Time to think again.

Strict diesel emissions requirements enacted by the US EPA, known as “Tier 2 Bin 5†combined with the Ultra-Low Sulfur Diesel (ULSD) fuel needed to meet them has kept diesels out of most U.S. passenger vehicles the past few years. Combining oxidation catalysts with diesel particulate filters to eliminate soot, and a SCR catalyst utilizing urea injection to virtually eliminate nitrous oxides means BMW’s latest diesels can meet not only Euro4 emissions requirements, but the even-stricter U.S. requirements as well. What does this mean? Diesels are coming back!

The ability to meet 2010 emissions standards isn’t the only reason for the comeback of diesels. More than half of BMW vehicles sold in Europe are equipped with diesel engines, primarily for fuel economy reasons. As gas prices head toward the stratosphere, diesels, and diesel-hybrids, become increasing attractive to consumers because of their greater fuel efficiency.

The elimination of diesel smoke and near-complete elimination of clatter combined with higher fuel economy means the great majority of consumer objections to owning a diesel have been eliminated. Add to that the monster amounts of torque BMW’s diesel engines can provide, along with a 5,000 rpm redline, and suddenly diesel starts sounding more like a performance option than a sacrifice made for mileage.

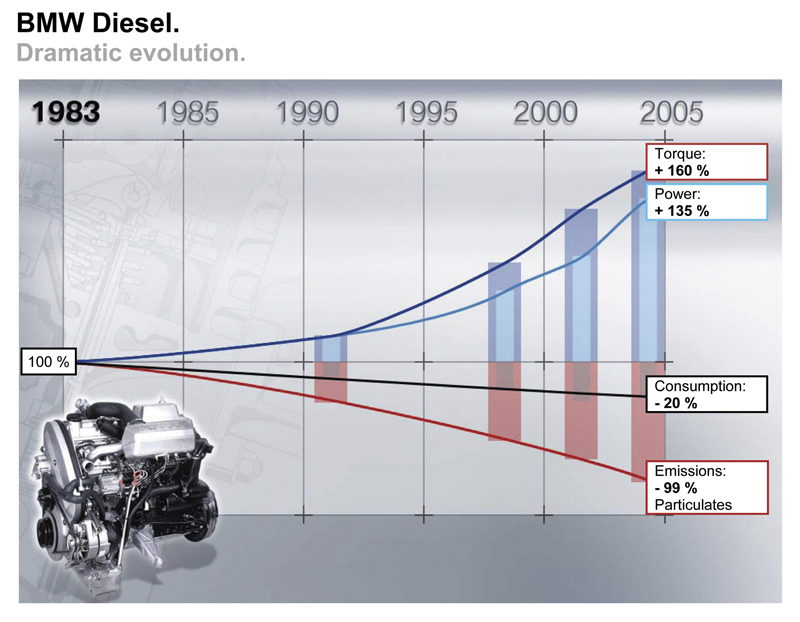

BMW is not a newcomer where diesels are concerned. The 1983 524td was the fastest diesel passenger car of its day.

The twin-turbo 335d in Europe makes 286 hp and an astounding 427 lb-ft. (578 Nm) of torque. The (European-only) 2.0 liter diesel sold in the BMW 1 Series achieves an astounding 54 mpg, while retaining a sporty 7.9 second 0-60 mph time. And that’s just the beginning of the story. For North America, here’s how BMW is going to do diesel.

