What you need to know about how pad and rotor quality, and proper procedures, will assure that your customers stay happy.

For all truly professional shops, avoiding customer comebacks is a top priority when selecting replacement brake pads and rotors. One of the leading causes of comebacks is brake squeal, something the use of genuine Nissan or Infiniti parts minimizes while providing effective braking performance. Aftermarket pads may look like a bargain, and may even stop the car adequately, but few are extensively tested for a specific Nissan or Infiniti model. In the “black magic†world of brake friction recipes, rotor materials, and caliper design, a lack of part-to-vehicle matching will often result in brake noise that’s objectionable to a significant percentage of your customers along with premature wear, not to mention poor performance. Here’s why.

The trick with brake squeal often isn’t actually eliminating it, but having it occur at a frequency that’s so high human ears can’t hear it. The way this is done is by selecting unique combinations of rotor material, pad material, shims, retainers, and lubricants. Even with all this, a set of brand new brakes properly installed and functioning may be silent most of the time, but may squeak a little on limited occasions, such as a cold, damp morning.

Why do brakes squeal?

|

“We use O.E. pad applications in everything we service. Why? It minimizes or eliminates noise problems. There may be warranty issues to consider as well. We want to do the best job possible for our customers.” -Scott Destemper, |

Brake squeal is a high-frequency vibration of the brake pad and rotor — the energy is being released as sound waves. Typically, squeal is produced during low- to mid-level applications of the brake. It can be caused by a number of factors:

- Pad lining material

- Pad shims not installed at reline

- Glazed pads or rotors

- Inadequate piston retraction causing dragging (which also leads to glazing)

- Misaligned caliper or bracket

- Calipers with bent floating pins, or inadequate lubrication of the pins, not allowing the caliper to properly float

- Lack of a bevel on the pad leading edge

- Proper application of grease at specific locations

What are they actually made of?

The quest for the ideal friction material has been sort of like a drawn out version of Thomas Edison’s search for a suitable light bulb filament. All kinds of things have been tried for over a hundred years. The spoon brakes used on the first cars usually had wooden blocks, but they were sometimes supplemented with a leather lining. Band type brakes were either metal to metal, or used wood or leather, too. The earliest drum stoppers (invented by Louis Renault in 1903) had iron shoes against steel, then some strange materials were used, such as the walrus hide linings of the English Wolseley.

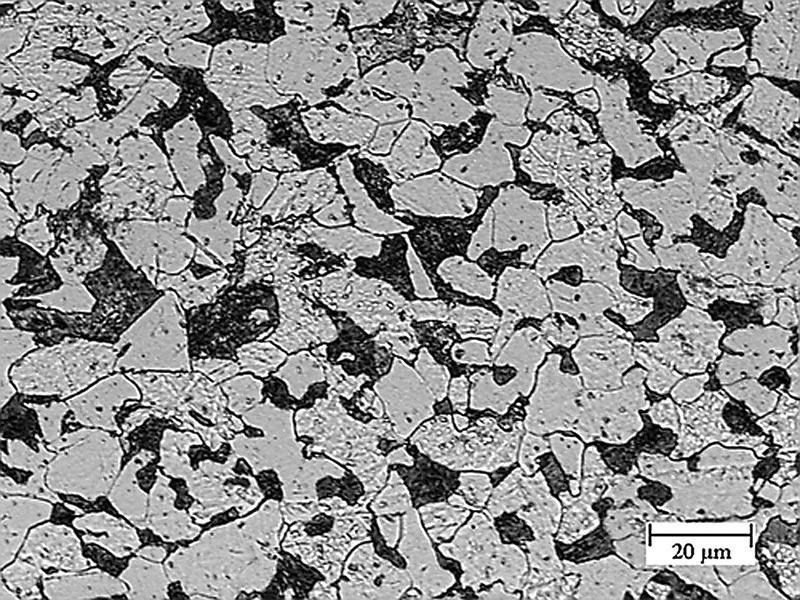

The science of formulating brake friction materials has become so sophisticated that the traditional labels and definitions are becoming meaningless. For example, “organic” used to refer to asbestos linings, but now is sometimes used to describe materials that are either semi-metallic, or ceramic. Also, neither semi-met nor ceramic is perfectly accurate for most modern formulas because one may contain a certain percentage of the other, and some amount of several other different materials.

What’s really in brake pad material? There may be Kevlar, steel, or fiberglass strands as a replacement for asbestos fibers, resin to glue it all together, iron, brass or copper dust, particles or strands, lubricants, some form of clay (if the pads are ceramic), and other “top secret†materials. There may be 15-20 different ingredients in all. The different materials perform differently.

