Tracking down the cause of one problem can lead to other issues. A speedometer repair on this BMW evolved into something deeper.

|

Tools used: |

|

90 amp clean and stable power supply |

|

INPA with laptop, Launch EasyDiag with Android tablet |

|

Bluetooth Oscilloscope and Android tablet |

|

Multi-meter and amp clamp |

Imagine this 2001 BMW 740i in very good condition that’s had some past TLC but had other recent shops “have a go at it.†This adventure all starts with a question: “Can you get the speedometer working?â€

This is a first time customer that was advised from another customer/friend about; “having the correct tools.â€

For the uninitiated technician that’s never seen one of these models, this is an example of a complex and early CAN adapted vehicle.

The approach and customer interaction

The conversation should begin with some background and specifically; who owned it, how and where the vehicle came from. One piece of information came from a paid invoice from a BMW dealer that diagnosed a right rear wheel speed sensor defect. It is assumed the speedometer uses the R/R speed sensor data to operate the speedometer.

Hint: Never assume and keep it simple.

A short road test may be the best way to see speed sensor data with the vehicle owner, while attempting to prove some answers to multiple theories. This model does have a DLC (OBD II) very close to the cup holder mounting of the center console. The customer did note “This is where the other shop plugged in a tool.†DME and EGS data can be accessed at the OBD II connection.

