Noise, Vibration and Harshness (NVH) is an important topic and one that auto manufacturers take very seriously. Large amounts of time and money are devoted to research and development in this area. Engines and transmissions spend hours on NVH test benches before ever making their way into production. Prototype vehicles are driven on dynamometers inside of sound chambers, fine tuning acoustics and eliminating unwanted noise. There are even college courses and certificate programs devoted to the automotive NVH field.

Noises and vibrations are not all created equal, and owners have come to expect a smooth ride with little to no road noise heard in the cabin. These factors make tracking down a vaguely described intermittent noise a difficult proposition indeed. Higher frequencies may not be heard by everyone, especially older technicians who have lost some hearing from years in the shop (which is why it is important to always wear hearing protection when using air tools like air hammers and grinders). Lower frequencies can sometimes be felt more than heard. This can be problematic when attempting to get a good description of a noise or vibration from a customer. If possible, it is always good to have the technician who will be servicing the vehicle go on a ride along with the customer to make sure both parties are on the same page.

What is NVH?

So what is NVH and why is so much attention paid to it? The acronym is simple enough, standing for Noise, Vibration and Harshness. This covers a wide range of sounds and sensations a vehicle owner can experience while driving. These may just be an annoyance, or they could present a serious driving hazard. Nissan offers an online eLearning module entitled “Introduction to Noise, Vibration, and Harshness.” This is an excellent web based course that is available through www.Nissan-TechInfo.com. There is a subscription fee for accessing Nissan service and training information, but there are several affordable options depending on a shop’s needs.

As technicians we usually deal with the N and V more than the H, but let’s take a look at examples of each and their definitions according to Nissan.

Noise: For the purposes of this article, a noise is defined as an unpleasant audible sound that can only be heard with one’s ears. These can occur with the vehicle stationary, like a belt squeak, or the vehicle may need to be moving, as in the case of a faulty wheel bearing. Noises may come from under the hood, from the driveline or suspension, or from inside the passenger compartment.

Vibration: Vibration is a physical feeling that lasts a few seconds or more and can be felt through the steering wheel, brake pedal, seat cushion, etc. Vibrations can be the result of an out of balance tire, damaged axle joint, or an engine misfire. Vibrations are often related to a specific vehicle speed or engine rpm.

Harshness: Harshness is an impact vibration that is abrupt or short in duration. Some possible causes of harshness are over-inflated tires or selecting an inappropriate setting on an adjustable suspension system. Some vehicles have a harsher feeling over bumps due to a more rigid suspension. In these cases, a client concern may actually be normal operation. An extreme example of harness would be “locked struts.” This is a phenomenon that can happen when a vehicle is raised on a hoist and the suspension is left hanging fully extended. Once the vehicle has been lowered the struts remain in a “locked,” fully extended position. This is not very common, but can happen, especially on older or higher mileage vehicles and usually requires strut replacement.

Lighter Weight = Heavier Sound

The old bromide, “They don’t make ‘em like they used to” applies well to automobiles. The days of solid steel frames and body panels with little thought for fuel efficiency and sustainability are long gone. Aluminum, plastics, and carbon fiber have replaced much of the steel used in production. As vehicles become lighter though, the risk of noise and vibrations goes up. Electric vehicles are particularly susceptible to this because electric motors are nearly silent compared to internal combustion engines.

The advancements in lighter weight vehicles have necessitated advancements in noise and vibration abatement technology. Nissan has used an Electronic Controlled Engine Mount vibration cancellation system on certain models for many years. According to Nissan service information, electronic engine mounts are “specifically designed to reduce the effects of the engine combustion process during low speed operation. An Engine Mount Control Module sends a signal to the engine mount which creates an opposing force to the engine vibration level. This in turn reduces the engine vibration feeling in the vehicle.“

Another technology being used on select Nissan and Infiniti models is Active Noise Canceling. Noise cancellation in the passenger compartment works much like noise canceling headphones. Nissan’s “Introduction to Noise, Vibration, and Harshness” online course provides a great overview of the system. Vehicles that use this technology are “equipped with an Active Noise Control Unit and multiple interior microphones usually located in the headliner area. The system works in conjunction with the vehicle’s audio system and is working whenever the engine is running. The interior microphones capture low-end drivetrain frequencies and send them to the control unit. The control unit creates a precisely-timed, opposite phase audio signal and sends it to the audio system speakers. This opposite or reverse phased signal reduces or cancels out the unwanted noise.“