Twin turbo six

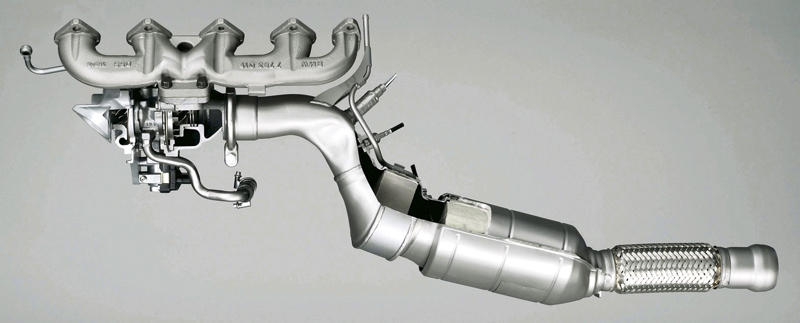

The “first assault†to hit American shores will be BMW’s 3.0 liter, twin (sequential) turbo six cylinder, designated as the M57TU2TOP. A pair of turbos, one small and one large, combine to reduce turbo lag, while providing the massive amounts of boost diesels benefit from at higher rpm. As with the domestic light truck diesels you may be familiar with, large amounts of cooled EGR are utilized to meet emissions goals. A Bosch common-rail fuel system running at 24,000 psi (1,600 bar) provides multiple injection events (as many as five) per firing event to virtually eliminate diesel clatter and lower emissions. Glow plug operation isn’t needed unless temperatures descend below 5 deg. C.

Diagnosis of the Bosch fuel injection system on the new BMW diesels will require the use of a scan tool. Hundreds of new diagnostic trouble codes (DTCs) will assist the technician in pinpointing any problem areas. If the latest crop of American-made diesel engines are any indication, cooling EGR gasses tends to precipitate carbon and other debris that clogs passages and EGR valves, which may require service attention. Sufficient DTCs are in place to detect issues such as “Low EGR Flow†that will point techs toward the necessary repairs. Refilling of the urea tank should be a minor service similar to refilling a windshield washer fluid tank. Which brings up the question, “Why does this engine need urea, and what does it do?”

Urea injection and piezo

Engineers found that urea injected into a hot exhaust stream releases ammonia, which chemically reduces oxides of nitrogen to elemental nitrogen and water. You may have heard that a European consortium of automakers have come up with a clean-diesel system called “Bluetec.†While BMW’s injection system works similarly, BMW chose not to adopt the Bluetec moniker.

In BMW’s case, a Diesel Exhaust Fluid (DEF) is used. It is urea-based with 32.5% demineralized water. It is clear in color.

The tank must be kept at an adequate level; otherwise a dashboard light will illuminate and the engine may be required by EPA regulation to put itself into a limp-home mode until refilled. The fluid is inexpensive and may last 10,000-15,000 miles.

For ultra-precise, multi-event fuel injection, BMW turned to Robert Bosch. Bosch’s third generation common rail fuel injection system utilizes piezo electric injectors that reduce engine emissions by 15 to 20% while significantly reducing both engine noise (diesel clatter) and fuel consumption. The system replaces magnetic core windings with a series of stacked piezo electric elements within the injector body. The piezo actuators switch in less than half the time required by magnetic switches, enabling briefer and more precise control of injection events.

This European model BMW 7 Series with long wheelbase and 3.0 l diesel engine (BMW 730Ld) is powered by the M57TU, which gives it startling acceleration and great mpg.

“It isn’t noisy and it doesn’t stink like a diesel pickup,†he says. “You can hear a slightly different sound from the engine at idle if you’re outside the car. And it feels like a big-block Chevy when you put your foot down.â€-Satch Carlson, Editor of BMW Roundel |

Dual stage turbos utilized in the European 2.0L diesel (not sold in the U.S.) increase its output to an astounding 100 hp per liter and more than 140 lbs. ft. of torque per liter, easily matching the torque of a gas V8 engine. As with all turbocharged engines, religiously regular oil changes are mandatory to ensure long turbo life. Although some other automakers recommend a “cool down†idling period after high-speed highway driving to allow the turbo to cool to where oil remaining in the turbo bearings won’t “coke†after shutdown, BMW has engineered its system so well that this annoyance is not necessary. Regardless, turbocharging is one more justification for the use of synthetic motor oil.

Compared to gasoline, even the Ultra-Low Sulfur Diesel demanded by BMW is still comparatively “dirty.†Water contamination is a common problem, and can lead to algae “infections†of the tank.

