OBD II has spoiled us. When we were kids, we had to find misfires BY OURSELVES! Now drivers have a blinking Malfunction Indicator Lamp and diagnostic trouble codes telling us which cylinder is in trouble. You would think that would make our job easier, but we still need to find the cause.

Ignition might be the first thing you think of as the cause of a misfire, but it’s sure not the only thing.

We all have those customers: People who come in for the smallest detail. They very often play 20 questions with you and it seems like they never lost a game in their lives. We understand. They’re giving us their-hard earned money, after all, and they want to make sure the car is going to be fixed right. You probably also have those customers who never come in until the car is on its last legs. Those are easy to diagnose because whatever is broken is so severe a simple inspection will often reveal the problem.

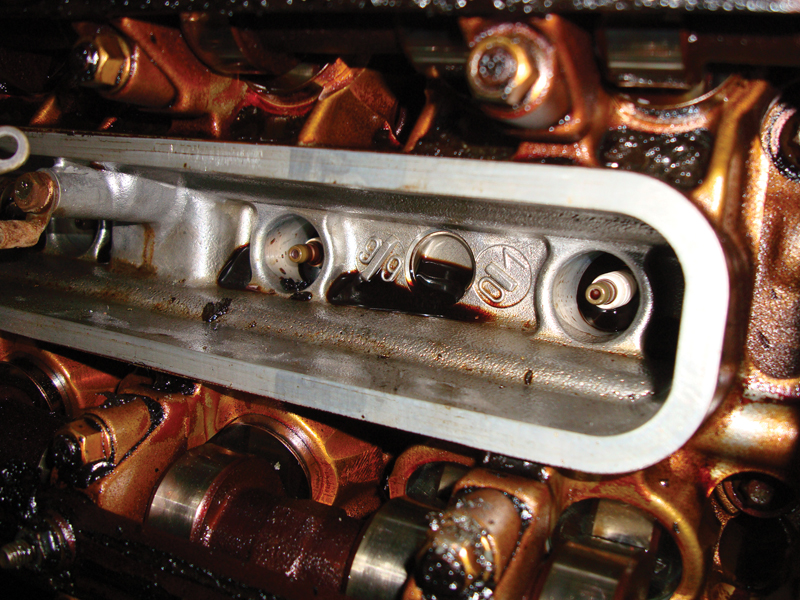

While oil itself will probably not cause the misfire, it does eventually soften the coils’ spark plug boots. This can allow the spark to arc down the spark plug hole and be lost.

The toughest troubles are the ones that are intermittent. Every so often such-and-such happens, but when you have the car it runs fine. Misfires come to mind. Sometimes the problem is glaring — a “dead†miss that never goes away. Those are usually simple to diagnose.

The other kind is a little harder. Sometimes the car misfires, and sometimes it doesn’t. We can perform the necessary diagnostic tests, but everything may look good at the moment. It helps if we can see and feel the problem. Now one of the problems is misfires itself. The cylinder is misfiring. A misfire is a cylinder that is not contributing as much power as the others. Each cylinder that fires exerts a force on the crankshaft causing it to twist. A misfiring cylinder will not exert as much force as the other cylinders and therefore the crankshaft slows down. A misfire is a misfire, we don’t know what the cause is and OBD-II may tell us which cylinder(s) it is but not why. It is our job to find the cause of the misfires. There are many possible causes of a misfire. We are going to have to perform tests on the engine to isolate the cause.

Testing? What Testing?

From an emissions standpoint, a misfire is about the most dangerous malfunction that can occur in a vehicle. Not only does it pump raw hydrocarbons out of the dead cylinder, but this extra fuel can cause the reaction inside the catalyst to become so hot that it loses its ability to do its job.

So, OBD II regulations state that the instant the management software detects a misfire, it doesn’t just switch the MIL on, it flashes it once per second. The flashing stops only when the vehicle is being operated outside of the load and speed modes that could damage the cat. Even then, the MIL stays on steadily.

The engineers working on OBD II found that misfiring eight to ten percent of the time will damage the cat, so they labeled that percentage a Type “A” misfire. Then, they designed the system to keep track of misfires over a 200-revolution time frame — a buffer keeps the average. If the software sees no crankshaft acceleration where there should be some, it registers a misfire immediately.

