Those generics out there that claim to meet most automakers’ specs aren’t what the Stuttgart engineers and chemists had in mind when they designed the cooling system

“Perfect togetherâ€: Mercedes-Benz anti-freeze coolant and distilled water in a 50-50 mixture in the cooling system. An aftermarket brand that meets the Mercedes-Benz specification and/or deionized water will give the same good protection.

Changing the anti-freeze/coolant in a Mercedes-Benz vehicle, or even topping up the reservoir, is a straightforward procedure. But picking the right anti-freeze to use is not so straightforward. There are many anti-freezes on the market, and most are advertised as compatible with all others in all cars. StarTuned would like to tell you why not to use just any anti-freeze in a Mercedes-Benz, even if it’s a reputable brand.

You may be thinking, “Mercedes-Benz is just trying to sell its own approved anti-freeze. It’s just another one of those not-invented-here things.†Sorry, but that isn’t true, and we think we can explain — and hopefully convince you — to use either Mercedes-Benz’s own anti-freeze, or only an aftermarket equivalent that meets the current Mercedes-Benz specification. This is particularly true today, when most of the anti-freeze aftermarket brands you’ll find are very different in important respects.

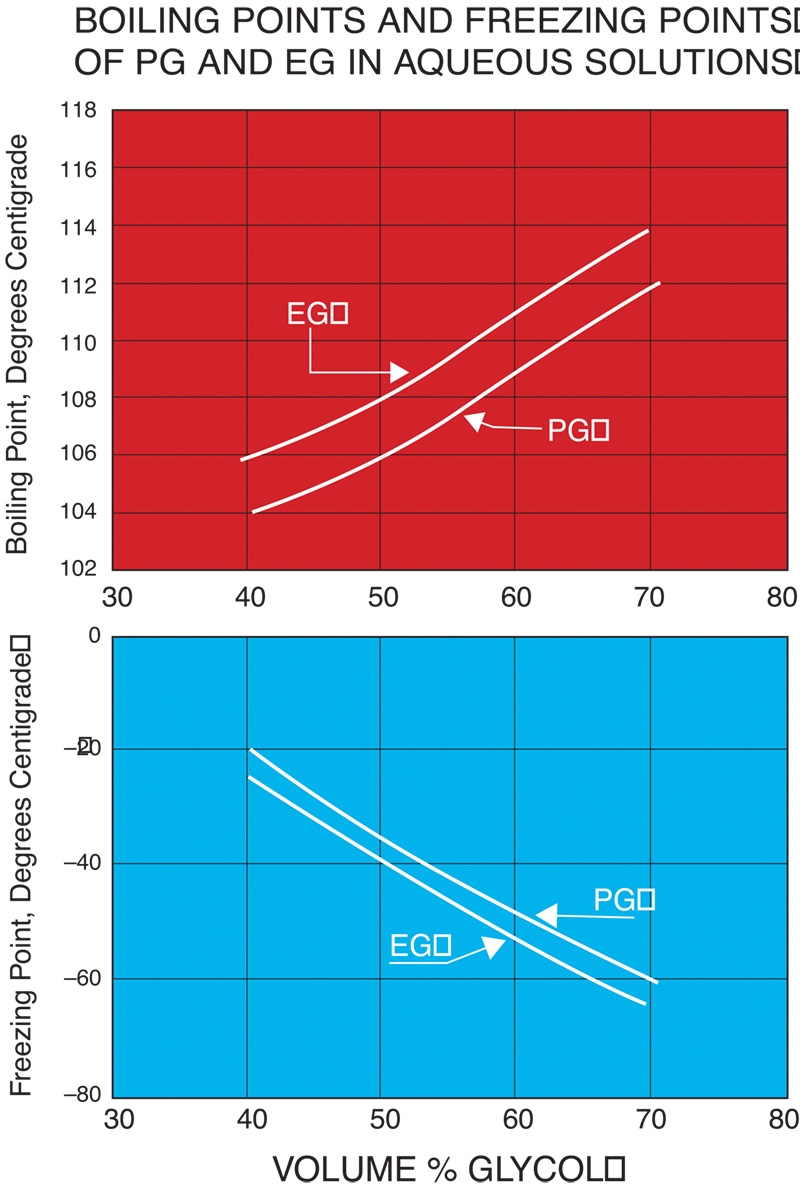

Charts show boiling and freeze points of anti-freezes in a 50-50 mixture with water. Note that EG (ethylene glycol, the glycol used in most anti-freeze) has a slightly higher boiling point and a slightly lower freeze point than PG (propylene glycol). At concentrations above 70% anti-freeze, the freeze point of the coolant actually starts to rise, so more anti-freeze is not better. The 50-50 mixture provides the best combination of freeze and boilover protection, and good heater transfer from the engine.

First, let’s explain that because Mercedes-Benz vehicles are marketed worldwide, the manufacturer must make allowance for great differences in water quality. The coolant in an engine normally is a 50-50 mixture of water and anti-freeze, and the water both improves heat transfer at high temperature, and lowers the temperature at which the coolant will freeze.

