By John Anello

I was called in to a shop for a complaint of tip-in stumble on a 1995 Jeep Grand Cherokee with the 4.0L engine (Figure 1). The vehicle had about 100,000 miles on the clock, and the shop had just replaced the engine because it had a bad knock in the bottom end. After the engine was replaced, the shop was married to the hesitation problem. It’s a dilemma I’m sure we’ve all experienced. The big question was whether the problem was created by the recent heavy labor operation, or was it pre-existing? The owner of the vehicle may just deny that there was ever a problem prior to the engine job, so it just falls in your lap, and you have to deal with it in order to get paid for the job you were hired to do.

The shop had done some basic performance checks on the engine such as fuel pressure and distributor rotor indexing to make sure the ignition timing was within specs. You can’t just drop the distributor in wherever your heart desires. You need to turn the crank until #1 is at TDC of the compression stroke, and rotate the distributor shaft with the cap off until the tip of the rotor lines up with the #1 cylinder location on the distributor housing. The final adjustment can be done with the engine running using a good known cam-crank sensor correlation waveform file and a scope. This procedure must be followed after any type of distributor, timing chain or engine replacement on this particular vehicle.

The techs checked everything they could, and even resorted to throwing some parts at the problem. The hit list included a TPS sensor, MAP sensor and even a PCM, but nothing made any difference. It’s not uncommon for a shop to start hanging parts after extensive testing with no results. A technician may start to lose faith in himself, and use the “failure pattern†tactic. This is something we’ve all done, including myself, in times of diagnostic despair. But nobody should be proud of “shotgun troubleshooting.â€

When I arrived at the shop, the tech demonstrated the problem with the vehicle. He started it up, opened the throttle gradually and it revved up fine. He then snapped the throttle hard and the engine bogged down like it was running out of fuel. By snapping a throttle, you’re drawing a tremendous amount of air into the engine instantly, and what must follow is a good supply of fuel, sufficient KVs at the spark plugs, and unrestricted exhaust.

My first step was to place a ST-125 HEI spark tester (Figure 2) on the #1 spark plug wire. I wanted to see if the ignition system had sufficient KVs to jump the spark gap during a snap-throttle. With the quick rush of air into the cylinders, a high KV demand is created at the plugs, and I’ve seen many weak ignition coils and bad distributor rotors cause hesitation on a quick throttle opening that mimics a fuel delivery problem. The spark tester itself is actually a stress test that will put about a 25 KV load on the ignition system. This is one test I perform on every drivability problem I encounter.

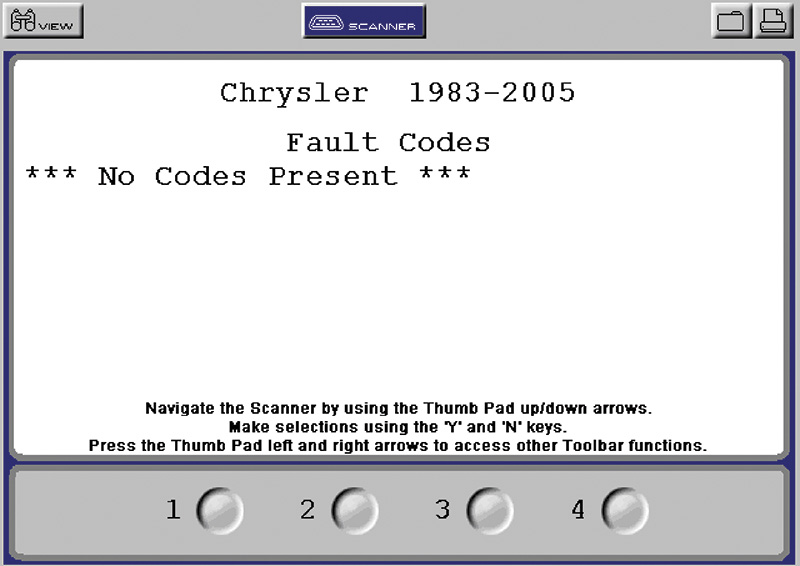

The spark tester proved out good KVs, so my next choice was a scan tool to provide me with a window through which I could see what the PCM was seeing. This was an OBD I vehicle, so a factory-enhanced tool was needed. I input the VIN, and selected the code menu. I checked for any trouble codes stored in memory, but there were none (Figure 3). The vehicle probably was not run long enough after the engine job for the onboard computer to set any codes. Remember that these OBD I systems were not sophisticated enough to test for within-range failures, and were mostly set to fail for an open or shorted circuit. So, OBD I vehicles really test a technician’s understanding of system operation, and also his or her knowledge of where sensor values should be under different operating conditions.