When Nissan/Infiniti brake engineers specify a certain formula for a particular model, they have numerous goals in mind such as exceptional stopping performance, long service life, low noise potential, as little dusting as possible, and rotor longevity.

While technicians may try to choose pads of a certain composition or reputation to address specific situations, chances are that there will be unintended consequences. The majority of customers seeking brake service simply want brakes that work the way they did when their Nissan or Infiniti was new and a lack of objectionable noise. Techs can guess which pad will appeal to a particular customer, or by going with O.E. pads, minimize the chance for objections in all categories.

The other side of the coin

Where rotors are concerned, some other high-performance vehicle makers consider them sacrificial and so employ very aggressive, abrasive friction materials. This means that the discs wear out at about the same rate as the pads. Other drawbacks may include increased pedal effort, a “grinding” pedal feel, and possibly noise.

Nissan/Infiniti has a much more practical philosophy that your customers will appreciate. By using advanced brake design and very careful attention to the subtleties of friction formulation, the company has achieved excellent stopping performance and rotor life.

Of course, there are frequently cases where new rotors are required, especially in vehicles that tow heavy trailers or are driven aggressively in city traffic. You may be able to eliminate problems such as DTV (Disc Thickness Variation) or deep grooving with your brake lathe, but since Nissan/Infiniti makes new O.E. rotors available at such a reasonable price it often makes sense to replace them. In fact, there is a trend going on among repair shops to do just that and to use their lathes less and less.

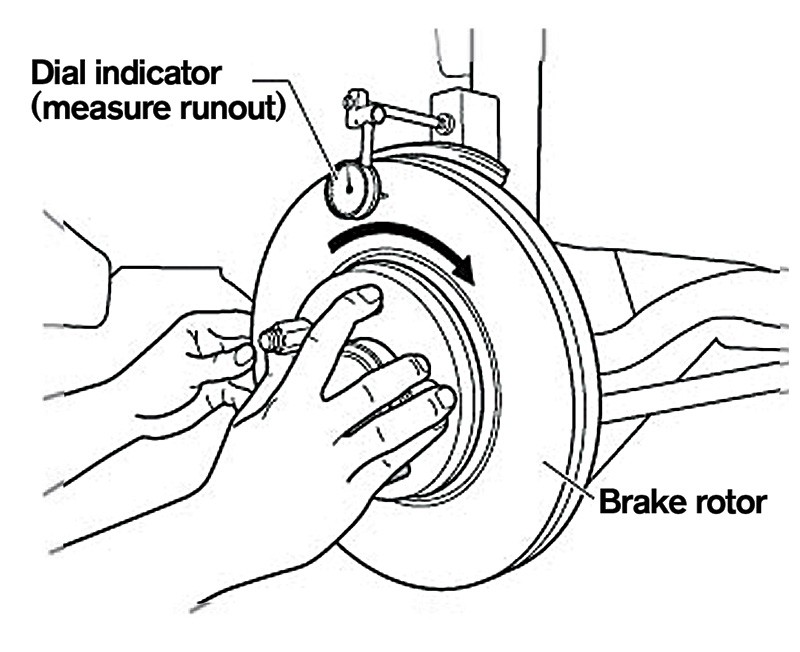

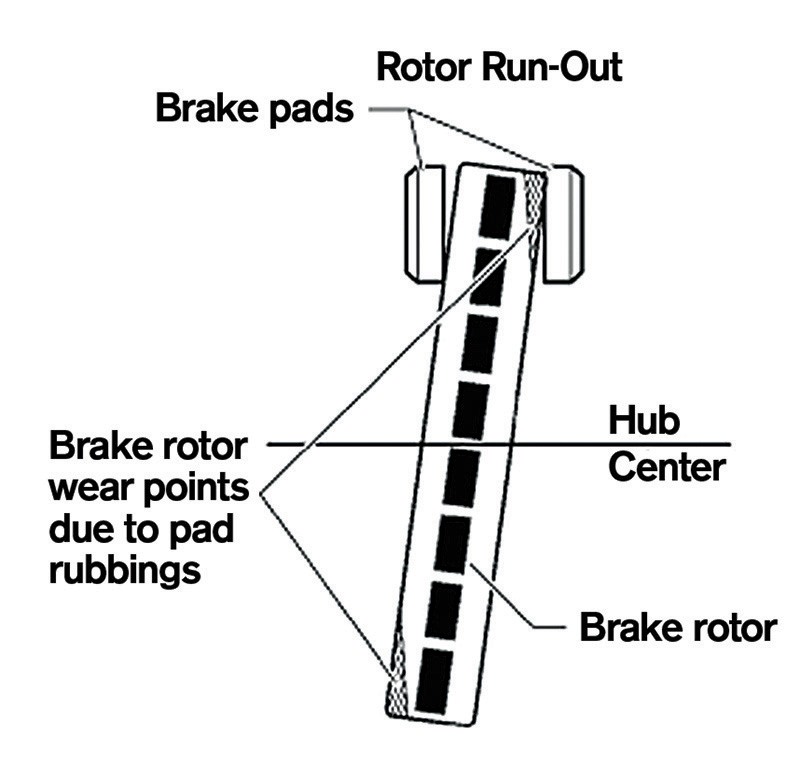

If runout is beyond specifications, check for mounting errors before you machine or replace the rotor.