Water quality not only affects the rust/corrosion inhibitors in some anti-freezes, but it may contribute to electrolytic corrosion in the cooling system, which can produce deposits that affect coolant flow and heat transfer. And if the water is very hard, certain anti-freeze inhibitors — particularly phosphates — may react with the calcium and magnesium (and even iron) in hard water to produce deposits that add to the coolant flow and heat transfer problem. See accompanying report: “When to Use Tap Water in a Cooling System, and When Not Toâ€.

A refractometer provides the most consistently accurate indicator of freeze protection of a coolant mixture, and should be used by a professional technician, instead of a hydrometer or test strip.

Mercedes-Benz anti-freeze is formulated without phosphate inhibitors that produce these particular concerns about deposits. Does that mean you can use any anti-freeze without phosphates? You shouldn’t, even in areas without a hard water problem, because the factory fill already has established a specific type of rust/corrosion protection mechanism. A different type of rust/corrosion inhibitor package will not continue with that form of protection and might even cancel out protection.

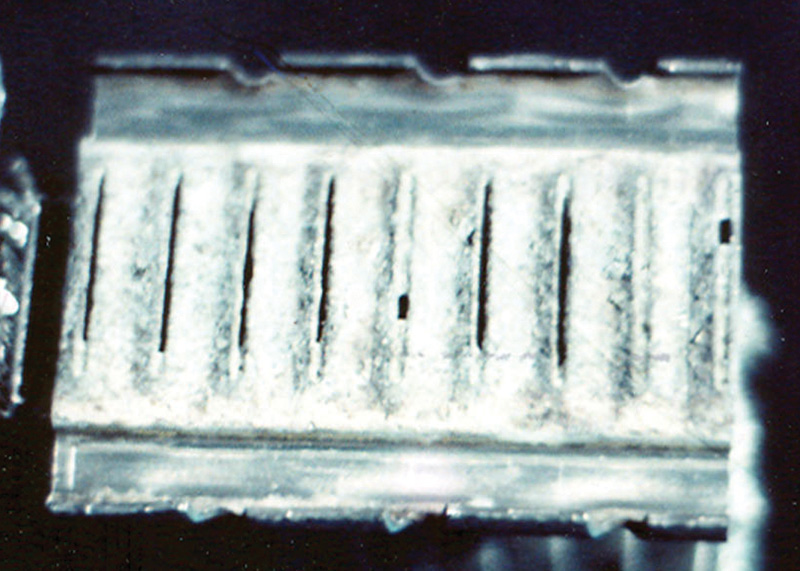

Excessive electrical activity in the coolant produces electrolysis damage – corrosion that restricts coolant flow through the radiator and heater core.

Consider a situation in which the amount of each different inhibitor package is split, from use of two anti-freezes with different rust/corrosion protection mechanisms, so that each is under 40% of the coolant (as low as 25% even with a 50-50 concentration). Neither inhibitor package may be strong enough to provide its normal type of protection.

Further, Mercedes-Benz is the only passenger car/SUV manufacturer to build into the cooling system a slow-release protection device, that on some late-models permits a 15-year, 143,000 or 150,000 mile coolant replacement interval. The protection device — a packet of silica gel in the coolant reservoir — is designed to work with a Mercedes-Benz specification coolant, and not others. And that’s not just a claim. We’ll be very specific. (Note: That new service interval has not been extended to all models yet, and it should not be applied retroactively to older models).

