BMW pioneered the all-aluminum vehicle suspension. The resulting weight reductions and strength gains helped pave the way for rapid adoption of multi-link suspension and four wheel independent systems. When diagnosing and repairing these complex suspensions, technicians must go beyond traditional bushing replacement. They must also consider the other components that may be affected by the bushing installation process, or, based on the age of the replaced bushings, are likely to also need replacement soon.

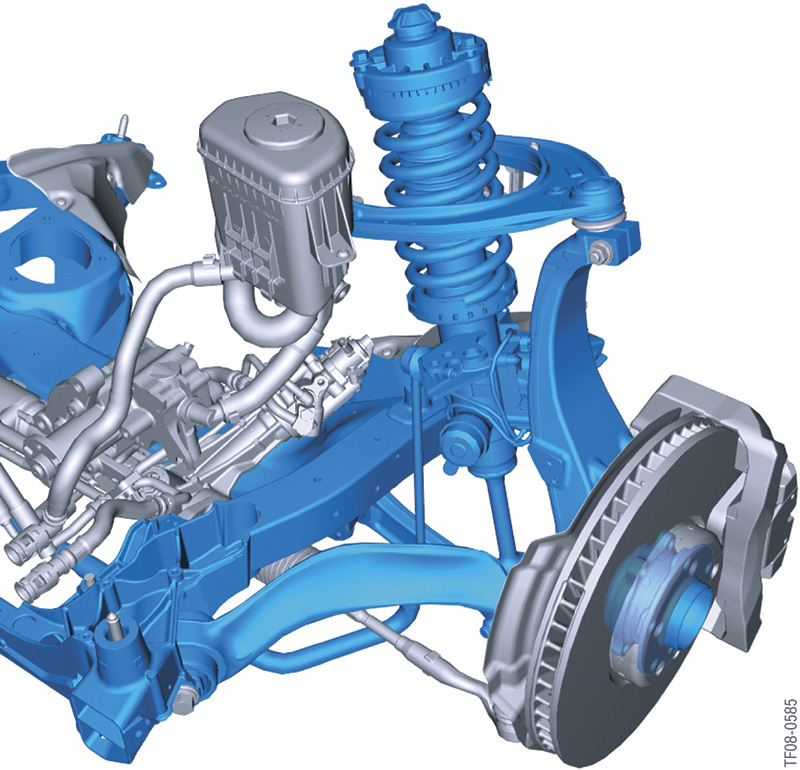

In BMW’s Electric Power Steering (EPS) system, a torque sensor measures the force the driver applies to the steering wheel, and adjusts the vehicle’s steering characteristics. BMW calls the system “low maintenance†– translation: You can replace rubber boots and adjust alignment, but everything else is factory-sealed.

Unsprung: The Revolutionary BMW E39

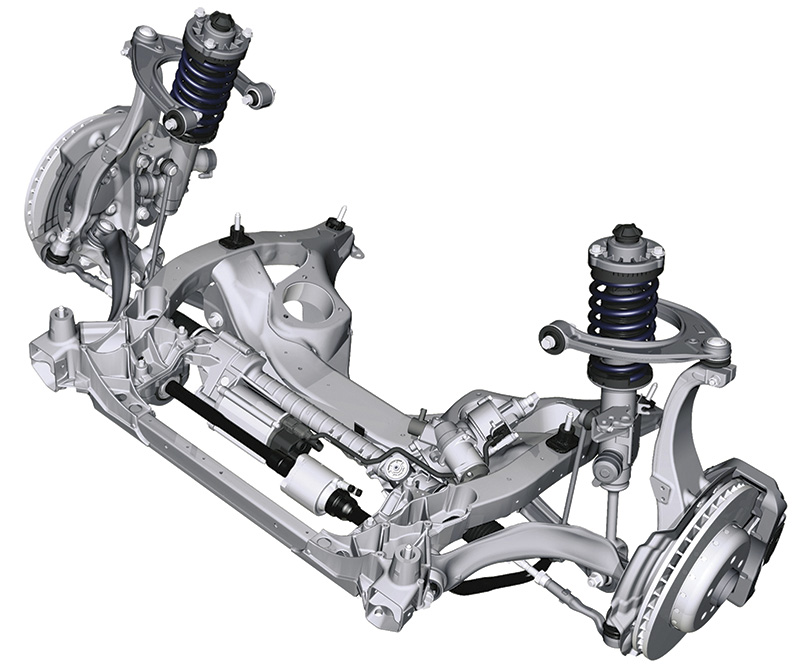

The BMW E39 1995-2003 5-Series was the first production vehicle sold with almost all-aluminum front and rear suspension.

The axle carrier, control arms, outer strut tubes, steering knuckles, — everything except the wheel bearings, were aluminum alloy. The result was a significant savings in unsprung weight, which benefitted handling, ride quality, and fuel economy.

Aluminum alloy control arms were lighter while simultaneously stronger and smaller. The increased space and power these smaller components provided allowed BMW engineers to pack even more chassis control technology onto the vehicles, even while decreasing overall weight.

