Power seats have been around for decades. In early applications, a simple set of switches provided power and ground to DC electric motors. Today’s memory seating, however, requires some sophisticated electronics.

Who’s In Charge?

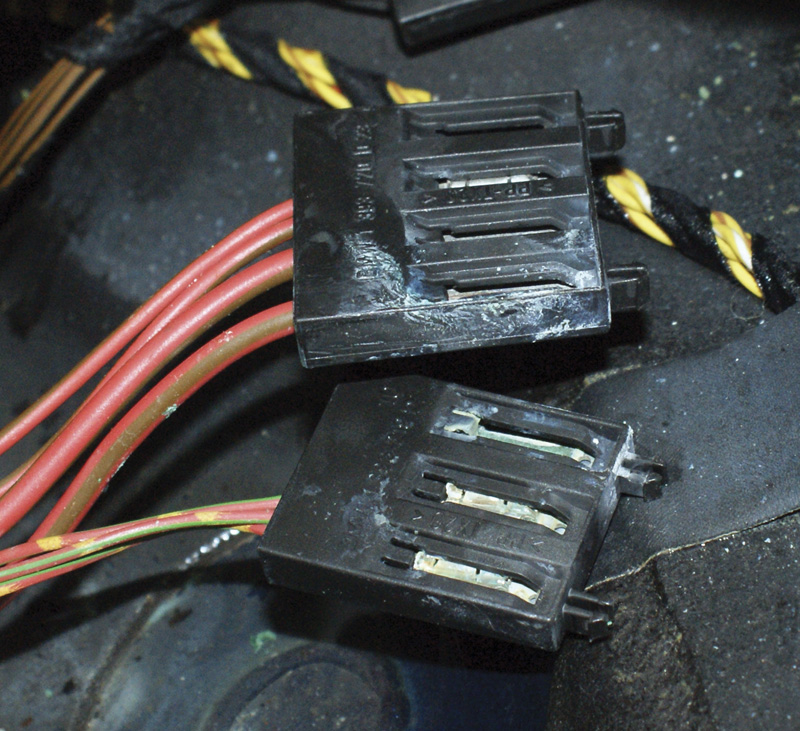

You may have checked fuses, but that does not mean adequate voltage has made it to the control unit and seat motor. On this E38 chassis, the power distribution point for the motors (the R/Br wire) has been immersed in water and corrosion has created a voltage supply problem.

In the early ‘90s, BMWs were equipped with manual or electric power seats. Higher-end models such as the 7 Series had memory seats as an option. This required a control unit to make the necessary logic decisions, and BMW opted for a combination Seat/Steering Column Memory Control Module (SM/LSM) to perform this function on early- to mid-’90s vehicles. However, it is not the only module controlling memory functions.

There is a matrix of modules working in concert to control the movement of the side-view mirrors, steering column and, of course, power seats. The SM/LSM controls the memory functions for the seats and the steering wheel. The power mirror memory functions are stored in their respective door modules.

The memory switch input is wired to the driver’s door module. The modules communicate the memory selection via a P-Bus to the SM/LSM. The door modules and SM/LSM operate the various motors to move them into their set positions. The motors are solid-state controlled. They have a power supply, a ground and a single control wire that carries a square-wave signal from the SM/LSM. This signal positions the motor. You can use a scope or graphing multimeter to monitor the signal.

Evolution Of The Breed

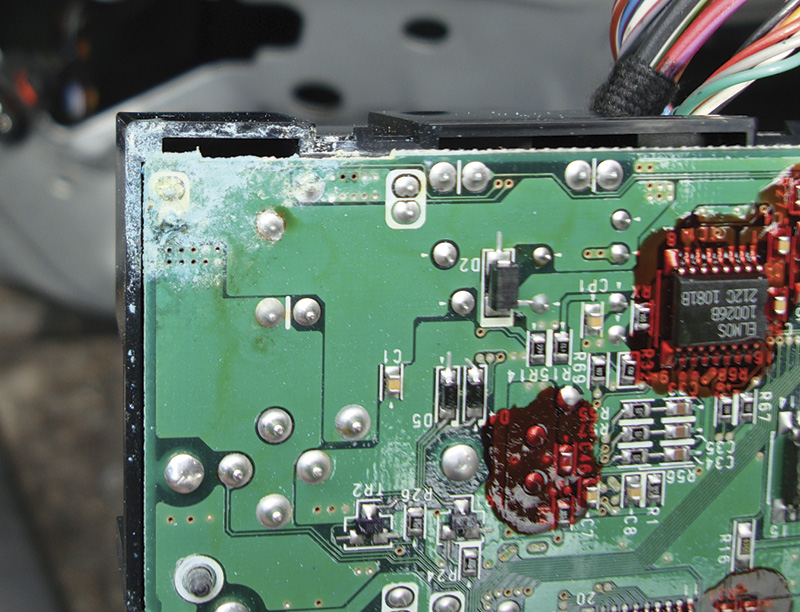

Sometimes the first step in the diagnosis is the most critical. If the power seats are working fine, but power mirrors and other memory functions are not, remember that the switch signals may pass through a door control module. This one shows signs of water damage.

