In 2000, the U.S. government responded to serious issues related to automobile tire safety with the TREAD (Transportation Recall Enhancement Accountability and Documentation) Act. This mandated that an elaborate computer-controlled system had to be added to every passenger vehicle to monitor tire pressures. It’s our job to keep these systems up and running.

Some of you may remember the stories of tread separation and tire failure in the late 1990s and the fatalities that occurred. The National Highway Traffic Safety Administration (NHTSA) monitors trends like this, and after compiling accident report data it started to look for a cause. Numerous factors were discussed such as properly matching tire construction to vehicle design, recall oversight, and, above all, tire maintenance. It was concluded improper tire pressure was the most common cause of catastrophic failure.

As a technician, you are probably instructed to check the tire pressure at every oil change you do in the shop. In an ideal world, tire pressure should be checked at least once every two weeks. But the driving public is not known for diligence in this matter, and we do not get to see their vehicles every two weeks. We should inform our customers that a properly inflated tire will not only provide better traction under various road conditions (rain, snow, road surface temperature, etc.), they will also last thousands of miles longer and provide the best fuel economy the vehicle can offer. This advice could save them a lot of money in the long run, but it mostly goes unheeded. With the mileage the driving public increasing every year, something had to be done in the name of tire safety.

What was done?

In 2000, the federal government stepped in and mandated that all manufacturers that sell vehicles in the United States would have to install a Tire Pressure Monitoring System (TPMS) on every new vehicle. This was only one of the stipulations of the mandate, but it is the one we as automotive technicians need to be most concerned with. After all, it is our job to make sure that these warning systems continue to operate as designed.

When trying to determine if you’re working with an indirect or direct system, look for the lock nut holding the sensor to the rim. This means it is a direct system. Use only plastic valve caps because galvanic action will corrode the metal type on the valve stem making them difficult to remove.

TPMS has evolved as more information was learned about the effects of improperly inflated tires. What makes an unsafe level of tire inflation? Radials have steel or fiber cords running across and in-line with rotation. If the air pressure drops, the sidewall of the tire must support more of the weight of the vehicle. As a tire rotates, the sidewall compresses directly above the point of ground contact. The tire then expands again as the tire continues to rotate. This sidewall flexing results in heat build up. Heat is also generated by friction between the tread and the road surface. On a hot sunny day, the road surface temperature will also add to the overall heat the tire is subjected to.

If the heat generated exceeds what the tire can tolerate, the tread will separate and the tire will “blow-out” or come apart. If this happens at highway speeds, the driver could lose control of the vehicle and have a serious accident. Engineers looked at many ways to detect tire inflation pressure. One method is known as “indirect.” A particular tire will have a specific circumference when properly inflated — the distance around the tread of the tire. When all four tires are rotating as the vehicle is being driven, the wheel speed sensors measure the relative speed of each wheel. If one tire is underinflated, its diameter, hence circumference, will be smaller than that of the others, so it will have to spin faster. ABS and DSC computers are sensitive enough to notice the change in wheel speed and flash a warning. BMW and Mini used indirect systems on early TPMS vehicles manufactured until about 2005.

The NHTSA eventually determined that the “indirect” method could not detect a loss of tire pressure until the unsafe level was already exceeded. Also, variations in tire wear (tread depth) as small as 4mm can make it difficult to determine whether or not tire wear is the cause of the warning, or if it really is under-inflation. On top of that, relative wheel speeds could appear the same if all tires lost pressure at similar rates.

Direct psi reporting

By the year 2007, all manufacturers were required to supply the “direct” method of measuring tire pressure. This is accomplished with a sensor mounted to the rim inside the tire that directly measures air pressure. This requirement meant the engineers had to develop an elaborate transmitting and receiving system that wouldn’t need maintenance for a relatively long period of time. It would be almost impossible to have slip rings carry a reference voltage, signal voltage, and a ground supply to a rotating sensor inside a tire. So, the sensors need batteries. How long will the battery inside the sensor last if it has to transmit a signal? Also, how will it transmit the signal? We can’t run a wire to a rotating tire! The sensor must transmit a radio signal that can make it through the tire, which means an antenna is necessary. The rest of the system must receive the radio signals, which a control unit interprets, and this information is sent to the instrument cluster to warn the driver if the tire pressure is low.

