Second Part of Our Series on Traction Control

With all the power of the 6-liter V12 on our cover, just what happens if the driver goes pedal-to-metal from a standstill with one drivewheel in the wet grass? With ASR and the later Mercedes-Benz traction control systems, the car drives off just about normally.

ASR – AntriebSchlupfRegelung Controlling drivewheel slip

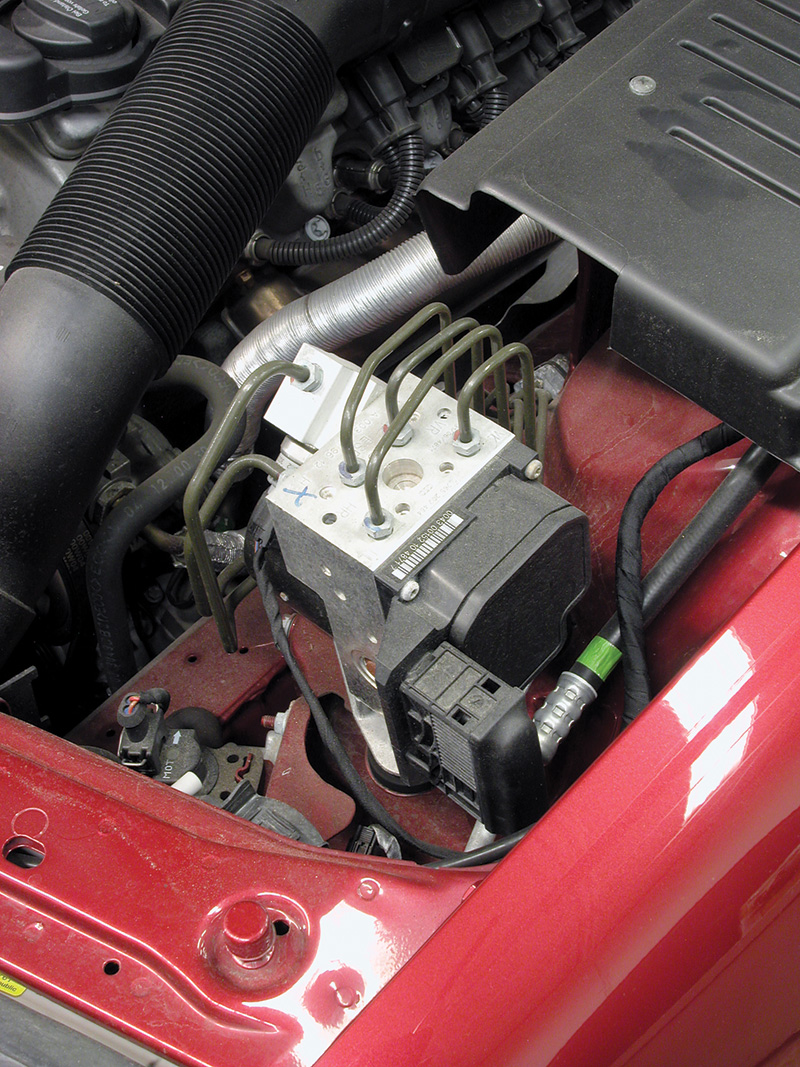

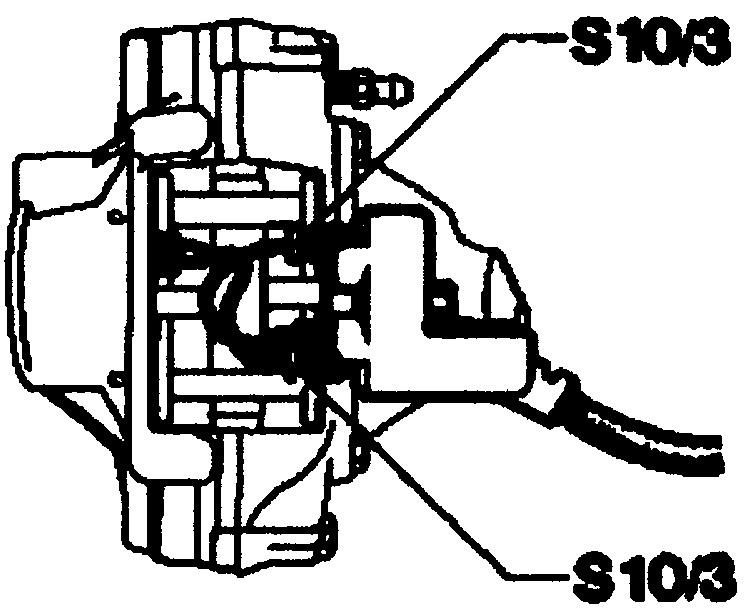

The hydraulic control unit for ASR (or here for ESP) straddles the lines between the brake master cylinder and the four brake calipers. Current versions use two-position solenoid valves to direct the hydraulic pressure; older versions used three-position solenoids.

The ASR system on Mercedes-Benz cars imported to the US first appeared on the 124, 126, 129 and 201 and went through three revisions since the introduction, the last for model year 1995. All the ASR systems imported officially to North America were of the second or later versions. In Europe there was an early, original ASR briefly available only on the 126 from late 1987 to 1989, using separate hydraulic units for ASR and ABS. You might find an example of this early version in a ‘grey-market’ car, one privately imported, not through the carmaker’s American division. There were even rarer and earlier versions going back to 1981, we read. Each ASR version imported here by Mercedes-Benz itself shares hydraulic units with ABS. The most common version, ASR V, was built on everything with ASR since model year 1995.

ASR is the next logical step after ABS, the subject of our main feature in the last issue of StarTuned. Just as ABS retains steering and directional control while maximizing braking effectiveness by pulsing specific brakes off if the connection between tirepatch and road starts to slip, ASR retains driving and acceleration force when the corresponding drivewheel slip begins. ABS pulses brake pressure down and off; ASR pulses brake pressure up and on, both to retain traction under different circumstances. ASR also can close or sometimes open the throttle more or less than the driver signals with the accelerator pedal, all to retain drivewheel traction.