Fifteen years/143,000 or150,000 miles? That must be one of those new anti-freezes you’ve heard about, that are used in other manufacturers’ vehicles. No it isn’t. And despite anything you read about “compatibility,†these new anti-freezes are not approved for use in Mercedes-Benz vehicles, for specific technical reasons. So you understand the technical basis for these different anti-freezes, a brief technical summary of what they are follows.

| WARNING: Contains ethylene glycol (107-21-1), diethylene glycol (111-46-6), sodium 2-ethyl hexanoate (19766-89-3), and sodium neodecanoate (31548-27-3). PRECAUTIONARY MEASURES: Do not drink anti-freeze or solution. Do not beathe mist or vapors. Avoid prolinged exposure. Avoid skin and eye contact. FIRST AID TREATMENT: If swallowed, do NOT induce vomiting. IMMEDIATELY call a Poison Control Cnter or hospital emergency department. If breathing is affected, move into fresh air. If in eyes, rinse thoroughly with water for 15 minutes. If on skin, remove contaminated clothing and wash skin well with soap and water. If irritation develops and persists, call a doctor. Ethylene glycol causes birth defects in laboratory amimals. Solution is poisonous to animals. KEEP OUT OF REACH OF CHILDREN |

But first, a couple of preliminary points:

All original equipment anti-freezes and most aftermarket brands are about 93-95% ethylene glycol, about 3-5% rust/corrosion inhibitors, plus about 2-3% water and/or solvent (required to keep the rust/corrosion inhibitors in solution in the container and as the anti-freeze is poured into the system)—and a leak-trace dye.

A few aftermarket anti-freezes are made with propylene glycol, which often is promoted as a less-toxic chemical, but which is not quite as effective at freeze protection. So when an anti-freeze producer says his product is “compatible†with all original equipment anti-freezes and other aftermarket brands, he’s basing this on his own laboratory tests, which simply identify a possible “battleground†issue. That is, when chemicals are “incompatible,†there is quick metal damage that shows up.

However, “compatibility†doesn’t mean equal protection. Even if an anti-freeze works well in one make of vehicles, it doesn’t mean it will work well in all others, as we’ll explain when we talk about the different types of rust/corrosion inhibitor packages.

