Antifreeze seems to come in all colors of the rainbow these days.

Which one is right for BMWs?

| Weight Percent EG (%) |

Freezing Point (deg F) |

Freezing Point (deg C) |

| 0 | 32 | 0 |

| 10 | 25 | -4 |

| 20 | 20 | -7 |

| 30 | 5 | -15 |

| 40 | -10 | -23 |

| 50 | -30 | -34 |

| 60 | -55 | -48 |

| 70 | -60 | -51 |

| 80 | -50 | -45 |

| 90 | -20 | -29 |

| 100 | 10 | -12 |

| Ethylene glycol freezing point vs. concentration in water |

||

To be precise, the liquid you pour into a radiator should be referred to as “antifreeze/summer coolant†because it not only keeps the icebergs away in winter, but also helps prevent boilover in summer. In addition, antifreeze contains an additive package that protects against corrosion and degradation of aluminum, steel, and iron components that are wetted by the coolant. Most brands and types of antifreeze on the market today are based on ethylene glycol (more on this later…).

It is interesting to note that these various ethylene glycol solutions continue to lower the freezing point down to about -60 deg. F., with a concentration of 70% antifreeze, 30% water. Beyond a concentration of 70%, the freezing point of the coolant actually rises, with pure ethylene glycol antifreeze freezing at about 10 deg. F.

On the other hand, the boiling point of a solution of ethylene glycol antifreeze continues to rise with the concentration of the antifreeze, with pure ethylene glycol boiling at about 387 deg. F.

And consider this: each pound of pressurization in a cooling system raises the boiling point by about three deg. F. So a ten-pound pressure cap will raise the boiling point of pure water to about 242 deg. F. And that same pressure cap used with a 50/50 mixture of antifreeze and water will yield a boiling point of about 255 deg. F., which can spell the difference between comfortable motoring on a hot summer day, or a boilover by the side of the road.

It All Started With Alcohol

| Weight Percent EG (%) |

Freezing Point (deg F) |

Freezing Point (dec C) |

| 0 | 212 | 100 |

| 10 | 215 | 102 |

| 20 | 215 | 102 |

| 30 | 220 | 104 |

| 40 | 220 | 104 |

| 50 | 225 | 107 |

| 60 | 230 | 110 |

| 70 | 240 | 116 |

| 80 | 255 | 124 |

| 90 | 285 | 140 |

| 100 | 387 | 197 |

| Ethylene glycol boiling point vs. concentration in water |

||

As recently as the 1950s, automotive antifreeze was alcohol-based. Formulations of the day prevented freeze-ups, but presented several shortcomings. They lacked the additives that have become so important in more modern cooling systems, and the alcohol tended to boil off and vaporize, resulting in less protection against freezing, and bringing the need for frequent replenishment in order to restore freeze-up protection.

So, in that long-ago era chemists came up with blends based on ethylene glycol, which has become the basis of nearly all antifreezes since. These products, in a typical 50/50 mixture with water, provide freeze-up protection to about -34 deg. F. The 50/50 mixture is a convenient number to remember, and ethylene glycol is not subject to the evaporation that degraded the freeze protection of alcohol antifreeze.

In its natural state, ethylene glycol is clear, syrupy, and odorless, although it does have a bit of a sweet taste. And therein lies a concern. Ethylene glycol is toxic, and can be fatal if ingested by humans or animals. A bittering agent is typically added to ethylene glycol-based coolants, but its basic sweetness, and usual bright coloring, make it appear to be an attractive beverage, especially for children and animals. So care must be taken when handling and disposing of these products.

Now for the Rest of the Story

Just looking at the coolant in the overflow reservoir won’t tell you much. You’ll get a better idea of the level and corrosion situation by removing the radiator cap (engine cold, of course). The floating stick is a nice touch.

In the typical 50/50 antifreeze mix, the water and ethylene glycol account for about 97% of the volume; the remainder consists of a variety of additives that fight corrosion, resist foaming, dye for identification purposes, and probably bittering agents to help avoid poisoning.

The anti-corrosive additives often include silicates and phosphates. Silicates work well in preventing corrosion of aluminum cooling system components. Phosphates work equally well in preventing corrosion of steel components, like water pump impellers, but lose their effectiveness over time.

Today’s antifreeze additive packages tend to fall into one of three categories:

- Inorganic Acid Technology (IAT)

These additives include both silicates and phosphates which, combined, help ward off corrosion of aluminum and steel components. But because they tend to precipitate out and break down, they should normally be replaced and replenished every two years. This worked reasonably well for decades. Its biggest shortcoming is the need to replace it fairly often or risk corrosion of vital cooling system components. - Organic Acid Technology (OAT)

With this type of additive package, chemists have replaced the silicates and phosphates with other materials, like carboxylate, sebacate, and 2-ethylhexanoic acid (2-EHA). These blends offer freeze protection comparable to IAT, but provide a much longer service life, although at a price premium.Of particular concern in newer BMWs and other cars, however, is the presence of substantial quantities of 2-EHA, which is a “plasticizer.†That means it tends to soften plastic cooling system components, which presents problems with vehicles that have PTRs (Plastic Tank Radiators), plastic expansion/overflow tanks, thermostat housings, water pump impellers, spacers in various gaskets, etc. Some manufacturers substitute sodium benzoate in place of the 2-EHA, but that too functions as a plasticizer and is to be avoided in systems with plastic components.Â