Nissan has also been working on new insulating materials for some time now. Their latest development involves a product called meta-material. Advanced Material Engineers at Nissan have found a way to turn meta-material, which originated in the field of research antennas, into a sound dampening material. This acoustic meta-material is a significantly lighter weight option to traditional adhesive rubber padding or spray on insulation, but it is just as effective in quieting the passenger cabin. The new material is also less costly to manufacture, which means it won’t be relegated to the higher end vehicle models only.

Tools of the Trade

There are multiple tools on the market to aid in diagnosing NVH problems. Some are traditional tools that have been used for decades, and others are newer additions to automotive field. Nissan recommends the STEELMAN® brand of ChassisEARS, and EngineEARS when trying to isolate sounds on the powertrain or chassis of a vehicle. These are tried and true testers that have been around a long time. They are versatile, but do have some limitations, especially when dealing with rotating components on the engine or drivetrain.

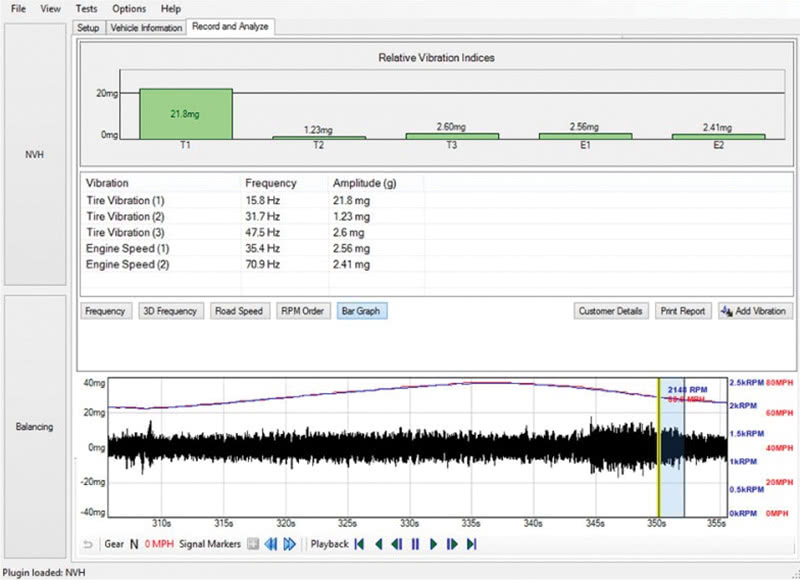

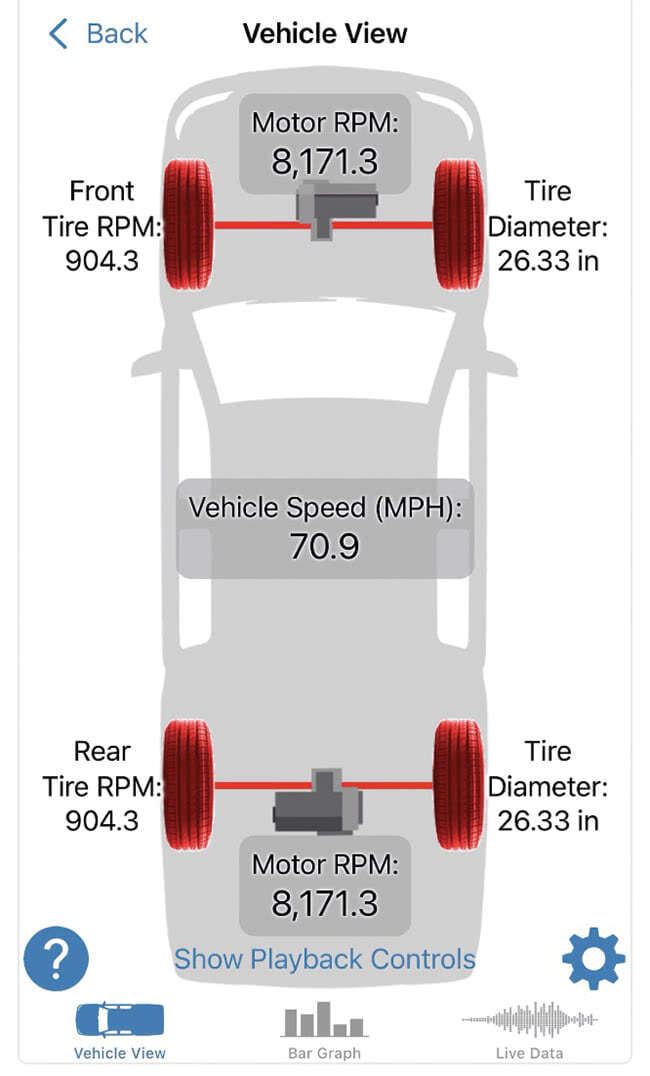

There are several software based NVH testers available also. These testers use complex software that analyzes the frequencies present on a vehicle and compares them to engine rpm and vehicle speed to determine possible causes of a vibration. The NVH App is a smart phone based vibration tester available for Apple and Android products. Using the accelerometers in the phone, the app can accurately analyze the vibrations present during a road test and pinpoint a likely cause. As far as apps go, the NVH App may seem pricey, but it is significantly less expensive than the lab scope based testers. This could be a good option for a shop looking to try software based vibration analyzers with minimal investment.