Larger brake systems, double wishbone and double-pivot front and multi-link rear suspension, and higher precision suspension angles were just a few of the benefits of aluminum alloy use. The BMW E39 quickly earned a reputation as a superior handling vehicle.

Absorb and Isolate

On the BMW E34, E28 and E32, the upper control arms are attached to the front subframe through bushings that handle a lot of the load on the front end when braking. These bushings are typically fluid-filled rubber cylinders surrounded by a metal sleeve. Bushings are typically used in BMW control arms and also in thrust arms.

On all but the sportiest platforms, BMW uses either soft rubber or hydraulic bushings for driving comfort. For racing applications, harder rubber and urethane compounds provide more durable bushings. These tougher bushings contribute to a stiffer suspension than is desired by most luxury vehicle owners. The bushing end of a control arm helps isolate the vehicle body from vibration and noise due to minor road surface roughness. Bushings also help maintain wheel positioning, preventing undesirable camber and toe changes as the vehicle moves over uneven road surfaces, or through hard turn or braking maneuvers.

The resulting torsional, or twisting, load on the bushings over time causes the rubber to weaken and the fluid to leak out. The driver will eventually notice reduced suspension performance and poor handling.

Dry cracks, leaks and rattles are signs of excessive bushing wear. Bushings can wear so much that, in extreme cases, the wheel can lean enough to touch suspension components.

But don’t automatically assume that the bushings are the only parts that need replacement.

The Joint is Jumping!

The other end of the control arm typically contains a ball joint that functions as the interface between the arm and knuckle in a suspension system. The ball joint rotates and swivels in any direction to allow the wheel the maximum freedom of movement while still providing steering input, or helping maintain proper suspension angles. If the vehicle has six-figure mileage, it is likely that the ball joints have suffered significant wear.

An easy first check for wear is to raise the vehicle off the ground, grab the tire at the bottom and rock it toward the outside of the vehicle and back while squeezing the ball joint with your other hand. If you feel movement in the ball joint or hear a knocking sound, the joint needs replacing.

If you are unsure, measure ball joint play using a dial indicator. If there is more than 0.5 millimeter of play in the joint with the suspension unloaded, it is time for ball joint replacement.

Also, if the rubber cover has been torn or otherwise compromised, the joint will lose lubricant, take on water in wet weather, and be vulnerable to road debris and rust.

Lack of Control

If the vehicle has also been driven in an environment of poor road conditions, you may have a bent control arm or thrust arm. You may be able to determine if the vehicle has damaged arms by taking it out on the highway for a careful and thorough test drive.

Bent control arms can cause steering vibration that becomes more noticeable at highway speed. A steering wheel vibration during braking is another sign of bent control arms. excessive wheel movement, and noise while turning. One meeting with the wrong pothole can result in bent suspension components, although other causes of braking vibration, imprecise steering and noise while turning include bad tires, bent wheels, and warped brake rotors.

In addition to a road test, control arm and bushing problems may be discovered by means of a visual inspection, or with the car on an alignment rack.

Bushing, Ball Joint or Control Arm?

The Double-pivot front suspension with rigid front axle carrier, wishbone control arms, low-friction ball joints and rack and pinion Electronic Power Steering helps maintain structural stability and gives BMW vehicles superior road handling performance.

On many models, BMW gives technicians the option to press in new bushings. Use due care when pressing bushings out and new ones in, so that you do not distort the aluminum control arm, which is more easily damaged than steel.

If you replace one or more bushings, replace both the driver and passenger sides. Wear on one side that was enough to cause steering issues or noise is a good indicator that the other side is close to also presenting problems.

Just pressing in new bushings may appeal to budget-conscious customers. However, if the bushings are worn, the ball joint on the other end of the control arm is likely to have also suffered significant wear. Measure ball joint play, especially on a vehicle with over 100,000 miles on the odometer.

Even if the ball joints appear in decent shape, it may make sense to replace the entire control arm on a high mileage vehicle. The labor time to press in new bushings may bring it close to the cost of control arm replacement. Your BMW dealership parts department can supply you with fully-assembled control arms and thrust arms, ready for installation. This will also give your customer the confidence that he or she won’t need to come back soon to address ball joints shortly after bushing replacement.

Ball joints are sold separately for some BMW models, generally those with steel control arms (E46, E53, etc.). However, complete control arm assemblies are the only option available for most newer BMW models; ball joints for these cars are not serviced separately. On those cars with replaceable ball joints, there are reports of cars returning with noise complaints shortly after ball joints have been pressed in. So it is prudent to simply secure a new control arm assembly from your BMW dealership parts department in order to preclude problems down the road.

Unintended Consequences

The upper control arm reduces camber changes during jounce and rebound events. The arrangement of the front suspension includes bushings at multiple swivel points. This helps reduce friction, which allows the damper to respond extremely quickly to road surface irregularities.