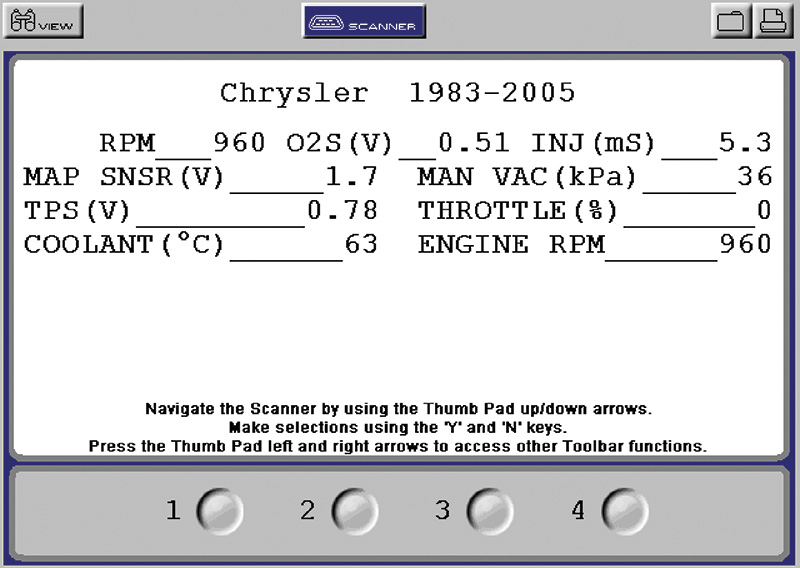

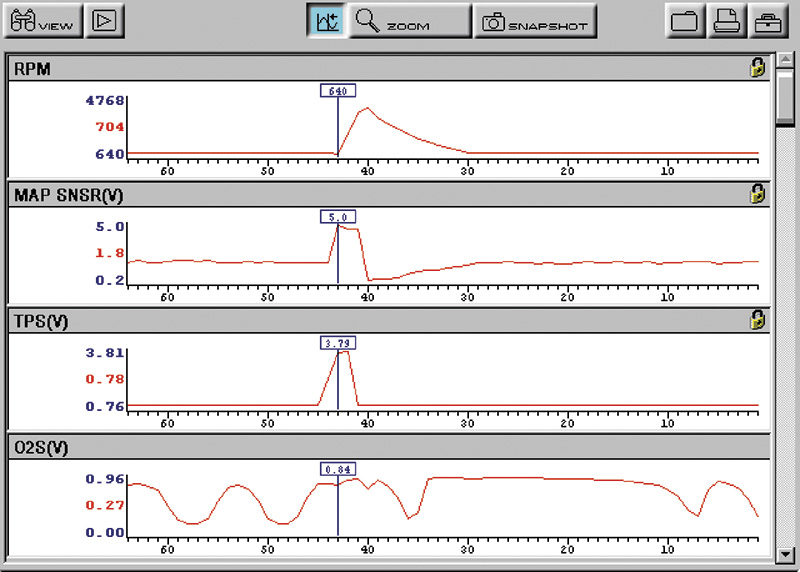

I decided to view some basic data that was associated with fuel enrichment on acceleration. The problem was present all the time even in open loop operation directly after initial start up, so I tried to focus on sensors that were key players. This vehicle uses a speed density system to map out fuel delivery — there’s no MAF sensor — so it was critical for me to choose the correct data PIDs. I chose the rpm input, TPS, MAP sensor and coolant temperature sensor. The data values on the screen at idle (Figure 4) seemed to be within the proper range, but I needed to place the data in a graphing mode before I could validate the information any further. Looking at data in a numeric format while snapping a throttle is not what I want to do. The human mind is not good at number crunching multiple data inputs, so I would rather leave that up to the power of a graphing meter that provides me with the visual associations I need to compare signals over time.