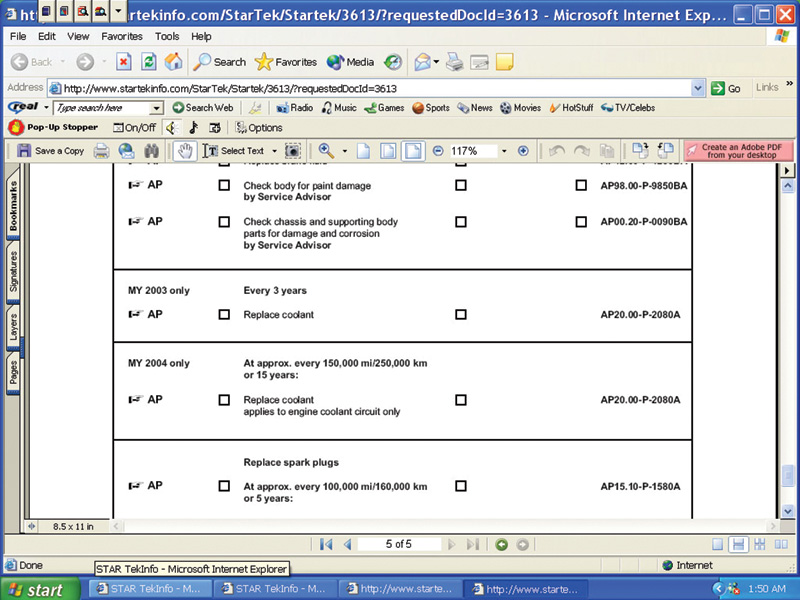

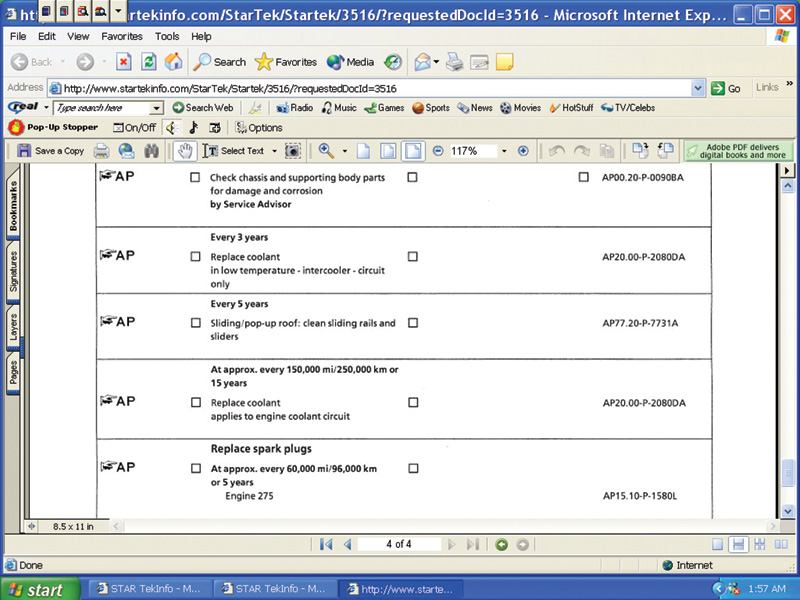

Section of a Mercedes-Benz maintenance chart. Note that the “replace coolant†interval is 15 years or approximately 143,000 miles. The mileage interval is as high as 150,000 miles on some vehicles with the long-life recommendation, based on the scheduled maintenance interval.

You also should understand that the leak-trace dye simply identifies a leak. It does not tell you the type of anti-freeze. The most popular anti-freeze colors are green (various shades), yellow/gold, orange, blue, red and amber. In some cases, the colors were chosen by the anti-freeze producer to differentiate a change to a different formula, but not necessarily a specific one. In others, the color was picked because it was considered unlikely to be confused with fluid leakage from another component (washer fluid reservoir, transmission, power steering, etc.). Mercedes-Benz anti-freeze presently is dyed yellow/gold, but so are anti-freezes with totally different formulas and rust/corrosion protection mechanisms. The bottom line: ignore dye color.

Anti-freeze inhibitor packages are classified as “conventional,†and “extended life.†The service interval for “conventional†typically is 2-3 years and/or about 24-40,000 miles. To date, extended life may be “moderately extended†(3-4 years) or five years or more, and up to 150,000 miles. Mercedes-Benz, as noted with its 15-year/150,000-mile interval, has broken new ground.

Rust/Corrosion Inhibitor Packages

You don’t have to be a chemist to understand the rust/corrosion inhibitor packages. All you should do is note the ingredients, see that they differ and realize why Mercedes-Benz anti-freeze protection mechanism truly is different, and the reasons why.

“Conventional greenâ€: The inhibitors are sodium silicate and phosphate, both proven protectors for aluminum, plus benzoate and borate (broad-range metal protection) and a “triazole,†one of a group of inhibitors that protect copper-brass, plus an inhibitor that protects cast-iron.

“Japanese†green or red “conventionalâ€: It typically contains phosphates and benzoate, a triazole; plus molybdate (cast-iron protection) and nitrate (a specific type of aluminum protection). It contains no silicate.

Organic acid technology/extended life coolants (called “OATsâ€): Although benzoate is an organic acid, it is not used in an exclusive package with other organic acids in an OAT. The organic acids used in American anti-freezes include one 2-EHA, among others (such as sebacate and neo-decanoate). They contain no silicates and no phosphates. Japanese OAT anti-freezes do not use 2-EHA but they do contain phosphate. Note: 2-EHA (2-ethylhexanoic acid) is a “plasticizer,†which means it softens plastics. Gaskets are made with plastic and there have been laboratory tests reported by other manufacturers, that raise concerns about coolant-sealing gasket leakage with 2-EHA.