Road test with the customer

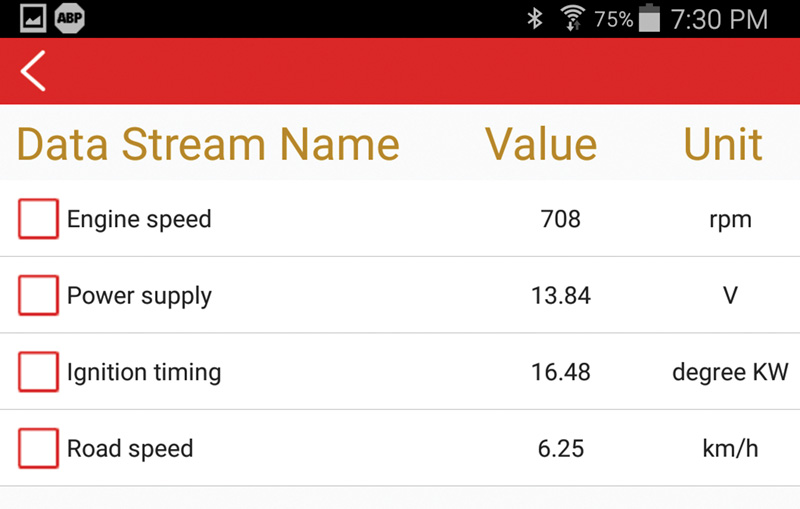

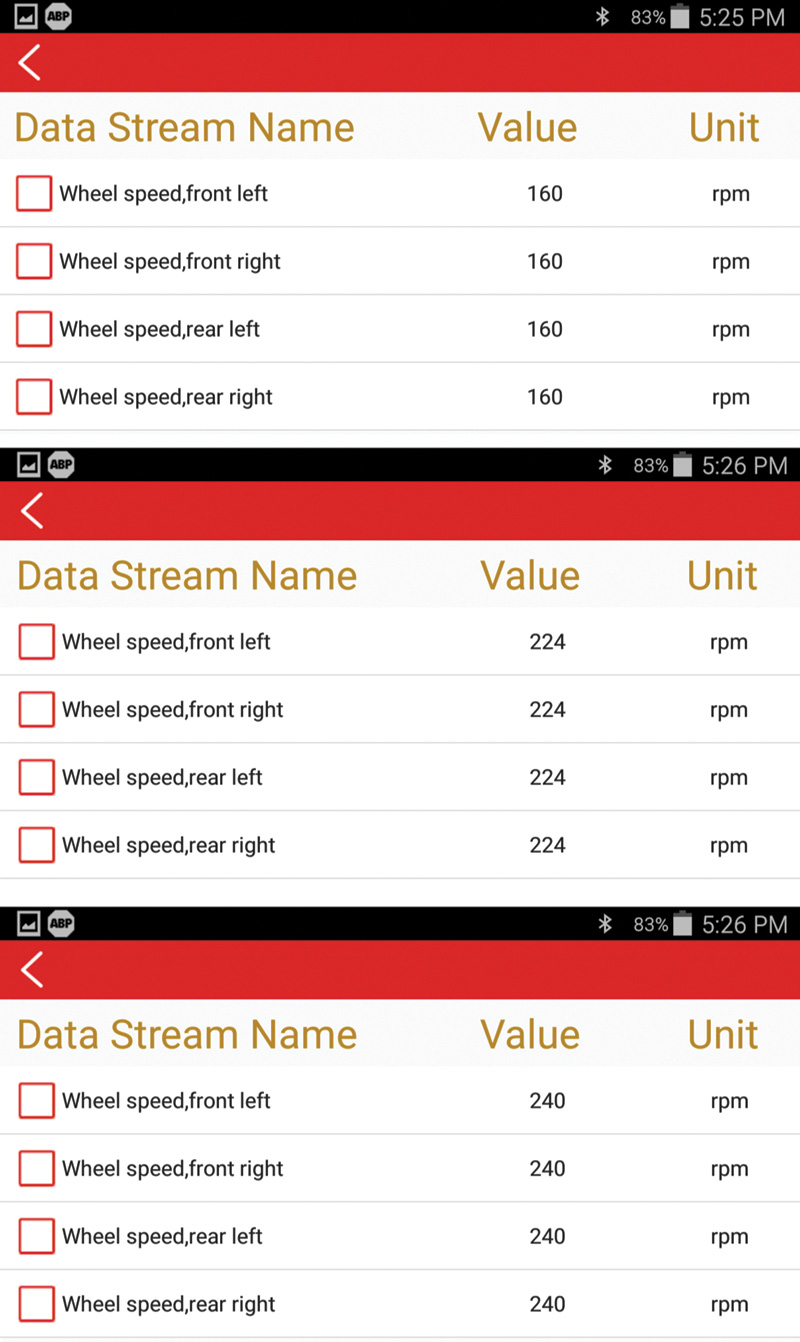

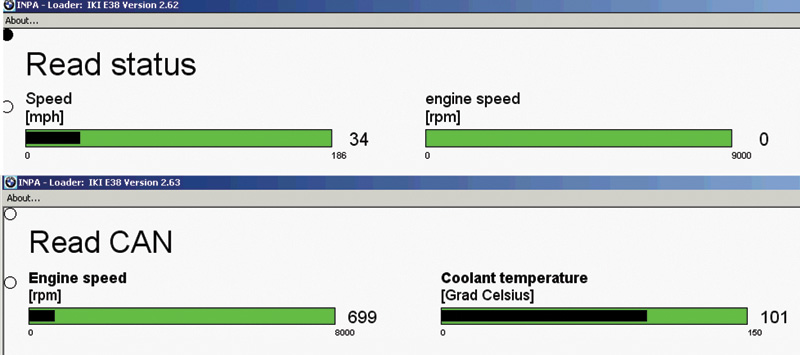

Quick and simple is the tool that offers wheel speed data that is current and is visible with screen captures. One choice is a tablet/Android device that offers wheel speed data in real time. With recorded speed at the EGS and no instrument speed, there was a problem that needed some investigation. The images were “stitched together†to offer current EGS data and give the customer the insight of what one controller has access to.

Simply explained for the customer is how the wheel speed data is transferred (shared) via CAN from one (multiple) controller(s) to another. The OBD II connection is not going to offer all of the information needed to solve the primary question.

