For more than a century, lead-acid batteries have been used in automobiles. Here’s a new take on testing them.

The 1886 Benz Patent Motor Wagen is generally considered to be the first viable automobile. Its battery was used exclusively for ignition.

Most service-lane complaints regarding batteries go something like this: The customer had to have his or her vehicle jump-started because of a “dead†battery. After this happens a second time, the unfortunate motorist decides to bring the car to you. Diagnosis at this point consists of confirming the correct operation of the charging system and ruling out excessive parasitic drain, followed by charging and testing the battery. Prior to handing the vehicle over to a tech for diagnosis, the service advisor should fully determine the circumstances leading up to the dead battery since nowadays driving habits and consumer-added electrical devices are often partly to blame.

By the 1920s, of course, electric starting and lights had made motoring in a Mercedes-Benz much more convenient and safe.

Damage from a lengthy discharged condition

By far the greatest amount of life-reducing damage is done to automotive SLI (starting, lights, ignition) batteries by unintentionally leaving them partially or completely discharged for days or weeks. Unlike marine or “Deep Cycle†batteries, SLI batteries are designed to be recharged immediately after delivering the brief burst of current needed to start the engine. There are stories of batteries on a vehicle assembly line dying after a mere four or five days of sitting around partially discharged from workers intermittently operating power windows, sliding doors, or just listening to the radio. One deep discharge is capable of significantly reducing the capacity and lifespan of even a brand new battery.

The problem comes when consumers unintentionally leave their vehicle’s battery in a state of partial discharge without ever realizing it. Without an ammeter, which most cars haven’t had for decades, how could they know? With heated seats, front and rear defrosters, dual-zone air conditioners, electric power steering and water pumps, dozens of electronic modules, navigation systems, and all sorts of consumer accessories plugged into the multiple cigarette lighter outlets, a short, low-speed run to the grocery store is just as likely to discharge the battery on a modern vehicle as it is to charge it back up. Increasing traffic congestion is gradually eliminating the high-speed travel that used to fully recharge batteries. What’s the solution?

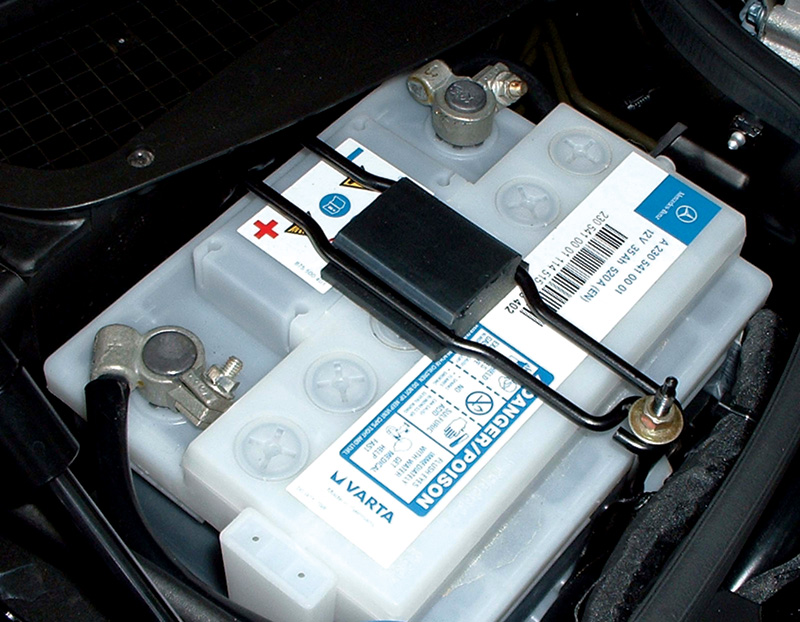

Today’s lead-acid batteries have evolved to be vastly more powerful, dependable and long-lived than earlier specimens. The improvements were absolutely necessary considering the huge electrical demands of modern cars.

A lead-acid battery will self-discharge at a rate of about 1/100th of a volt per day without any current draw whatsoever. This means that a fully charged battery, at 12.6 volts, will drop to 12.3 volts, which is 50% discharged, in around 30 days, just sitting parked in the garage. Add even a “normal†parasitic draw of 10-30 milliamperes to keep the radio and PCM memories alive and you can quickly see how a couple of weeks in an airport parking lot is all it takes to create a no-start situation. By the way, the simple answer to long-term parking woes is a solar battery charger placed in a south-facing window, or a trickle charger for a car stored in a garage. MBUSA makes a perfect charger available for this purpose — P/N W900 589 02 63 00.

