By Dave Russ

If you’re tempted to use a plug and get that distraught motorist out of your face ASAP, resist. Not only would you be taking on a big liability, but you won’t be able to charge nearly as much for the job.

You’re an automotive service shop that doesn’t repair flat tires and you’re thinking maybe you should try it out for extra sales or for the convenience of the customers you’ve been sending down the block to your local tire dealer. Or maybe you already DO repair tires. Then this could be considered a refresher course that’ll help assure that you’re doing it right.

If you’re new to the game, you’ll need a tire changer and a tire spreader, along with some other equipment. What for? You can repair ‘em without taking them off the car, right?

Yes and no. Certainly, it can be done. You can buy on-the-wheel repair kits. For example, one company sells such a kit for $19.99 and says, “You can easily repair punctures in tubeless tires in less than 60 seconds with (name of their product). No need to remove tire — simply load the tool with brass-tipped rubber plug, insert the tip into puncture hole and pull the handle out of the tire. The plug stays in place, providing a permanent repair.â€

Another company sells a fancier version with tools and enough material to repair a few dozen tires, all wrapped up in a metal carrying case for $89.95.

Tire Industry: NO On-The-Wheel Repairs, Period

If you go down that road, don’t tell the tire manufacturers and their industry association because they frown on it. Shoot, they downright blast the practice.

Take this emphatic statement from the Rubber Manufacturers Association (RMA): “NEVER PERFORM A TIRE REPAIR WITHOUT REMOVING THE TIRE FROM THE RIM/WHEEL ASSEMBLY FOR INTERNAL INSPECTION. DO NOT perform an outside-in tire repair or on-the-wheel repair.†All that and more, including another warning – that tire repair can be dangerous and should be performed only by trained people using the proper tools and procedures – is on a nifty wall chart that shows the right way to repair a tire. You can get one from the RMA at www.rma.org arpminc.com/.

Industry experts and techs say the reasons for removing the tire from the wheel are simple – something caused the puncture and air loss and that something may still be embedded in the tire and must be removed. Sure, you can pull out a nail that you see on the surface, but what about internal damage, or what if the nail-or-whatever-it-is has worked its way below the surface? What if the object is “floating†around inside the tire?

Another reason is that there may be more damage than meets the eye – too much damage to make a safe repair. The only way to make sure is to remove the tire from the wheel.

The RMA doesn’t mince words when it comes to recommendations — “NEVER use only a plug†and “NEVER use only a patch to repair a puncture. The injury must be completely filled with a vulcanizing material or rubber stem and a patch must be applied to the innerliner to prevent air loss.â€

How About if We Slip in an Inner Tube? No.

Can we repair the crown, shoulder and sidewall? The crown and shoulder maybe; the sidewall generally no.

Tire manufacturers are equally adamant about removing the tire from the wheel. Michelin tells consumers, “If you are offered a plug (outside) repair — refuse! Plug repairs do not involve taking the tire off the wheel for a proper inspection. A plug is simply inserted into the punctured area. Plug repairs are not reliable and can cause the tire to blow out. Insist on a full inspection and patch repair on the inside of the tire.â€

To see more, check out the RMA and tire company websites.

Common sense tells you that a hole the size of a baseball can’t be repaired, but how big is too big? The industry pretty much agrees that 1/4†is the limit. The RMA says tires with punctures larger than that should be referred to a “full service tire repair facility.†Those are generally located at tire retreading centers that concentrate on truck tires, which means the repair cost could approach the cost of a new tire. Speaking of retreads, that’s why you don’t see that many passenger tire retreads any more: the cost of retreading these days can be right up there with the cost of a new tire.

Do the Right thing

Now that we’ve established what NOT to do, what is the right way to repair a tire?

Here’s what Goodyear says:

- The objective of the puncture repair is to seal the tire against loss of inflation pressure and to prevent damage to the carcass from moisture. In all puncture repairs approved by Goodyear, the hole must be filled with a plug, and a patch covering the hole must be applied to the inside of the tire. Never repair tires that are worn below 2/32 in. of tread depth.

Repair Area

- Repairing is limited to the tread area only within the outside grooves. No repairs are allowed in the tread area beyond the outside grooves.

Materials

- Precured rubber plugs 1/4 in. (6mm) in diameter, patches or plug/patch combination (there is some disagreement about the use of a one-piece plug and patch or whether it’s OK to use them separately; Bridgestone-Firestone advises you use a one-piece plug-patch combination).

- Chemical vulcanizing cement

- Pre-buff cleaner

Repair Procedure

- Carefully remove the tire completely from the rim.

- Locate the puncture on the inside of the tire and circle with crayon.

- Remove the puncturing object if it is still in the tire.

- Carefully inspect the tire on a tire spreader. Look for cracks, breaks, punctures or damaged or broken beads.

- Check the inner liner for cuts, cracks, or holes, which may cause the inner liner to lose air.

