Refer to the rotors

If brake pad lining remaining above the wear sensor is minimal, it’s time for new pads. Never try to re-use wear sensors. They’ll be brittle from thousands of heat cycles and will almost certainly break if you try to remove them.

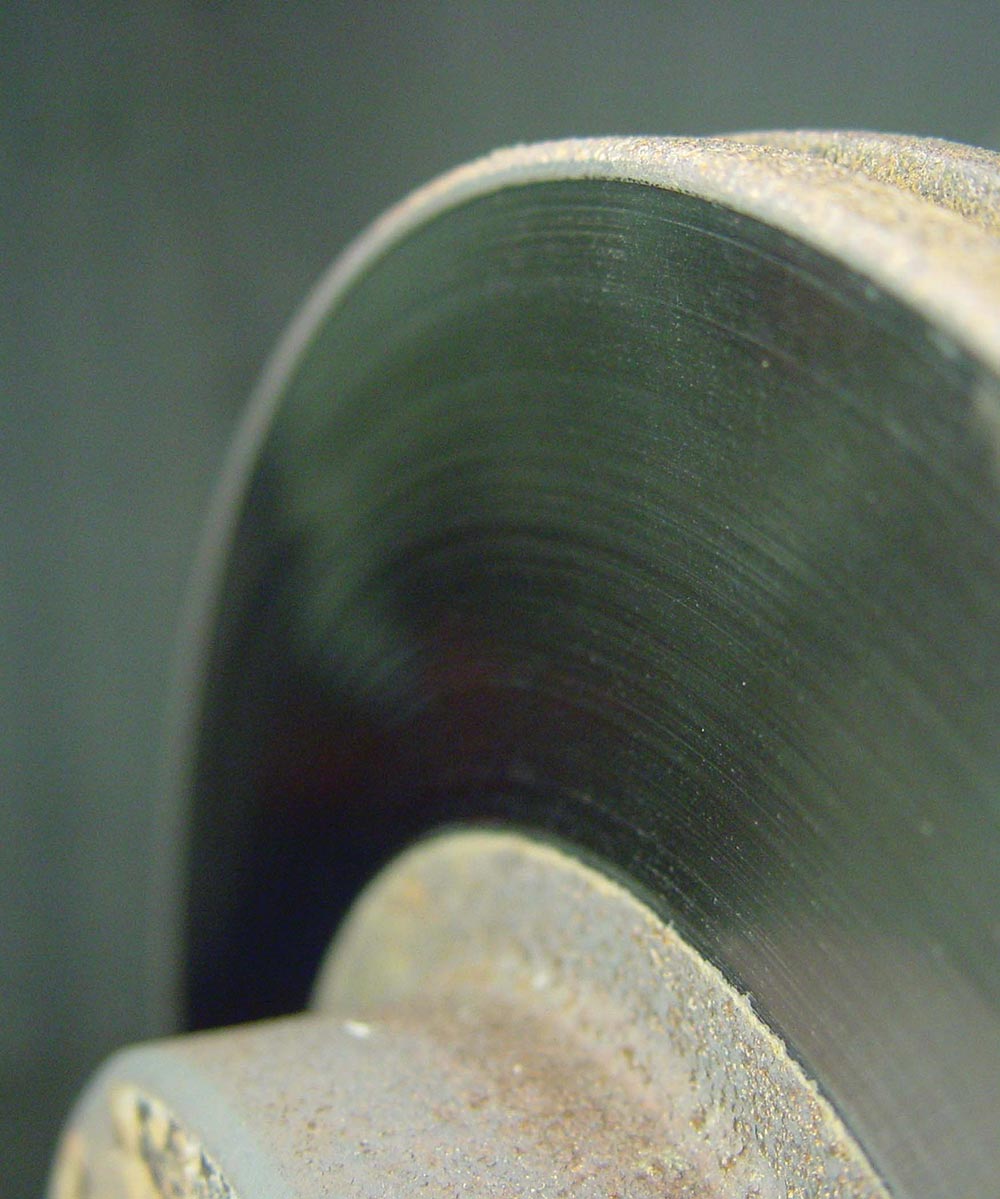

Evaluating the condition of the discs requires more accuracy and judgment than any other part of brake service. Some clues are visual, some are measurable, and some are even invisible.

