No one disputes the fact that, “It is better to light a candle than curse the darkness,†but if you really want to split the night wide open, select BMW’s “xenon headlight†option. In 1993, BMW became the first carmaker to offer xenon headlights (also known as High Intensity Discharge or HID headlights) in the United States. Initially, xenon headlights were only available on the 750iL (E32) model, but these powerful lights are now offered throughout the BMW lineup.

Xenon offers several benefits compared to old-school sealed beams, regular halogens, and even composite headlights:

- Longer bulb life. Xenon bulbs typically last three to five times longer than conventional halogen bulbs. In some cases, xenon lights have lasted nearly 10 times longer than halogens.

- Blue/white light. Xenon headlights have a distinctive blue/white light compared to the yellow tint from other headlights. This light is closer to natural daylight, which is why xenon lights are brighter. Illumination color is measured in Kelvins (K). The higher the K, the whiter the light.

- Daylight = 4,500 to 5,000 K (white)

- Xenon = 4,000 to 4,500 K (blue/white)

- Halogen = 3,200 K (yellow)

- Less power consumption. Xenon bulbs consume less energy, and the bulbs don’t get as hot as halogen lights.

- Increased light output. Light output or power is measured in “lumens.†Xenon bulbs produce 2.5 to 3 times more lumens than halogen headlights.

- Better driving visibility. The combination of higher lumens and color temperature makes xenon headlights superior to other lighting technologies. A xenon beam is wider and brighter, so more of the road is illuminated.

- Less driver fatigue. Night driving with xenon headlights is less fatiguing for a driver. The brighter light increases the contrast and improves vision. In poor weather conditions, the driver has more spatial vision.

Model Specific

With halogen bulbs, (left) the driver’s vision is limited and you can barely make out the bicycle rider to the right of the road. With xenon bulbs, the light is brighter, you can see further, both down the road, and off to the side.

Â

Bosch and Hella both provide xenon headlights for BMW. When you order replacement parts from your local BMW dealer, you must order by specific vehicle type to be sure you get the correct part.

For the E38 (740/750 models from MY 1995 through MY 2001) there are two generations of xenon headlights. The first generation is Generation 2.1 and can be identified by the flat bottom edge of the headlight housing. Generation 3, introduced in MY 1999 can be identified by the rounded (scalloped) edge of the headlight assembly.

Because of federal regulations covering headlights, replacement parts are not available for some of the earlier model xenon headlights. The following table lists the available parts for these BMWs.

| Model/Vehicle | MY | Manufacturer/Version | LWR* | Individual Replacement Parts Available |

| E32 (750iL) | 93-94 | Hella Light and Control Module Generation 1 | No | No |

| E38 (750iL) | 95-98 | Bosch Light and Control Module Generation 2.1 | No | Yes |

| E38 (All) | 99-01 | Bosch Light, Hella Control Module Generation 3 | Yes | Yes |

| E39 (All) | 99-02 | Hella Generation 3 | Yes | No |

| E46 | 99- | Bosch Light and Control Module | Yes | Yes |

| *Headlight self-leveling | ||||

Â

Operation

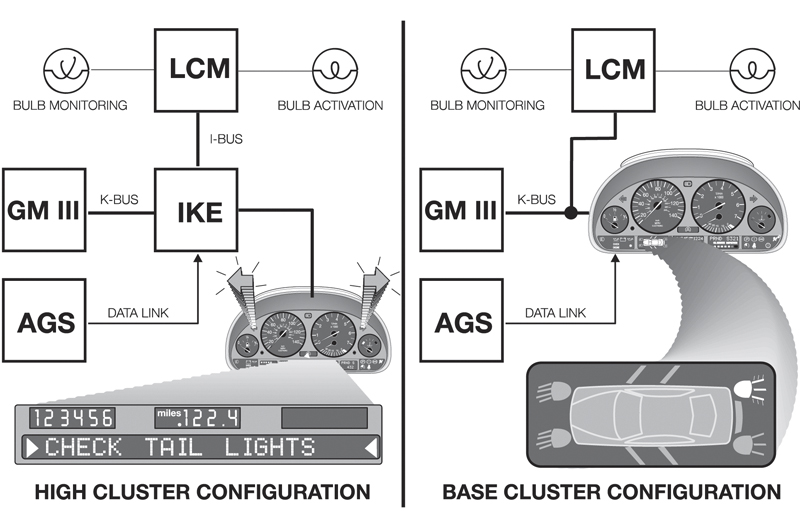

The light control module (LCM) monitors all exterior lights and warns the driver whenever any light is not working.