Fast forward to the E46 chassis and you find the more things change the more they stay the same. Control units still control most memory features, but there are now two modules. One is the Driver’s Seat Memory Control Module, and the other is for the passenger side, and they are essentially identical. If replacement is required, you do not have to code for the driver’s or passenger’s side application. Harness pin #13 will inform the Seat Memory Control Module if it is mounted on the driver’s or passenger’s side. On the passenger’s side, pin 13 is grounded; on the driver’s side it’s left open. If the wire in pin 13 on the passenger’s side were broken, the circuit would be open and the K-Bus line would not be able to differentiate between the driver’s and passenger’s seat. As a result, neither seat may operate as designed.

Some BMW Cabriolet models are equipped with the Easy Entry feature. You can determine if a vehicle has this option by looking at the seat back lock handle near the top of the backrest. A switch in the handle commands the driver’s seat module to move the seat rearward and the steering column up to make entry easier.

If this feature is not functioning, check the driver’s seat control module with your scan tool and monitor the lock handle switch input. If this is okay, there are still two other signals required for the feature to work. The vehicle speed input can interrupt the Easy Entry feature. But this is not a likely cause when the engine is not running and the vehicle is not moving.

While you may think the GEM (General Module) has a lot to do with interior electrical functions, it does not control the seats. It does, however, monitor the diagnostic functions for the K-Bus. You should scan the GEM for codes when having problems with power seating systems.

The last input is the driver’s side door switch. If this switch is not indicating the door is open, then the feature will not work. The driver’s door switch input is wired directly to the GEM (General Module). Through the K-Bus, the driver’s door signal is passed on to the driver’s seat module. With an iComm or aftermarket equivalent scan tool, you can monitor the door switch input both in the GEM and the driver’s seat module.

Who is Protecting Whom?

Some car owners keep their vehicles very neat and clean. Others not so much. Throw a child seat in the back and there is a good chance that a toy or something similar can end up on the floor behind the driver’s or passenger’s seats. If this object limits seat movement, you can easily damage something in the power seat system.

BMW seat modules monitor amp draw and either motor ripple counts, or a Hall-effect sensor, to determine the seat’s position. The forward and rearward (or up and down) stops are recorded. If the applied motor were to jam, the amp draw of the motor would increase. The seat module will remember this event as an end stop. Even after the object is removed the end stop will remain. To reset an end stop, you simply continue to operate the button in that direction. The motor will continue moving in that direction in short increments until you have reached the actual end stop. At this point, the retrieved end stop is stored and normal function should resume. If not, you may have a bad seat motor.

In other cases the motor may be fine, but the position sensor (ripple counter) may not be functioning. On early 2000 models, you do not have direct access to the position signal. It is transferred through serial data communication between the seat motor (w/solid state module) and the seat control unit. A scan tool with factory capabilities is necessary to monitor this data directly.

Testing, Testing, Testing . . .

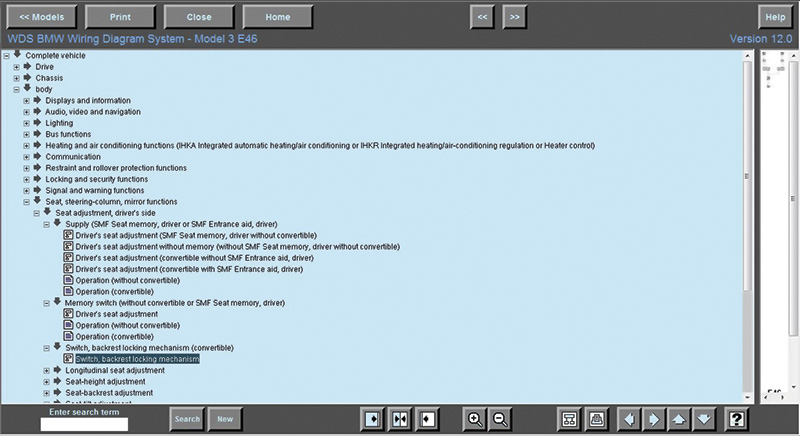

While selecting the proper wiring diagram for a particular vehicle you will see in the navigation function that there may be many variants for a given system. Aftermarket information systems may not show all of these variations. A paid subscription to www.bmwtechinfo.com will give you all the information you need.