For visible flaws, look for scoring, grooves, discoloration, or cracks. That’s the easy part.

The measurable part, however, requires the use of a suitable micrometer and dial indicator, both in good calibration, and skill on your part if you are to achieve safe and satisfying braking. Your first check should be for minimum thickness, since this is the characteristic most likely to call for replacement. A dedicated disc brake rotor micrometer, whether mechanical or digital, will tell if a rotor is at, or near, its minimum safe thickness, a figure that, by law, is cast into the hub of every disc. Remember, the rotor thickness will still have to exceed its minimum even if you choose to machine it on a lathe to cut to a smooth surface past grooves from scoring. In most cases, BMW only allows 0.064 in. (1.6 mm) of material loss before the discard thickness is reached, which amounts to additional justification for advocating the sale of new rotors to your customers.

This brings up the subject of “rotor forecasting.†That is, extrapolating from the amount of metal lost during the wearing out of the last set of linings to what the thickness will likely end up being by the time the new pads you are installing reach the end of their life. Typically, this reduction will be on the order of 0.032 to 0.040 in. (or 0.8 to 1.0 mm) per cycle. If the rotor has more than that left, and no machining is necessary, you can reuse the discs and just install fresh pads. On the other hand, if that subtraction puts you below the discard spec, you’re leaving yourself open to both complaints and liability. It’s easy math to explain to your customers, and if you handle it right you should sell a lot more new rotors.

You should use your micrometer for measuring disc thickness variation (DTV), too — where some areas of the rotor are thicker than others. Any appreciable DTV will cause the pads to move in and out as they try to stay in contact with both rotor surfaces, causing pulsation in the brake pedal. They can also, at higher vehicle speeds, cause the disc brake pads to skip over low spots. This not only reduces brake effectiveness; it also causes the pads to contact only certain areas of the rotor, making them much hotter than surrounding areas, and therefore more subject to warping or becoming “hard spots,†which can produce different friction characteristics in various spots on the surfaces. BMW recommends a maximum of 0.0002 in. variation in rotor thickness.

This is typical wear and scoring on a well-used BMW disc brake rotor. While it may not appear severe, it might just put the rotor beyond allowable specs.

Finally, you’ll need a dial indicator to measure disc runout. While this “wobble†itself may not be the actual cause of pedal pulsation, it leads to that by promoting the uneven wear that results in DTV. Simply put, runout may be present even if the rotor is thick enough, and even if thickness variation is within specs. Runout can be a result of heat-induced warpage, but it can also come from rotor mounting errors (get those hub mounting surfaces clean!) and tolerance build-up in the spindle, hub and bearing assembly. BMW recommends a maximum of 0.001 in. of runout.

To turn or not to turn?

In years past, machining rotors has been a common practice, as long as the finished piece still had a thickness that exceeded the minimum figure stamped into it. And recently we’ve seen on-car lathes being promoted as providing more precise machining than bench lathes. Each type has benefits and drawbacks. Bench lathes can produce an adequate friction surface, but may not run true on the vehicle due to tolerance build-up. On-car lathes yield surfaces that run true on the car, but these lathes are costly and setup can be slow, involving time-consuming set-up and calibration for runout.

Rare is the BMW dealership that machines rotors today. Instead, nearly all will recommend and install new rotors in order to assure the most consistent and effective braking.

In the final analysis, turning rotors is time-consuming, and necessarily leaves the disc that much closer to its discard thickness, which can compromise its ability to withstand warping. Since new rotors are affordable, most technicians today opt to simply install new discs rather than machine the old ones. It’s certainly best to replace rotors in pairs to assure even, balanced braking.

Since technicians report frequent problems with cheap aftermarket rotors produced off-shore, it’s safest to source new rotors from your local BMW parts department. Note, too, that BMW specifies that disc brake rotors on M-series cars, or any others that are cross-drilled, should never be machined.