Mercedes-Benz type hybrid: Originally developed to work well with both diesels and gasoline engines, this anti-freeze uses a low-silicate formula. It also contains benzoate and borate, plus benzo-triazole for copper-brass protection, nitrate and nitrite (protects cast-iron liners in diesels). It was demonstrated to be a robust formula that would work for extended intervals, and with Mercedes slow-release “refreshment†of the coolant, capable of long life in a well-maintained system.

It’s the Mercedes-Benz cooling system itself — the metallurgy, the gasket materials, the flow pattern of the coolant plus the use of the silica gel packet — that combine with the field experience to assure that a particular anti-freeze is the right choice.

The long-term validation of the Mercedes coolant in a Mercedes cooling system avoids the need to deal with the concerns about OAT coolants. Why would you want to take a chance with anything other than the Mercedes-Benz recommended hybrid type? If you buy your anti-freeze from an aftermarket source, use a reputable brand that meets current Mercedes-Benz formulation, typically labeled a G-05 coolant. We bought Mercedes-Benz authorized anti-freeze from a Mercedes-Benz dealer, and the list price was only a dollar and change more than the price of national brand anti-freezes in an auto parts store.

Note: some anti-freeze suppliers claim their products meet specifications of all manufacturers, and provide a long list of manufacturers’ specifications their products meet. However, over the years all vehicle makers have used a number of different specifications, not all of them current. The list may not apply to the models you’re working on, so be cautious.

Anti-freeze producers also may claim that if you drain the cooling system, you avoid any performance issues when you switch coolants. However, this is not necessarily true in a Mercedes, where specific protection has been established with silicate inhibitor and the system is designed for continued “refreshment†from the silica gel. Further, it is very difficult to completely drain the modern cooling system in all cars, although use of good coolant changing equipment should remove about 90%. So long as the new coolant is the same type as the old, there’s no question about its performance.

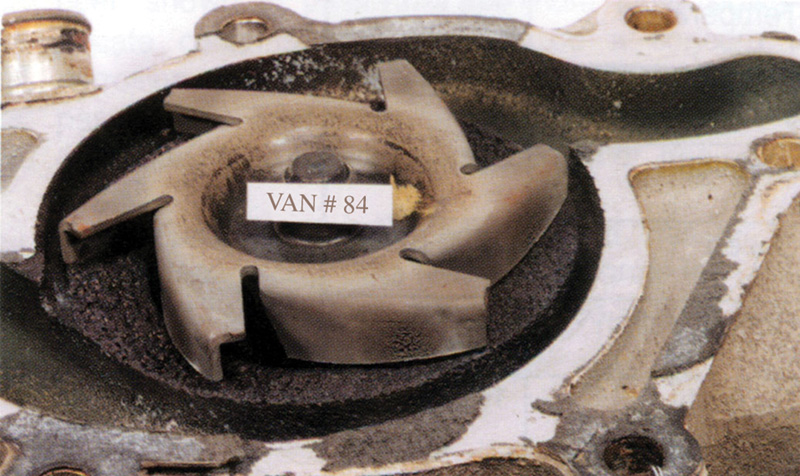

This coolant pump chamber was pockmarked by cavitation erosion-corrosion, which would eventually reduce performance of the pump.

Why some ingredients and not others?

Seven times multiplication of the coolant pump surface clearly shows the pockmarking that leaves metal unprotected, and subject to corrosion.

Both silicates and phosphates work very quickly, and are very effective in protecting aluminum, “painting†the cooling system surfaces with an anti-corrosion coating. Silicates also are regarded as a harder coating, and not a problem in hard water, so they are the Mercedes-Benz choice for primary protection.

The speed of protection is important. Not only do silicates work quickly in new engines, but also to protect new parts that are installed, and in a situation called “water pump cavitation erosion-corrosion.†Under some operating conditions (particularly high temperature, high-load), the coolant may form low-pressure bubbles as it’s drawn into the water pump, and these bubbles collapse as they flow through the pump chamber. The collapse occurs with explosive force, chiseling and pockmarking the pump surfaces protected by the anti-freeze inhibitors. This eroding of the surfaces of the pump chamber exposes unprotected “bare metal,†which corrodes. The long-term effect: deterioration of water pump performance, leading to overheating and in winter, to poor heating performance from low coolant flow. That’s why Mercedes and many other vehicle manufacturers rely on silicates.

