Not quite, but there’s definitely a trend toward replacement. Here’s why…

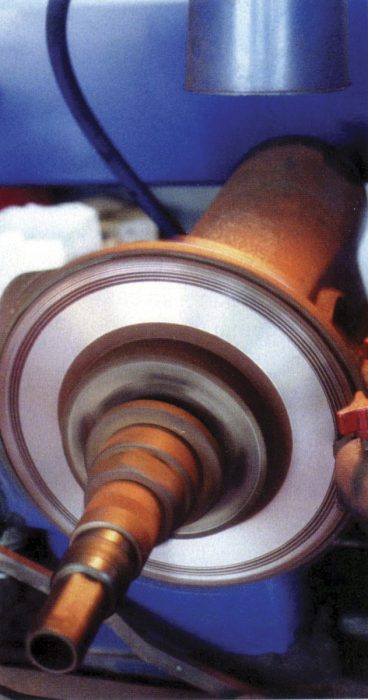

Our brake lathe went in the trash,†a Mercedes-Benz service manager tells Master Technician. A veteran brake trainer says, “Within the next five years, you won’t see a brake lathe in a

shop.†A successful Euro car specialist tells us, “We’ve gotten rid of our brake lathe. The tolerances on late models are so close, any appreciable wear demands that the rotors be replaced.â€

Yup, fewer and fewer professionals in the auto service business are machining discs. They’ve sworn it off in favor of buying new ones. Now that’s a profound change considering that it wasn’t very long ago when every shop in the galaxy automatically turned rotors during a reline providing they weren’t already down to their legal throw-away thickness. That process was supposed to give a nice, fresh face that would break in along with the pads. Well, as Greg McConiga, former NAPA/ASE Tech of the Year and honored colleague at MT, puts it, “We need to take a stand on the old ‘turn ‘em every time’ baloney and tell them that if there’s no runout or DTV (Disc Thickness Variation), and if they’re thick enough, you can’t beat a work-polished rotor surface.â€

Early Glimpse

We were tipped off to this trend way back in ‘97 by a Pontiac TSB. During normal pad replacement, it said, use the discs as-is providing the grooves aren’t deeper than .060 in. If those concentric furrows exceed that limit, replacement is the remedy. And in high-pedal-effort situations, GM wanted you to buy new rotors if the originals have ever been turned. In essence, the biggest carmaker in the world was telling us brake lathes are obsolete.

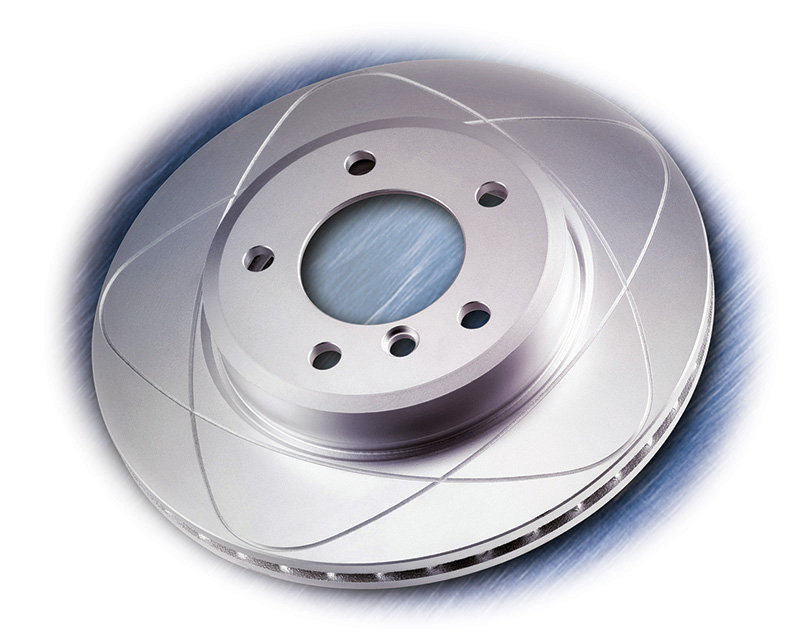

Blasphemy and revolution! But there were two good reasons why this bulletin came down from on high. One, rotors have gotten pretty skinny, and the thinner they get the less able they are to absorb and dissipate all that heat, and to withstand warpage. As one brake company tech trainer tells us, “I agree with the GM recommendation that if the rotors aren’t in bad shape and there’s no complaint, why refinish them? There isn’t a whole lot of extra meat to take off today.†While the notion of “hanging pads†might be offensive to your sense of craftsmanship, just get over it.

Two, noise and hard pedal complaints and prematurely worn-out linings are very common with some of the brakes out there (the big company was having lots of trouble with friction formulas in those days). The factory service engineers believe these problems are promoted and compounded by poor machining procedures that leave a rough or inaccurate surface. Also, it’s been proved that discs should be as smooth as possible in order to produce maximum stopping power, and sloppy turning will actually make a rotor rougher than it was when it came off the car.

So that leaves replacement, which, besides being fast, amounts to a profitable parts sale for the shop. That doesn’t mean, however, that there are never cases where machining is appropriate, as we’ll explain.