- Check the injury by probing it with an inspection awl.

- Determine size and angle of the injury.

- Check for ply or belt separation.

- Reject any tire that has separation, loose cords, damaged bead(s), or any other non-repairable injury.

- If the hole is simple and round, the puncture repair procedure will probably be successful.

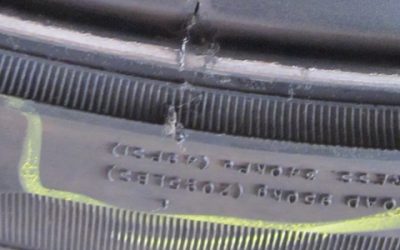

- If the hole shows evidence of fabric splitting, such an injury cannot be properly repaired using this puncture repair procedure. Such an injury must be skived out and repaired as a section (reinforced) repair.

- Use a pre-buff cleaner and a scraper to remove contaminants from the liner in the area to be buffed around the injury.

- Use a 7/32 in. carbide cutter for 1/4 in. repairs to clean out the puncture.

- Make sure that the drill follows the direction of the puncturing object. Always drill from the inside to the outside of the tire.

- Using chemical vulcanizing cement, lightly coat at least 1/2 of the tapered end of the repair plug. Install the plug according to the manufacturer’s instructions. Trim the liner side of the plug slightly higher than the surface of the liner without stretching the plug.

- Center the patch or patch template over the injury without removing the backing. Follow the instructions regarding positioning as related to bead location. Mark around the outside edge of the patch, approximately 1/4 in. larger than the patch.

- Buff the liner and plug at the puncture location. The buffed area should be slightly larger than the patch. The buffed surface should be finely grained and even for proper bonding. Don’t burn the rubber with the buffing tool, or buff through the liner, or into the marking crayon.

- Clean the buffing dust from the tire using a vacuum cleaner or brush. Don’t use gasoline or other petroleum solvents

- Apply an even coating of the chemical vulcanizing cement to the liner surface and the patch. Allow the cement to dry thoroughly. Do not touch the cemented areas.

- Install the patch with the beads of the tire in the relaxed position. Position the patch over the puncture according to the markings on the patch. Stitch the entire patch starting from the center, keeping the strokes close together to avoid trapping air under the patch. (FYI, tire repair stitching is done with a small wheeled tool to remove all the air – it isn’t needle-and-thread stitching.)

- Cut off the protruding end of the plug about 1/8 in. above the tread surface.

Final Inspection

- The repair must seal the inner liner and fill the injury. After remounting and inflating, check the repair with a soap solution on both beads and valve to assure a complete seal.

If you’d like to see a video or a PDF of this procedure, check out Patch Rubber Company’s website — patchrubber.com. Patch is a long-time supplier of tire repair materials and equipment.

Patch Rubber brings up a major issue – and potential safety hazard – in its video: The use of aerosol tire sealants. They may make for a quick, conventional flat repair, but the gas that enters the tire could be explosive (how about propane?), so ask the customer if he or she has used one for an emergency repair. Bleeding all the air from the tire can help dissipate the gas – and be sure your repair person isn’t smoking and that there are no open flames nearby.

Sealants can be effective in a pinch, under severe conditions or if you’re out in the boonies far from a tire changer. One sealant manufacturer sponsored a motorcycle with sealant-filled tires at the Baja 1000 and the bike – and chase and support vehicles – breezed by many a competitor sidelined by flats with nary a puncture.

The Need for Speed

What about speed-rated, runflat tires, tires with low-pressure warning systems, or tires with runflat wheels such as Michelin’s PAX System?

There is general agreement that speed-rated tires can be safely repaired. Goodyear says its H-rated-and-above speed-rated tires “may be repaired to correct a commonly repairable nail hole puncture in the tread area only,†but the speed rating drops one notch, for example, from V to H. If the tire isn’t repaired by the book, the speed rating goes south and the warranty may be affected. Moreover, only one repair is allowed; any more and you have a conventional, non-speed-rated tire.

As to repairs on vehicles with pressure monitoring systems and runflat tires and devices, see “Don’t Wreck the Tire Pressure Monitoring System†in our January issue.

What does the National Institute for Automotive Service Excellence (ASE) have to say about tire repair? ASE doesn’t publish or establish standards for tire repair, according to industry veteran Tony Molla, ASE vice president of communications and esteemed MT columnist. “We rely on OEM materials for both vehicle and tire information and specifications,†Molla said. In other words, “Leave it to the experts.â€

A friend of ours – and probably many like her – will never come to you for a tire repair. She has had four flat tires in her driving “career†and has always driven on the flat tire to a safe location, where she has the spare put on by a service person. She ruins the tire every time – but runs no risk of being approached on the side of the road by a “good Samaritan†who might be a wolf in sheep’s clothing. She figures the cost of a replacement tire is well worth her safety. And who can argue with that?

0 Comments