You’ve certainly noticed that cars in general, and BMWs in particular, just keep getting better and better, and last longer and longer. Given good maintenance, engines and transmissions can go hundreds of thousands of miles without major repairs, steering and suspension components take seemingly forever to wear out, serpentine belts run much longer than the V-type they replaced, electrical systems rarely give any trouble, and the electronics that control everything these days are practically bulletproof.

There are a couple of areas, however, that require about the same amount of care as they always have. Brakes, of course. And what keeps that terrific engine from melting itself down in an orgy of self-destruction? The cooling system, our subject here. Although some other automakers have pushed the recommended service intervals on this system to foolhardy limits, BMW maintains a sensible and conservative philosophy on this maintenance. Having seen so many ruined engines due to severe overheating, we applaud this attitude.

Fundamentals

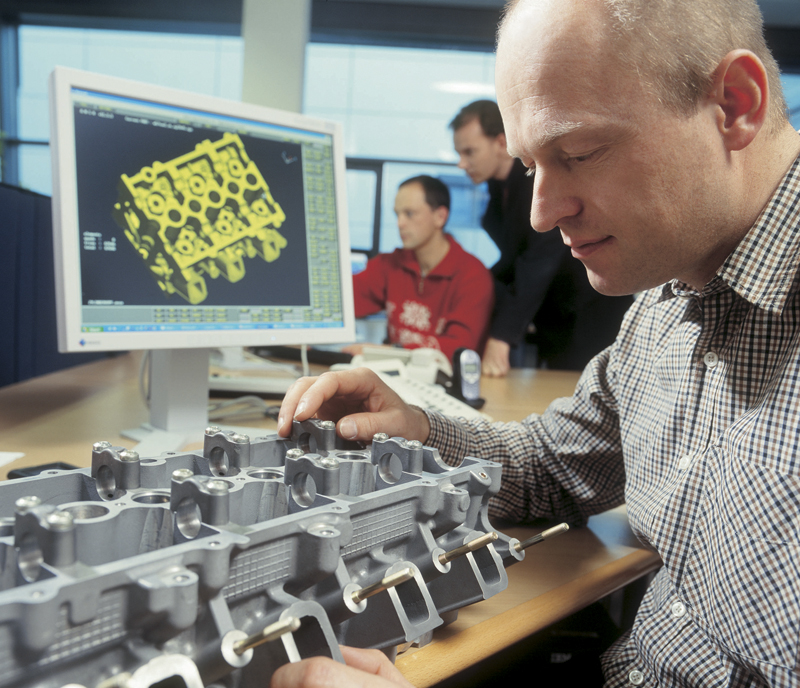

Even high-efficiency diesels, such as this one being developed at BMW’s Steyr plant, still can’t convert enough heat into mechanical work to be able to do without a cooling system.

You need a fundamental understanding of cooling system principles or you’ll be apt to flub diagnosis, and you won’t be able to explain the need for maintenance to your customers.

To begin with, if automotive engines were perfectly efficient, they wouldn’t need a cooling system. All the energy contained in each gallon of gasoline — about 125,000 BTUs worth — would be converted into useful mechanical work.

Alas, something is lost when the theories of physics and thermodynamics are translated into the reality. If we’re lucky, we can get maybe 30% fuel efficiency. There are experimental adiabatic (that means no heat loss) diesels that are striving for a much higher level, but don’t hold your breath.

So, any internal combustion engine produces far more heat than it can convert to mechanical work. Some is lost to the atmosphere as exhaust, but there’s a stubborn remnant that has to be forcibly extracted. Hence, the cooling system, which amounts to a heat sink. If everything is working as designed, this carries away the excess heat, thus keeping the engine below the point at which its parts would start to melt, warp, scuff and seize.

Actually, it’s this way for nearly all mechanical systems — especially those that generate usable power. We have no alternative to making excess heat that’s not being turned into useful work, or to using marginal, relatively-crude mechanical systems to extract or convert the energy, then finding ways to shed the excess BTUs before they destroy our fragile mechanical contrivances. We’re getting better, though. Electronic engine management, and improved coatings, materials, lubes and designs are gradually increasing the amount of energy we can get from our chemical reactions, but into the foreseeable future we are going to be stuck with cooling systems on cars.

