor all eight ignition coil primary circuits to see if any coil trigger was dropping out. I moved all my leads to the coil drivers and continued to monitor the engine’s operation. Today was my lucky day because this problem was only getting worse and it decided to stick around and give me a joy ride. When I captured another event (Figure #8), I was surprised to see that I was losing all eight coil drivers at the same time. The PCM was letting go of the ASD relay coil and it did not start to trigger the ignition coils again until about 300ms later. There was something making this PCM halt all operations momentarily, or I possibly had a bad new PCM on hand. It would not be the first time I have come across a defective new part.

I decided to call Bernie Thompson from Automotive Test Solutions just get his opinion on things because everything I have done so far has lead me to erratic PCM operation and I just could not pinpoint the cause. I could see what the PCM was doing, but what was its reasoning? Bernie basically wanted me to go back to my scope and look below the zero line for any secondary voltage kickback that could cause a PCM-reset condition. That’s when outside noises penetrate the PCM through electromagnetic interference and disrupt its normal algorithms, making it momentarily skip a beat. The engine in no way or fashion had an engine misfire due to a bad ignition coil or spark plug, but it still seemed like a logical possibility.

I went back to my primary pattern and this time lifted it off the zero line to expose any activity below (Figure #9), and I was surprised to see multiple cylinders getting hit with secondary kickback voltage. Cars using PCMs that directly control coil primary may have a little secondary kick that may not have any effect on PCM operation, but if the kick does get great enough it could give the PCM a momentary heart attack and make it skip a beat, or, worse, do permanent damage to the PCM or an internal coil driver.

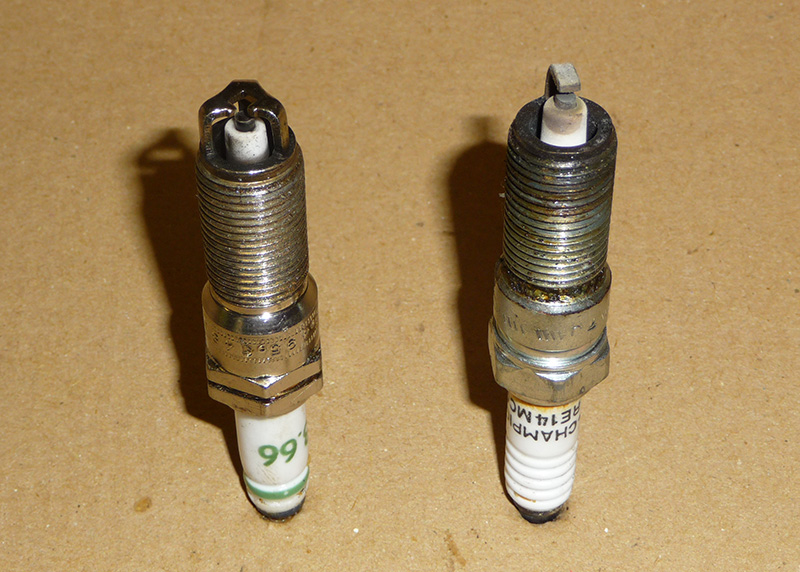

I knew the original coils were put back in, but I was not so sure about the spark plugs. I had the shop pull a spark plug to get a look at what was currently installed in the engine. I then compared that spark plug to the original (Figure #10), and there was something funky about it. It had a triangle-shaped electrode for a special performance feature it offered. I had the shop remove all the spark plugs and put factory spec spark plugs back in. Once this was done, the problem was completely resolved.

I can only tell you that I was taken aback by this turn of events. It is just so hard to believe that a company could manufacture a spark plug for performance purposes without any regard to its effects in a coil-over-plug environment. The problem it created mimicked a failed PCM that any tech would have automatically changed in the field. There were no codes, no sensor failures, or wiring issues. A multi-trace scope would have to be used to find a cascading effect of events that would point you in the right direction. I own many one-, two- and four-trace scopes, but with so many circuits involved with onboard control modules today, it sometimes makes more sense to use a bigger net to throw at a problem rather than fishing around with only a few hooks.

0 Comments