A review of police records spanning several years showed that there were hundreds of rollovers that resulted in some 200 fatalities and injuring hundreds more.

The crashes were linked to tire failure caused by driving on under-inflated tires. Heat buildup and other stresses from under-inflation caused the tread to suddenly separate from the tire. Although a skilled driver who knew how to handle a blow-out probably could control the vehicle and bring it to a safe stop, many drivers lost control and rolled the vehicle.

The SUV rollover problem alerted much of the nation to a fact that automotive service professionals already knew: Most drivers don’t check tire pressure often enough and many cars are running on one or more improperly inflated tires. A 2001 NHTSA “Tire Pressure Special Study†showed 27 percent or more of all vehicles on the road have underinflated tires.

Out of the morass of media coverage, lawsuits, and government hearings, came major changes in federal tire safety standards. One of the biggest changes mandated by Congress and NHTSA was that all cars, SUVs, and light trucks under 10,000 lb. gross vehicle weight must be equipped with automatic monitoring systems that warn drivers when their tire pressures were too low. If drivers won’t spend five minutes every two weeks to check tire pressure, then the tires would notify the driver when they needed more air.

Two Technologies

As of this writing, only the “direct” type of tire pressure monitoring system (as opposed to “indirect” — we’ll explain) is accurate enough to comply with federal regulations. That is, it must turn on a warning light whenever any tire is 25 percent or more below the recommended cold tire pressure rating. Development work continues on the indirect type with hopes that it may eventually meet the standard, but so far it’s only able to tell you that one tire has gone flat.

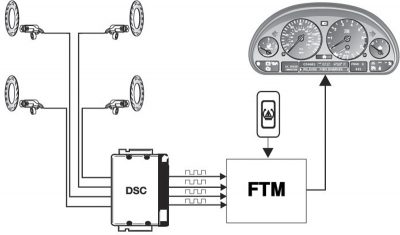

The indirect system piggybacks on the technology of the vehicle’s anti-lock brake system (ABS). The same speed sensors monitor tire speed while the vehicle is moving. A tire that’s going flat will have a smaller circumference than a fully inflated tire, so it must turn faster to keep up. When the wheel speed sensors detect a significant enough difference in the rotational speed of one tire compared to the others, a warning light is turned on. The only advantage of an indirect system is that it is fairly inexpensive. The speed sensors and related hardware are already in place for the ABS. All that is needed is additional programming to track rotation as the vehicle moves down the road and signal a warning when a flat is detected.

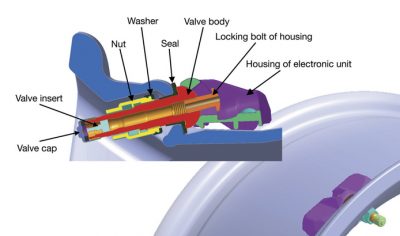

A direct system has pressure sensors and transmitters mounted inside each wheel. The sensor/transmitter is made in one piece with a special threaded metal tire valve stem, which acts as the antenna. The stem is fastened in the hole in the wheel by means of a gland nut, and the sensor resides inside the tire.

Actual tire pressure is monitored continuously. Whenever the pressure in any tire falls below a preprogrammed level, the system activates a warning. Unlike the indirect system that only notifies a driver of a flat, the direct system can tell the driver which tire is low. The direct system can warn a driver not only if there is a sudden loss of pressure, but also if there is a slow leak in any tire that causes a gradual reduction in pressure.

A direct pressure system is essentially independent of all other chassis electronics on a vehicle. The individual sensors and transmitters inside each wheel generate a signal that is picked up by dedicated receivers. The signals are coded to identify the transmitter in each wheel. So, the benefits of a direct reading system are offset by its significantly higher costs.