But consumers have more tricks up their sleeves than just long-term parking and electrically-powered cupholders to run batteries down. Their use of unapproved accessories can defeat the best in engineering, and is simply a fact of life we must deal with. Aftermarket stereos, with subwoofer amps that remain powered on after the ignition is turned off are infamous battery killers. Ditto for miswired remote starters, security systems, phone systems, and faulty trailer hitch wiring. Kids left watching DVDs in the grocery store parking lot with the ignition on can run a battery down. By far, consumer-added accessories that remain constantly powered “on,†creating unsuspected parasitic drains, are the biggest culprits when it comes to dead batteries these days.

High-tech battery chargers, such as this small “overnight†unit from Sweden, use multi-level voltages to add amps without doing as much damage as old-fashioned chargers.ÂÂ

Age, heat and dehydration

Other battery-killers include age, heat and dehydration resulting from overcharging. As techs, we’re always under time constraints, but a fast charge, even when done using a computer-controlled charger, is never as healthy for a battery as a slower, lower-amperage charge. Overcharging can quickly boil off enough electrolyte to expose the plates, leading to battery-killing sulfation of the air-exposed portions. What’s sulfation? It’s when non-conductive crystals of sulfate form instead of lead sulphate reconstituting itself back into elemental lead and sulfuric acid as a battery charges. Sulfation is the primary chemical process by which batteries die of “old age.†Various hi-tech, computer-controlled and“pulse†chargers promise to “zap†sulfation and help “recondition†a tired battery, but, as always, your mileage may vary.

Never allow a battery being charged to exceed 100° F., boil, or feel hot to the touch. Heat isn’t good for batteries, and not just because it leads to dehydration. When Consumers Reports recently tested batteries, they used a 100 hour discharge/charge cycle while soaking the batteries in 157° F. water to simulate harmful underhood temperatures. Maintenance-free batteries are less prone to dehydration than regular batteries, but suffer from the fact that you can’t top them up if they ever do get low on electrolyte. The very low-humidity environment you find in places like Arizona further contributes to battery “dehydration.†In these locales, running low on electrolyte may contribute more to premature battery deaths than elsewhere – and is a valid reason for replacing maintenance-free batteries with traditional ones that have removable caps for adding water – distilled, of course.

If heat is so bad for batteries, why do so many cars need a new battery at the first bitter cold snap of winter? A sub-freezing engine, with oil as thick as molasses, can require as much as 50% more current to turn over than one kept toasty in a warm garage. And a battery at 32° F. can only put out 85% as much current as it can at 70° F. So, a battery that might have adequate capacity for cranking in spring, summer, and fall, simply can’t clear the bar when the real cold hits.

The measure of a battery

There are two measures of a battery: state of charge, and, for lack of a better term, “capacity.†Like a water tower on a hill, a battery can only supply so many amps of current for so long before it’s empty. Cranking Amps and Cold Cranking Amps are both industry standard measures of capacity, at 32° F., and 0° F., respectively. As a battery ages, its CA and CCA will decline, just like a water tower slowly clogging up with rust and sediment.

Let’s say you have two batteries rated at 550 Cold Cranking Amps, and they both show 12.4 volts open circuit, (completely disconnected, no loads applied). How can you tell the good battery from the bad one? The answer is using either a load tester, or a conductance-based battery tester.

To use a traditional carbon-pile load tester, such as a VAT-40, the battery needs to be fully charged beforehand. With a conductance-based tester, such as a Midtronics, testing can occur without charging – although the readout on the tester may be “Battery Needs to be Charged.â€

A fully charged battery should read approximately 12.6 volts, a 50% discharged battery 12.3 volts, and a 75% discharged battery 12.2 volts. If you hook up a DMM, or other test device that incorporates a voltmenter, and you read more than 12.65 volts, you’ve got what’s called a “surface charge†on the battery. Burn it off by turning on the headlights for three minutes, wait a minute, then proceed with the rest of your testing.