In the last issue of StarTuned we mentioned these traction constants: First, the slip of the treadpatch against the pavement can’t go beyond a certain low (single-digit-percent) threshold, or the tire loses its grip on the road completely, and that slipping wheel contributes nothing further to acceleration, braking or steering. Second, the rear wheels must stay ‘glued’ to the pavement longer than the fronts, or the car spins first sideways and then around, losing all directional control. While a slipping tire contributes nothing to directional control, it still holds the car off the ground, of course, the pneumatic tire’s original purpose (at least until the heat of sliding friction blows the tire).

The business of keeping a specific wheel firmly attached to the road is fundamentally the tiremaker’s stock in trade, but the carmaker can optimize this for a particular car by building steering, suspension and traction-control systems that react quickly to changes at each wheel and execute well-thought-out programs to maximize the traction objectives for the vehicle.

Just as with ABS, the ASR operating strategy is not simply to maximize traction under all circumstances. Directional stability and steering control take precedence, if they would be compromised by an ASR activation. How could that happen? Well, suppose a driver were close to WOT in a turn. Under the right circumstances, the inside wheel, lightened somewhat of its load by the centrifugal weight shift, could begin to slip under the drive torque. If the ASR system merely applied the brake at that wheel enough to slow it to the traction-retention speed, that could leave enough engine torque left over, torque now available through the open differential to the other, loaded drivewheel, to suddenly break its connection with the pavement. Now instead of a mere acceleration-traction slip, the driver would have to deal with a rear end instantly coming around, racing the front of the car for the guardrail you hope is out there.

For that matter, there are limits to desirable traction for any vehicle. Which would you rather have, a gradual slide of the car once you get to the extremes of a turn and the limits of tire adhesion, or so much traction that the car rolls over, instead? That answer is obvious, but the answer to every other conceivable traction questions is not necessarily so obvious. Yes, Mercedes-Benz traction-control systems are complicated, but not just because the engineers like complexity (though they do, of course). But instead, because many of the problems the system sets out to solve are themselves so complex.