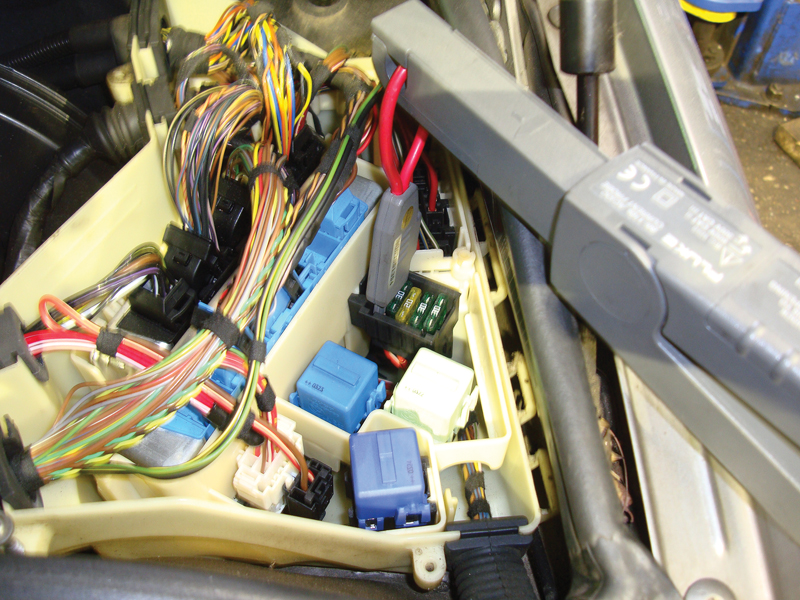

By looking at a wiring diagram on www.bmwtechinfo.com, you can see that the coil power is fuse Number One in the fuse holder of the electronics box. Here, we’ve put a loop around it and are using our low-current probe to scope the amperage draw of the injectors.

A Type “B” misfire isn’t quite so dangerous, but is bad enough to cause emissions to exceed one and a half times the standard. This is monitored over 1,000 revolutions by a different set of buffers. It doesn’t light the MIL the first time, but only on the second drive cycle. Typically, this is a one- to two- percent misfire. You will feel the Type “A” catalyst-damaging misfire in the seat of your pants when you drive the car, but the less severe Type “B” misfires you will probably not feel.

In order to diagnose a misfire, you should perform tests to verify that the systems involved in complete internal combustion are working correctly: ignition, fuel injection, and the mechanical engine (the old “FFC” — fire, fuel, and compression).

Since most modern BMWs have a coil-over-plug (COP) ignition, one of the first things you should test are the ignition coils. You are going to have to remove them to check or replace the spark plugs anyway. While you have the coil off, you may want to check it by inserting a spark tester. The ST 125 is probably the best tool to quickly verify that the spark is strong enough to ignite a mixture under load. It stress-tests the ignition coil to 28,000kV, more than enough to produce an arc and ignite the mixture. It is certainly much better than sticking a screw driver into a coil tower and holding it close to ground while someone else cranks the car. This is the quickest way to test if the ignition system is strong enough, but not the most complete.

The Devil Is In the Details

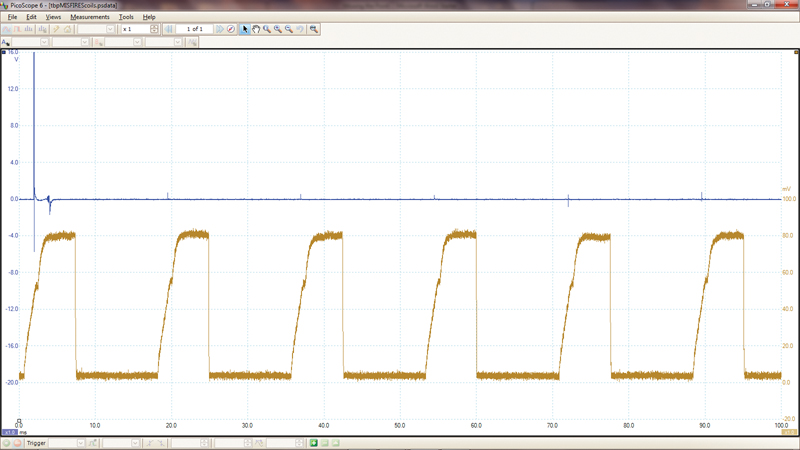

By looking at the scope pattern you can see the Number One coil trigger pattern as the upper trace. The lower trace is the amperage draw of each coil in the firing order. Since the firing order is 1-5-3-6-2-4, read the six patterns from left to right to identify the cylinders.

If you only pulled a P0300, you’re going to have to identify the cylinder yourself. You can use your iCommISTA scan tool and monitor misfire data, but it will only tell you which cylinder is misfiring, not why. If the DME has identified a cylinder you can simply switch coil positions and see if the DTC moves to another cylinder. If you have the BMW iComm/ISTA package you can use “rough running†data. This is a calculated value that gives you a percentage of power that deviates from what is expected. The higher the number means that cylinder is not contributing as much to the crankshaft speed as the others. Once again, this identifies the cylinder, but not the cause. Specific testing is going to help you finger the culprit.

We already mentioned using the ST125 to stress-test the coil. If you have the equipment, you can use an inductive probe, rest it on the coil and monitor the scope pattern. You can scope a cylinder that is running normally and compare the patterns. Once again, when interpreting a scope pattern what you are looking at is the result of combustion and possibly not the cause of the misfire. A weak coil can cause a misfire, but swapping the coil position should have told you that. A more accurate way to test your ignition coil is to monitor the current draw. With a paid subscription to www.bmwtechinfo.com you can view a vehicle-specific wiring diagram. Find the power source for the ignition coils and put your low-current amp probe around that wire. Have another channel of your scope monitor the ignition trigger of the number-one coil. Set up the time division of the scope to display each cylinder.

Using Our Heads

The injectors also receive a power supply feed from the fuse holder in the electronics box. By using a loop in place of the fuse, you can install are low current probe and measure the amperage draw of each cylinder.