Direct TPMS systems were first installed in the early generation E65/E66 7-Series and in the E46 chassis in about 2003. These systems are sometimes referred to as TPC, RDC, RDW, RPA, DDS, and DWS, but all deal with measuring the air pressure in each tire directly. These are BMW proprietary TPMS systems and use a design specific to BMW, but still resemble those of other manufacturers. In later years as TREAD regulations evolved, the BMW system evolved along with them to meets specific guidelines. These two systems have some major differences in how they operate. If you are going to diagnose a problem in the system, you should know these differences.

The early system has a TPMS control unit, which for the sake of this article we will refer to as the RDC control unit. It interprets the tire pressure data and signals the instrument cluster or the driver information display. The RDC control unit directly receives this information from four discretely-wired antennas mounted in each wheel well, behind the splash trim. These antennas pick up the RF (Radio Frequency) signal generated by the TPMS sensor mounted in the tire and transmit them to the RDC control unit.

The Wheel Transmitter Module

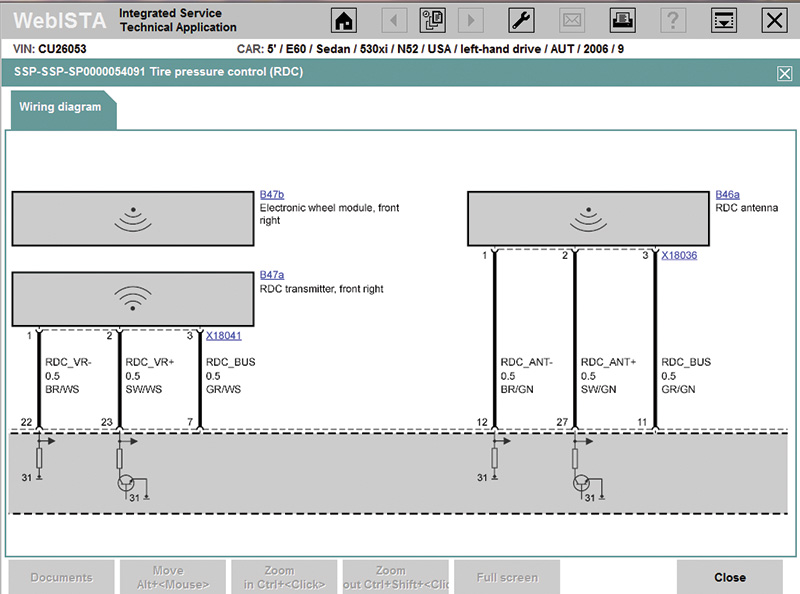

With a paid subscription to HYPERLINK “http://www.bmwtechinfo.com”www.bmwtechinfo.com, you can pull up a wiring diagram of the TPMS installed on the vehicle you are working on. Here we have a direct system and it is the “trigger” type. Remember, the trigger transmitter only wakes up the wheel module it wants to report, and the central receiving antenna receives the information from the wheel module.

What makes this system possible are the TPMS sensors that BMW refers to as wheel transmitter modules. They’re more than simple air pressure sensors. They also measure tire air temperature. Since they’re battery powered, steps have be taken to design the module/sensor to conserve energy and therefore increase its service life. Under normal conditions, the wheel module monitors air pressure and temperature every minute, but if air pressure increases or decreases by only a few psi the sensor will start transmitting every half second. A module mounted in a well-maintained tire can last approximately five years. You might want to explain to your customers, if they drive around with the low tire pressure light on and/or low tire pressure, the battery life of the sensor is going to be shortened and they will need to replace the modules sooner. In addition to transmitting air pressure and temperature readings, each module transmits its own identification number. This is so the RDC control unit can inform the driver of exactly which tire has the air pressure problem and highlight that one in the display.

When pressure drops as little as three psi, the RDC control unit will request that the TPMS warning be illuminated. At this point, tire pressure needs to be corrected, but what is the correct pressure? For years, many of us have had our own value for setting tire pressure according to our experience, what we were told, or what felt good to us. Now, the RDC control unit is coded with a specific tire pressure that it wants to see. Look at the driver’s door jamb and you will see the placard that states the correct COLD tire pressure setting. You’ve already learned that tire heat will increase with road surface temperature and the friction generated from rubbing against the road. If you set the tire pressure when the tires are hot, it may drop too much when they cool off and illuminate the light. Now that we have the correct tire pressure in all the wheels (including the spare), we’re going to have to reinitialize or reset the system so it looks at the new pressure readings. Also, if you have rotated the tires the ID numbers have moved and the system is going to have to be reset. Finally, if the module battery is dead and you need to replace the sensor, you will need to reset the system.