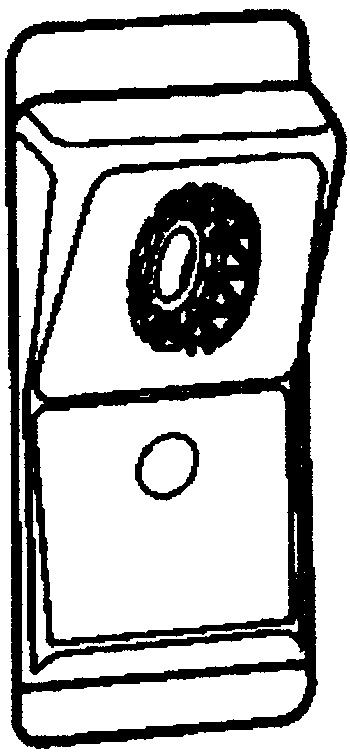

The warning lamps come on as a bulb check

when first starting. Then the warning triangle in the speedometer comes on to signal ASR activation. If the motorist toggles the snowchain switch, the warning light stays on, flashing when wheelslip conditions occur.

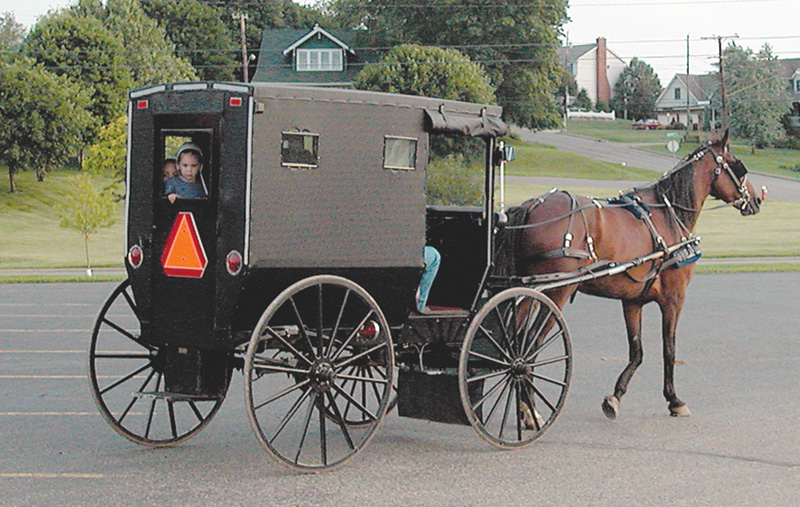

The Amish farmer’s buggy horse, finding several hooves slipping in sequence, corrects for the slip and/or reduces speed, but it uses the entire equine neurological system to do this, a system far more complex than any vehicle wiring harness. As it pe forms similarly complex traction-retention tactics, the Mercedes-Benz ASR system flashes the warning light in the dash to signal a heads-up to the driver. Except in political-ideology fantasies, there are few simple solutions to complicated problems.

ASR begins as does ABS with the wheelspeed sensors, except that ASR requires individual wheelspeed sensors for the drivewheels, while as you’ll recall from our article on ABS a single differential sensor works for the braking system. Additional inputs come from the brakelight switch and the parking brake switch (because you want to toggle ASR off under any and all braking conditions) and over the data bus from the engine controls. The system includes the control unit, in the control unit compartment by the bulkhead on most cars, and the hydraulic unit, mounted in the front left area of the engine compartment in most vehicles.

All the traction-control systems function to begin with from the wheelspeed sensors input data. ASR uses sensors for both rear wheels, not just one at the differential, because it must identify which rear wheel slips to apply braking to the slipping wheel. The sensors are essentially the same inductive pickups used for all traction-control systems.