There is one caveat, though. Many aftermarket replacement rotors simply do not match the quality of O.E. specimens in either manufacturing or materials.  If you’re not a metallurgist and don’t have X-ray capabilities, how can you tell what you’re getting? We’ve seen cases where off-brands weighed several pounds less than the originals. That can contribute to the warpage that can result in DTV, pedal pulsation, and a reputation-damaging comeback. If you’re going to put on new rotors, choose only O.E. from your local dealer’s parts department for quality and tight run-out specifications.

Your part

The idea of replacing rotors is all fine and good, but how can you be sure you’re not buying trouble? Only by insisting on O.E. quality from your Nissan dealer’s parts department.

The evolution in lining material has made rotor finish much more critical than it used to be. Some experts say that getting this right will eliminate 80% of noise comebacks. Smoothness is the rule. Where 80 100 RMS was once considered correct, now 40 60 RMS is recommended. In other words, in cases where you are turning the rotors on your lathe and are finishing up with a non directional swirl, use 120 to 150 grit paper instead of the traditional 80.

One brake expert tells us that some people get confused about this because new rotors come with a directional finish. “What’s important is the fineness of the finish,” he says. “New rotors will probably be in the 30 40 RMS range, which is hard to achieve with the average shop lathe. Adding that non- directional finish with an abrasive is a means to an end.”

Unless you’re a metallurgist, how will you know whether or not those non-O.E. rotors have a cast iron composition that’s up to Nissan’s standards?

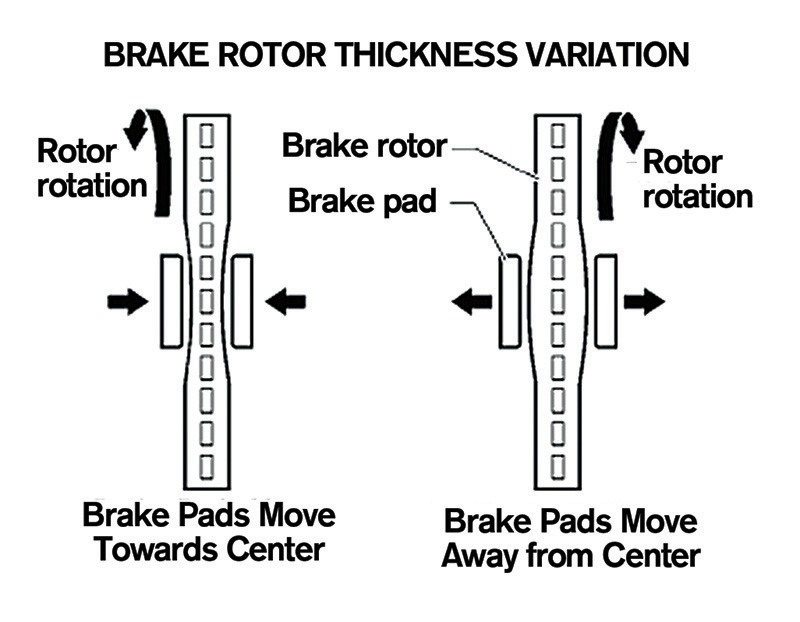

Speaking of brake lathes, the on-car type is an excellent choice for several good reasons. First, it eliminates the possibility of rotor mounting errors that can result in runout. While runout itself won’t cause pedal pulsation or “judder,” it leads to disc thickness variation (DTV), which certainly does manifest itself as that distressing condition. Runout causes the rotor to wear unevenly as it hits those abrasive pads in one spot on each side every revolution of the wheel. The contact areas will end up thinner than the rest of the disc. Any lack of parallelism between the two sides of a rotor is the direct cause of pulsation — the fat places knock the pads and piston back, and that little column of fluid transmits this movement to the pedal.

Second, avoiding the dreaded squeal is often considered another justification for the purchase of this equipment. An exec for a company that makes on-car lathes tells us, “Noise comes from vibration. If you can get all the thickness variation, runout, and taper out of a rotor, you can be pretty sure it won’t be the cause of noise.”

Finally, an on-car lathe is by far the best way to deal with vehicles that have rotors that require major surgery for removal.

0 Comments