By contrast, OAT coolants may take 5,000 miles to protect a metal surface. Although OAT coolant inhibitors are very long-lasting (hence their use in extended-life anti-freezes), their slowness to protect is a problem when there is cavitation erosion in the water pump.

However, silicates are “used up†in providing protection throughout the cooling system. This is not in itself a problem, so long as the “painted†silicate protection is maintained. However, as noted, some silicates continue to be needed for extended service, to perform such functions as water pump internal “repair†protection.

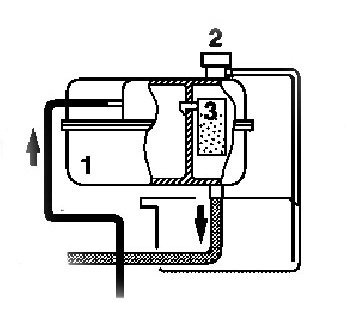

Although most manufacturers have recognized silicates’ advantages, others were apprehensive about using a high-silicate formula to get long-term protection from it. Mercedes-Benz has been using the silica gel in a meshed-plastic container inside the coolant surge reservoir for many years to gradually “refresh†the silicate content over a period of years.

You may be wondering about the use of silica gel, which is well-known as a desiccant (to absorb moisture) in many packaged goods exposed to ambient humidity, and even in some older automotive air conditioning systems.

However, in a coolant reservoir, it works differently, by absorbing enough coolant to establish a “balance†and dissolve very slowly to replace silicates used up to protect metal surfaces in the cooling system. The silica gel packet gradually adds a very tiny amount of silicate inhibitor to the coolant over the years, reaching a “plateau†in the coolant.

You don’t have to replace the silica gel. In fact, laboratory tests show that even after many years, most of the inhibitor remains in the gel, still available to add protection. An anti-freeze chemist described it as a “silicate trust fund.†Actually, the concept is somewhat similar to the use of time-release additives in the coolant filters of some “big rig†(Class 8) diesel engines.

Anti-freeze inhibitors have different metals to protect, so the Mercedes-Benz formula is totally-balanced to protect them all. To be able to extend the service interval from three years (still the service interval on some new models and all older ones), Mercedes has re-engineered components as required. That’s why the service interval was increased so dramatically only after both re-engineering of cooling system components and the long period of field and laboratory experience with the silica gel “refreshment.â€

Section of a Mercedes-Benz maintenance chart for the SL. Notice that this one lists a three-year coolant replacement interval for 2003. The 15 year/150,000 mile interval only applies since 2004 model year, as explained in the listing that follows.

Mercedes-Benz coolant service intervals

Mercedes-Benz with its hybrid coolant has long been able to recommended a moderately-extended service intervals of three years, 50% longer than with conventional coolants. After cooling system re-engineering and testing, plus the rust/corrosion inhibitor refreshment by the silica gel packet, the interval has been extended to 15 years (143,000 or150,000 miles, the variation based on the regular maintenance schedule).

However, the new interval applies only to certain late-models and should not be applied retroactively to older ones.

Further, Mercedes-Benz continues to recommend that the coolant level be checked, and adjusted if necessary,: (using authorized coolant/water mixtures only) at each scheduled maintenance service, which ranges from 10,000 to 13,000 miles or once a year.

There’s also are special situations. One is the 6.0-liter V-12 “bi-turbo†engine, which has a second cooling system circuit (with an electric coolant circulation pump) for the turbocharger intercooler. That circuit still carries a three-year coolant replacement, which should be performed as part of scheduled maintenance. Another is the 2005 SLR McLaren, which carries a four-year coolant replacement interval.

Although the following list of models sold in the United States was drawn from the Mercedes-Benz scheduled maintenance forms, you also can refer to the owner’s manual if you have any doubt about the correct interval. And if you use the Mercedes-Benz technical information website (www.startekinfo.com), you’ll be able to check service literature for any changes.

Section of the Mercedes maintenance chart for the S-Class shows a three-year coolant replacement interval for the “low-temperature circuit,†which is the turbocharger intercooler. The interval for S-Class engines is 15/150.