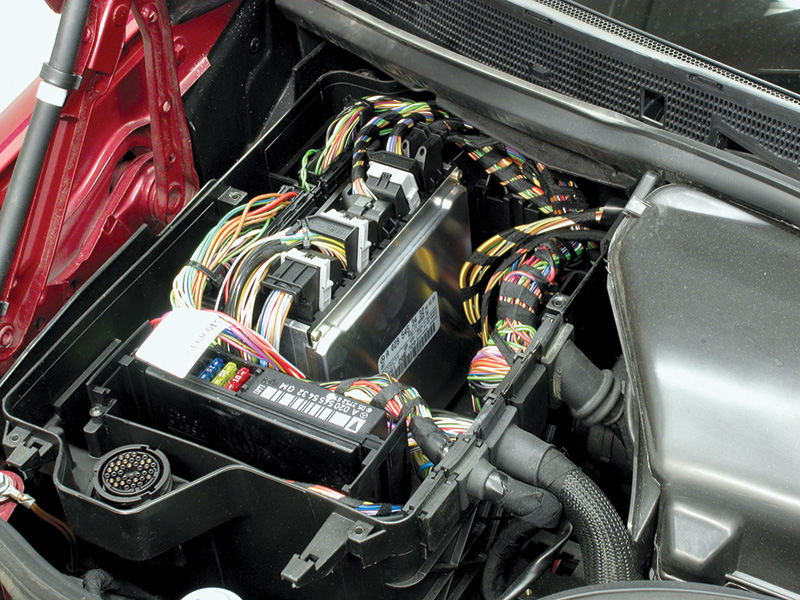

The electronic control unit connects to all the sensors and all the actuators through the harness, as well as to the voltage supply, usually through the overvoltage protection relay (some are different, though). The hydraulic control unit has six hydraulic lines, two from the master cylinder and one to each of the wheel cylinders. It also houses the electric motor and hydraulic pump to provide pressurized brake fluid in sufficient quantity to actuate drivewheel brakes as needed. Power for the electronic control unit comes through the overvoltage protection relay.

ASR is integrated with ABS, so in important respects they’re one system. However, it is possible for ASR to fail in a way that leaves ABS fully functional. The contrary is not possible, though. Anything that disables ABS also disables ASR. This results from the structure of the two related systems: ABS is fundamental; its sensors form the core, and its actuators can reduce the pressure applied at any brake caliper depending on conditions. If something in the pressurizing system fails, that could leave ABS unaffected, while it disables ASR. The MIL for each system reflects this: The ASR MIL can come on alone; the ABS only in company with ASR.

Since it controls individual drivewheels, ASR requires individual wheelspeed sensors for each of the rear wheels. Early systems fit the sensors in the differential on either output flange; later versions carry the sensor through each wheel’s backing plate.

ASR application strategy changes through three phases. Straight ahead, up to a speed of 40 km/h (25mph), the system will first apply a brake to a slipping drivewheel. If two drivewheels slip, it will apply both brakes. If there is still drivewheel slip, the system will reduce engine torque output until the slip ends. The system determines there is slip by comparing the drivewheel speed as reported by the drivewheel speed sensors with the front, driven wheelspeed sensors. If the first are turning faster than the second by a certain percent, that represents drivewheel slip, and the system begins its countermeasures.

Above the speed of 40 km/h (25 mph), the system reverses the sequence of countermeasures. First it reduces engine torque output; then it applies braking force to a slipping wheel. The reason for the difference is to maximize traction up to 40 km/h (25 mph) and to maximize directional control above that speed. The third ASR phase is in turns above 12 mph. In this phase the threshold for wheelspeed differences is greater, as you’d expect, but the drivewheel slip countermeasure strategy is exactly the same as in the second phase, drive torque reduction first, brake application second.