BMW indirect

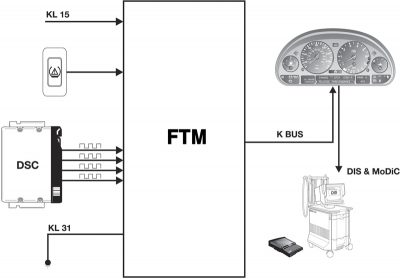

BMW has used both indirect and direct pressure monitoring systems in its vehicles. The indirect system is generally called FTM (for Flat Tire Warning). As we said, the indirect system uses ABS sensors to monitor the rotation speed of the wheels. It compares the rotation speed of the wheels on the diagonal (left front and right rear, to right front and left rear) and calculates an average vehicle wheel rotation speed. This value is stored in the control module. The earliest FTM systems on the E39 M5 and the E52 Z8 had an individual control module. Since MY 2001 FTM does not have a separate controller. Tire pressure monitoring is now another function incorporated into the DSC (Directional Stability Control) module that also regulates ABS, traction control, and stability. If the vehicle has a dedicated FTM control module, in most cases you will find it behind the glove box in the control module carrier, although it may be elsewhere (refer to the proper service information for the model at hand). In addition to receiving the four wheel speed signals, the module receives power (KL 15), ground (KL 31) and a ground signal input from the set/push button switch in the console. The control module is connected to the K-Bus for:

- Output display in the check control matrix or Warning Light

- Diagnostic communication through the instrument cluster with the DISplus tester or GT-1.

With indirect monitoring, three different messages can be displayed on the dash:

- TIRE PRESSURE FAILURE will display when the system senses a 30 percent under-inflation condition. A warning alarm will also sound. The display and alarm remain active until the ignition is turned off.

- TIRE MONITORING INACTIVE is displayed if there is a system fault, or, in the first M3 models, when the driver has manually turned the system off.

- TIRE PRESSURE SET is displayed during initialization. You must initialize the system whenever you change tire pressure during servicing, when new tires are installed, or when the control module or speed sensors are replaced..

After completing the service work, start the engine and press the dashboard button for at least four seconds. When you see “TIRE PRESSURE SET†(for E85, the Yellow Indicator light will come on), the tire pressure monitoring system has been initialized. When the vehicle is driven, the system will automatically store rotating wheel speed values based on different road speeds.

On the E85 system, a red light indicates loss of tire pressure. If the yellow light comes on after initialization, it indicates a failure of the system. After a short drive (no more than three minutes), from a vehicle speed greater than 10 mph, the system learns the new wheel speed sensor reference values and the RPA indicator light (yellow) goes out. When a flat is detected, the RPA indicator light will be red or flashing yellow, depending upon the model.

The indirect system has additional limitations in addition to not actually monitoring individual tire pressures directly. It may not work, or could trigger a false signal:

- When the system has not completed initialization for a certain speed range.

- During rapid acceleration, severe braking, or high cornering.

- At very slow speeds, generally under seven mph.

- If there is a high slip differential among individual wheels.

Because the indirect system has no direct connection to the wheels and tires, there are no special service considerations when mounting, dismounting, balancing, or aligning the wheels or tires.

Direct monitoring

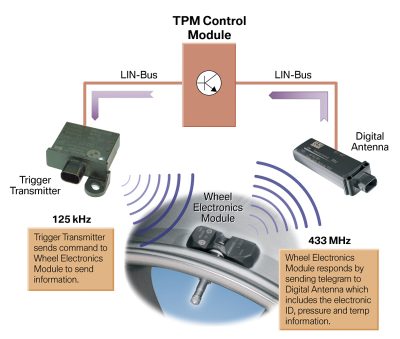

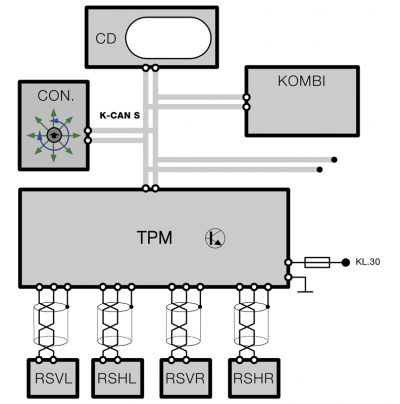

TPM is BMW’s direct pressure monitoring system. The system monitors pressure when the vehicle is moving. If the vehicle has a full-size spare tire, it is equipped with a transmitter, but its pressure can only be monitored when it is mounted. Temporary Spares do not have a wheel sensor. If a temporary spare is mounted at any wheel position, the TPM switches to “Inactive” after several minutes. The electronic transmitter module inside each tire measures the tire pressure and temperature at regular intervals and transmits the information by radio frequency to the TPM control unit.