Picocope offers an NVH tester with 3 and 4 axis options. This is a very powerful tool that uses similar software to the NVH App to analyze all the frequencies on a vehicle and determine if a noise or vibration is coming from the tires, driveline, or powertrain. The results are displayed in graph form with zoom and playback controls allowing for detailed analysis.

One downside of Pico’s tester is that the tool works through a labscope, so a 4 channel Picoscope is required. The Picoscope NVH tester and lab scope are available for purchase on Nissan’s TechMate website.

Another newer technique involves using a frequency generator that then feeds into the vehicle’s audio system. With the key on and the radio volume turned up, a sweep can be run on the generator starting with lowest frequencies first. When the frequency coming out of the audio speakers matches the frequency at which the suspect noise resonates, the noise will be heard and easily tracked down. This techniques works well for dashboard or body panel rattles, but can also be used for suspension noises. Audio systems equipped with a sub-woofer make this method more effective as well.

Don’t Forget the Bulletins

Technical service bulletins are an excellent place to start when dealing with a noise or vibration issue. Often times Nissan engineers have tracked down a common problem and have already developed a solution. Searching for bulletins before spending valuable time driving or disassembling a vehicle is the best practice to follow. Be sure to search multiple systems and keywords for bulletins though, as a rattle may be found under the heading of suspension, brakes, or even powertrain.