One other concern with OATs arises if the coolant level in the system is allowed to fall. While these additive packages prevent corrosion in aluminum and steel, they are only effective as long as the metal parts are constantly immersed in coolant. If the coolant level drops, metal surfaces do not retain the anti-corrosion properties of the formula. As a result, oxidation develops rapidly, forming deposits that can grow, break off, and obstruct vital coolant passages in the engine and elsewhere.

- Hybrid Organic Acid Technology (HOAT)

As the name suggests, HOAT blends include some proportion of various different technologies. HOATs are similar in chemical composition to OATs, but typically with silicates and/or phosphates added. The concentration of these materials is large enough to provide corrosion protection for metals in even if the cooling system is not kept full, while being small enough to avoid most plasticizing action.

HOATs have an even longer service life than OATs, but with a corresponding price penalty. On the more positive side, HOATs are more likely to perform well in hard water solutions, where IATs and OATs are more effective when used with distilled water. Testing has shown that phosphates can react with certain elements found in hard water, such as calcium, iron, and magnesium, forming deposits that can seriously compromise the effectiveness of the cooling system. So, sophisticated coolants like genuine BMW antifreeze/coolant are phosphate-free.

But What About Waterless Coolants?

We beg to differ. Depending on the design, construction and materials found in the cooling systems of today’s cars, no single antifreeze blend can properly protect and preserve sophisticated cooling systems.

There are some antifreeze products on the market that are offered as waterless, and are intended to be used full strength straight from the jug. Often, these are propylene glycol-based as opposed to more conventional ethylene glycol-based antifreezes. Propylene glycol does have some advantages over ethylene glycol. Remembering that these products are intended to be used in 100% concentrations, they have a very high boiling point so they can be used with minimal system pressurization, and they never freeze at any temperature. Also, they are non-toxic.

As with most things in life, however, there are trade-offs. These products are far more expensive than conventional antifreeze, which can prove doubly costly if a burst hose or cooling system leak should cause a total loss. Further, they are not compatible with ethylene glycol-based antifreeze, so topping off of the coolant must be done with the same type of product, which is not commonly available at retailers, parts stores, or service facilities. So, while such products may be suitable for certain heavy-duty, commercial, racing, and industrial applications, they are not well-suited to passenger car use.

