Bring out the birthday cake and light the candles, the second generation of on-board diagnostics, universally known as OBD II is now 10 years old. And if the candles don’t light, plug your scan tool into the cake and see if any DTCs (Diagnostic Trouble Codes) have been set!

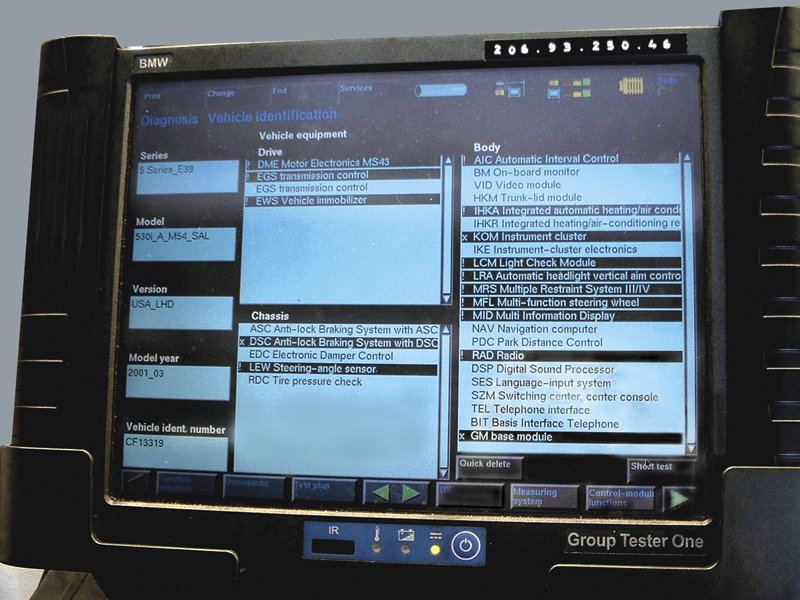

The tenth anniversary of this powerful tool seems like a good time to review just how OBD II came to be and the basics of how it works in a BMW. A good understanding of how OBD II works in a BMW is especially important if you haven’t made the investment in the BMW GT1 diagnostic tool.

Historical perspective

While the Check Engine lamp has been around since the beginning of OBD I, for OBD II its function has changed and it’s referred to as a MIL (Malfunction Indicator Lamp).

When the first emission control standards were imposed in the 1960s (PCV was federally-required for the 1963 model year) and on into the 1970s, carmakers initially relied on mechanical systems to meet the standards. As anyone who drove or serviced cars of that era knows, mechanical technology to control emissions left a lot to be desired. Vehicles ran hot, got terrible gas mileage, and had anemic performance. The myriad of different systems and the spaghetti of vacuum lines made service frustrating work.

As emission levels got stricter, electronic and computer-controlled systems were needed to monitor exhaust gases and adjust both ignition and fuel to limit harmful emissions.