The electronic control unit for most ASR systems resides in the compartment on the passenger side of the bulkhead in most vehicles. Electronic control units are generally very reliable components, so if your diagnosis points toward one, be sure to inspect the wiring harness throughout the traction control system, not excluding the connection pins. Impact damage where the harness runs along the lower edge of the fender or corrosion damage from saltwater, leaked or spilled vehicle fluids, can all result in problems that mimic control unit failures.

The reasons for preferring traction over stability for the lower vehicle speeds is that getting stuck is more likely and spinning out of control is less so, and vice-versa for the higher speeds and turns. An added benefit for the higher speeds is that engine torque reduction can occur much faster than brake application. While it does take some time to close a throttle, actual torque reduction can occur with the next power stroke by retarding the spark advance. The control units are internally much faster than any mechanical events in the engine, so they can finish their calculations and exchange information between power strokes, even at relatively high engine speeds. Since all of the vehicles with ASR also employ the electronic accelerator (‘drive-by-wire’), the system quickly reduces the throttle setting as well, but this obviously can’t occur as quickly as spark retard for the next power stroke.

Besides the wheelspeed sensors, ASR has input also from a number of switches. The brake and parking brake switches disengage any ASR action with the slightest movement of the brake pedal. After all, you don’t want drivewheel traction control if you’re trying to stop or park.

The system includes a snowchain switch on the dashboard. If toggled, this switch disengages the engine torque reduction function of ASR, but not brake activation. It also selects slightly higher slip thresholds after a fractional-second delay. When the switch is pressed, the LED in the switch comes on. If the vehicle accelerates beyond the upper speed threshold for the snowchain function (about 40 mph), the subprogram shuts off. On later versions, the warning triangle in the center of the speedometer comes on and begins to flash under circumstances when the system would have engaged the engine torque reduction if the switch had not been on. Brake activation works normally throughout the event, except for the extended spin threshold. The reason for this curious exception to ASR operation is to allow the drivewheels to spin to some extent in deep snow, mud, gravel and the like. Under some conditions like these, tires with snowchains (or sometimes just tires alone) can profitably mill away at the snow or mud to let the vehicle get underway.

The system includes a snowchain switch on the dashboard. If toggled, this switch disengages the engine torque reduction function of ASR, but not brake activation. It also selects slightly higher slip thresholds after a fractional-second delay. When the switch is pressed, the LED in the switch comes on. If the vehicle accelerates beyond the upper speed threshold for the snowchain function (about 40 mph), the subprogram shuts off. On later versions, the warning triangle in the center of the speedometer comes on and begins to flash under circumstances when the system would have engaged the engine torque reduction if the switch had not been on. Brake activation works normally throughout the event, except for the extended spin threshold. The reason for this curious exception to ASR operation is to allow the drivewheels to spin to some extent in deep snow, mud, gravel and the like. Under some conditions like these, tires with snowchains (or sometimes just tires alone) can profitably mill away at the snow or mud to let the vehicle get underway.

Keep in mind with all Mercedes-Benz traction control systems employing wheelspeed sensors that you should install snow chains on all four wheels, not just the drivewheels. Otherwise the system can set a sensor fault and toggle itself automatically off.

Rear pad wear sensors are necessary with ASR because a driver who frequently calls on the traction control feature has to consume brake pads faster than a more conservative motorist. Later versions have only one sensor.

Because ASR actively employs the drivewheel brakes, cars with that system have rear brake wear sensors except for the first year for the option. Early systems use four wear sensors; later versions use one. These wear sensors can trigger the brake lining warning, but they won’t set codes or disengage the ASR system itself, even if pad wear is excessive.

Early versions of ASR depend on the pressure reservoir for the brake pressure required for brake activation. Later versions employ a pump of greater capacity and do without the reservoir. The pressure reservoir is behind the trim panel on the driver’s side fender. A pressure sensor switch turns on the pump when the reservoir needs recharged.

All of the traction control systems employ electric motor pumps to build the brake fluid pressure required to activate the brakes during ASR activations.