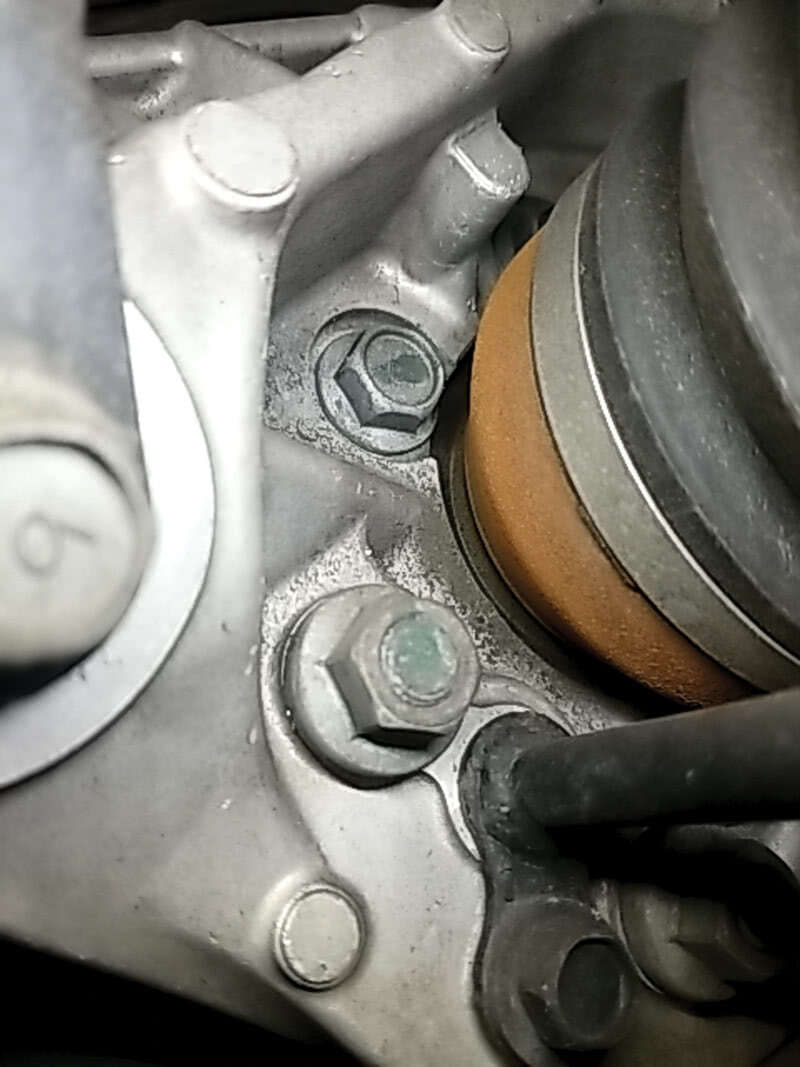

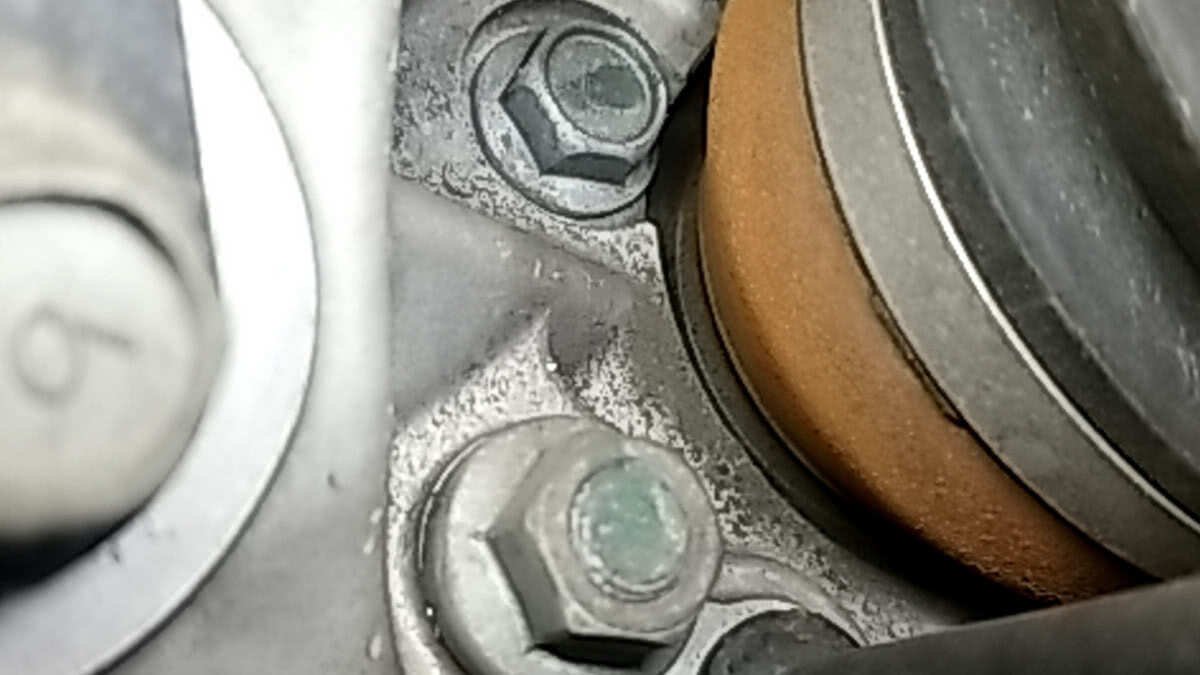

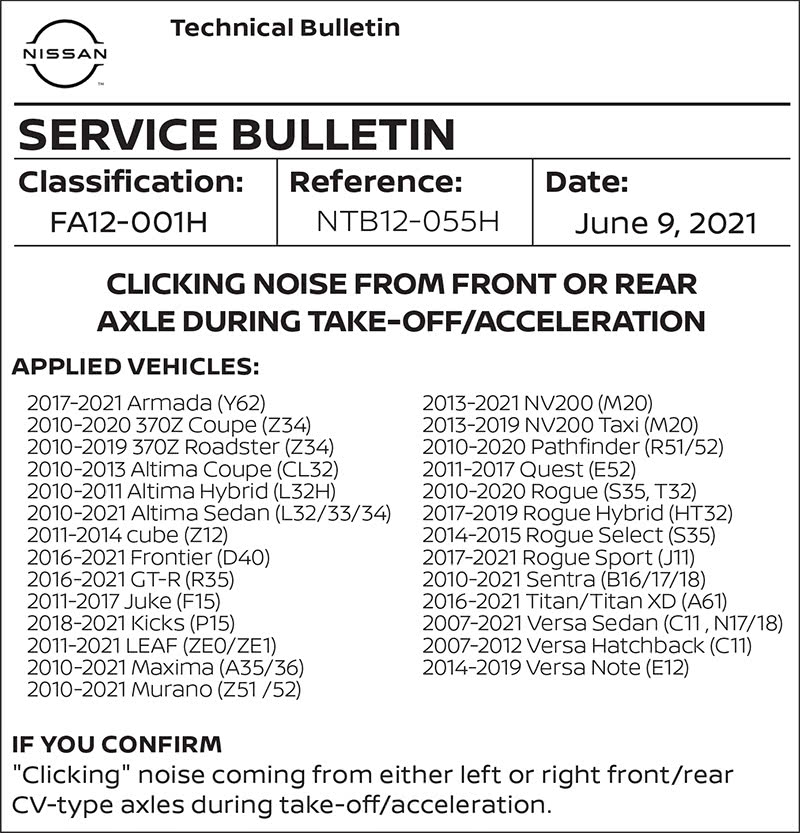

Here is an example of a TSB that saved a great deal of time on a 2020 Nissan GT-R with an intermittent clicking noise when accelerating. Bulletin NTB12-055H provides instructions for dealing with this clicking noise on a variety of Nissan models and years.

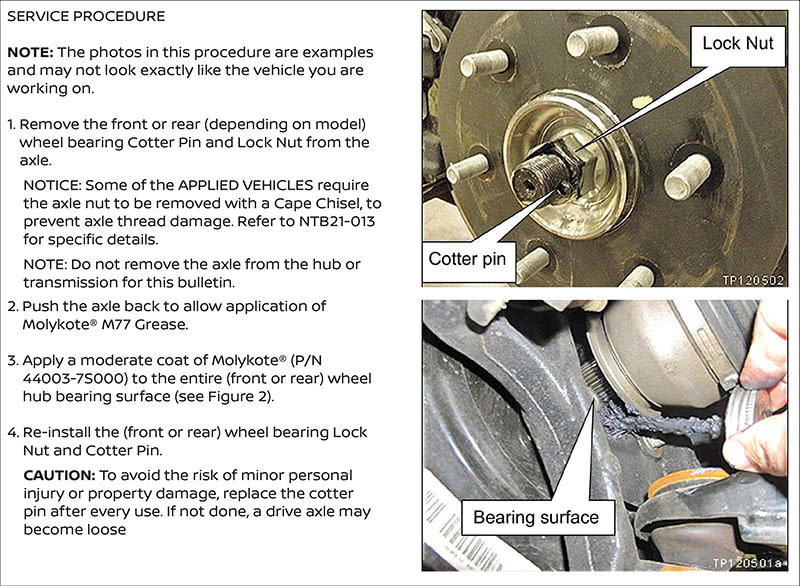

A moly-type grease (part number 44003-7S000) needs to be applied to the hub bearing surface of the front or rear axles depending on where the noise is coming from. The axles do not need to be removed from the hub, just pushed back an inch after the wheel bearing lock nut. The lock nut needs to be tightened to the correct torque specification with a new cotter pin, and on certain models the lock nut and washer also need to be replaced.

