Let’s take a look at Nissan’s Continuously Variable Transmission, including a basic overview of its design, and focus on the independent repair shop’s role in servicing, diagnosing, and repairing this different means of applying twisting power.

The Continuously Variable Transmission has been around since Leonardo Da Vinci conceived it during the Renaissance. Of course, then there were no machine tools to manufacture it, and no possible applications if you could. Nissan has taken the concept and implemented it to a greater degree than any other vehicle manufacturer. With nearly infinite gear ratios, Nissan is capitalizing on what no other type of transmission can do. The CVT eliminates the primary problem with the internal combustion engine: the fact that peak power and efficiency only occur at a certain RPM ranges. With today’s heightened concern over mpg and emissions, there’s no wonder why Nissan is using the CVT in many of its new vehicle applications. Will you be prepared to service and repair this next generation of transmission technology?

How it Works

Briefly described, the CVT transmission uses a belt and two pulleys to create different gear ratios. One pulley performs the “input shaft†function, and the other pulley behaves like the “output shaft†on a standard transmission. Each pulley is composed of two moveable conical discs that slide together or apart on an axle (traditionally, these were called “split sheaves”). The Transmission Control Module (TCM) commands one set of discs to move closer or farther away from each other, which will cause the belt to ride higher or lower on the pulley face effectively changing its working diameter. Both pulleys constantly resize, creating different transmission ratios at the whim of the TCM. The computer uses various sensor inputs to calculate the necessary pulley positions.

The belt is an impressive, snakeskin-looking band made up of hundreds of tiny metal plates conjoined with high-strength steel bands. The belt pushes against itself to transmit force, rather than the standard “pulling†behavior of an accessory drive belt. As a result, it lasts longer and should not ever require service or adjustment because of stretching. Wear is minimized by the specialty CVT fluid, which is formulated to prevent the metal of the belt from directly contacting and wearing away the pulley surfaces. Failure to use the genuine NS-2 fluid will damage the transmission, not to mention void your customer’s warranty. It may be tempting to use a “multi-purpose†ATF in your customer’s CVT transmission considering the cost of

NS-2: Don’t do it!