The operative word here is “system.†It’s a radiator, it’s a pump, it’s flexible hoses to connect an engine that rocks with torque to a stationary chassis. It’s coolant, fans, belts, thermostats, restrictors, reservoirs and radiator caps . . . and one thing out of shape will put us over the top and into thermal overload. We all know the results of neglected cooling systems. Muddy coolant aside, there are scored pistons, blown head gaskets, overheated and destroyed engine and transmission oils. The modern cooling system is a violent place, full of localized hot spots, boiling, pressure surges, cavitation and flow restrictions, slag or pockets that create low pressure swirls that flash hot coolant into foam.

Move it

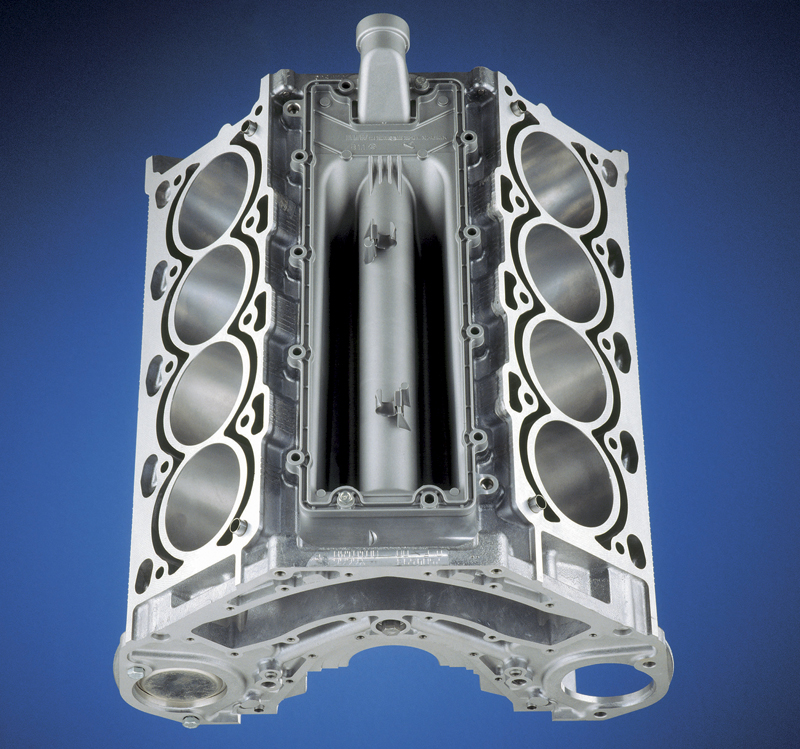

This V10 water pump may be highly-evolved, but it’s still vulnerable to seal damage if the engine should overheat.

Water pumps are an interesting subject. In designing an engine, you want to put the pump as low as possible so that it won’t start to cavitate if the coolant level should fall. That’s where all powerplants have it except for one French car we remember that actually had it at the very top — it’s no wonder that that make isn’t being imported anymore.

You may have noticed that water pumps tend to start leaking shortly after an overheating incident. That’s because the rubber components are subjected to temperatures far beyond what they can tolerate, and they harden and crack. Naturally, lack of coolant makes the whole engine red hot, but it also results in dry contact between the rings, which adds friction to the equation. This can cause another failure: warpage of the sealing elements.

We’ve heard it said that hard particles, such as a collection of the silicates and phosphates from anti-freeze, or core sand, can score and fracture those precisely-made rings, but engineers tell us that the space between the sealing faces is too small to allow those particles to enter. There is the possibility, however, that using plain water instead of a 50/50 blend of H2O and anti-freeze will deprive the seal of the lubrication it needs to survive.

Hot, hotter, hottest

Plenty of pressure and unimpeded flow is needed to achieve even cooling throughout all those passages.