The transmitters are inside the tire, integral with the tire valve, forming an assembly. In most BMWs, you’ll find the controller behind the glove box on the controller carrier, although it could be elsewhere depending on the model. The individual reception antennas are located behind the splash shield of each wheel house. Each transmitter includes a pressure sensor plus a 3.6V lithium battery with an expected service life of five to seven years. Each transmitter has a unique identification code. When the system is initialized, the TPM controller assigns a position (left front, right front, etc.) to each ID code. Signals from the transmitter are sent to the digital wheel house antenna each time the tire valve passes it.

Like the indirect system, TPM must be initialized whenever you add or remove air from a tire, the tires are rotated, or the tires are changed. Initialization is done in the “Settings†function of the Control Display. During initialization, the system recognizes each transmitter, assigns locations to the transmitters, and stores the “setpoint†(recommended pressure) for the tires. Recommended tire pressure must be at the psi specified on the “B” pillar label, and all tires must be within six psi (0.4 bar) of each other or the system will not complete initialization. Initialization will typically occur within two minutes of driving. “Initializing TPM!†will be displayed on the Instrument Cluster until the process is complete. When initialization is complete, the tires of the car on the graphic turn green. An older TPM system will turn on the warning light whenever it detects a tire pressure that is eight psi below its initialized setting, but the latest systems react at five psi. Some versions (but not the latest) automatically adjust recommended pressure settings based on changes in ambient air temperature, and if ambient temperature is 68° F. cooler than the original initialization temperature for 14 days, the system will display an “Autumn Warning†light, to prompt the driver to recheck and inflate the tires because of cold weather. This feature was deemed unnecessary for the newest systems.

Servicing TPM wheels

You can balance wheels and tires with pressure sensor/transmitters as you normally do because the sensor is securely mounted inside the tire. However, when mounting or dismounting tires, follow these steps:

- Remove the Schrader valve from the stem to let all of the air out of the tire. Remove any balancing weights.

- Press the tire off the safety shoulder inside and out. ALWAYS APPLY THE PRESSURE OPPOSITE (180° away) FROM THE VALVE. If you apply pressure near the valve, you could damage the sensor.

Note: If you’re worried about damaging the sensor/transmitter during tire demounting, you could resort to a trick that’s finding favor in the real world of auto service: Remove the gland nut that secures the valve stem, then push the stem through the hole so that the assembly falls into the tire. - Clamp the wheel onto your mounting machine according to the manufacturer’s directions. Rub mounting solution on the tire bead and rim lip. Position the head about six inches away from the valve to prevent damage to the sensor.

- Place the lever on the tire bead.

- Lift the tire bead with the mounting iron/tire shoe over the installation head and pull the tire away.

- Pull the lower tire bead away. Position the installation head approximately six inches behind the valve, and make sure the tire bead does not press onto the sensor/transmitter assembly during the removal operation.

When mounting a tire, start opposite the valve and sensor. Be very careful that the tire bead does not contact the sensor during installation. Install the valve insert and slowly inflate the tire to its recommended pressure. Install the cap on the valve. Do not substitute any other cap. Use only the original.

Inspection and installation

Visually inspect the rim, wheel, sensor/transmitter, and tire valve body for any damage. The valve and sensor assembly must never be cleaned with compressed air, solvents, or other cleaning solutions. Do not use any type of installation paste on the assembly. If the sensor assembly is dirty, wipe it with a clean, lint-free cloth.

If you diagnose a defective TPM sensor, get the replacement from your local BMW dealer. There are several types of aftermarket sensors with different frequencies and shapes. By getting the replacement units from a BMW dealer, you can be sure the sensors are the correct type for your customers vehicle. In North America, the BMW TPM sensors transmit at 315 MHz, except for the latest versions that transmit at 433 MHz. They do not have a beveled spacer ring.

A replacement unit includes the tire valve, sensor, a self-locking mounting screw, spacer ring, collar nut, valve cap, and mounting pin.

To install a new sensor:

- Push the valve into the sensor and then into the valve hole of the rim.

- Put the spacer ring on the valve and turn the screw collar nut down until it is seated.

- Put the installation pin into the valve and then tighten the collar nut to 3.5 Nm. As soon as you have tightened the collar, remove the mounting pin.

- Press the sensor lightly into the deep well of the rim, then tighten the mounting screw to 3.5 Nm. The valve and sensor assembly should be flat in the drop center. If not, the installation is incorrect.

- Remount the tire and inflate to its recommended pressure.

- The TPM must be initialized and recalibrated as explained above.

0 Comments