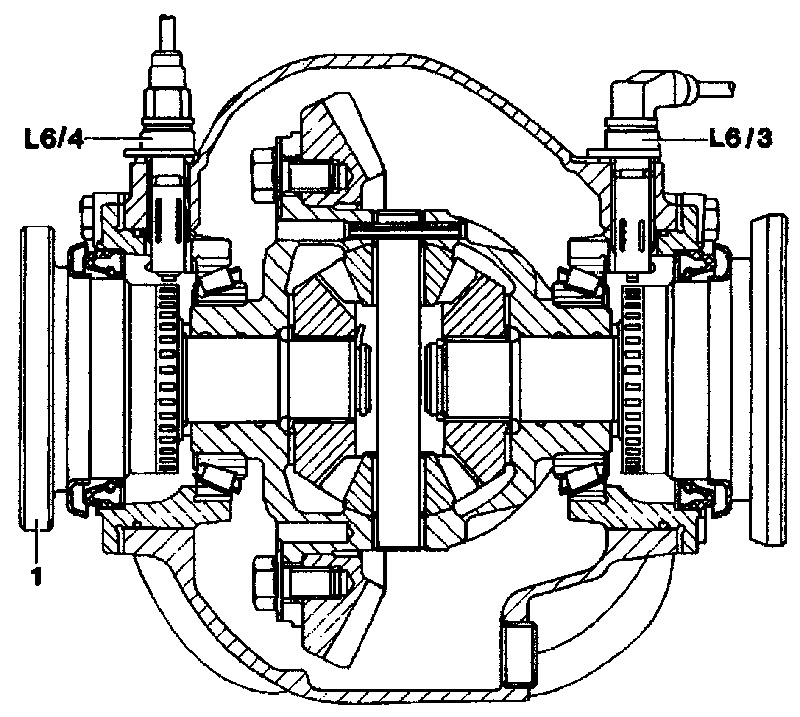

There are actually three pumps with two electric motors. Both motors and thus all three pumps run at the same time. One pump, often identified as M15 in the carmaker’s technical literature, is the pressurizing pump. This pump can be in the lower trim panel with the reservoir or near the master cylinder. It builds ASR system pressure up to 1.8 to 11 bar. The second, the return/charge pump in the hydraulic control unit is two pumps in one (the charge portion being reduction geared for higher pressure). That second pump provides return fluid flow for ABS events as well.

ASR uses the same three pressure modes as does ABS: pressure buildup, pressure holding, pressure reduction. The major difference is that in ASR the brake fluid pressure can be greater than what flows from the master cylinder when the control unit directs pressure to specific wheel calipers.

The pressure reservoir uses a spool-shaped piston in a cylinder (See the diagram on page 25). Nitrogen gas at about 100 bar forms the initial charge. You may recall in the last StarTuned we pooh-poohed the idea of using nitrogen to inflate tires because the likelihood of significant moisture in a tire is so low. The nitrogen gas chamber of the pressure reservoir, however, is another matter. It would be unreasonable to take even the slightest risk of allowing trace moisture – and thus rust – anywhere inside the brake system’s hydraulic system.

A hydraulic test of the system checks the pumps and the pressure reservoir. Use only a pressure gauge employed only for brake pressure measurements, specifically not a Diesel injection pressure gauge. The very last thing you want any trace of in a brake system is mineral oil. First, release the pressure in the reservoir as described in our sidebar on brake bleeding (page 25). Then monitor the pressure increase. The charging pump should build somewhere between 1.8 and 11 bar. That may seem like a wide threshold, but the purpose of this gerotor pump is to supply volume, not pressure, so the specifications are right. Then observe the pressure buildup in the reservoir. If there is no pressure buildup or if it takes longer than 60 seconds, you have a pump that is not performing satisfactorily. If the pressure reservoir is defective, either the pressure rises quickly to 50 bar and then slowly up to the maximum or quickly and constantly up to maximum.