Hint: A defective ABS system will allow the rear wheels to spin up at road speed on the hoist. An operating ABS system will NOT allow the rear wheels to spin at road speed. Here’s why.

If the vehicle has the rear wheels spinning and the fronts are not, the ABS assumes the vehicle is in a skid or front wheel lock-up.

It’s no different when driving on loose gravel or snow. If any of the wheels are determined as “locked†or “stopped†while rotating and one or more of the other wheels are still in motion, the ABS activates.

This BMW has this behavior on the hoist with the rear wheels spinning. If the ABS has a defect, the ABS doesn’t intervene and now the rear wheels rotate faster without ABS intervention.

Many vehicles have similar qualities. The difference is with all wheel drive with all four wheels spinning. The vehicle may complain, but it can get some road speed.

For added measure, the customer felt far more confident when the diagnostic tools were attached to the BMW 20 pin proprietary port with a live session.

Definitely old school

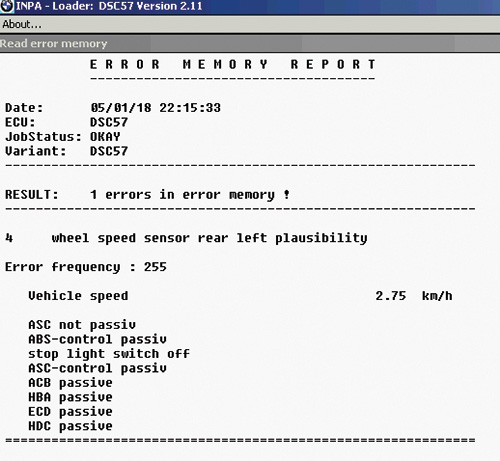

Start was with a complete scan and measure/save the condition of all installed network controllers within this vehicle. Do this at the 20 pin port.

Maybe there can be something recorded and usable for future diagnosis. Also noted is the BMW 20 pin data link at the R/F fender. At this connection, the entire network and all controllers are accessed.

The current lists of recorded faults are:

- DME – 8C (Activation map cooling)

- EGS – 3C (Transmission switch)

- MID – 03 (no valid status response TELEPHONE)

- ABS – 5C (Pressure sensor test) recorded during the road test

- ZKE – 07 and 08 (Seat heater circuit open both L and R)

A quick road test with the customer confirmed that the speedometer was not operating, but the EGS displayed wheel speed data with an Android software package at the 16 pin OBD II connection.

Note that all 4 wheels were sending equal rpm road speed data from the ABS control unit, to the EGS, via CAN messages.

The vehicle owner now has the confidence that the previous repair facility may not have diagnosed the primary concern correctly and that this assignment is to continue and repair the primary concern, which was an inoperative speedometer.

Old and new thinking – different but the same

Tracking down the cause of one problem can lead to other issues. A speedometer repair on this BMW evolved into something deeper.

INPA with a laptop is quite the versatile tool when dealing with older models that require a diagnosis with access to bi-directional control. The Launch EasyDiag is a quick diagnostic tool running on a tablet but does not have access to bi-directional control.

Note that this Launch specific test offers road speed at the DME.

This test offered no visible road speed indication at the instrument cluster.

Can the ABS sensors be measured?