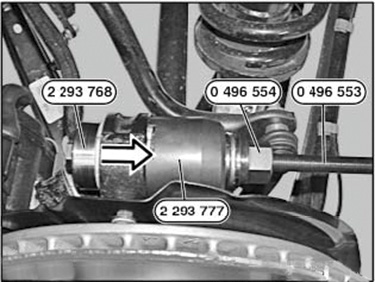

We’ve heard horror stories of people attempting to press out bushings using a large socket wrench or other inappropriate tool. They get the bushing out, but often not without also enlarging the inside diameter of the opening in which the replacement bushing must be seated. The new bushing can be loose, compromising vehicle handling and, potentially, driving safety as well. BMW and other suppliers offer special tools that allow bushing removal and installation with no seat damage.

If you find the need to replace bushings, be certain to only perform final tightening of related fasteners once the vehicle is back on the ground with the suspension in the normal loaded condition. Otherwise, if you final-tighten these fasteners with the wheels hanging free, when you put the vehicle on the ground the bushing will twist and remain in this tight, twisted state. This “pre-set†torsional load reduces the ability of the bushing to handle suspension changes due to driving maneuvers and road conditions, and can result in erratic handling and much faster wear than normal.

The Rubber Bushing Remover is used along with Sleeve 2 293 777, Spindle 0 496 553 and Nut 0 496 554 to remove the Upper Wishbone Bushing. For complete instructions for this tool, refer to ISTA Repair Manual section 33 32 029. The same tool is also used to remove the bottom trailing arm bushing (see ISTA Manual section 33 32 031 for details).

There are also related components whose functionality can be affected by something as simple as bushing or ball joint installation.

For example, on some BMW models the Antilock Braking System (ABS) wheel speed sensor is mounted in the steering knuckle and points to a toothed ring in or near the bearing. Bushings must be mounted a certain way in order to ensure that the wheel sensor is pointed exactly where it should be to support Antilock Braking System (ABS) function. Refer to BMW repair procedures to see if the vehicle you’re repairing requires special procedures for precision mounting the bushings.

Another example is the Electronic Power Steering (EPS) system. You can replace the rubber boots and adjust alignment. Everything else is sealed at the factory, and therefore other components are not serviced separately.

Alignment Time

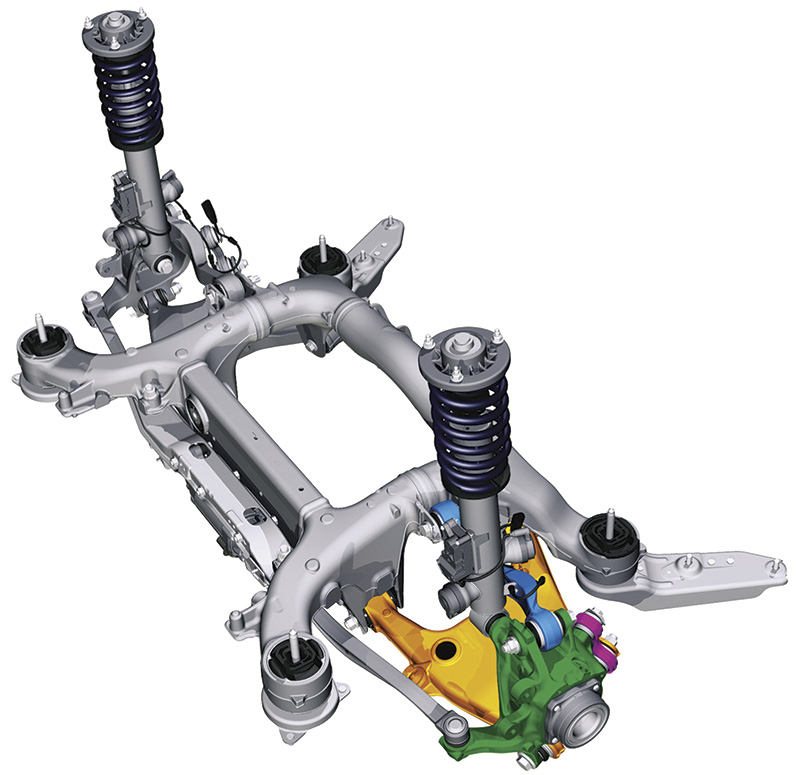

The dynamic forces applied through the wheel contact point into the suspension are taken up by the wheel carrier (green), rear axle carrier, an A-arm (orange), and three bushings (at the track rod ends and the A-arm).

If you replaced worn bushings, ball joints, or control arms, it is time for wheel alignment. This will restore all suspension angles to factory specification, and is an important customer satisfaction tool. If the steering wheel was off center before your service, the customer will notice that it is now straight. He will certainly appreciate that the repaired vehicle handles noticeably better as well.

Just be sure to check the BMW service procedures for the alignment requirements of the vehicle. Some BMW models do not have provision for caster adjustment. Some can have camber adjustments, but require vehicle-specific procedures and special tools. Also, it may be necessary to unload the suspension in order to make camber adjustments. And, as usual, toe is the final adjustment to be made after caster (if adjustable…) and camber.

The next time a vehicle with steering shimmy, braking vibration, or noisy turning complaint comes your way, remember that worn bushings, ball joints, and control arms all impact vehicle handling. It often is cost-effective to replace all three simultaneously.

0 Comments