The working pressures for the system, the points at which the dual pump (a ‘quill’ pump familiar from ABS) should turn on and turn off, are approximately 160 and 180 bar, requiring about 30 to 50 seconds for the recharge. It may seem odd to have such high pressures since they are seldom or never applied to a brake caliper, but because of the incompressibility of brake fluid (of fluids in general, in fact) pressure application is nearly immediate when a solenoid in the control unit changes state. Not much actual fluid flow is required for the activation, so what the system really needs to store is pressure – hence the 180 bar.

ASR also employs the engine management system to retain torque. Early systems control only the throttle position; later versions (from ASR III on) can retard spark as well. Obviously, this means we’re talking about cars with one or another form of drive-by-wire, so the ASR unit can send instructions to the engine management computer to close the throttle. The telescoping rod in the linkage to the accelerator pedal accommodates any difference between what the driver wants the car to do and what the traction conditions allow. Ordinarily, if there is a disabling fault in the electronic accelerator system, that will also disengage the ASR, triggering both warning lamps.

The very earliest ASR systems had no self-diagnostic capacity, so if there was something wrong with the mechanism you had to test individual components mechanically, hydraulically or electrically. After that you can extract trouble codes with the impulse counter, Hand-Held Tester or the equivalent. Keep in mind, as always, that trouble codes point to suspect circuits, not components. If you just replace the part corresponding to the code, you’ll replace some functional elements.

Thanks to the parts and service crew at Mercedes-Benz of Bedford (Ohio) for their cooperation in these and many earlier photos.