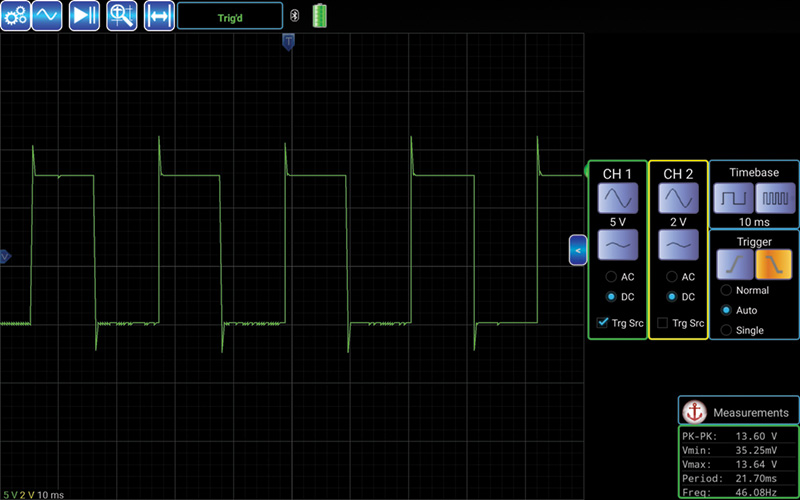

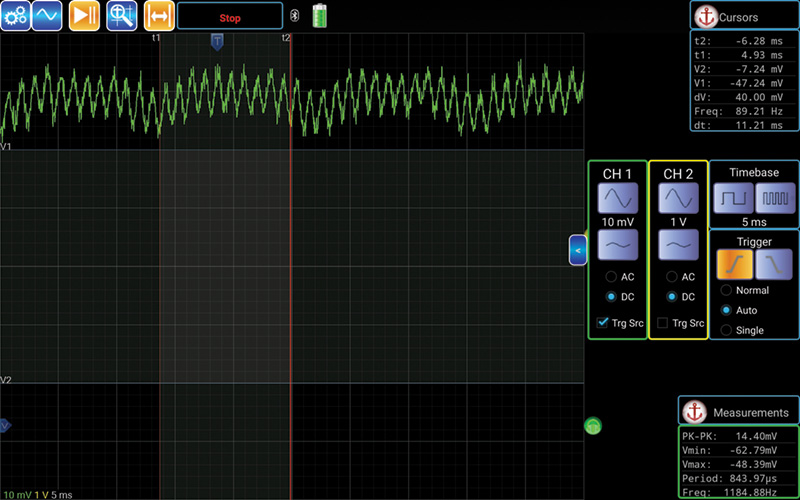

At the ABS controller, the sensor previously diagnosed by the dealer was tested with an oscilloscope and with the rear wheels spinning in Drive and at idle.

R/R ABS signal – Note that this signal was “stretched in DC mode.†This signal also sends the trip odometer data.

One interesting piece of information was discovered looking at the “defective LCD display.†The trip odometer was counting but with no road speed indication.

Was the instrument cluster defective?

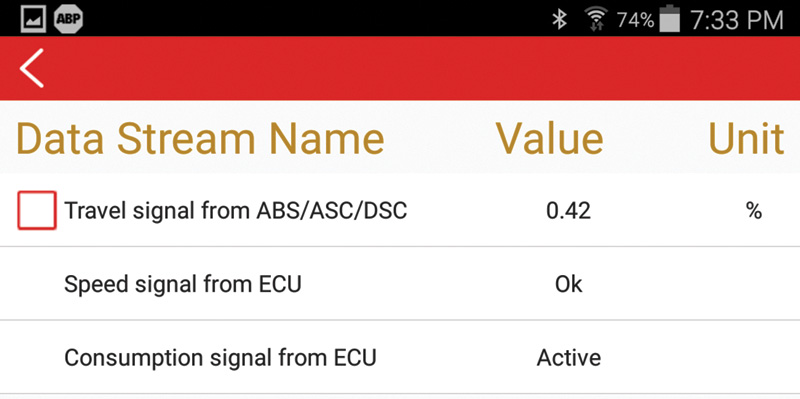

Proof and a measurement are in view at Instrument Cluster Electronics. The ABS is sending the correct Travel Signal message with no road speed indicated at the cluster.

Is there something missing?

Some patience and a detailed schematic will help, constant testing and searching for fault recordings may take time to “catch the culprit.â€

Side note: What are the chances that the upper radiator outlet was leaking (intermittent spray when hot) during the hoist tests? Is that why both tools recorded the “140 Output Thermostat Mapped Cooling†error?

Replace radiator and bleed the system immediately.