Wobbly

But installing new discs isn’t necessarily a guarantee that you won’t get a repeat pulsation complaint. As Wally Marciniak, Manager of Technical Services for Affinia Under-Vehicle Group (Raybestos brand, www.raybestos.com), puts it, “A lot of people assume that just putting new rotors on will eliminate the problem. But you need to clock them in to get the least possible runout. Check and record runout in all of the possible mounting positions, and use the one with the least. The true runout of any rotor is when it’s tightened down on the hub.†Most authorities say you shouldn’t have over .002 in. of wobble, while others say .001 is the limit.

A neat way of reducing runout to just about nil is to use tapered shims, such as those made by Brake Align (www.brakealign.com), between the disc and the hub. Of course, you already know that you’ve got to get those hubs as clean as possible so you don’t get a mounting error.

Chain of Events

You may be asking, “Floating and sliding calipers should just ride with runout, so what’s the big deal about some wobble?â€

Aha, there’s a trick to it, something that many people don’t understand: When it comes right down to basics, the direct cause of pulsation is DTV, which can also be seen as a lack of parallelism between the two sides of a rotor. The wobble we’ve been talking about causes the disc to wear unevenly as it hits those abrasive pads in one spot on each side every revolution. In other words, the contact areas will end up thinner than the rest of the rotor. One on-car lathe manufacturer claims that, typically, .002 in. of runout with zero-clearance bearings will cause about .0004 in. of DTV in 3,000 to 5,000 miles. Some authorities want thickness variation to be held to .0002 in., while others say it will take twice that to generate a complaint. Regardless, you can see that allowing any appreciable wobble out the door can be dangerous to your reputation.

There’s yet another factor that aggravates the development of DTV on late models. To reduce rolling drag, in many vehicles the engineers opted for pre-loaded, zero-clearance front wheel bearings, which require a less scuff-producing toe-in setting. But with no end play to absorb hub and rotor imperfections, any runout at all causes contact between the pads and rotor, increasing the wear that results in thickness variation.

Hand #2

But there’s always the other hand, isn’t there? As you may have noticed, two of the absolutists quoted in the introduction specialize in European cars. At the shop where we were recently working, we’d sometimes pull the wheels off an upscale Euro and know that those discs needed to be replaced by just looking at them. We’re not talking grooves. We mean a visible wide depression made by pad contact.

This is what we call the “Autobahn brake phenomenon.†As Mohammad Vakili, Manager of Technical Affairs for Continental Teves-ATE (www.conti-online.com), explained to MT, “Vehicle

sensitivity in Europe is different … linings are aggressive and tend to produce noise, which is dampened by a soft rotor. In Europe, they design them to wear each other proportionally. They use softer metallurgy than in the U.S. or Japan, where they have milder pads and harder rotors.†So, where we Americans have become accustomed to thinking that rotors should last forever, in European vehicles they’re supposed to wear out along with the pads. That’s the price you pay for being able to “stop on a dime and get nine cents change,†as a brake expert once said to us.

Most of us aren’t Euro specialists, however, so we typically get reline jobs where the rotors are still plenty thick. As we said above, if your test drive reveals no pulsation, swallow your prejudices and hang those pads. In cases where pulsation was the reason the customer appeared at your door, you are probably doing the right thing by machining away the DTV. That is, as long as you take the time to maintain your lathe and use it properly. That’s fodder for another article.

Looks About the Same, But…

When replacement is the proper path, how do you choose among the rotors on the market? Do you try to save the customer a few dollars, or would you rather feel confident that the job won’t come back to haunt you?

Vakili tells us that since ATE already makes O.E. rotors, it doesn’t fool around with manufacturing a cheaper version for the aftermarket. If you buy that brand, you simply get original quality. Marciniak of Affinia says, “Whenever a new car comes out, we buy an O.E. rotor and dissect it so we know we’re producing original quality designs and metallurgy.â€

Besides metallurgy and internal structure, there’s a factor that might cause serious problems with off-brand rotors that most people aren’t aware of: hub chamfer. If the angle doesn’t match the hub exactly, the disc won’t seat right, leading to big trouble with runout and heat dissipation, yet some cheap items just use, say, 45% as a one-size-fits-all manufacturing convenience. Our advice: Buy brand name only if you want to protect your relationship with your customers and your schedule.

In a Nutshell

In keeping with Master Technician’s mission of offering immediately useful solutions, we’ll boil the above down into a few rules:

- If there’s no pulsation and the rotors are still thick enough (look it up), just hang pads. You may, however, want to service non-unitized wheel bearings, in which case you should mark the rotor and hub so you can assemble them in the same relative positions.

- Whenever you install discs, new or otherwise, get that hub perfectly clean and make sure you mount them in the position that gives the least runout. Also, tapered shims are a great way to eliminate wobble.

- If the grooves are deeper than .060 in., you’re justified in buying new rotors. An easy way to measure the depth of a rotor groove is to use a dime. If the top of F.D.R.’s head is still showing, you’re within the .060 in. limit. If the groove’s too narrow for the coin to be inserted, don’t worry about it.

- If there’s a pulsation complaint, you have a decision to make: machine or replace. If there’s still plenty of thickness left, you can machine off-car and hope for the best (we’re assuming you know how to produce a properly smooth surface — contrary to popular belief, a mirror-like finish would be ideal). Or, you can increase your chances of success by using a good on-car lathe (make index marks for future reference). Finally, there are good reasons to opt for new high-quality discs: They’ll be less apt to warp because they’ll be thicker, you won’t be spending time with the lathe, and you’ll make a nice parts profit. Of course, if the bumpy braking condition is due to a crack, the decision is made for you.

By Bob Freudenberger

0 Comments