Xterra Case Study

Sometimes a technician needs to channel their inner MacGyver when tracking down a noise concern, as in this vehicle study of a 2005 Nissan Xterra with 120K miles on the odometer.

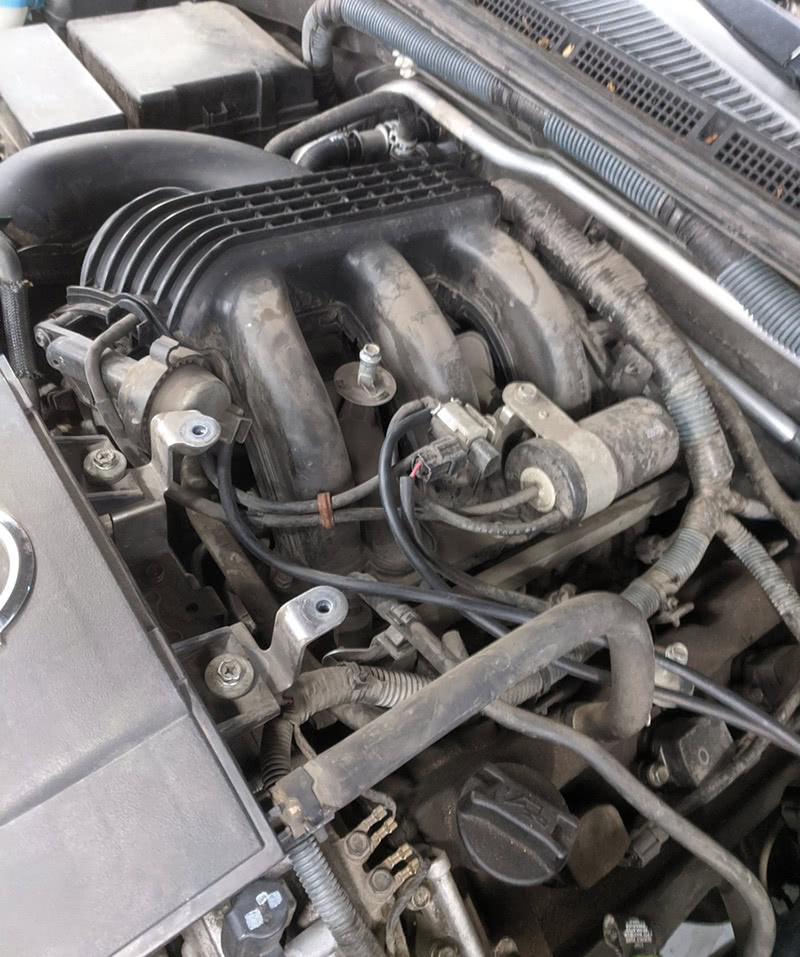

The SUV was brought in with a complaint of a ticking noise. The sound was very intermittent, happening only when the engine was fully warmed up and only at a specific mph and rpm range. The noise was definitely from the engine bay, but it was difficult to pinpoint and seemed to resonate from all over under the hood.