There is some good fortune at times when “repeat the test†offers a result that may confirm a suspicion. After the radiator replacement and during the road test, one new fault was recorded.

Fortunately for the vehicle owner, a new BMW replacement sensor for the R/R side was previously purchased. That sensor is now used for the L/R side.

Replacing the sensor however was a traumatic affair. After 17 years of attachment to this BMW, it was “difficult to convince it to let go.â€

Hint: Never allow a BMW to get the better of an argument!

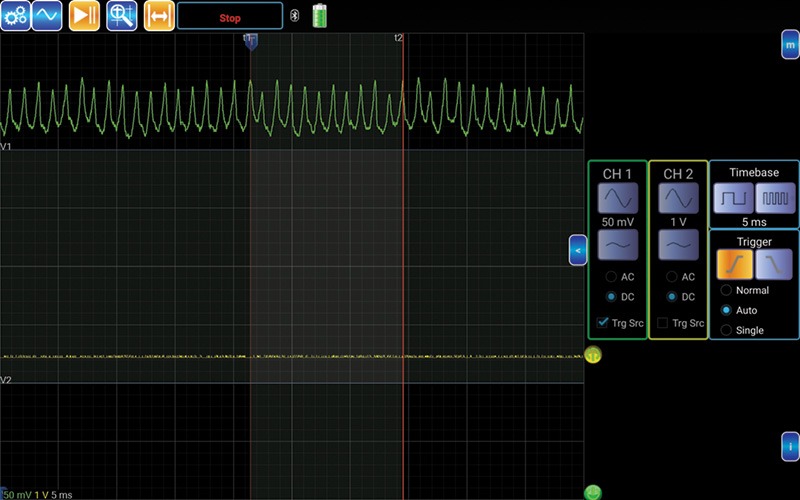

With the new sensor installed, the following image offers some satisfaction that the “trauma†was worth it in the end. The primary question is answered.

A road test with INPA confirms the IKE reads the correct data with no faults.

Note that this INPA specific test offers road speed at the Instrument Cluster and is trimmed to fit this article. The image to the right indicates no rpm, but the “Read CAN†button was used to acquire rpm via CAN. At the IKE, the correct rpm signal is read within the lower image, off throttle and coasting.

The view of the speedometer solves one interesting mystery but the road test repeated the ABS/DSC fault previously recorded. During the fault recording, the ABS warning lamps were active. Fortunately, the vehicle owner was aware of the initial fault recordings and ABS warnings on the cluster.

The DME again recorded a previous fault. It required a new map controlled thermostat assembly.

ABS – 5C (Pressure sensor test) recorded during the road test

DME – 8C (Activation map cooling)

Explanation and operation “If – Then – Elseâ€

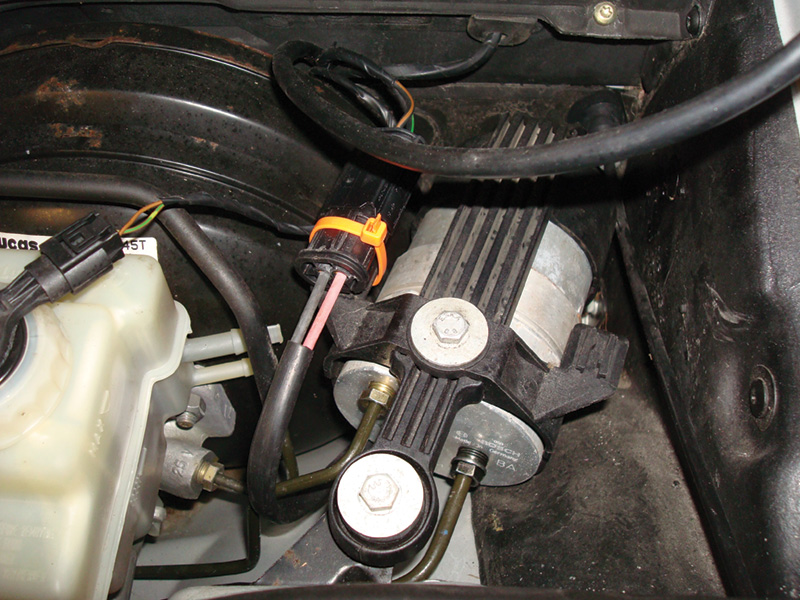

The ABS/DSC pressure sensor test is described as such:

- In BMW terms, the device in question is called a pre-charge pump.

