In the first year of the new millennium, BMW introduced a new air suspension on its X-Series vehicles. This compensates for load by controlling the ride height of either the rear axle, or all four wheels in later versions. But what do we do when they stop working?

We generally don’t take any notice of things we use every day as long as they’re working fine. We just take them for granted. The moment something goes wrong, however, we are often at a loss as to what happened. This is especially true of our cars. We rely on them, we depend on them. When something goes wrong we need to get it diagnosed and repaired as fast as possible.

There is no doubt vehicles are getting more complicated. Some of the add-ons may appear frivolous, but some of the technology significantly adds to the safety of a vehicle. This is particularly true of the suspension system. BMWs are typically known for their sporty, precision handling – it’s a big part of their reputation. It improves safety by providing the driver with excellent cornering control. After all, the most important safety feature of any car is its ability to avoid a collision in the first place.

What’s the Purpose?

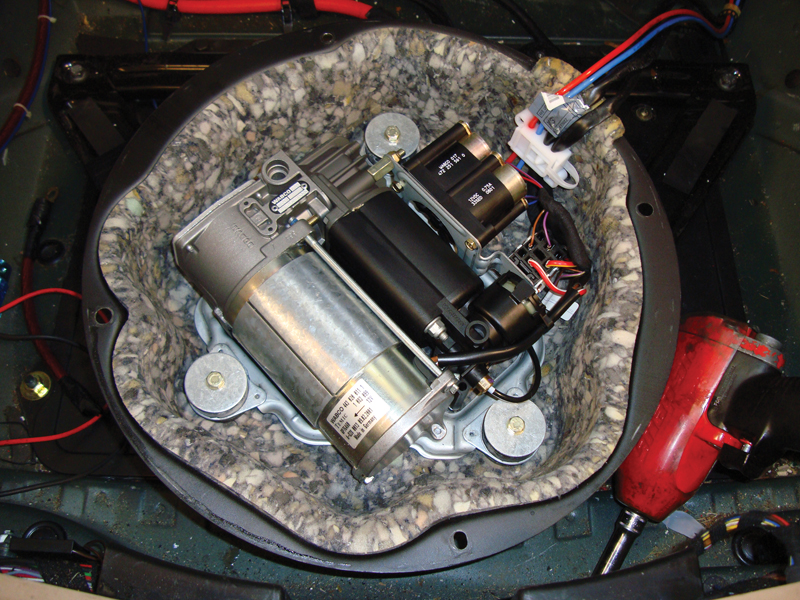

The air compressor assembly is mounted underneath the spare tire. This is the EHC I system, so what you are seeing here is the compressor, compressor relay, and the two air spring solenoids. You can electrically test everything from here. EHC II is a little more involved.

The BMW X5 represents a new breed compared to the standard-issue SUV. It was dubbed both an AAV (All Activity Vehicle) and SAV (Sport Activity Vehicle), and it provides a level of handling that’s superior to that of most of its competitors. One of the factors in that is its finely tuned sporting suspension system with electrical compensation (very similar to that of the E39 wagon). The X5 uses a multi-link rear suspension system that carefully controls the caster, camber, and toe of the rear tires to provide optimal handling as the vehicle is subjected to a variety of situations ranging from hard cornering to light off-road excursions.

It also has a larger load carrying capacity than its sedan counterpart. This means the additional load may change the ride height, throwing off the carefully-designed suspension geometry of the rear axle. Not only will this change the handling characteristics of the vehicle, but if driven long enough will cause uneven tire wear patterns requiring more frequent rotations and replacement. So, a system that can maintain the same ride height regardless of the weight in the vehicle will preserve handling and tire life.

Starting in 2000, the X5 got EHC (Electronic Height Control). This system uses pneumatics to maintain the ride height of the rear axle to compensate for weight carried in the luggage compartment (this is why a nearly identical system is found in the E39 wagon). As stated earlier, this keeps the suspension at the correct geometry to provide similar handling characteristics compared to when the vehicle is carrying no extra weight. In 2002, this evolved into EHC II, which controls the ride height of both front and rear axles. This also gives the driver manual control of the suspension – he or she can raise the ride height to give more ground clearance over rugged terrain. EHC II is also a pneumatic system.

