A shop called me in to investigate a no-start condition on a 1996 Dodge Caravan with a 3.3L engine (Figure 1). This shop only had a scan tool in its arsenal of diagnostic equipment. No scope, no graphing meter combined with a component tester, not even a repair information system. With no codes in memory, the techs resorted to the “feels like” tactic. They used their best instincts to replace parts associated with their visual inspections and old-school test procedures.

Bad PCM, but why?

The spark tester they were using only showed spark on one coil, so the list of parts replaced included the coil pack, crank sensor, cam sensor and a PCM. The old PCM was bad due to a damaged coil driver that was holding one coil primary constantly on. I’ve seen this many times in the field caused by a bad coil assembly with a shorted coil primary winding. So, I could justify their replacement of the coil assembly and the PCM, but the vehicle still wouldn’t start. This shop is not alone in the way it diagnoses cars. All too often I cater to this type of shop, and I try my best to educate on-site how important it is for the technicians to keep themselves up to date on training and to have the proper equipment available for performing the tasks that will save them time and avoid replacing perfectly good parts. This will obviously make them better technicians in the long run. It’s never too late to step up and take it to the next level. The worst thing in any business is to let technology surpass you. You will only find yourself stuck in the past with not much of a future ahead of you.

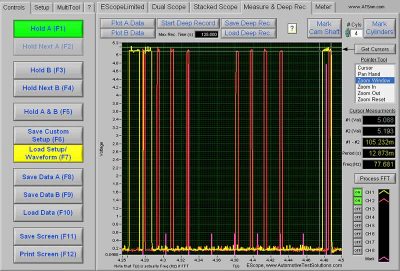

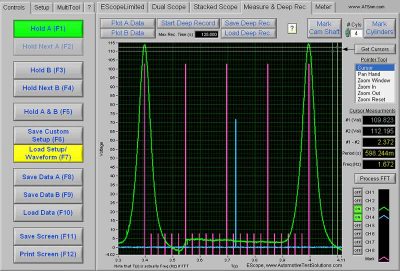

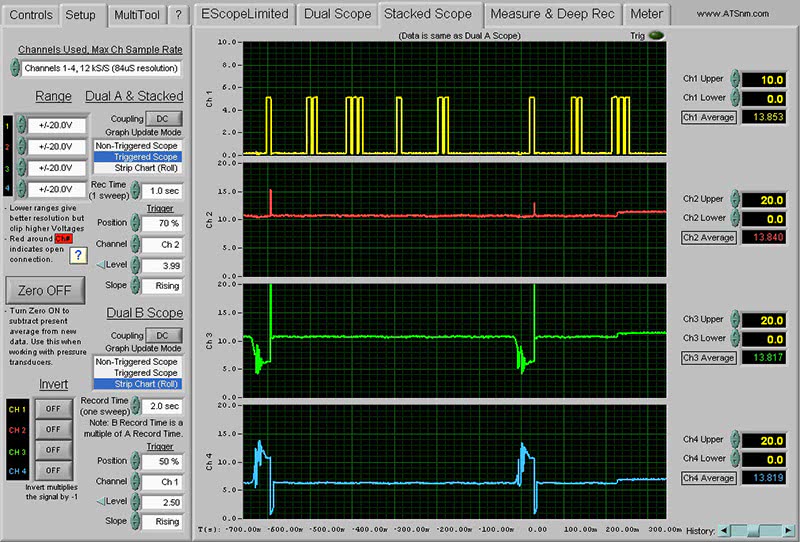

When I arrived at the shop I attempted to start the car, but it only spit back a few times as if it wanted to start. The tech told me that #2/5 ignition coil was the only one firing during cranking. The other coils did not fire at all. At this point I decided to hook my scope up to some selected signal lines to get a visual concept of what was going on exactly. I used my EScope Limited 4-trace scope and placed my channels on the cam sensor and all three coil drivers. As I cranked the engine, I could see that the cam sensor was providing the proper signal pattern, but the PCM had a problem controlling the coil drivers (Figure 2). One driver attempted to ground the coil while another driver was held on for as long as 600mS of on-time. By current ramping the one working coil against the crank and cam signals (Figure 3) I could see that the coil driver was maintaining about 8.5 amps of current for almost one camshaft revolution. There is no way any driver would hold a coil primary that long unless that driver was in love and just did not want to let the coil go. It was a relationship that went bad, and no one was around to give advice to just let go. That got me wondering if this might have caused the failure of the coil driver in the old PCM.