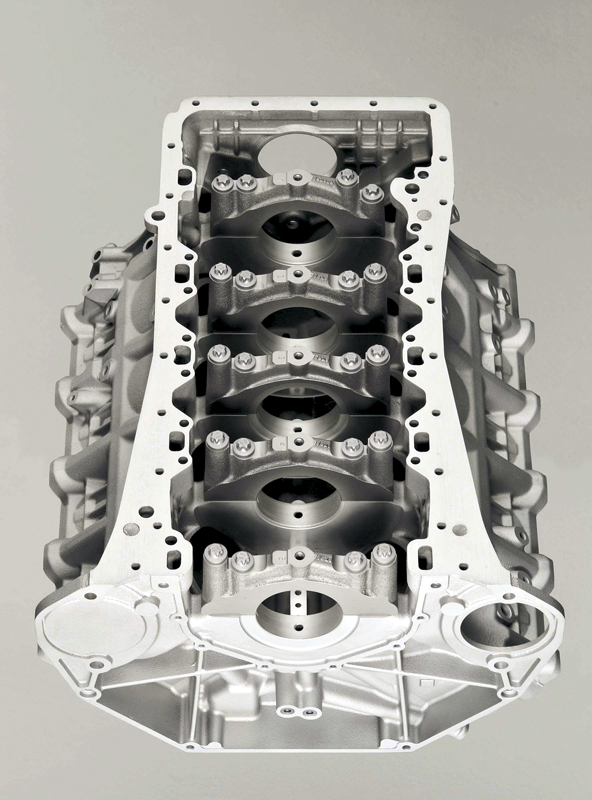

The extremely strong block of the V8, which is no longer being produced, features four-bolt main caps.

What will the second BMW diesel to arrive in North America be? There wouldn’t seem to be any compelling reason why the particulate-filter and urea-injection system developed for the 3.0L I-6 couldn’t be applied to the 2.0L inline four currently offered in the European-only 1-series, allowing BMW to offer both “heavy†and “light†performance diesel options. A tech who has seen the 2L disassembled suggests its construction is motorcycle-like, with hollow cams, twin balance shafts, timing gear and high pressure pump at the back of the engine. As for BMW, the company offers “no official comment†on a second diesel, while admitting diesel-hybrid research is ongoing.

Given the popularity of the X5 in North America, a diesel would provide an “economy-performance†option, offering this heavy vehicle greater acceleration AND improved fuel mileage. The existing six-cylinder sequential turbo diesel would more than suffice for the X5, but supply may be a bigger issue than demand for this particular engine.

For techs who don’t have significant diesel diagnostic and repair experience, the “new†diesel offerings from BMW and others are about as gas-like as they can get. The only thing they’re missing is spark plugs. Glow plugs automatically turn on at low temperatures, but everything else is virtually identical to the fuel injection you’d find on a gas engine (at vastly higher pressures, to be sure). A mass airflow sensor measures airflow to allow ultra-precise injection, schedule EGR, and the majority of other components, both electronic and mechanical, are similar. Only the engine’s higher compression, and the increased structural demands this makes on blocks, pistons, connecting rods, and so forth are fundamentally different from what’s found on a gas engine.

But wait. A typical diesel doesn’t have a throttle plate, and lacks intake vacuum. So, how does BMW coerce EGR to flow from an equally low pressure exhaust system into the intake, especially after running it through an intercooler? Designers typically turn to one of two approaches to coerce EGR flow in diesels; either artificially generating back pressure in the exhaust stream, or reverting to gasoline engine technology and adding a throttle plate to generate a partial vacuum in the intake manifold.

BMW’s new-generation diesels should be eminently dependable because they’re not only tested in the lab. In 2004 Paris-to-Dakar rally, this X5 placed first in the diesel category.

One engineering possibility is to command a variable-vane turbo to generate back pressure with which to force EGR flow into the intake. But the potential exists for deposits to gradually result in a loss of vane control. BMW’s approach on the M57TU2TOP is to use an EDK throttle valve in the intake, which might also be described as a damper. The EGR valve itself is incorporated into the throttle body. According to a website, “Depending on [the damper’s] angle, it governs how much fresh air is taken in, thus increasing the vacuum. The second important job of the electronic damper: if necessary, it closes completely, which, in turn, purifies the particle filter located in the exhaust system.â€