- The BMW number is 34516781435 with a heart attack when priced.

- The pre-charge pump operates under the following conditions:

- Road speed greater than about 20 mph

- Engine speed greater than 2000 rpm

- Engine torque greater than 100 Nm

A simple test

If the driver accelerates above the set conditions and the ABS warning lamps are ON and a fault code is set, it is a suggestion that the pre-charge pump is defective.

If the fault is cleared and the driver accelerates below the set conditions, it is likely the ABS lamps may not switch to ON (not a perfect suggestion).

A sure test is to apply battery voltage to the heavy electrical connections at the pre-charge pump. A defective pump will likely NOT spin:

Battery positive to RED : Battery negative to BLACK

Replacement – quick and dirty:

- Battery positive to RED : Battery negative to BLACK

- Bleed the fluid at the outlet side until no air is visible, then torque the line.

- Reverse the connections to allow any trapped air back to the reservoir.

- Reconnect the scan tool and delete the ABS/DSC fault code and road test again.

Optional replacement – complete brake system flush

So a radiator, thermostat assembly, coolant, ABS wheel speed sensor and pre-charge pump were all replaced. All remaining brake fluid was washed away with a soapy water solution.

The original speedometer issue was resolved, with other anomalies and defects dealt with one at a time. Any remaining fault codes were cleared, and screen images were captured with a final road test. The BMW was returned to the owner.

Murphy’s Law: “Anything that can go wrong will go wrong.â€

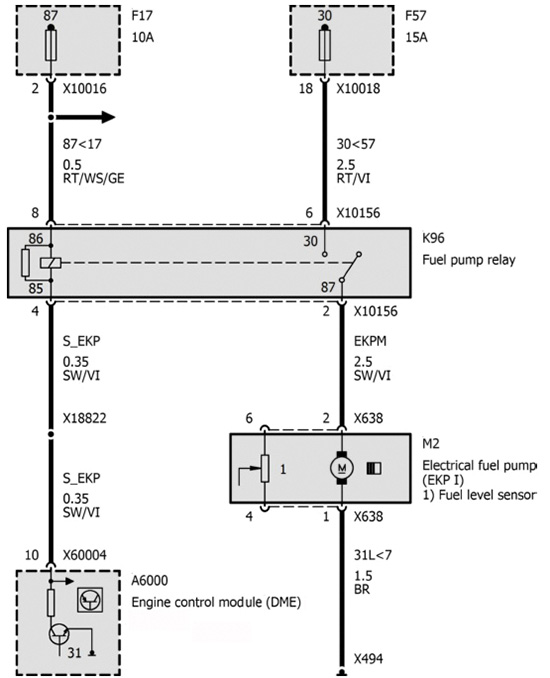

The BMW returned in a week or so for a no-start condition. With a fuel pressure gauge and by cycling the ignition key, no fuel pressure was evident. A 30 amp fuse was found to be burned, using a schematic.

A replacement fuse at F57 did enable fuel pressure to return, the engine ran with no faults but – for the uninitiated there is another mystery. There is a reason that seemingly points to a failing fuel pump. Can the fuel pump and entire circuit be measured? Can the pump be monitored?

The image “Amp clamp 01″ of the Fluke meter and a simple amp clamp offers some information with a 30 amp re-setting fuse to protect the circuit at F57.

What does the fuel pump look like with an oscilloscope and amp clamp?