Think of it this way: When you subtract the labor of turning rotors in a workmanlike manner on a well-maintained lathe, then cleaning them thoroughly (the avoidance of which is a common cause of squeak and squeal), the cost difference between that alternative and installing new isn’t so great after all, and with the latter choice you can be more confident in the results.

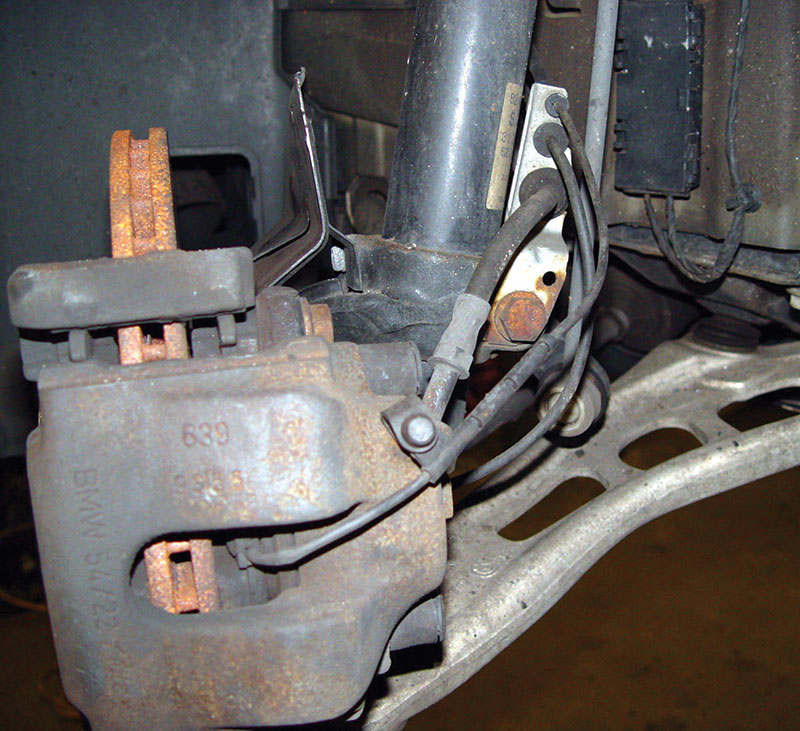

Caliper concerns

It’s best to use a dedicated rotor micrometer for measuring disc thickness, since this tool will have pointed tips to extend down into wear grooves. Conventional micrometers with flat tips will not provide an accurate representation of the condition of the rotor.

Brake calipers are generally not replaced as part of a routine brake job, but that doesn’t mean they shouldn’t be carefully inspected to find out if that step is necessary. But what, exactly, does “necessary†really mean? In truth, there are really just two reasons to condemn a brake caliper — leaking seals, or sticking/stuck pistons. Happily, both conditions are easy for a technician to determine — but only if he looks.

Liquid brake fluid in the vicinity of the caliper’s dust boot, or a dust boot swollen because it’s filled with fluid are the give-aways of leakage. On multi-piston units, uneven pad wear is a sure sign of a stuck piston, while on the single-piston type, such pad wear is evidence that something is interfering with the necessary side-to-side transfer of force, such as a burr or corrosion on the pins or sliding surfaces of the caliper halves — the piston may be causing one pad to wear without pulling the other pad against the rotor.

This uneven wear can manifest itself in one of several ways. You might notice that pads on one side of the car are worn much more than those on the other side of the vehicle. That’s a sure sign of a stuck piston or a restricted hydraulic line or hose on the side with little or no wear. One or both pads at the same wheel that are worn at an angle signifies a problem with caliper bushings or mountings. So you have to be discriminating in your diagnosis.

Few service technicians rebuild calipers anymore; it’s just too time-consuming to be profitable or practical. While some may choose to install remanufactured aftermarket calipers, their quality and durability are reported to be spotty, and a comeback on a brake job will be a profit-killer for sure. So it’s best to purchase new genuine BMW calipers and replace them in pairs, since the failure of one caliper suggests that its mate is not far behind. Replacing calipers in pairs will also assure even braking on both sides of the vehicle.