German-English Alphabet SoupWith all the traction-control acronyms, it’s easy to confuse the corresponding but different Mercedes-Benz traction-control systems. Where available, we’ve included the German-language description, but we should tell you that, while German does make long compound words by joining several shorter words together, it does not capitalize, boldface or italicize individual letters in the middle of words – we’ve done that here just to highlight where the acronym comes from. Sometimes, too, the official translation is not a literal one; sometimes there’s more than one official translation, depending on how many cooks were stirring the soup. Finally, Mercedes-Benz sometimes uses an English name for a system even in the original German technical information. Ah well, cut ‘em some slack – they’ve only been at this for 117 years or so. Some non-traction-control subsystems, like the speed-sensitive power steering on Model 140, also fall under the traction-control system purview because the sensors and microprocessors are already there, so a cost-savings results from including them. For that matter, once everything connects to everything else on a data bus, there’s really only one system, anyway, whether you’re talking about the radio or the turn signals or the ignition timing or the courtesy lights. ABS (AntiBlockierSystem) prevents wheel lockup during braking. This retains steering and directional stability while optimizing braking performance. ABS works by reducing or releasing brake hydraulic pressure at the wheels once the system recognizes the beginning of lockup. In most circumstances, ABS increases the effective braking performance (that is, reduces the braking distance), but not in all: It retains steering and directional stability first and only then improves braking. Read your last issue of StarTuned for much more on ABS. ASR (AntriebSchlupfRegelung) prevents drivewheel slip during acceleration. Preventing drivewheel slip also retains steering and directional stability while optimizing acceleration traction. ASR works by either braking slipping drivewheels or reducing engine output torque, depending on the circumstances. ASR can get you going on a very slippery surface when no amount of delicate work with the accelerator coupled with brake-pedal feathering to control wheelspin will do the job. But it’s not magic. The facts of physics still control the extent of movement: If you’re floating on the bellypan in gumbo mud and spinning your drivewheels in cloudy swampwater, you’re probably going to stay there until the tow truck arrives, ASR or no. BAS, the brake assist system, is related to the traction control systems proper but is somewhat different. Through a sensor that reports the speed of brake pedal movement (actually the speed of the vacuum booster diaphragm movement), its control unit identifies emergency braking situations and, by venting atmospheric pressure to the rear of the booster diaphragm, applies full braking power immediately in such circumstances. This system was developed after Mercedes-Benz researchers discovered that in most such stopping emergencies people apply the brakes quickly enough, but too tentatively, with insufficient force, as though fearing to lock the wheels up. With an ABS system, of course, you’re not going to lock up the wheels by stamping on the pedal, so an emergency situation calls for full-forcebraking from the very first instant to reduce vehicle speed as quickly as possible, beginning as far from the location of potential impact as possible. Traction control comes into play with the now almost routine prevention of brake lockup through the ABS system. BAS exploits the safety margin of ABS when it senses the emergency stop and applies full braking at once. Depending on the vehicle speed, traction conditions and so on, this can shave as much as 30 feet off the braking distance to a standstill. In many emergencies, that could mean no accident would occur at all. In others, it means the force of the impact is much lower. EBR or MSR (MotorSchubRegelung), Engine braking control, prevents wheelslip at the drivewheels caused by engine braking under deceleration. You sometimes find this system described as “overrun control.†The major purpose of this part of ASR or ESP is to retain steering and directional stability when the driver lifts a foot off the accelerator pedal in a fast turn, though it also works to prevent deceleration drivewheel slip (and thus retain directional stability) in a straight line. EBR works by opening the throttle when engine braking threatens to make a drivewheel slip in a turn. For most Mercedes-Benz vehicles, that throttle opening by EBR/MSR is limited to 17 or 18 degrees of throttle opening, more than enough to reduce the deceleration vacuum and increase the engine torque output sufficiently to let the wheels grip the pavement. On Diesel engines, the engine braking control subsystem increases the amount of fuel injected, though you’ll recall from our previous articles on Diesel engines that there is not much inherent engine braking in a Diesel engine since there are no significant pumping losses, the source of engine braking. In reverse gear, below 20 km/h or if the transmission control system fails, engine-braking control shuts off. ASD (Automatisches SperrDifferential) prevents or reduces drivewheel slip by locking the differential so the axles turn at the same speed. This relatively infrequent option appeared mostly on smaller gasoline engines and Diesels before ASR, ESP and later traction-control systems. ASD does not include any special measures to prevent the simultaneous slip of both drivewheels, though the physics of friction and the limits of the available torque from the smaller engines help in that respect. 4MATIC is the first of the all-wheel-drive systems, connecting all of the wheels together with front and rear drivetrains connected through a transfer case. 4MATIC prevents drivewheel slip by selectively locking rear or center differentials to direct engine torque to the wheels with the most traction. The system also unlocks all the differentials for ABS operation, to prevent one wheel with traction from forcing another without to slip through the locked differential they share. Again, the system provides an impressive increase in traction. ETS (Elektronisches TraktionSystem/electronic traction system) and 4ETS systems are the successors of ASD and 4MATIC, achieving through selective brake applications the same effects as differential lockup in ASD and in 4MATIC. All-wheel-drive, of course, maximizes traction up to the limits of the tires’ physical adhesion to the pavement during acceleration. Instead of achieving drivewheel traction by locking the differential, however, it works by braking the slipping wheel. This amounts to achieving the same level of control at significantly lower production cost, and avoids the need for the now-redundant differential lockup clutches and hydraulic system. ESP (Elektronisches StabilitätsProgram/electronic stability program) is the latest and most complex of the Mercedes-Benz traction control systems, though there are more and even subtler systems in the pipeline. Its function is to prevent loss of traction from over- or understeering. With additional sensors to report yaw movement and lateral acceleration and through control of individual wheel brakes as well as engine torque output through the electronic accelerator system (‘drive-by-wire’), ESP keeps the vehicle going or turning in the direction the driver indicates with the steering wheel, up to the limits of tire adhesion. If the front wheels slip sideways, the ESP system brakes the rear wheel opposite the slip; if the rear wheels slip sideways, ESP brakes the front wheel toward the slip. In each case, the ESP braking works the way right and left handbrakes do on a bulldozer or tank, pivoting the vehicle toward the braked side. With ESP, we’re getting very close to the limits of what kinds of traction controls are even possible. Further developments will surely involve radar-like sensors of surrounding objects and systems that may even overrule the driver’s input in the interests of safety and stability. |

0 Comments