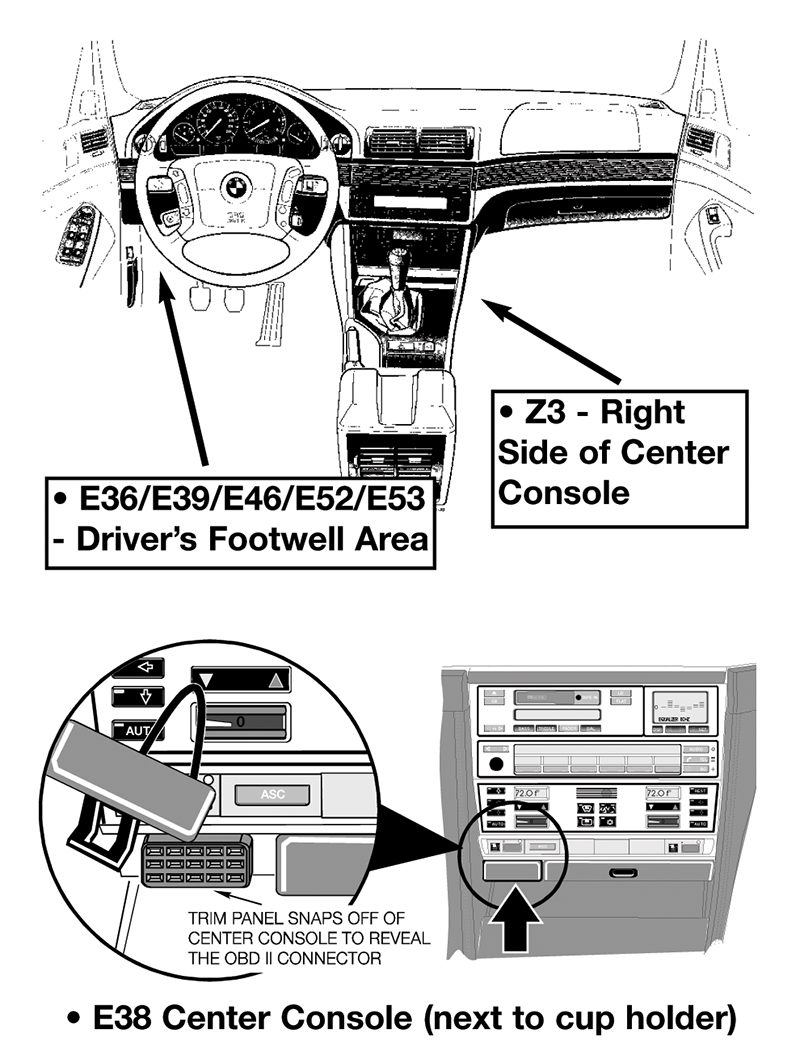

Most BMWs have the OBD II DLC (Data Link Connector) under the dash to the left of center. There are exceptions, however, such as the Z3 and the E38.

The more sophisticated electronic technology allowed manufacturers to meet strict standards, but there was a problem. Emissions remained within regulated limits as long as everything was working properly. But a problem in any system could send emission output soaring. Unless the defect had a severe impact driveablity, motorists would not notice that anything was wrong. They would continue operating their vehicles even though they pumped out unacceptably high levels of pollution.

To ensure that drivers knew when their emission control systems were not working properly, the federal Environmental Protection Agency, following the lead of California (which has always been the pace setter in U.S. emission standards), mandated that by 1989, carmakers develop and install a system that showed when there was a problem with anything aboard a vehicle that could affect emissions. BMW complied with the federal mandate for OBD I.

OBD I launched the era of the instrument panel “Check Engine†light that was turned on when the vehicle’s computer detected a problem. On a BMW, the trouble or fault codes stored in the computer could be accessed by using the BMW 2013 and MoDiC diagnostic units, or by counting the flashes of the “Check Engine†or “Service Engine Soon†light using a key on/engine off procedure. The Check Engine light prompted drivers to have their vehicles serviced, even if they didn’t notice any problem with performance.

Every piece of diagnostic equipment that purports to be OBD II-compatible must have this standardized connector.

These initial diagnostics monitored electrical/electronic components used in emission control, especially the quality of sensor signals, but it was necessarily passive — it had to wait for a problem to occur before setting a code and turning on the warning lamp — and its trouble codes amounted to hints to technicians. There was much more to be learned about the state of the electronic engine management system by accessing the data stream, but many techs either never bought the equipment to enable them to do that, or never learned how to interpret the information.

In the early 1990s, the federal government, pushing for even stricter emission control, mandated the next generation diagnostic system, OBD II, be in place by model year 1996. The first BMW OBD II system was used on MY 1995 vehicles with the 12-cylinder engine. All BMWs had OBD II starting in MY 1996.

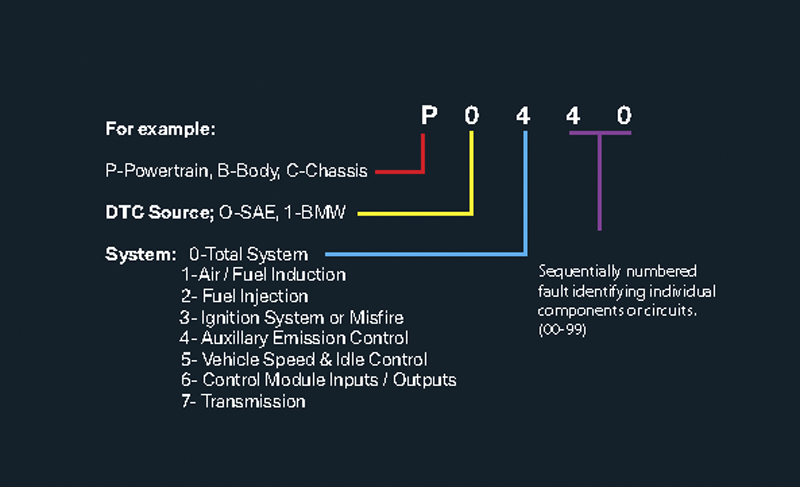

Uniformity is one of the basic goals of OBD II. This has several facets, all based on SAE standards. For example, we got a standard 16-pin DLC (Data Link Connector) regardless of what brand of car we’re working on. With just a few exceptions (such as the Z3), it must be located under the dash to the left of center. Some of its pins are required to have specific purposes, while others are for the carmaker’s own use, or are left unused at this time with the possibility of being employed in the future. Scan tools can be from any aftermarket manufacturer, but they must fit the 16-pin DLC and display all the required information.