The hottest area is the head, particularly around the back of the exhaust valves/ports. There’s less heat as you approach the crankshaft since cylinder pressure and temps drop as the piston is pushed away from the combustion chamber, which is concurrent with the flame extinguishing in the cylinder.

Why hold boiling point up? Obviously, we need to keep the coolant inside the system, so tightly capping it accomplishes this, but also raising overall pressure keeps the coolant from boiling in tight turns or sharp radii inside the system and at the suction side of the pump. Foam or vapor is a lousy heat transfer medium. The walls need to be fully bathed to transfer heat. Plus, the collapse of vapor bubbles in the system as they transition from low pressure to high leads to a condition called cavitation erosion, typically seen on aluminum surfaces near the water pump.

Crevice corrosion occurs in tight spaces where a lack of flow keeps the trapped coolant from mixing with the main flow, thus depleting additives and setting up high rates of corrosion. This occurs mostly on hose nipples where the clamp is positioned improperly. They should be as near to the nipple flange as possible to keep coolant out of the space between the nipple and hose. It’s not uncommon to see the metal pocked with ruts and holes, or even rotted through.

Damage from poor coolant system management takes one of three forms. There’s erosion, the thinning of material by mechanical force or impingement — remember we’re dealing with the vigorous movement of coolant, and abrasives or debris slamming into soft materials can literally “sand blast†its way through. There’s also corrosion, the result of a chemical attack on the metals or rubber, much as acid would do. And there’s electrolysis, the stripping of donor material from one source for deposit in another location — sort of a mini plating cell — created by stray electrical currents passing through the coolant stream. In all cases, one of the largest contributors to the destruction of the system is water. Chlorine, calcium and magnesium from treated or hard tap water dramatically accelerate the onset and progression of erosion and corrosion. Most experts are beginning to recommend de-ionized or distilled water for fill or makeup (see the sidebar).

Modern maladies

The big buzzword in the cooling system hose business today is ECD (Electro-Chemical Degradation). It refers to the fact that every place in the system where dissimilar materials are joined actually acts as a kind of weak electrical cell. The rubber companies tell us this kind of damage can happen in as few as four years.

To find out what problems are prevalent out there in the real world these days, we talked to seasoned service experts. A few of the more common items mentioned:

- Hot spots inside the engine, which can cause serious damage such as galled or even seized pistons. The major culprit is deposits.

- Head gaskets that have rotted out to the point that they leak.

- Restrictions in head gasket coolant holes.

- The formation of heavy, hard deposits (“Like stalactites,” one shop owner said).

- Restricted airflow through the radiator due to leaves, fast food wrappers, unfortunate birds, etc.

For the most part, these troubles can be attributed to – surprise! – Poor maintenance.

But there are other cooling system maladies that are rarely talked about. Don’t underestimate the importance of bleeding the air out of convoluted modern cooling systems. Not only will trapped air ruin the intended flow pattern, thus causing hot spots, but it’ll increase corrosion dramatically. Streamlining cars to reduce drag is great, but it means that airflow through the radiator and over the engine is a controlled matter in most late models. Make sure all shrouds, belly pans, and deflectors are present and properly secured.

Eye exam

A refractometer is fairly expensive, but nothing else comes close to its accuracy and speed of use. You don’t have to wait for all those floats in a hydrometer to settle down to get an idea of the coolant concentration.

When it comes to diagnosis and service, you need a logical procedure that both streamlines the work and helps you avoid missing any opportunities. The following is intended to give you just that.

Begin with a thorough visual exam. Does the coolant resemble raw sewage? Is the radiator plugged or ready to burst a tube? Are the hoses biodegrading into their basic elements? Do the belts look like they’ve tangled with a chain saw? Is there seepage at the radiator, heater core, freeze plugs, water pump vent hole, hose connections, or the trans cooler lines? Is that declutching fan permanently declutched? Grab the fan and rock it from side to side. If there’s excessive play in the water pump bearings, you may have just saved your customer the cost of a new radiator, fan, etc. because things really get chewed up when a pump shaft snaps.