Out of synch

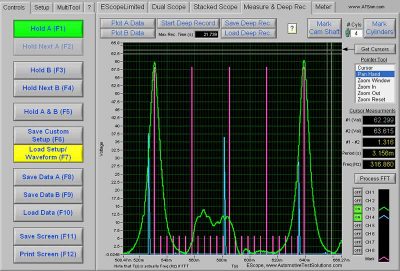

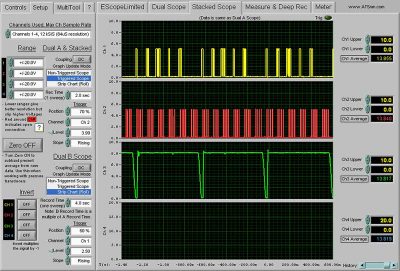

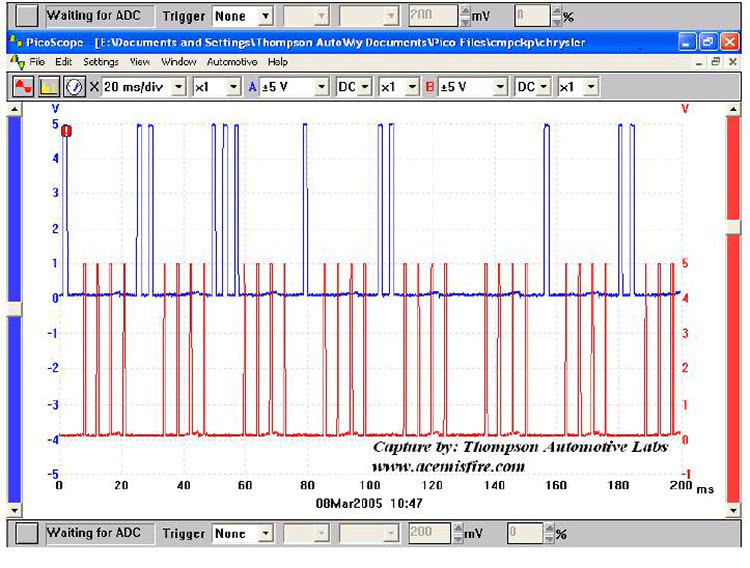

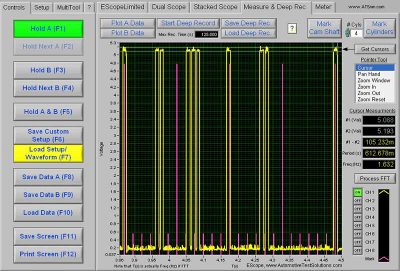

This erratic coil operation could only be caused by a defective PCM with an internal driver failure, a corrupted crank/cam signal input, or a crank/cam sensor correlation problem. The cam and crank sensors seemed to be producing the proper patterns with correct amplitude, but I needed to compare their synch correlation. I used my Ace Misfire crank/cam waveform database and pulled up a known-good crank/cam pattern for this vehicle (Figure 4). You can see how the cam sensor pattern repeats the 1-2-3-1-2 pattern while the crank signal repeats the 4-4-4-4-4-4 pattern. It is between where the cam pattern ends and begins that there should be equidistant 4-4 patterns. I imported the cam sensor signal into the measuring section of the scope (Figure 5) and placed cursors to show one complete event of the cam sensor. By hitting the Mark Camshaft button, the program automatically placed five purple cursors on the screen creating four divisions each representing 180 degrees of crankshaft rotation and five smaller purple cursors creating six subdivisions each representing 30 degrees within each 180 division.