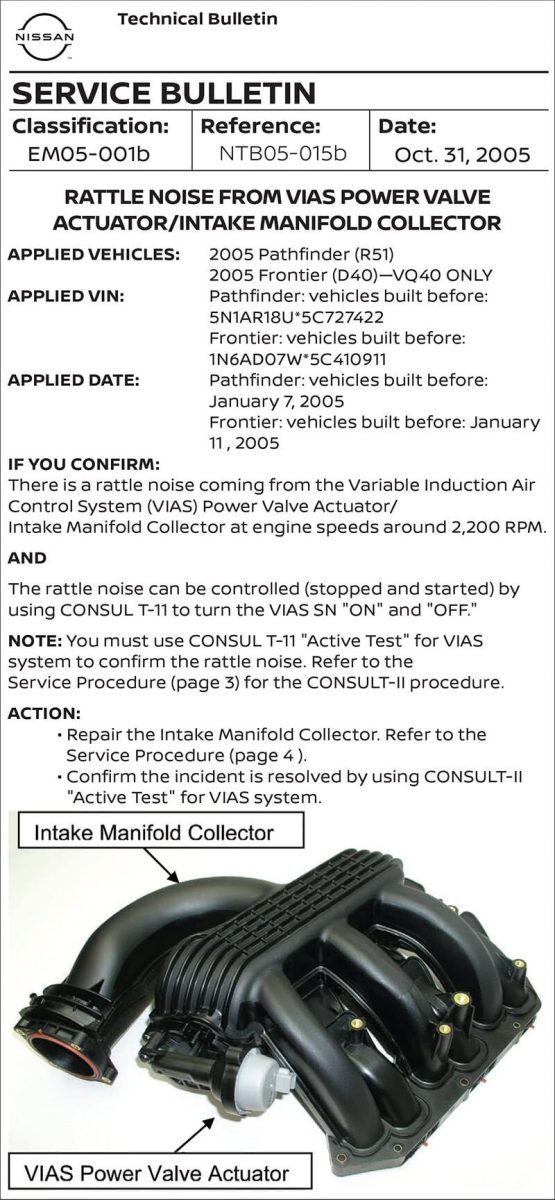

Initial research found there was a technical bulletin that could hold some promise. The bulletin was for a rattle noise caused by the Variable Induction Air Control System (VIAS) at a very specific rpm range. The VIAS uses an electric control solenoid to supply engine vacuum to a runner valve inside the intake manifold. While the TSB was not specific to this year and model Xterra, it was for the VQ40 engine, and this engine was equipped with the variable intake manifold runner.

This is where the tech needed to get creative. He used bulk hose to extend the vacuum lines to the IMRC and run them safely into the driver’s seat. Using a hand vacuum pump connected to the extended lines would allow the technician to road test the vehicle and, when the noise was present, change the vacuum supply to the intake flap and see if the noise changed.

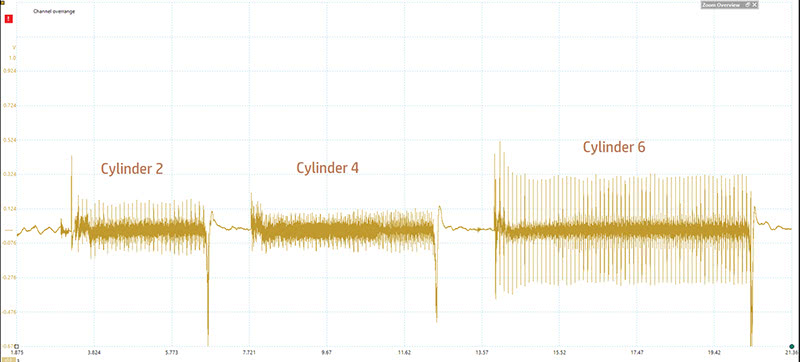

After several unsuccessful road tests to recreate the ticking, the technician was able to find the magic combination of engine temperature and throttle angle needed to produce the noise. Unfortunately altering the control vacuum to the intake manifold had no effect on the ticking noise. It was back to drawing board. After further trial and error the noise was able to be duplicated in the service bay by brake torquing the engine under just the right conditions. This allowed for a second alternative testing method to be tried on this Xterra, a pulse sensor connected to the end of a mechanic’s stethoscope.

With a helper power braking the engine in Drive, the technician used the lab scope powered stethoscope to probe around under the hood. The “loudest” point of the noise as seen by the pulse sensor was on the left valve cover. The sensor picked up larger vibrations as it was moved towards the back of the valve cover. This test indicated an upper end engine noise from cylinder 6, all without removing any bolts. The service history of the vehicle was unknown, but it was likely that it had missed some oil services over the years, resulting in excessive wear to the valve train. In the end, the client admitted the noise has been going on for almost two years and decided to not spend any more money to remove the valve cover for further inspection.

NVH concerns are only going to increase as cars become lighter and as more electric vehicles enter the market. We hope that this information will remove some of the dread and apprehension that are often associated when a vehicle with an NVH complaint is brought into the shop.

0 Comments