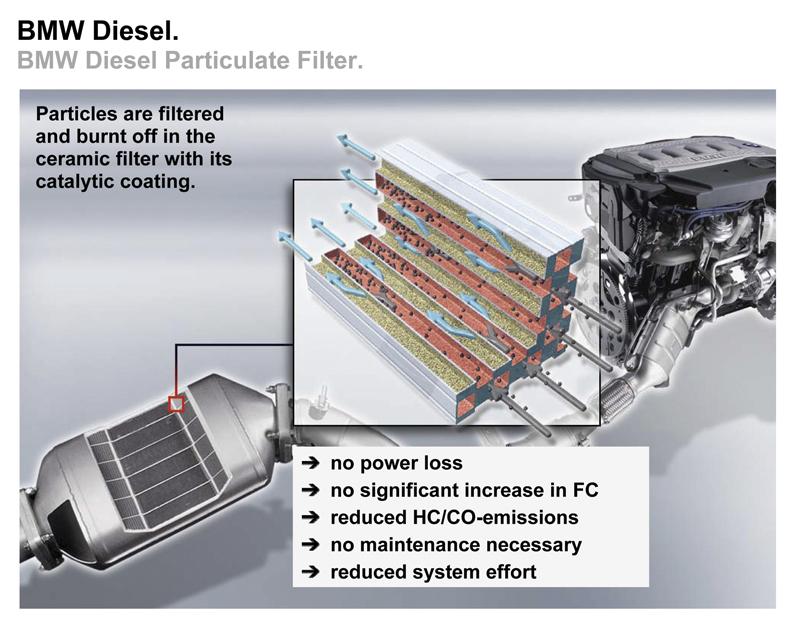

The second sentence brings up an important issue with the “new dieselsâ€: Diesel Particulate Filter (DPF) regeneration. A diesel DPF slowly clogs with particulates from the combustion process. Like a self-cleaning oven, it occasionally has to be “cooked off†to combust the accumulated soot into ash. “Regen†is scheduled by the ECU (DDE module) whenever possible to occur at highway speeds, and is accomplished by restricting the airflow into the engine and firing the injectors after the combustion event to add extra fuel to the exhaust stream. Detection of pressure differentials before and after the DPF is typically used to “trigger†regen.

The addition of the multiple catalysts means sensors related to those catalysts may require occasional service. Whether an 02 sensor, or pre-and-post DPF pressure sensor, any sensor exposed an exhaust stream lives a hard, dirty life, and is prone to contamination and/or clogging. Hopefully, self-testing of particulate filter-related sensors will, like 02 sensors on gas engines, provide a prompt and simple diagnostic approach.

Another likely service scenario for independent BMW techs is the consumer who fills his or her tank with gasoline rather than diesel. The engine will start running badly within a few miles of leaving the station, and the consumer will often realize what he or she has done. Repair typically consists of draining the tank, replacing the fuel filter, and re-starting the engine. Sometimes serious damage will have occured. Consumers may also need to heed any BMW recommendations for fuel selection in extremely cold weather, when addition of Diesel #1 is sometimes required to prevent fuel gelling.

Techs familiar with turbos and wastegates may find surprises waiting for them with the new sequential turbos. Specifically, an ECM-controlled vane directs the flow of exhaust gas towards the smaller, or larger turbo, depending on engine rpm and load.

Last on the “new and distinctive†list for this and other BMW diesels is a vacuum pump, used to power the brake booster, and perhaps for ancillary vacuum needs. Diagnosis of vacuum pumps is usually pretty straightforward; when the customer complains of a stiff brake pedal, the vacuum pump and lines need to be inspected and tested. Whether or not there is any scan tool communication or DTCs relevant to the vacuum pump operation is unclear at the time of this writing.

So, there it is, a revolutionary new diesel engine from BMW that doesn’t clatter, doesn’t smoke, redlines at 5,000 rpm, provides gut-wrenching low end torque, and, on top of all of that, provides markedly better fuel economy than gasoline engines, even approaching that of some hybrids (and exceeding them on the highway). While a few consumers may remember their father’s diesel and be hesitant to make a transition to diesel power, the undeniable advantages of this engine are likely to make it enormously popular with American consumers wanting performance AND economy in full-sized vehicles.

0 Comments