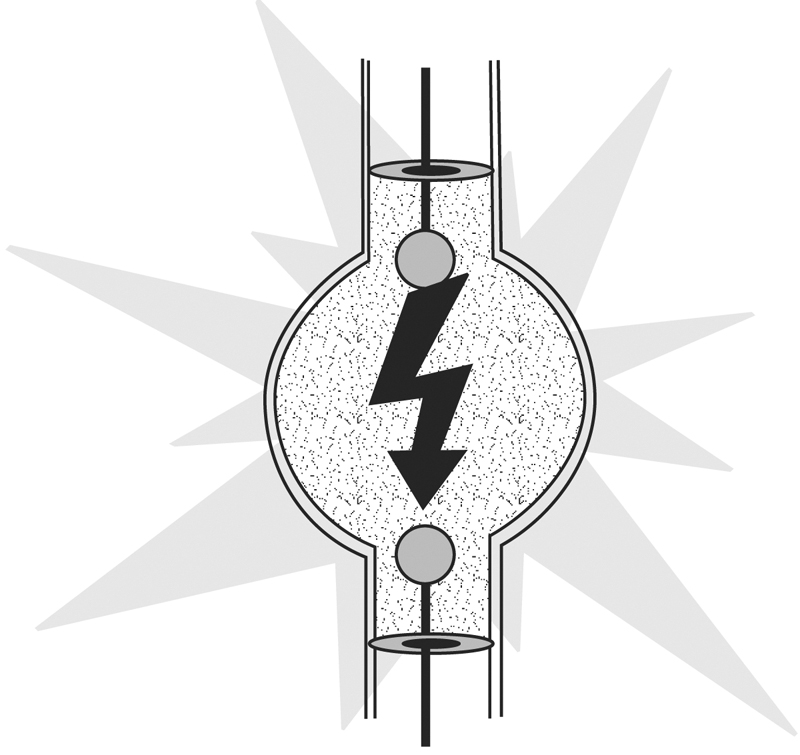

The inside of a xenon bulb has two electrodes with a small gap between the electrode ends. The bulb is filled with with xenon gas. When an electric current jumps the gap between the electrodes, the current flow and heat reacts with the xenon gas, producing the characteristic blue/white light.

During start up, a strong current jumps the electrodes inside a xenon bulb, creating an electrical arc.

A xenon headlight goes through three phases when first turned on.

- Phase one is the starting phase. The circuitry in a BMW sends a high voltage current (18-25 kV) to the bulb to create the arc across the electrodes.

- Phase two is the warm-up. After the arc is formed, power is regulated to 2.6 amps, generating a lamp output of 75 watts. During warm up the xenon gas begins to brightly illuminate. The warm-up phase stabilizes the environment in the bulb ensuring continual current flow across the two electrodes.

- Phase three is the continual phase. After the bulb is fully warmed up, the system automatically switches to a continuous mode of operation. The supply voltage for the bulb is reduced and the operation power required for continual bulb illumination is reduced to 35 watts which is less than that of a conventional halogen bulb.

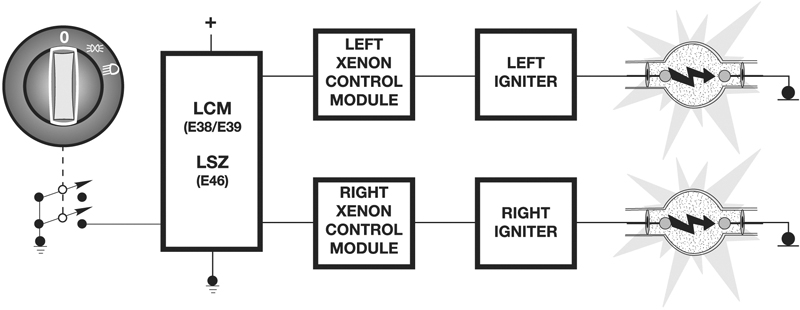

Each xenon light is regulated by its own xenon control module, which controls light operation as the bulb goes through the three phases. Coils within the igniter provide the high voltage necessary for the start-up phase. After start-up, the igniter coils are no longer charged, but the igniters themselves remain connected to complete the headlight circuit.

Xenon bulbs, like all the lights on later model BMWs, are monitored by the Light Control Module (LCM). If a light is defective, a warning notice appears on the dashboard. All other lights monitored by the LCM are tested both “hot†(“warm†in some manuals) and “cold.†A “hot†test is done when any light is turned on. The LCM does a “cold†test by very quickly and briefly powering the light circuit. You can think of the “cold†test as a very rapid “hot†test done automatically by the LCM at regularly programmed intervals.