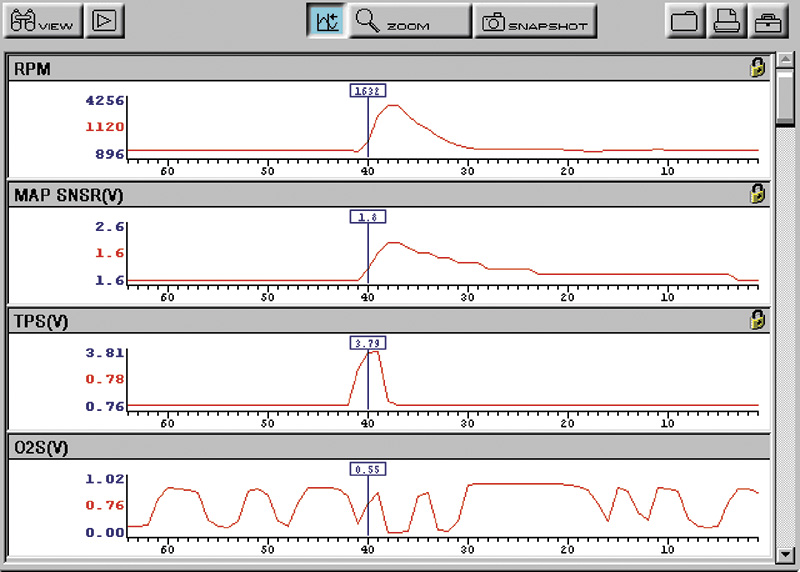

I placed the data in a graphing mode (Figure 5) and snapped the throttle very hard. You could immediately see that the MAP sensor only reached a threshold of about 2.6 volts, and it had a very slow response and recovery rate as seen by the voltage ramp as it climbed and descended. This could have been a lazy map sensor, but the shop had already tried a brand new one and it didn’t solve the problem. I could power brake the engine as I slowly increased throttle opening and there was plenty of power, so this was not a clogged exhaust. So, what was causing such a bad tip-in stumble?

I felt it was time to check the vacuum supply to the MAP sensor because this could affect the output signal and create a lean command on a throttle snap.

The line came off an intake port and ran to the MAP sensor at the firewall (Figure 6). It’s not uncommon for these ports to become plugged with carbon, which diminishes the vacuum supply to the sensor. I asked the tech to unscrew the port for inspection, but he told me he had already been there and done that. I went one step further by pulling the MAP line off the car to inspect it. It was a small-diameter plastic tube, so I decided to blow through it to check for restrictions. I’ve seen many vacuum lines over the years that were blocked with debris, or had a weak spot that collapsed under vacuum. As I blew through the line I had a hard time getting air through it. When I turned it over, I was surprised at what I saw. The underside of the tubing (Figure 7) had melted, probably from a prior exhaust manifold leak, and was partially collapsed. The technician had never noticed this because the tube looked okay from the top. I immediately had the tech get me a new supply line to replace the tube and tried my snap test again. I opened the throttle fast and hard, and the problem was now gone. I took another look at my graph (Figure 8), and you can see how quick the response time from the MAP sensor was. Notice the quick threshold rise and speed of the MAP sensor as it now reached close to 5.0 volts. Also, the fall rate of the sensor changed as the throttle was released. Prior to that, the engine would run roughly on decel recovery and load up with fuel due to the slow increase of vacuum within the MAP sensor that prevented the PCM from getting the signal necessary for it to command the deceleration enleanment mode.

This problem can be compared to a crowd of people in a ballroom all dancing and having a good time in the chamber of love. Then someone yells “Fire!†and they all have to get out through the same doorway as quickly as possible. But the door will only open part way. The crowd will just not make it out quick enough. There can’t be anyone left in that chamber or it’s an indication that the party is still going on.

The PCM needs to see atmospheric pressure on a hard snap in order to deliver the proper amount of fuel, then an instant switch to manifold vacuum when the throttle’s released to shut off injection. Understanding how sensors work and how to test them is the key to driveability diagnostics. The sensor itself has to have a proper power feed and ground, uninterrupted mechanical input (vacuum, in this case), and its signal wire must be correctly routed back to the PCM. You have to be sure that whatever this sensor is testing is actually being taken into consideration because the sensor can only report what it sees. I hope this story hits home for many of you out there in the field.

0 Comments