This means if you have a six-cylinder engine to make sure you have a least six coil amp draw patterns after your ignition coil trigger pattern. The first ignition coil trigger pattern will also show the amperage draw for the number-one cylinder. The next five following amp draw patterns are the other cylinders in the firing order. Let’s take the BMW 335i with the M54 engine as an example. If the fourth amperage draw pattern on the screen is lower than the others, this would indicate a problem coil. The firing order of the M44 engine is 1-5-3-6-2-4. This tells you it’s the sixth cylinder that is misfiring because of a weak ignition coil. If the amperage draw patterns are all the same, then the coil is probably not the cause of the misfire. You may want to look at the secondary pattern for that cylinder as this might provide a clue as to what the cause of the misfire is.

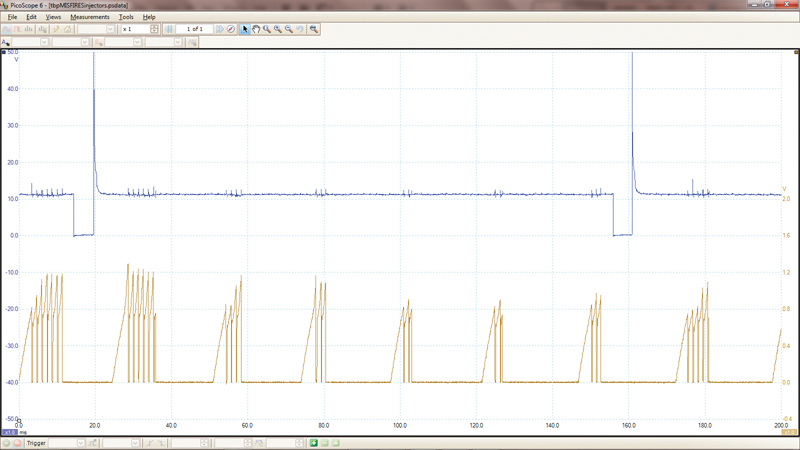

You can perform the same test on the injectors. Find the power supply and sync it off the number-one injector. You can put a loop in place of a fuse or a relay and wrap your low current inductive amp clamp around the loop. Remember, you will be measuring the amp draw of every component powered up by that fuse or relay. If you see one bad amperage draw pattern on the injector of the cylinder that is misfiring, then it’s safe to say the injector and resulting fuel flow is the cause of the misfire. Keep in mind that if the misfire is severe enough to set a code, the DME can shut off the injector to reduce harmful emissions. You should clear the code before attempting your diagnosis and the DME will return to grounding the injector. By the way, the logic of the DME control unit can identify and set a code for misfires that are the result of a low fuel level. This causes the fuel pump to draw air as the fuel sloshes around in the tank.

Often Overlooked

Here you can see the six amperage draw patterns on the lower trace, and we are syncing the pattern off of the upper trace that is the Number One injector. Use the same firing order to determine which cylinder has the problem. You can also use your iComm/ISTA to verify the troublesome cylinder.

If you have a five-gas analyzer, you can perform a fuel contribution test. This involves taking an undiluted exhaust gas sample (tapping into the exhaust pipe before the catalytic converter) and unplugging each ignition coil one at a time. Your analyzer should see the HC rise as you unplug a coil. They should all rise about the same if they all flow the same amount of fuel. If one injector is clogged the HC will not rise as much as a result of the low fuel flow (it’s sort of like the old-fashioned method of removing spark plug wires and seeing which one has the least effect on idle rpm). That is your problem injector. Even though the DME can shut down an injector from a severe misfire, the cylinder can get washed down with raw fuel and lower compression. While you have a spark plug out, take the time to perform a dry and wet compression test just to verify that the cylinder is good. Some of us have been embarrassed performing all these high-tech tests only to find that the bad cylinder had a burnt valve that a five-minute compression test revealed.

If all of your testing shows no clean conclusions, you are going to have to rely more heavily on scan tool data. Since misfires can be caused by many things and we have verified ignition and injector pulse, we need to quickly determine if the problem is in the fuel mixture or engine mechanical systems. Great tools to use are the Additive and Multiplicative fuel readings in the data of your iComm/ISTA scan tool. The DME of the car you are working on looks at the engine temperature, throttle position, engine load (MAF) and determines the correct fuel injector pulse. If the resulting oxygen sensor readings do not match up, the computer adds or subtracts fuel injector pulse to correct the mixture. The greater the correction the greater the Additive and Multiplicative readings become. Additive is fuel correction at and just above idle speeds, and Multiplicative is fuel correction at part-throttle openings. In more extreme cases, the fuel mixture being off may lead to misfires and this condition should be repaired before any other repairs are attempted.

Having a plan when approaching a diagnostic problem on our customers’ vehicles keeps us focused on a cost-effective repair. This makes us profitable and our customers relieved to know their problems are being taken care of. You BMW parts department can provide you with OEM quality parts and www.bmwtechinfo.com gives you the necessary information about specific vehicles. You and BMW are a team that will help both you and your customers. Who wouldn’t want a teammate like that?

0 Comments