All genuine BMW rotors have minimum thickness specs cast into them. Part of the technician’s responsibility is to project whether the remaining thickness of the rotor will last as long as the expected life of the pads.

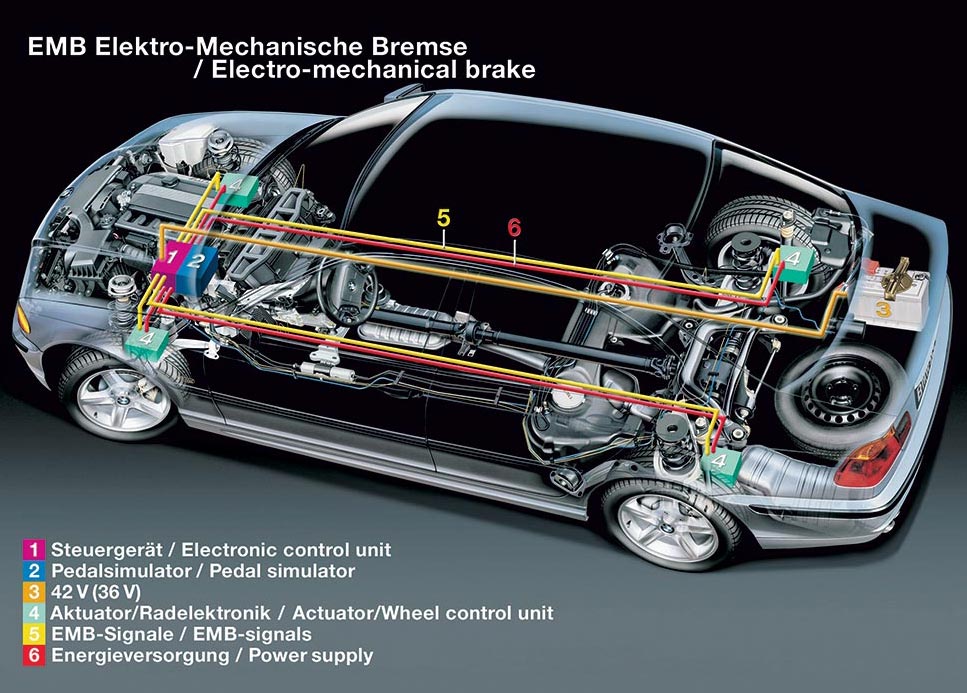

Note, too, that new-generation BMWs are fitted with electric parking brake mechanisms. When performing rear brake service on these vehicles,, you’ll need to retract the brake pads with the use of a laptop computer or electronic reset tool. BMW service literature calls for disconnecting the vehicle’s battery and using an auxiliary power supply during this procedure.

Small parts, big value

Pads, rotors, and calipers are certainly the Big Three when it comes to service, but they don’t represent all that goes into a proper and professional brake service. It’s important to check flexible brake hoses for cracking or signs of abrasion that can compromise their integrity, leading to a huge safety risk. Ditto for the steel brake lines, which must be inspected for dangerous corrosion during every brake service, especially in areas where road salt or splashing salt water is to be expected. Remember, too, that irregular pad wear can be an indication that a brake hose has failed internally, preventing proper flow of brake fluid.