While an iComm or aftermarket equivalent scan tool is helpful in diagnosing complex bus communication problems, simpler problems can be handled with a DMM (Digital Multi-Meter). We have noticed that the fuses are either the first or the last things checked when diagnosing a problem. Aside from the simple blown fuse or data communication line problem, you can still check power feeds, grounds, and switch inputs without special tools.

Memory seats use control units to carry out the necessary functions. Every computer system needs inputs and outputs. Although we know that there are inputs coming in from the K-Bus network, there are still other signals from the various switches and output controls sent directly to the motors. The key to efficient troubleshooting is knowing what to look for.

An accurate wiring diagram is essential to a repair. Aftermarket information systems are often incomplete, and may not account for the variants of a system. There are two-door models, four-door models, wagons, and convertibles. In addition, there are standard features, and other advanced integrated features that are optional. This means that there is a possibility that a given vehicle may have eight or more different wiring diagrams, with the possibility of additional changes being made during a production run. With a paid subscription to www.bmwtechinfo.com you will have access to accurate wiring diagrams that cover all the variations involved in the system. Obviously, memory seats require inputs to an on-board computer. This means you are not just dealing with 12-volt switches providing power to a motor anymore. You may have a five-volt reference that, when pulled to ground, tells the control unit to energize the motor, and there has to be a switched input for each possible direction the motor can move in.

Switches and resistors can be engineered using something called “resistive multiplexing.†In this configuration a reference voltage comes from one wire. Wires can pass through two separate resistors depending on which way the circuit is designed. One resistor drops the reference to one specific voltage, while the other resistor drops the voltage to another specific voltage on the same wire. Each individual voltage tells the control unit to perform a different function. This way one wire can carry two different signals. This cuts the amount of wiring in a system in half, reducing both weight and complexity. Check your switch inputs with a DMM. On the same wire you will see two different voltages depending on the switch position.

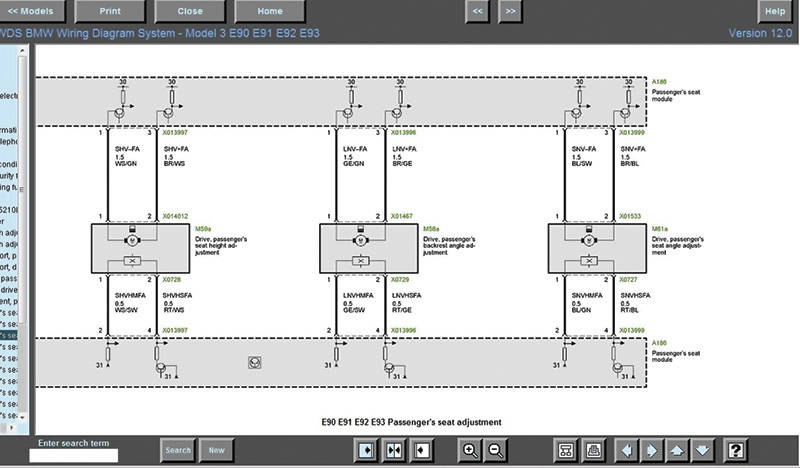

This wiring diagram shows that on the late-model 3 Series there is a control unit that manages the seat motors. The wiring is fairly straightforward. There are power supplies and a grounds you can test. There are also two wires to test for the position signal voltage.

When it comes to power seat motor outputs, diagnosis is pretty simple. One wire carries the supply voltage and the other carries the ground. A control unit can easily alternate between 12 volts and ground on a single wire. That means it only takes two wires to control a motor. By connecting your DMM between these two wires you will see either +12V or -12V depending on the polarity of the motor. In BMWs, a small control unit mounted inside the motor assembly provides the necessary power and ground according to needs. This control unit is supplied with a 12-volt power feed and a ground so it has everything it needs to work with. You can easily check this power supply and ground circuit with a DMM.

What is less clear is how to determine the signal from the memory seat control module to the control unit on the motor. Although it’s not as definitive as scan tool data, you may be able to analyze the signal wire with an oscilloscope or a graphing multimeter. You should see square-wave patterns. As a command is sent, you should look carefully to see if the patterns change. Any change at least shows that a command is being sent. Clearly, this is not an ideal situation, but when scan data is not available this is all we have to work with. With the BMW website and a passthrough tool for programming, BMW makes iComm diagnosis programming and software available to you on your laptop. This is an excellent way to get access to factory scan data at a reasonable price.

Finally

BMW offers many different features on its vehicles that necessarily bring with them a certain level of complexity. When troubleshooting, you’ll need to sift through that complexity, interpret the wiring diagrams and implement a logical diagnostic plan. This will help increase the speed and cost-effectiveness of repairs and provide excellent customer satisfaction. •

0 Comments