Evo

Use the thumbwheel on the turn signal stalk to scroll until you see the TPMS reset screen. Push the “BC” button on the turn signal stalk while in this screen. You will then see a check box illuminate in the screen informing you that the TPMS is now initialized and you should drive the vehicle over six kph for 15 to 30 minutes to finish the process.

This BMW-specific systems started to get phased out in 2005, and the later system was fully implemented by the 2008 (9/2007) model year. The newer system has some different operating characteristics that don’t change its operation, but may affect the repair if the system fails. There is still an RDC control unit, but it is now referred to as the TPM control unit. This is no longer discretely wired to antennas, but is wired to four transmitter modules through the LIN bus along with a single Central Receiving Antenna. The TPM control unit commands the transmitter modules, mounted in each wheel well, to transmit a 125KHz wake-up signal to each of the wheel modules one at a time. Each wheel module then starts to transmit its ID information, air temperature, and pressure, which are then picked up by the central receiving antenna. This is important because wheel modules transmit at either 315 or 433 MHz as per TREAD guidelines. Other vehicles driving in proximity to the antenna may be broadcasting their wheel sensor information at the same time, and BMW doesn’t want the TPC control unit to possibly report false information from another car’s sensor. The TPC control unit only expects to read information from the wheel module that was just commanded to report.

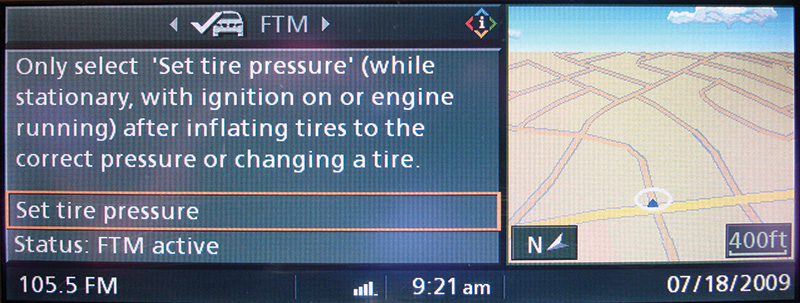

When you have adjusted air pressure, rotated the tires, or replaced a wheel sensor, you are going to have to reinitialize the system. If the TPMS commanded the warning light on, you are going to need to reset the system whether it is indirect or direct. This procedure varies slightly with indirect and direct systems as well as with older and newer direct systems. Most BMWs have an FTM button mounted in the center console. Simply turn on the ignition key and press the FTM button for a few seconds. The TPMS warning telltale will flash and then go out. You will have to drive the vehicle from 15 to 30 minutes in most cases to complete initializing the system. On vehicles with a CID, you will need to use the thumbwheel to scroll through the reset menu. When you see the TPMS tell-tale, press the BC button on the turn signal stalk for over five seconds. You will now see a check box next to the “INIT” abbreviation in the instrument cluster. On vehicles with a CID (NAV display), you need to use the “soft-key” procedure with the iDrive. From the “Vehicle Settings” menu, toggle to FTM, then select “Set Tire Pressure.” You will see the status field change from “FTM Active” to “Initializing.” Drive the vehicle for 15 to 30 minutes and each individual wheel pressure should be displayed on the screen with the tires in green if all of the pressures are good. A yellow tire means pressure needs to be corrected, and a grey tire means the TPM control unit has not received a signal from that wheel module.

If the vehicle has a NAV screen, use the soft-key reset with the iDrive. After pushing the iDrive button, scroll left or right to the FTM screen, then select “Set Tire Pressure.” After answering “Yes,” the status bar should read “initializing.” Now, drive the vehicle until the individual wheel pressures are displayed in the NAV pictogram.

Summed up

As with any system, there are idiosyncrasies that could increase your diagnostic time by making you misinterpret failure messages. For example, you have been told the TPMS sensor broadcasts information on either 315 or 433MHz. This information is printed on the label of the RDC control unit. You cannot use different frequency sensors, and the antennas in the wheel well are also frequency-specific. The 433MHz antenna is black, and the 315MHz unit is dark grey. Also, on a direct system the sensor in the spare needs to be pointed toward the right rear wheel so that antenna can pick up the signal. The more you know about these systems, the better you’ll be able to provide your customers with the quality service they have come to expect from you. This will keep them coming back for years to come.

0 Comments