If the coolant looks bad, chances are it’s been in there too long (the adjective “permanent” when applied to antifreeze just means it won’t boil off like the plain alcohol that was used in the old days). Right on the back of the jug of original BMW antifreeze/coolant, it says, “Change coolant every three years for maximum protection,” and we agree. There’s no reason to be asking for trouble by trying to get every last month out of a load of coolant, especially when this amounts to relatively inexpensive maintenance.

In inspection situations where fresh coolant isn’t necessarily included, at least use your hydrometer or refractometer to determine the amount of anti freeze present. The traditional 50/50 blend is still correct whether you live in Florida or Alaska, and this is one place where more isn’t better. Too low a percentage of water will reduce the system’s ability to move those BTUs, and the silicates that protect aluminum from corrosion can fall out and plug passages if the concentration becomes too high from adding straight antifreeze to maintain the level, something do it yourselfers are famous for.

But perhaps you live in a really frigid climate where the -34 deg. F. (-37 deg. C) protection a 50/50 mix provides is marginal. In that case, BMW says it’s okay to go to a blend of 60% antifreeze, which will take protection down to -62 deg. F. (-52 deg. C). If you live where it gets colder than that, move.

Seek the leak

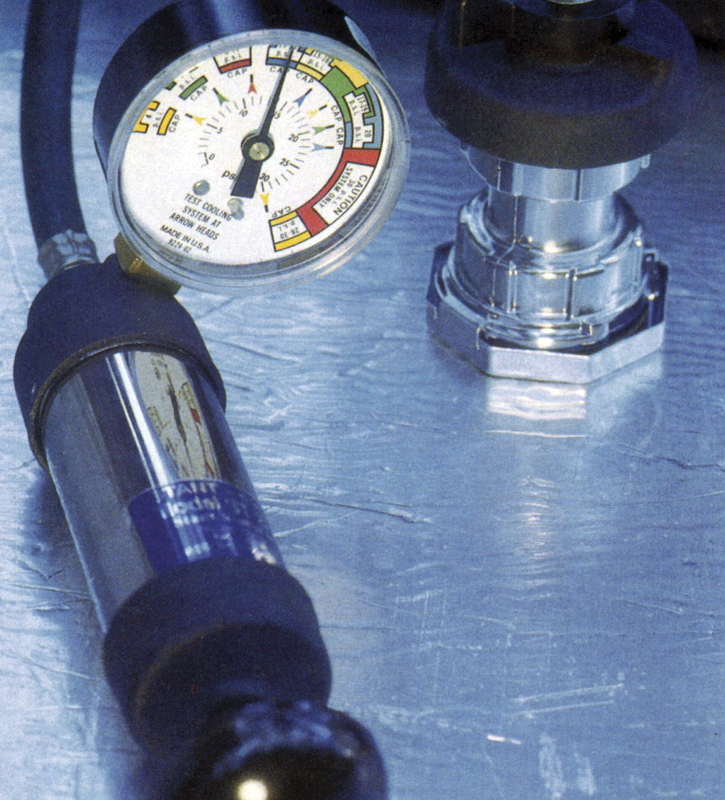

If a visual inspection doesn’t uncover the source of a leak, the next step is to hook up your pressure tester. You’ll need the right adapter for BMWs that have the pressure cap on the overflow jug.

Hook up your pressure tester to make sure the system will hold its specified psi for at least two minutes. While you’re at it, find out if the cap blows off at the correct pressure. Sometimes it’s difficult to zero in on a leak. One good way is to add fluorescent dye to the radiator, run the engine for a sufficient time (this can take a while it might even make sense to have the customer bring the car back the next day), then have a look with your UV/black light. Seepage will jump out at you in bright yellow.

But, according to a couple of experts, some leaks need yet another procedure: Keep 16-20 psi in the system with shop air and a pressure regulator (as you’ll find in the analyzer shown in the accompanying photos) from warmed up to totally cool. That way, the seepage will give itself away regardless of when in the engine’s temperature range it appears.