I superimposed the crank signal on top of the cam signal and zoomed in on the end and the beginning event of the cam signal (Figure 6). Notice how the crank signal has shifted at least 30 degrees to the left. This indicated that the crank and cam sensors were not properly synched. The cam sensor indexed off the front of the engine while the crank sensor indexed off the torque convertor at the rear of the engine. Now, I had to decide whether this was caused by a problem in the front or rear of the engine. With 108,000 miles on the clock it was a better sell from a maintenance point of view to disassemble the front of the engine to inspect the timing chain components than it was to pull the transmission to check the flywheel assembly. The cause at this point could be a jumped timing chain, sheared crank keyway, sheared cam gear roll pin, or even a damaged flywheel. There was no flywheel noise while cranking the engine, so where do you start with this dilemma without having to spend unnecessary labor?

Cylinder pressure

The answer to this question is a new test procedure I’ve been using to check valve train problems that uses a simple 300 psi pressure transducer. You remove the spark plug from a selected cylinder and install a hose adapter to accommodate the pressure transducer. Next, you place a spark tester on the plug wire of that same cylinder, put an inductive clamp around the plug wire and crank the engine. The resulting patterns will show you a peak-to-peak cylinder pressure rise representing a 720 degree crankshaft event and an induction square wave representing the spark event in the cylinder. You then place your cursors on the compression peaks, select the Mark Camshaft button and look at where the purple cursors are laid out. The lowest point (u-curve) before BDC of the power stoke is where the exhaust valve begins to open. This I have found to be about 30-45 degrees before BDC of the power stroke on most of the cars I have been checking. The waveform pattern (Figure 7) shows the exhaust valve to be opening close to 30 degrees before BDC of the power stroke. The spark was occurring only once in the cylinder when it should have occurred twice. The ignition only fired the waste spark and fired wrong at about 40 degrees after TDC of the exhaust stroke. This was due to the incorrect coil primary control caused by the crank/cam correlation problem.

Known good

By viewing a known-good pattern of a 1997 Dodge Caravan with a 3.3L (Figure 8) you can see that the exhaust valve opening event is happening at about 30 degrees before BDC of the power stroke. This file was from a running engine, so the advance timing was added to the base timing to bring the timing to about 25 degrees (always use the first rise of the inductive clamp square waveform) before TDC of the compression stroke for ignition spark and 25 degrees before TDC of the exhaust stoke for waste spark. This method is such a great way to learn about combustion strategy and, at the same time, give you another weapon in your arsenal to fine tune your diagnostics as far as which direction you want to head in. Even if this had been a dual cam set-up, you would have had no problem in finding out which cam was off from spec without even pulling a timing cover. Just by having this information validated from doing other known-good vehicles, it was safe for me to instruct the garage to pull the transmission and inspect the flywheel.

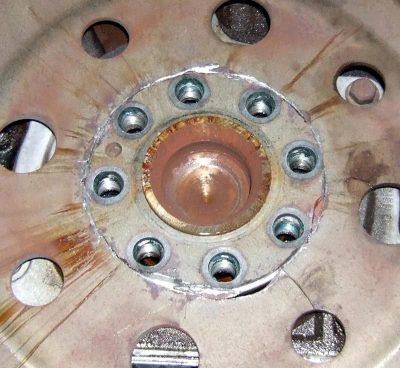

About an hour later the shop called to tell me that the transmission was pulled and I needed to come back to see the damage they found. When I arrived there at the end of my day, I was amazed. The center of the flywheel was completely cut out from the rest of the flywheel like a cookie would be cut out of rolled dough. The center piece spun slightly and wedged itself in place (Figure 9). The amazing thing was that there was no noise associated with this flywheel while cranking. I helped the garage remove the flywheel and placed it on the ground. I pushed on the center piece and it fell out. The only thing holding these pieces together was the center thrust plate and flywheel bolts.