The Players

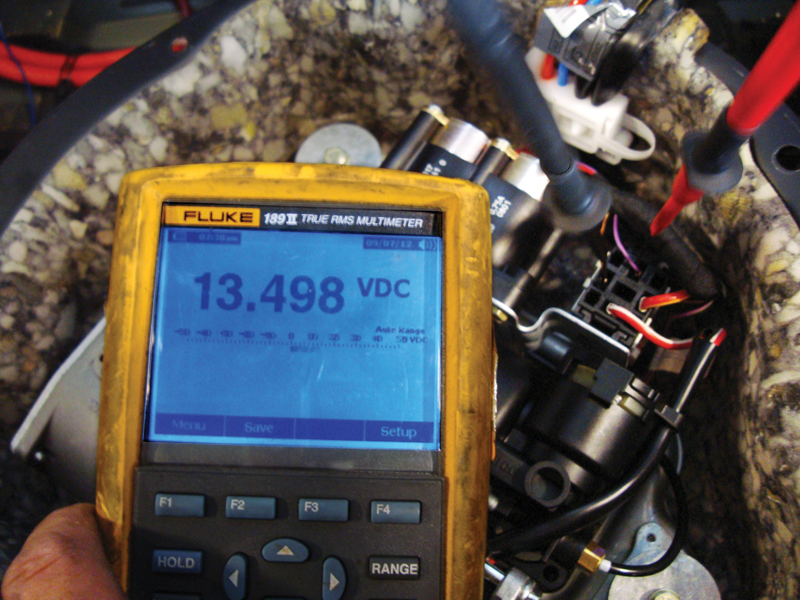

Here, we are activating the air compressor with an iComm/ISTA, and we can observe relay activation by reading battery voltage between the coil terminals of the relay. At this point, you should hear the compressor come on. In this case, there was a blown fuse. We replaced it and the compressor started running.

EHC uses an air pump mounted under the spare tire in the rear luggage compartment above the battery. It rests on a bracket in the spare tire well and is one of the components you have to remove to change the battery. It can supply up to approximately 250 psi to raise the vehicle. Built into the air compressor assembly are two solenoids that allow the high-pressure air to fill or bleed off each air strut independently. Of course, this means there are two air lines that supply two independent air springs that have two air reservoirs. To control each corner of the vehicle independently, there are two height sensors attached between the lower control arms and the chassis. They are Hall-effect type sensors with a 5V reference, a signal wire, and ground connected to the EHC control unit, which is typically mounted to the right of the air compressor in the spare tire well.

The EHC II system is significantly different. While it has the air compressor in the same spot under the spare tire and above the battery, the two solenoids now perform different functions, and there is an additional drain valve that limits the pressure to just over 300 psi. The air spring bellows do not have independent air reservoirs any longer. Instead, the compressor supplies a pressure accumulator/valve unit, which is mounted under the car between the passenger side frame rail and the inner rocker panel. This acts as the one main reservoir for all four air suspension springs. It also has the valve assembly attached to it that individually controls the pressure to each air spring using four solenoids and one air pressure control solenoid that maintains the pressure in the reservoir. There is also a sensor that sends the reservoir pressure reading to the EHC II control unit. There are four height sensors, one for each corner of the vehicle.

The Game

Here, we are measuring the amperage draw of the compressor. At this point the relay is closed, and our inductive amp clamp is measuring approximately 20 amps while the compressor is running. The compressor on this car would eventually go to 30 amps, a sure sign of a pump that’s on the way out.

Whether it is the EHC I or EHC II, the control unit performs the same function. It monitors the signal voltage from the height sensors when the door handle is pulled. Then, it activates the compressor and opens the individual bellows solenoids until the programmed ride height is achieved. Using an iComm/ISTA/P, you can adjust the ride height offset for each corner of the car. This is done by entering the measurement between the center of the wheel hub to the top arch of the wheel well in the service function menu. Once the programmed height is reached, the system will only make adjustments when the lift-gate is opened, or the ride height changes. A good thing about EHC is if you have to jack the vehicle up to change a tire, the system will shut off when it sees the maximum height from the sensor.

You should not need to reset anything unless there is a diagnostic trouble code for the EHC system. When there is a code present, the system shuts off preventing any changes to ride height. The EHC will also not make changes to ride height while the vehicle is driven through corners. The steering angle sensor is transmitted through the CAN so the EHC unit knows the height sensor values will change as a result of body roll. If there is a fault in the system, a CAN message is sent to the instrument cluster and the air suspension light is illuminated. You can read the height sensor and air pressure sensor values with you iComm/ISTA pass-through tool. You can also activate components such as the air compressor or individual air spring solenoids. You can perform tests to raise the front axle, rear axle, and individual air springs.

Now What?