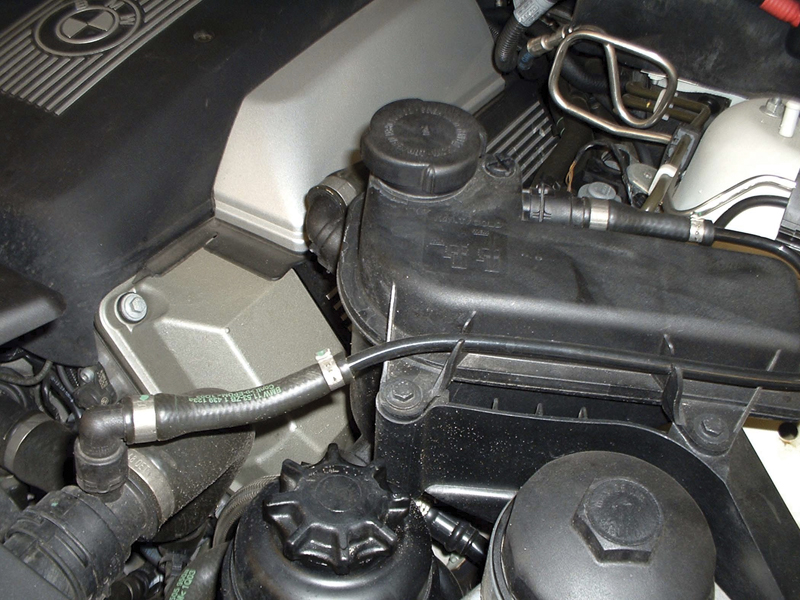

This late-model BMW overflow set-up uses a pressurized jug. It works fine, but you can’t look down into the radiator during troubleshooting. So, you’ll be using other means.

You can use your exhaust analyzer to find compression/combustion leaks into the cooling system by picking up a sample above the radiator neck on those models where that’s possible. But it’s easy to go too close and get coolant in the probe. A better way is to secure a large plastic bag around the neck with a rubber band, then punch a hole in the bag and insert the probe, keeping it a safe distance from the liquid. The bag trick can be used in another way: Clamp off the hose to the reservoir, put the bag over the neck as above, then start the engine and see if the bag inflates. There are also inexpensive leak detectors that you fill with water, then plug into the top of the radiator (again, where possible). If a stream of bubbles appears, the most likely cause is a gap in the head gasket.

Whether from a bad pump impeller or, more likely, a plugged radiator, a low flow situation can be hard to diagnose. A way of measuring the actual flow rate to determine if the water pump is still moving a sufficient volume of coolant would be helpful in determining if that essential component needs to be replaced. Such a thing exists (the Radi-Cool from Hickock), but very few shops have it, or have even seen it. So, you’ll probably have to use your own judgment. On older BMWs that have a regular cap on top of the radiator, take the coolant level down until it’s just above the fins and peer down into the neck with a flashlight. You should see a robust flow, similar to what you’d expect from a garden hose. The trouble is, late model BMWs have their pressure cap on the overflow reservoir, so you can’t see into the radiator. In these cases, remove a heater hose, stick the end in a bucket and start the engine. Finally, clear tubes are available that you attach in series with the upper radiator hose that allow you to see the flow.

Consider the WaterThe quality of the coolant’s other ingredient is important, too Anti-freeze formulas are a hot topic among all kinds of experts in automotive technology and service. They’ve been the subject of numerous industry association committees, SAE meetings, and, frequently, heated discussions.

You can buy a home water quality test kit at your local full-line lumber yard for about $10. This will tell you the levels of hardness, chlorine, pH, alkalinity, nitrate/nitrites, iron and copper. If your water’s unacceptable, you could install a water softener, then retest. It’s probably easier just to buy the good stuff, though, as we’ll explain. When you take such particular care to make sure lubrication and other services are done just right to preserve and enhance your reputation, why should you put potentially-damaging substances into your customers’ cars when you do a coolant change, or even a top-off? Especially when you consider that distilled/deionized water costs less than a dollar a gallon, there’s no sense in not avoiding problems such as internal corrosion and electrolysis and deposits that reduce flow and cut cooling efficiency. Also, you can distinguish yourself from your competitors by advertising that you use only distilled, or deionized, water to fill your customers’ cooling systems. |

0 Comments