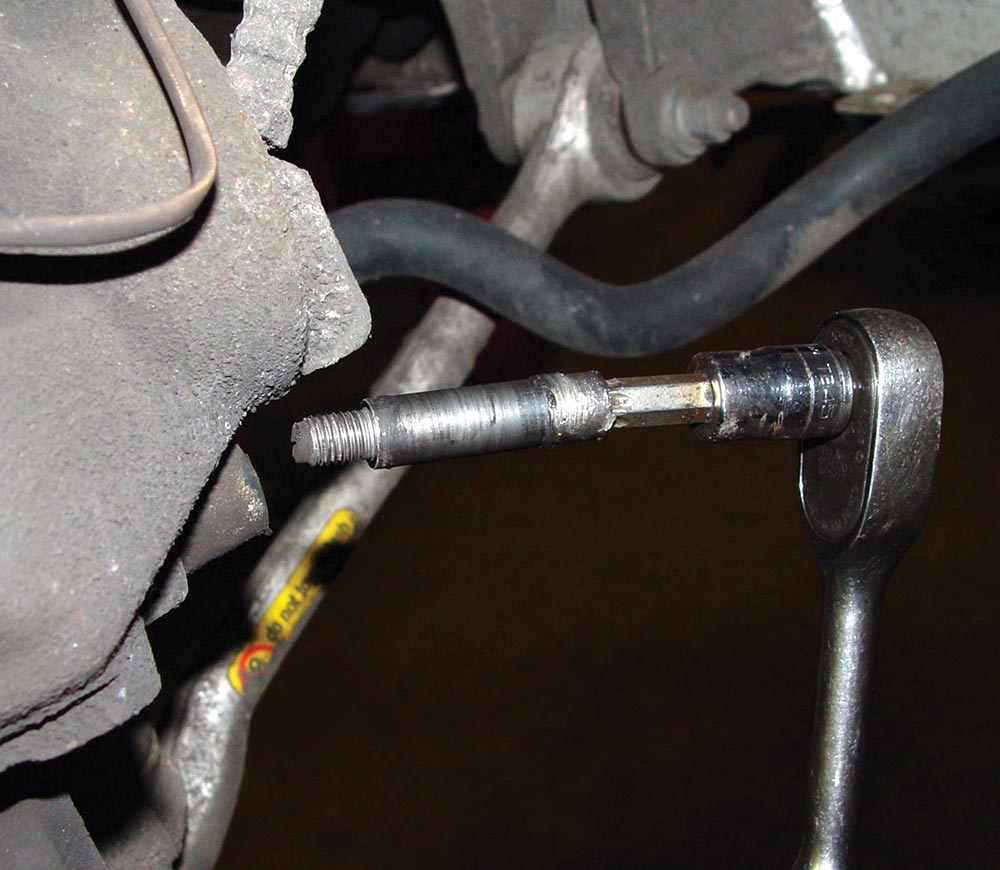

Worn or damaged caliper mounting pins can cause calipers to bind, preventing even and reliable braking. Corroded sliding surfaces can result in similar brake problems.

For example, if the hose has clogged so that fluid pressure to the cylinder is restricted, the car will most likely pull toward the opposite side when the brakes are applied. On the other hand, if the hose is restricted so that fluid pressure from the master cylinder can get through, but the weak retraction action of the square-cut piston seal can’t force the fluid back out when the pedal is released, expect to find an overheated “blued†disc and vastly accelerated lining wear on that side.

One cause of hose restriction that is often overlooked is heavy rust on the bracket that holds the hose to the chassis. The iron oxide can build up to the point that it actually crushes the hose. New parts from your BMW dealer are called for.

When removing brake calipers for any service operation, it’s important to properly support the caliper to avoid damaging the brake hose. Never let a caliper hang by its hose.

Some important details make an appropriate conclusion:

- Be alert to vehicles that are fitted with aftermarket or mis-matched wheels and tires. Such modifications can confuse the ABS and ESP modules and can produce unusual symptoms and fault codes.

- Don’t overlook the need for torquing all brake-related fasteners to specs. This includes wheel lug bolts — tightening them with an impact gun is a major cause of rotor warpage.

- On those BMWs that use spring steel retaining clips, check for cracks or flattening that can compromise their spring tension. Replace wear sensors as a matter of course. Be sure to inspect and adjust the parking brake shoes, and remember that BMW recommends flushing and replacing the brake fluid every two years, which is excellent insurance against expensive repairs.

- No brake service will be complete without resetting the CBS system, and the pad wear sensor warning system if it has been activated. Both of these operations vary according to the model and year, so log on to www.bmwtechinfo.com for the official details. We’ll just mention here that the CBS system will convey the updated information to the remotes.

- Finally, it would be foolhardy not to thoroughly road-test the car before you declare the job complete.

0 Comments