This flywheel was like a wheel of fortune just making the shop spend time and money without a cure in sight, and at the same time sending them on a wild goose chase. It held the torque converter and provided the crank triggers necessary to start the engine. Who would ever think a flywheel could break clean and spin, yet go undetected? I hope this story sheds some light on the value of a scope, which allows you to see beyond the normal reach of a scan tool.

by John Anello

Printable PDFs are available for download at the end of every HTML version of the articles found on mastertechmag.com

Printable PDFs are available for download at the end of every HTML version of the articles found on mastertechmag.com

this is so cool . can I get paper edition

this is so cool . can I get paper edition

And yes! Here it is:

&

And yes! Here it is:

&

Your article finished my diagnosis. My 2000 Dodge caravan 3.3L engine would occasionally cutout for 1/4 sec under acceleration. The heavier the acceleration the more the cutouts. Also had very occasional nasty starter sounds. I was thinking flywheel at the beginning but wanted to make sure before I took it to a tranny shop. I’m a fairly bright EE so I hooked up my scope to look at the cam & crank signals.Looked like they were OK but my problem was occasional.

So I was thinking I’d never be able to see an intermittent on the scope. I then programmed a microprocessor to count and record the cam and crank pulses fully expecting to see some missing ones. The result looked a little funny but the pulses were all there even through the engine cutouts. Well something has to be cutting out. So I looked at the coil driver signals..nothing missing there. Then the fuel injector drive. Yes there’s the cutting out.

But how strange. First a missing pulse and then some strange half voltage during another missing pulse and then back to normal until the next cutout.

I did a google search for ‘2000 Dodge caravan 3.3l fuel injector waveform’ and up came this article. After reading a little it suddenly struck me why the injector pulse looked so strange. The poor PCM is confused. I better look at the cam & crank signals again.

Zoomed in you can see the last of 4 crank pulses on the bottom trace and there’s the first of the 3 cam pulses(top trace) starting at virtually the same time. A broken flywheel!

Now I’m convinced that under acceleration the torque causes a slight shift in the broken flywheel delaying the crank pulses enough to confuse the PCM. So I think I have another example of a broken flywheel that doesn’t sound like it and stays in place except for a little twist. In my case the vehicle runs but has an intermittent problem.

Now I’m willing to get the tranny pulled to fix what I’m 99% sure is a broken flywheel

Your article finished my diagnosis. My 2000 Dodge caravan 3.3L engine would occasionally cutout for 1/4 sec under acceleration. The heavier the acceleration the more the cutouts. Also had very occasional nasty starter sounds. I was thinking flywheel at the beginning but wanted to make sure before I took it to a tranny shop. I’m a fairly bright EE so I hooked up my scope to look at the cam & crank signals.Looked like they were OK but my problem was occasional.

So I was thinking I’d never be able to see an intermittent on the scope. I then programmed a microprocessor to count and record the cam and crank pulses fully expecting to see some missing ones. The result looked a little funny but the pulses were all there even through the engine cutouts. Well something has to be cutting out. So I looked at the coil driver signals..nothing missing there. Then the fuel injector drive. Yes there’s the cutting out.

But how strange. First a missing pulse and then some strange half voltage during another missing pulse and then back to normal until the next cutout.

I did a google search for ‘2000 Dodge caravan 3.3l fuel injector waveform’ and up came this article. After reading a little it suddenly struck me why the injector pulse looked so strange. The poor PCM is confused. I better look at the cam & crank signals again.

Zoomed in you can see the last of 4 crank pulses on the bottom trace and there’s the first of the 3 cam pulses(top trace) starting at virtually the same time. A broken flywheel!

Now I’m convinced that under acceleration the torque causes a slight shift in the broken flywheel delaying the crank pulses enough to confuse the PCM. So I think I have another example of a broken flywheel that doesn’t sound like it and stays in place except for a little twist. In my case the vehicle runs but has an intermittent problem.

Now I’m willing to get the tranny pulled to fix what I’m 99% sure is a broken flywheel