Some research on this pump indicates 10 commutators.

The fuel pressure gauge matches the specifications.

The fuel flow rate matches the specifications.

The fuel tank is near full of premium fuel.

The fuel pump calculation is as follows:

60,000 milliseconds (ms) divided by 11.21 ms = 5352.36 rpm < Suspect rpm

The harness at the fuel pump under the rear seat offered identical results but the pump was still suspect and the engine ran for an extended period of time.

There were allowances of time to work with this BMW and attempt to duplicate the defect. In the shop, the BMW worked perfectly every time it was moved, driven and tested.

It certainly didn’t happen according to the “plan.â€

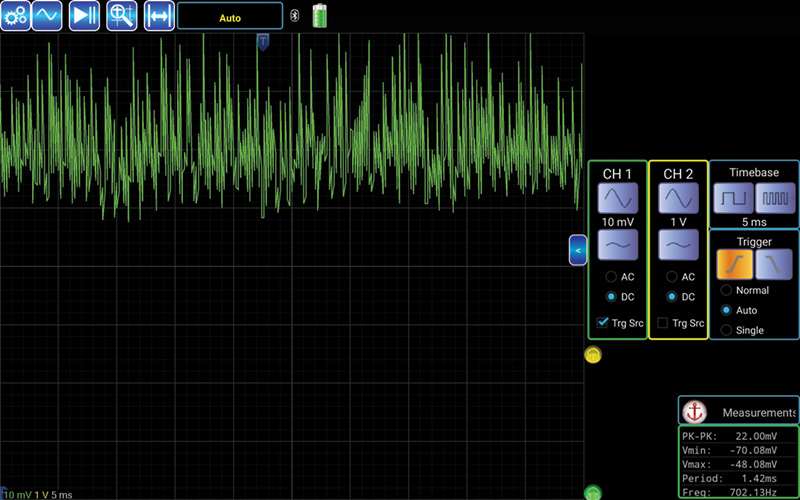

The fuel pump eventually failed (burned fuse) and the car returned in a few weeks. This time with the same tests, same tools and the oscilloscope, the test caught the pump failing in a dramatic fashion. Despite the failing pump, the engine ran with no faults recorded.

The oscilloscope never lies.

The fuel tank was quite close to full and, fortunately, the fuel pump was still operating. At the test port and adapter, the fuel was emptied safely into numerous fuel bladders and stored.

Again for the uninitiated, removal of the fuel pump is a simple task, but pay very close attention to the fuel pump motor connections. Anything that resembles blackened crimps at the wires is suspect. Replace the female blades with tight fitting versions and DO NOT solder the wires. Crimp the barrels with a suitable tool to ensure a proper fit.

What was learned?

Modern tools are simple in nature and work well. In this case, most of the diagnostics were completed with an Android tablet. This included live data and a Bluetooth-connected oscilloscope with a simple amp clamp.

The advantages are portability and the ability to connect quickly.

Taking the time to test, the older software still performs flawlessly.

The software on the laptop with INPA works very well with these older models. The major difference with INPA is bi-directional control with the entire vehicle. You get what you pay for.

Dust them off once in a while, there are secrets to uncover.

NOTE: Anything that was “ISTAfied†previously at the dealer will NOT allow the GT1 to access DME live data. – This was tested with two serial data interface connections and caused the loss of numerous hair follicles.

Anything else?

Fortunately the vehicle owner was quite patient with plenty of understanding for the anomalies. The “special†captured images tell such a story, especially since rodents had a party inside the BMW air box.

So this article is presented to give the reader something to think about when using equipment to measure anomalies or defects. Some different approaches were employed, and we resurrected “from the dust of time†older tools that still work.

Part of the article is also intended to provide answers to multiple defects found with the vehicle over a period of time. With each repair and captured images, the customer had the sense of trust that the repairs were warranted and required.

Download PDF

0 Comments