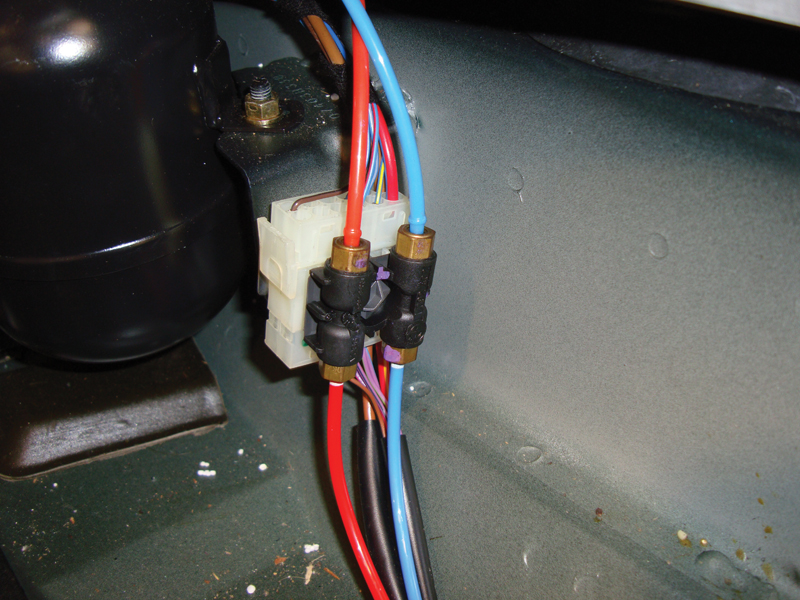

These are the air lines in the spare tire well. If the car is dropping overnight, spray a soapy water solution on the fittings and at the air bellows and watch for bubbles. A leak in the system will cause the compressor to come on every time the car is started, which will shorten compressor life.

If the fault ends up being in the control unit and you have to replace it, remember that the new unit will be in a “factory†mode and it must be ZCS coded to the car with the iComm. If you install new height sensors, you should recalibrate the ride height to the new sensor(s) in the service function menu mentioned earlier. If the fault is in the hardware of the system, you can use iComm/ISTA to activate components while testing them electrically. For example, the compressor receives power from the fuse box on the passenger side of the rear compartment. This power is supplied to the compressor relay, which is in the compressor assembly. The EHC control unit grounds the relay to activate the compressor. A normally functioning compressor should draw around 20 amps or less. When failure is imminent, they can draw over 30 amps and blow the fuse.

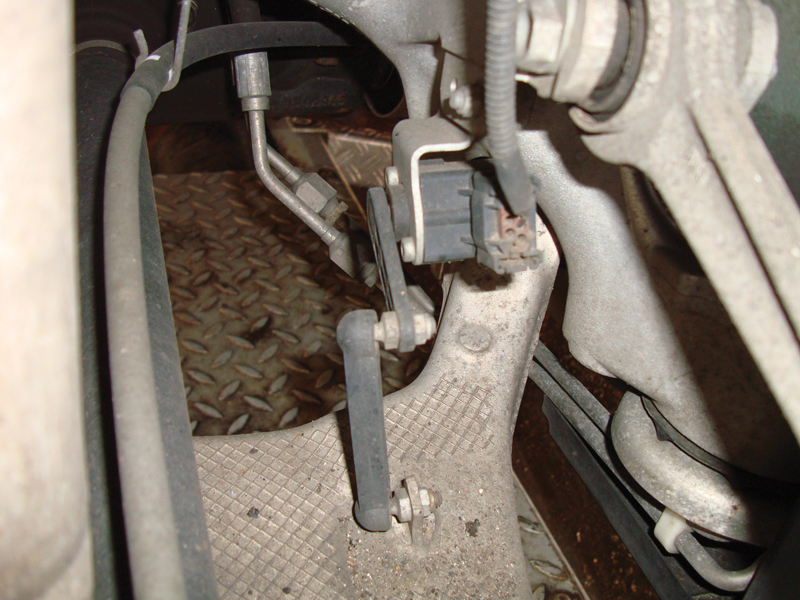

Mounted between the lower control arm and the sub-frame, the Hall-effect height sensors send their signals to the EHC control unit. This is the rear ride height of an EHC I system. If you have a problem with one corner of the car, check to see if the linkage has been damaged by road debris.

As with any pneumatic system, air leaks can develop at the lines and fittings. You can spray a soapy water solution on the parts and watch for bubbles, just as you would to find a tire leak. If the problem is with a sensor, you will need to check them electrically as well as with the scan tool. The height sensors and the air pressure sensor are of the three-wire type. The height sensors are Hall-effect, and they typically generate a signal voltage between .5V and 4.5V depending on the ride height. The air pressure sensor uses a 5V reference, signal, wire and a ground. Under normal atmospheric pressure on the sensor, you should find about .5V at the signal wire. As the pressure in the system goes up, the signal voltage will increase toward 4.5V. You can open the drain solenoid to release all the pressure, then read the pressure sensor signal voltage. Then, you can fill the system and watch the signals from both the air pressure sensor and ride height sensors change in value.

Knowing how the air suspension system functions is half the battle. Now you should be able to put together an accurate and cost-effective diagnosis that will save your customer money and still keep your shop profitable. With your local BMW dealer’s parts department as your partner — providing you with information and genuine BMW parts — you really can’t go wrong.

0 Comments