Conductance-based testing

As a battery ages, its internal resistance increases. It starts out with a very low resistance in series with the battery cells — in the milliohm range. As the battery ages, the resistance gets higher and higher. Because of this, the battery ability to put out current gradually reduces. This can be measured using a conductance-based tester. Mercedes-Benz, along with virtually every other carmaker, has approved the use of conductance-based battery testers, and many models incorporate several charging system analysis features as well.

With a conductance-based battery tester, you simply attach the leads to the battery terminals, punch in the battery’s stated cranking amps (CA) rating, and the tester displays the battery state of charge as well as the “Remaining Cranking Amps†available – the figure of merit used to decide whether to replace the battery or not. Even with added charging system testing features, they’re so quick and easy to use, it may make sense to take a preliminary reading on a vehicle’s battery and charging system in the service lane before filling out a ticket and committing the customer to a more in-depth diagnosis.

Load-based testing

Purists will never give up their carbon pile VATs. That’s because watching the needles swing as the applied load is increased provides the user with a “feel†for the condition of a battery being tested, something you don’t get with a digital readout. Someone skilled using a VAT40, or comparable, newer unit, can perform a complete battery and charging system analysis, including performing key voltage drop measurements, in a matter of minutes, with a very high degree of confidence in the results.

The bottom line in load testing is whether or not the battery can sustain 9.6V, the minimum cranking voltage, while a load approximating half its CA rating is applied over a specified period of time. How fast the voltage dives during the load test gives a direct indication of battery condition. Used VAT40s are easily found because at one time almost every shop had one. Newer, digital-readout load testers really don’t offer much more in the way of features, asides from step-by-step instructions for those techs who need it.

Gotcha’s

In the right hands, a traditional carbon-pile VAT is still hard to beat for finding out the truth about a battery’s condition.

The leading “gotcha†when it comes to battery problems are dirty or corroded terminals. Corrosion can add up to a full ohm of amperage-killing resistance. We once encountered a case on a vehicle with equipment for aiding the handicapped that required special steel terminals. A brand-new battery refused to accept a full charge. Two or three cranks and it was done. So, the tech ordered a replacement battery. When he removed the old one, the steel terminals, which looked absolutely pristine from the outside, revealed a thin layer of white corrosion on the inside where they clamped onto the lead battery posts. After cleaning this off, the battery charged and performed fine.

Had the tech first “stabbed†the lead battery posts and the steel terminals with the leads of his DMM with a significant load applied (such as during cranking) he would have been able to measure a noticeable voltage drop, say, 200 amps x .01 ohms = 2 Volts. This is one place where the voltage drop testing feature of a VAT tester can, in the hands of an expert user, quickly diagnose a problem. But simply cleaning the terminals is usually easier.

Consumer behavior is the ultimate “gotcha,†since they typically don’t realize what they’re doing that may contribute to a battery problem. Late model vehicles won’t put their modules to sleep until every last door and hatch is closed. If the motorist’s habits interfere with that, the on-board computers will stay awake and alert, and there will be a significant drain on the battery.

Three strikes and you’re out!

- Consumer complaint about having to jump start a vehicle – strike one!

- Lack of parasitic draws or charging system problems – strike two!

- Any significant loss of battery capacity – strike three!

This article might be summarized by saying, “When in doubt, replace the battery.†That’s because battery testing remains an inexact science, regardless of how high-tech your computerized, transconductance-based battery tester is, or how many years of experience you have using a carbon-pile VAT tester. The only measure of a battery that truly counts is, “Is it able to do the job the customer needs it to do?†If the customer wasn’t having battery problems, he or she wouldn’t have gone to the trouble to bring the vehicle in for diagnosis in the first place. The reasonable approach, then, is for the tech to rule out other likely causes of trouble, such as charging system problems, parasitic draws, and unusual consumer behavior, then test the battery. If the reading(s) leave any doubt as to the battery’s capacity to hold a charge, then it’s prudent to replace it.

Service Advisor Questions

How old is the battery?

Have you had any problems before this?

Did it seem to be getting weak, exhibit slow cranking, or dim headlights before this?

How long was the vehicle parked before this happened?

What did you have plugged into the cigarette lighter/accessory outlets?

How far do you typically drive the vehicle each day?

Have you recently had an aftermarket stereo/alarm/trailer hitch installed?

Did you leave any doors/hatches open, by chance?

Are any warning lights on the dash illuminated?

Has the battery been disconnected for any reason?

Has anyone else tested the battery or alternator, i.e. an auto parts store?

Â

0 Comments