A shop called me in concerning a no-start complaint on a 2001 Chevy pickup with a 4.3L Vortec engine (Figure 1). It had 232,000 miles on it, and had sat for eight months in a back yard until the owner decided to revive it and put it back on the road. The only history the owner provided was that the vehicle ran badly, and that he didn’t have the money at the time to fix it.

You know these customers all too well. These are the people who come to your shop claiming that they’re financially strapped and don’t want to spend a lot of money to fix their cars. Better yet, they feed you that famous line, “Just do it as cheaply as you can because I’ll be getting rid of it soon.” Meanwhile, they keep on using the same vehicle for the next decade or so.

The biggest problems with cars that sit so long are that the gas in the fuel tank goes stale, and the invitation to little critters to feast upon wiring harnesses. So, whatever issues a vehicle had before it went into hibernation can only be compounded by sitting. This one started, but ran poorly prior to its storage period, but now it was in a crank, but no-start mode.

The garage had already performed the basics by charging the battery, checking the fuel content, and changing the fuel filter. The spark plugs were soaked with gas from the customer’s attempt to start the engine, so the shop installed new ones. They only got soaked with fuel again within only a few cranks. The plugs were pulled again, and this time the tech performed a full compression test an all the cylinders. The results showed well above 150 psi. Next was a check of proper spark reserve using an ST125 tester. This stresses the ignition coil and forces it to put out close to 30 kVs. When the spark checked okay, the shop went one further step to ensure that the exhaust was not clogged. This was done by simply dropping the exhaust. At this point, nothing had panned out, so the shop decided to call me in to get a second opinion.

When I arrived, I talked to the shop owner to get a little history on the vehicle and a description of what tests had been performed. I decided to do a simple scan (Figures 2&3) to make sure all the PCM’s vital signs were in order. There were no codes in the system, and the data PIDs seemed to all be within range. Looking for codes and reading raw data such as coolant temp, air temp, TPS, or MAP can save a lot of time when dealing with an over-fueling engine, but sometimes you need to take a step back and look at the big picture. If the engine cranks and floods with raw fuel, it may not be due to a rich condition. It may be a lack of combustion created by valve timing, ignition timing, clogged exhaust, or even weak spark. The quickest way for me to validate most of these possibilities was simply to place a pressure transducer in any cylinder and use an inductive clamp to tag the spark plug wire of that same cylinder while it’s hooked up to a spark tester.

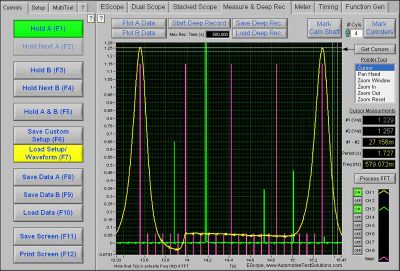

I chose to capture the events in cylinder #1 (Figure 4) using my scope program coupled with my pressure transducer and inductive probe. You first need to be aware that each large purple curser represents 180 degree increments, and the smaller cursers represent 30 degree increments. The peak rise is the compression stroke, and the peak-to-peak rise is one full cylinder event of 720 degrees of crankshaft rotation. The small upward slope after the peak compression fall is the point at which the exhaust valve begins to open. I usually find this to be about 30-45 degrees before BDC of the power stroke while cranking the engine. The waveform capture (Figure 4) shows the exhaust valve opening at about 30 before BDC of the power stroke, which proved that the timing chain on this high-mileage engine had not jumped, and that the crank-to-cam gear correlation was correct. If you look at the green square waveform pattern created by the inductive clamp, you can determine the time the spark occurred in the cylinder. There are other smaller green spikes, but these are usually caused by electrical noise the probe can pick up from other cylinders firing. The first rise in the square wave is the point where spark has occurred. By looking at the pattern, you can see that the spark was very late by firing about 255 degrees after TDC of the compression stroke. This engine was not out in valve timing, but had a serious spark timing issue.

Spark timing malfunctions can be caused by a crank sensor or cam sensor correlation problem from out-of-synch trigger wheels, or possibly an incorrectly indexed distributor. The engine did run poorly before it was stored and finally cut out, so maybe the distributor gear was wiped. I set the crankshaft at TDC compression for #1 cylinder, and removed the distributor cap to check for proper rotor indexing, but was taken aback by what I saw. The distributor rotor was no longer secured to the distributor shaft because both screws were missing (Figure 5). The amazing thing was that it still spun when the engine cranked over, thus providing a good repetitive spark at the plug, but at the wrong time. Any technician checking the spark could have easily been fooled into thinking the spark was okay, but without the proper equipment it would be impossible to know just when the spark was actually occurring in the cylinder. Further inspection revealed the two missing screws to be lying under the rotor tucked away like two peas in a pod (Figure 6). It was as if they longed to be together in the face of doom when they both decided to jump ship together.

What was amazing to me was how I quickly found this problem by simply using a pressure transducer and an inductive probe. Who would ever have thought 10 years back that there would come a time when I could actually see events occurring within a cylinder by simply looking at pressure readings on a screen. It’s well worth it to keep reinvesting in your business to keep up with the never-ending advances in technology. If there’s a piece of equipment out there that’s going to make my job easier, then I just have to have it. Getting to the root of a problem without wasting time and money on unwanted parts and labor is my idea of running a productive automotive business in today’s world of sophisticated cars. I hope this story can excite you to take yourself to the next level.

by John Anello,

“The Auto Tech on Wheels“

great articeljohn a wealth of diagnostics info