OBD II At Work

OBD II keeps tabs on literally everything that could impact emissions, including not only the electronics, but also all systems and processes. While that may sound similar to the previous generation of diagnostics, this goes way beyond that by actually performing tests on various systems and issuing a passing or failing grade. This technology ensures that the vehicle is always in compliance with applicable emission regulations. If a fault is detected, the MIL (Malfunction Indicator Lamp) is turned on, signaling the driver that the vehicle must be checked and serviced.

In a BMW, OBD II watches over:

- All engine sensors and the engine control module

- The transmission control module

- Any actuators used on the engine and transmission

- Fuel system integrity to detect any vapor leaks

Misfiring is definitely taboo, so whenever you find a spark plug with a large gap or fouling, that’s probably the cause of the flashing MIL.

To set a code and trigger the MIL, OBD II must see a problem, then see the same problem during a later drive cycle more than one time. If the MIL glows steadily, the problem(s) detected require prompt attention, but will not cause damage. If the MIL blinks, there is a misfire that could damage the catalytic converter. Drivers should stop driving and turn off the engine, as soon as it is safe to do so, when they see a blinking MIL.

A MIL that comes on, then goes off several drive cycles later indicates the system no longer senses the original problem. After a trouble code is stored in the system memory, if OBD II does not see the problem for three consecutive cycles, the MIL will be turned off. If OBD II does not see the problem for three consecutive cycles, the MIL will be turned off.

You should remind your customers that the MIL is different from the oil pressure or engine temperature warning lamps. When those warnings are illuminated, the driver must safely pull over as quickly as he or she can, turn off the engine, and get help.

The MIL only indicates that this BMW needs service, but the driver doesn’t have to stop immediately. When the MIL comes on, the motorist should call you to make an appointment to bring the car in for diagnosis.

In fact, you can build good will with your customers by instructing them on how to “fix†the most common fault detected by OBD II — a loose gas cap! OBD II will turn on the MIL if the system senses gas vapors escaping into the atmosphere because the cap isn’t on. Tell your customers to make sure the fuel cap is secured if the MIL comes on, especially if they have just refueled. Tightening the cap should cause the MIL to go out within a few drive cycles. The loose gas cap problem is so common, many late model BMWs have a warning light to advise the driver when the cap isn’t secure.

OBD II Drive Cycle

OBD II does not monitor all components all of the time. Some functions are checked continuously while others are checked only once per “drive cycle.â€Â Systems that are continuously monitored include:

- Misfire Detection

- The fuel system, including the duration of injector opening (pulse width)

- Any electrical circuits and components directly related to emissions control, including the engine control module, the transmission control module and the electronic throttle control module Systems monitored only once per driving cycle will trigger a code and turn on the MIL after certain driving conditions are completed. These systems specifically will not be checked if the engine is started and then shut off before reaching normal operating temperature:

- Oxygen Sensor Function

- Secondary Air Injection System

- Catalytic Converter Function (efficiency)

- Evaporative Vapor Recovery System

In a BMW, different vehicle operations can qualify as a drive cycle. For example, the following checks will be done during these drive cycles:

- During an engine cold start following by three minutes of idling, OBD II will check the Secondary Air System and, if equipped, the Evaporative Leak Detection system.

- During steady driving between 20 and 30 mph for about four miles, OBD II will check the oxygen sensors’ response time and switching time (crossover) after the engine reaches operating temperature and goes into closed loop operation.

- Steady driving at 40 to 60 mph for about 15 minutes will allow the OBD II to check catalytic converter efficiency and further check the oxygen sensors’ response and switching times.

- If the engine is idled for about five minutes, a tank leak diagnosis will be done. These drive cycle tests will be interrupted if:

- Engine speed exceeds 3,000 RPM.

- Vehicle speed exceeds 60 mph

- There are wide fluctuations in engine speed

The ability to cover all types of drive cycles within one trip depends on how closely the driver sticks to the criteria for each test phase.

Lighting the MIL

On a BMW, the MIL will be illuminated under the following conditions:

- After completing the next consecutive driving cycle where the previously faulted system is monitored again and the emissions relevant fault is again present.

- Immediately if a “catalyst damaging†fault occurs (misfire detection).

- If a condition requires the MIL to be turned on according to the Federal Test Procedure (FTP). Incidents that could trigger the lamp because of FTP include:

- A malfunction of a component that can affect the emission performance of the vehicle occurs and causes emissions to exceed 1.5 times the standards required by the FTP.