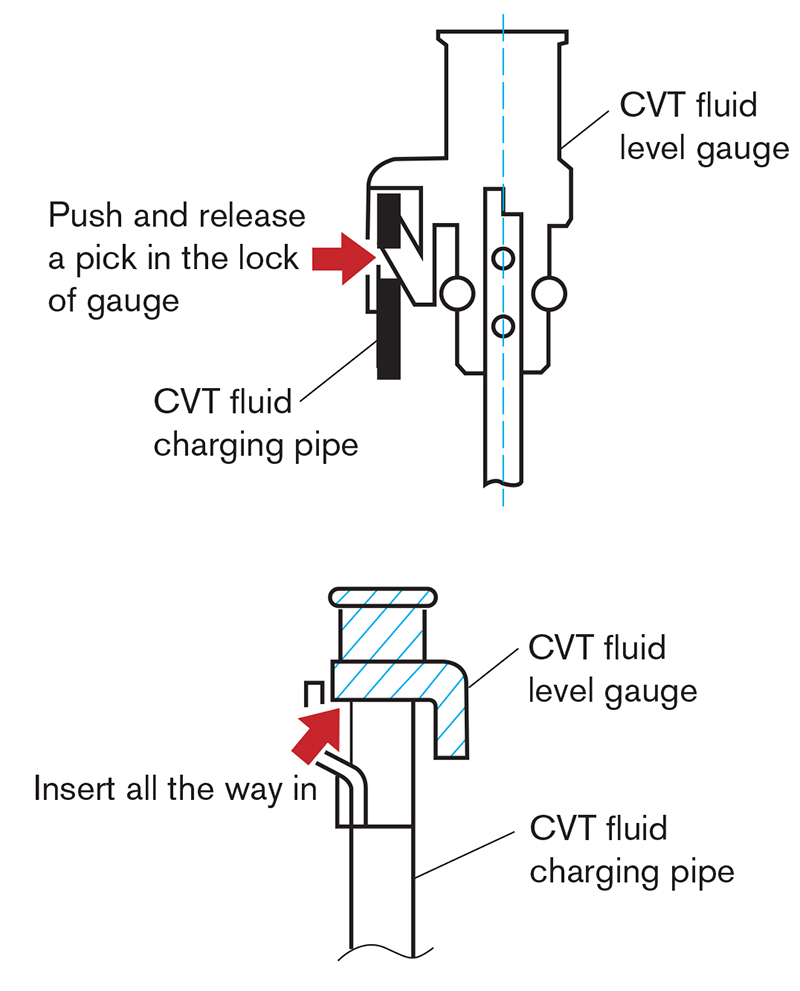

Considering the potential for error, most CVT-equipped Nissan vehicles do not have a standard dipstick for checking the fluid level and condition. This prevents vehicle owners from inadvertently damaging their transmissions by adding ordinary fluid, but it also requires the use of a shop tool to access the tube as a fill point for service.

CVT Maintenance

The NIssan CVT dipstick is designed to lock in place to prevent an unfamiliar technician or operator from adding incorrect fluid.

Nissan uses three different types of CVTs depending upon the vehicle’s requirements. The smallest unit, CVT1 (designated JF009E), is found on the Versa and Cube models. The middle unit, CVT2 (designated JF001E), is used for the mid-level Sentra, Rogue and Altima 2.5L models. The largest unit, CVT3 (designated JF010E), is strong enough to handle the power of Nissan’s world-famous V6 in the Murano, Maxima, and Altima models.

To check the fluid level and condition of any of the CVT units, begin by warming up the transmission to operating temperature (between 122 and 176 deg. F.). As usual, park the vehicle on a level surface, but before turning off the engine you should move the shift selector lever throughout the entire shift range and return it to the “P†position. Locate the CVT fluid level gauge, which will have a locking mechanism that requires the use of a small pick to release the dipstick. Remove the dipstick, wipe it off, and rotate the stick 180 degrees prior to reinserting so it doesn’t lock. Check the level and note the condition. Add fluid through this tube, which Nissan calls the “charging pipe,†as necessary.

For any CVT unit, Nissan does not have an official drain and fill interval for service, even under severe operating conditions. The only printed requirement is a 15,000-mile inspection of the fluid level and condition. Consult the chart below to determine whether the fluid condition requires service. Some independent shops may adopt a preventive maintenance schedule, but be mindful that the drain procedure requires more labor than it would on a typical automatic transmission and that the fluid is much more expensive!