However, because a strong electric current is needed to turn on a xenon bulb, these bulbs are only monitored “hot†by the LCM. There is no “cold†testing of xenon bulbs.

The lighting control module signals a xenon bulb failure when either no current flow, or a reduced current flow, is detected going to the bulb. The no/low current situation drops current flow through the xenon control module to 60mA. When the current is this low, the LCM then illuminates the warning notice inside the vehicle. Test procedures for xenon headlights can vary by BMW make and model. You’ll have to consult a manual or BMW on-line tech info for specifics. Older systems, prior to 9/98, may require a special adaptor (P/N 90 88 6 631 000) for testing. Since 9/98, you may need adaptor P/N 90 88 6 631 010.

Warning: Xenon headlights circuits have high voltage passing through them. Follow all safety procedures and observe any warning labels on the vehicle whenever servicing or troubleshooting xenon headlights.

Retrofit

To work properly, xenon lights should be ordered as original equipment on a BMW. Although retrofit kits are available on the aftermarket, these kits are not recommended for use on a BMW, especially more recent models. All BMWs now come with a light monitoring system that notifies drivers whenever any exterior light is not working. Unless the retrofit kit can be properly wired into the monitoring system, it is likely that the kit would continually set off “bulb failure†warnings because the onboard system would not “know†that the bulbs were on. You would have to explain to your customer why the “bulb failure†light would always be on. And then there is the little matter of your customer putting up with the steady warning “gong†sound that comes on when there is a bulb failure.

On The Level

Each xenon bulb has an individual control module and igniter, with the vehicle’s LCM (LSZ on some models) providing overall control.

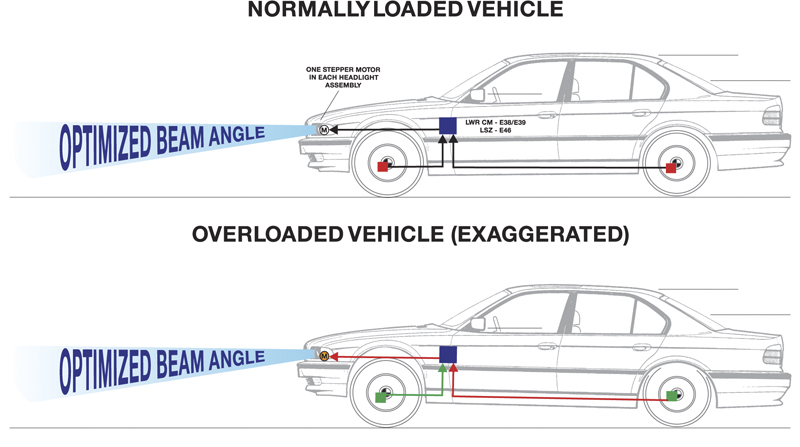

Because xenon lights are so bright, it is essential that they be aimed correctly to prevent annoying and possibly dangerous glare shining into the eyes of drivers in oncoming cars. Static adjustment works well as long as the BMW is relatively level while traveling. However, if the trunk or rear seat is heavily loaded, the rear of the car may sag, making the front to rise enough to cause a glare problem. To prevent this, BMW uses an automatic headlight leveling system (LWR) on vehicles equipped with xenon headlights. Although intended to compensate for heavy loads, the LWR also adjusts the lights during hard acceleration or braking. It goes into action as soon as the headlights are turned on. It has been standard on all BMWs equipped with xenon lights since MY 1999. It is not offered on any BMW without xenon lights.

BMW’s automatic leveling system keeps the headlights aimed correctly, even if the vehicle is not level.

Two hall effect sensors, one on the front suspension and one on the rear, regulate the operation of the LWR. Whenever the sensor input indicates that the BMW is not level, stepper motors, one for each headlight, pivot the headlight assembly up or down to keep the lights aimed correctly.

The stepper motors drive a threaded rod that moves the lower edge of the headlight carrier plate forward and backward as necessary to maintain level beams. The upper edge of the headlight carrier plate is fixed on a pivot. The pivoting movement adjusts the vertical position of the headlight beam.

After doing any service work on xenon lights, you should check headlight aim. Setting initial adjustment for xenon headlights on a BMW is similar to doing any headlight adjustment, with one minor additional step. After you have positioned the vehicle for setting the headlights, turn the lights on and wait at least 30 seconds. This gives the LWR time to cycle and set itself. After the LWR is set, you then make the base headlight positioning.

0 Comments