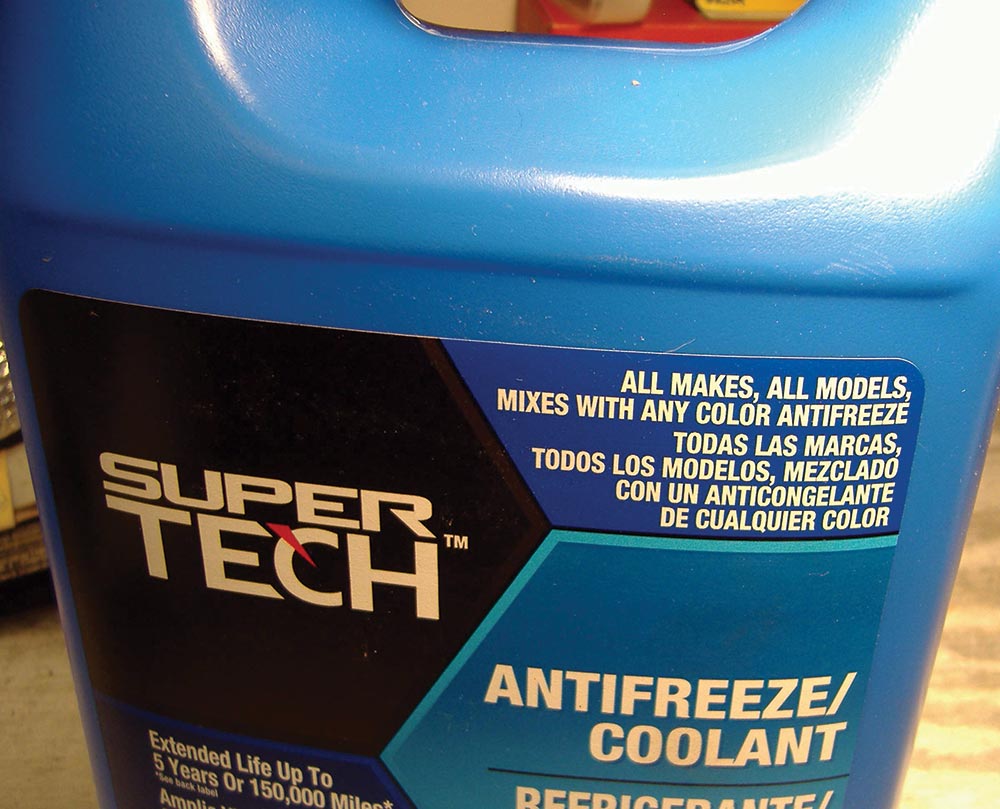

“Suitable for all Vehiclesâ€

Don’t believe everything you read. Well, you can believe everything you read here in the bimmer pub, but don’t believe everything you read on the Internet and in product advertising. Some retail brands of antifreeze are promoted as being suitable for any make or model of car, and compatible with any other type of antifreeze. But don’t fall for it. For all the reasons outlined above, there are certain advantages and disadvantages to the various additive packages used in antifreeze blends. And no one formula can meet the needs of a wide variety of makes and models built with various plastics, aluminum, steel, and other materials. Nor can compatibility with all of the various OE blends be assured, since the chemistry can vary widely based on engineering needs.

As a result, a “fitsall†antifreeze may not offer adequate corrosion protection for your customer’s BMW and, in fact, may contain additives that can actually degrade the materials in a BMW’s cooling system. Furthermore, chemical incompatibility may result in the formation of deposits or globules that can restrict radiator tubes, heater core tubes, and other small orifices, compromising the effectiveness of the cooling system and risking substantial customer expense and dissatisfaction.

So What Should I Use?

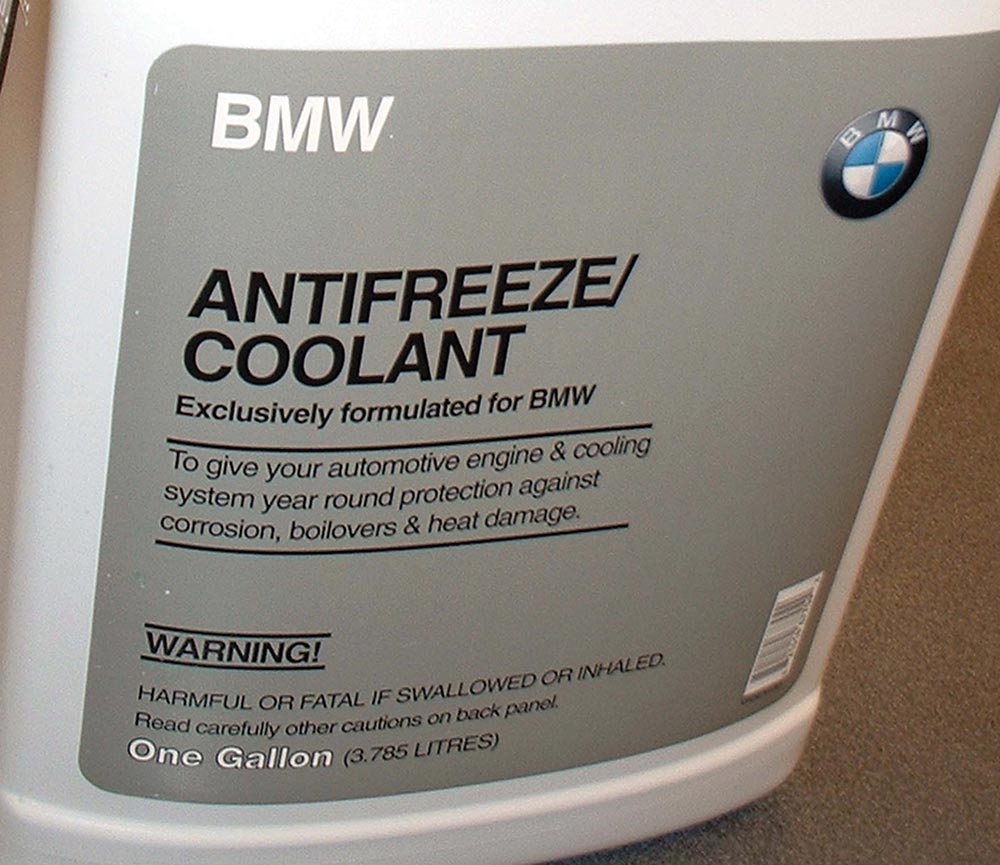

Only genuine BMW antifreeze is compounded to contain the precise blend of the proper chemicals to afford reliable freeze-up and boilover protection while being fully compatible with the various materials wetted by the coolant.

The answer is as close as the parts department of your local BMW dealer. That’s the only place where you can buy the bluish-tinted antifreeze compound that’s exactly right for the needs of your customer’s prized and precious BMW.

And there are many reasons — specific reasons — why you should use only this product in BMW cars. Genuine BMW coolant is engineered to meet the exacting needs of BMW vehicles. It is a hybrid coolant that contains no phosphates, no 2-EHA, low levels of silicates and, unlike some hybrid coolants, contains no nitrites, which can combine with other chemicals to form nitrosamines, which are carcinogenic.

Rather, genuine BMW coolant contains an exclusive blend of corrosion inhibitors, defoamers, dyes, and bittering agents that provide optimal cooling, corrosion protection, compatibility with all cooling system components, and provide a long service life.

0 Comments