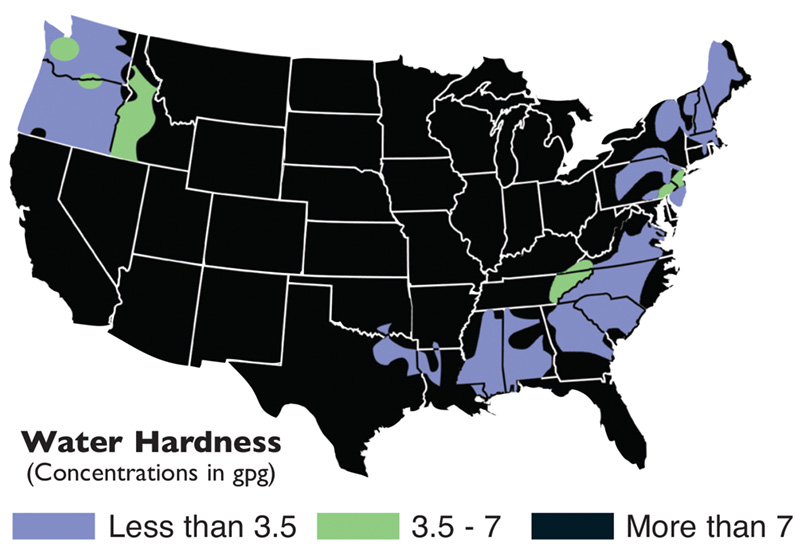

When to Use Tap Water in a Cooling System, and When Not toTap water, even if it’s good enough to drink, is not necessarily good enough for a car’s cooling system. Hard water is the primary issue, and water in the U.S. is generally hard. But what does hard really mean and how hard is too hard? Tap water that comes from underground wells and aquifers may pick up mineral and metallic particles, primarily calcium and magnesium, which are the key ingredients in “hardness.†Approximately 17 parts per million of these particles are the starting point, and any number over 120 ppm is considered somewhat hard. Most household “hard water†measurements are in grains – 17.1 ppm equals one grain, and 7 grains is equal to 120 ppm. In some areas the water hardness is as high as 850 ppm – 50 grains. For automotive use, you wouldn’t want to use anything close to that. In fact, the best policy is to use only water 7 grains (120 ppm) or lower, and the lower the better. Elsewhere in this report, StarTuned notes that Mercedes anti-freeze avoids the use of inhibitors that may cause special problems in hard water. However, don’t take that to mean that using Mercedes anti-freeze prevents any issue with hard water. It doesn’t. Hard water still is not good for any cooling systems, because the minerals and metals may result in deposits that could restrict heat exchangers. In addition, if the water is very hard, metallic particles may contribute to electrolysis failure of automotive heat exchangers. Virtually all coolant is at least slightly conductive. And if you ground a voltmeter and insert the positive probe into the coolant, you’ll find a small voltage–often under 0.1 V. Metallic particles in coolant add to the current-carrying ability of the coolant (equals higher voltage that forces current through the heater and/or radiator to electrical ground to complete the circuit). This electrical activity causes corrosion to form and the corrosive deposits may restrict either or both heat exchangers How can you tell if the water is “soft†enough for use? A simple way is to look at household use of water in your area. The water is hard if laundry requires more than the minimum amount of detergent to clean clothes, if deposits build up in sinks, tubs and washing machines, and if household spray irons and coffee makers plug up and require frequent cleaning. Water test kits are available, or ask a local distributor of water softening equipment to test for you. Or you can pick up containers of distilled or deionized water, sold in supermarkets. For well under $1 gallon, it’s an inexpensive item for which a customer should be willing to pay when you explain the advantage. Distilled water has been boiled to a vapor, which then is condensed, so virtually all of the hardness grains are left in the boiler. Deionized water (also called “demineralized waterâ€) is softened water. The water is passed through a resin bed, in which the calcium and magnesium ions are “exchanged†for sodium. Yes, the salt content of the water goes up a bit, but the water is even lower in content of the hardness grains than distilled water. So it’s suitable for automotive use, too. |

0 Comments