- Manufacturer-defined specifications are exceeded.

- An implausible input signal is generated.

- Catalyst deterioration causes HC-emissions to exceed a limit equivalent to 1.5 times the standard (FTP).

- Misfire faults occur.

- A leak is detected in the evaporative system, or “purging†is defective.

- ECM fails to enter closed-loop oxygen sensor control operation within a specified time interval.

- Engine control or automatic transmission control enters a “limp home” operating mode.

- Ignition is on (KL15) position before cranking (bulb check function).

Protocol

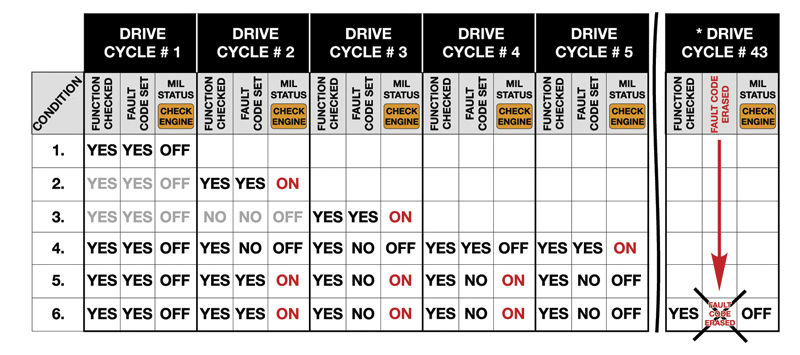

The following chart shows when the MIL can be activated based on your customer’s driving style:

Condition 1. A fault code is stored within the ECM upon the first occurrence of a fault in the system being checked.

Condition 2. The “Malfunction Indicator Light†will not be illuminated until the completion of the second consecutive “customer driving cycle” where the previously faulted system is again monitored and a fault is still present or a catalyst damaging fault has occurred.

Condition 3. If the second drive cycle was not complete and the specific function was not checked as shown in the example, the ECM counts the third drive cycle as the “next consecutive“ drive cycle. The “Malfunction Indicator Light†is illuminated if the function is checked and the fault is still present.

Condition 4. If there is an intermittent fault present and it does not cause a fault to be set through multiple drive cycles, two complete consecutive drive cycles with the fault present are required for the “Malfunction Indicator Light†to be illuminated.

Condition 5. Once the “Malfunction Indicator Light†is illuminated it will remain illuminated unless the specific function has been checked without fault through three complete consecutive drive cycles.

Condition 6. The fault code will also be cleared from memory automatically if the specific function is checked through 40 consecutive drive cycles without the fault being detected or with the use of either the DIS, MODIC or scan tool.

Because potential damage to the catalyst is so serious, OBD II will not clear a misfire detection code unless 80 consecutive drive cycles occur without the fault being detected again.

Readiness Code

With your scan tool, you can check to see if the necessary drive cycles have been completed by checking the “readiness code.†OBD II uses readiness codes to prevent anyone with an emissions related fault and a MIL on from disconnecting the battery or clearing the fault memory before taking an emission control test. A vehicle cannot be emissions tested if the MIL is on, it must be serviced before testing. (Note: Because of hardware and software issues, 1995 and 1996 BMWs with the V12, OBD II works properly, but does not set a readiness code. The federal EPA and I/M stations know about this problem. The code gives you a Yes/No indication of whether the checks have been done. You will get either a “0†or a “1†for the code.

A “0†means Test Not Completed or Not Applicable for six-cylinder engines or “Not Ready for V8s and V12s.

A “1†means Test Completed for six-cylinder vehicles or “Ready†for V8s and V12s.

A readiness code will be stored after any clearing of fault memory or disconnection of the ECM. A readiness code of “0” will be stored after a complete diagnostic check of all components/systems that can turn on the MIL is performed.

The complete readiness code is one “byte†or 8 bits of data. Each bit represents one complete test and will be displayed on your scan tool. For example:

0 = EGR Monitoring (=0, N/A with BMW)

1 = Oxygen Sensor Heater Monitoring

1 = Oxygen Sensor Monitoring

0 = Air Condition (=0, N/A with BMW)

1 = Secondary Air Delivery Monitoring

1 = Evaporative System Monitoring

0 = Catalyst Heating

1 = Catalyst Efficiency Monitoring

When all “readiness codes” are “1” (ready), the necessary drive cycles and system tests have been successfully completed. OBD-II is “ready†to begin monitoring the vehicle.

0 Comments