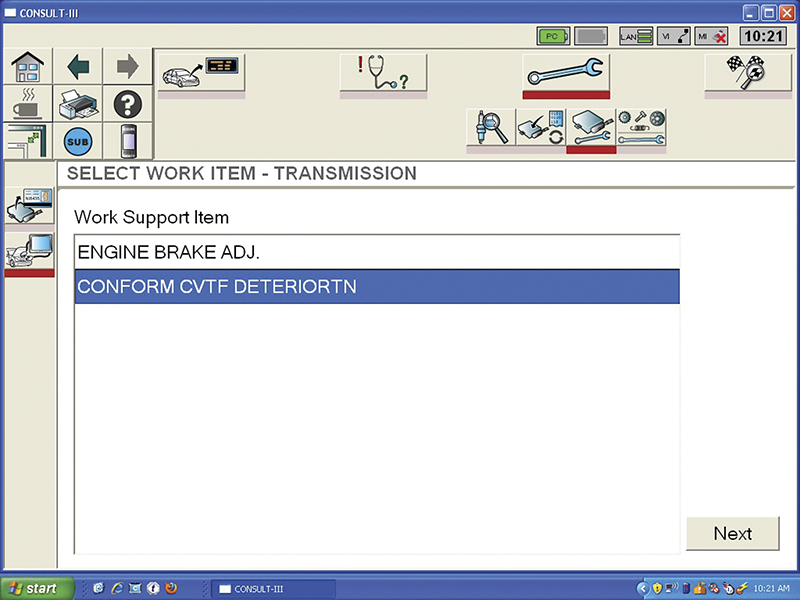

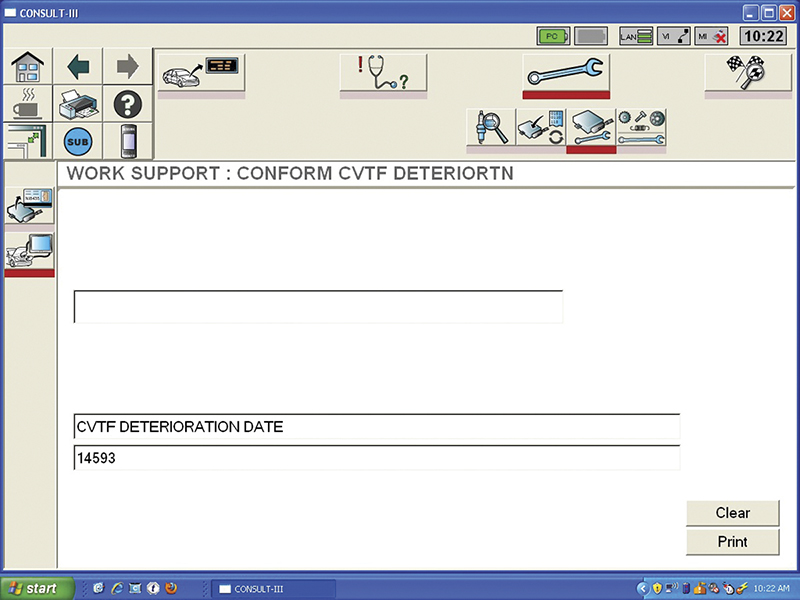

The CONSULT also includes a work-support function that will check the fluid condition as inferred by the TCM, based on drive cycles and history of calculated load. Connect the CONSULT, enter work-support mode, and check the value for CONFORM CVTF DETERIORTN. A value greater than 21000 requires fluid service.

If the CVT requires service, ensure that the fluid is at operating temperature as mentioned earlier, and locate the outlet cooler line at the radiator. With the engine idling, remove the outlet cooler line and start draining the CVT fluid. At the same time, fill the charging pipe until new fluid comes through the cooler line. Use genuine Nissan NS-2 fluid ONLY! NOTE: About 30-50% extra fluid will be required for this procedure, so be certain to over-estimate the fluid parts cost when discussing the service with your customers. Reconnect the cooler lines, recheck the fluid level, then finish the CVT fluid service by using the CONSULT to clear the above-mentioned value for CVT fluid deterioration. Failure to clear this value may cause unneeded service in the future.

According to the Nissan service manual, repeat the above fluid service twice to perform an official CVT fluid flush. DO NOT use an aftermarket transmission flush machine or fluid exchanger, and do not use any transmission fluid additives. It will damage the CVT unit and void your customer’s warranty.

Common CVT Problems and Their Diagnosis

Use the CONSULT to check the health of the CVT fluid according to the transmission control module. Access work support, then find the value.

Any major CVT malfunction will likely turn the MIL on with useful DTC information. First, check the fluid level and condition as discussed earlier. Then, connect the CONSULT to the vehicle and run an all-systems call to find relevant DTCs. According to Nissan TSBs, CVT failure typically occurs in one of the following manners: a control issue, a physical transmission defect, or both. Before we proceed with common scenarios, refer to TSB# NTB11-043, which applies to all CVT transmissions from 2007 up. It states that prior to any replacement of the TCM, even as recommended in the repair manual, the additional diagnostic steps of this TSB must be followed. For DTCs P1722 and P0725, there may be other sensor inputs causing problems that must be investigated and repaired prior to condemning the TCM. If P1722 is stored, there could be a malfunction with one of the ABS/VDC sensors or its wiring. If P0725 is stored, there could be a malfunction with the crankshaft position sensor or its wiring. In either case, if the code is accompanied by U1000, there is likely a problem with the CAN communication lines between the TCM and the ECU or ABS computers. Avoid costly and unnecessary repairs by staying up-to-date with the latest TSBs online at www.nissan-techinfo.com. CVT control malfunctions can occur when the TCM or the sensors it relies upon fail. Some failures of the TCM are software-related, and Nissan includes a procedure to reflash the computer without having to replace the transmission control unit. Sometimes, if the transaxle is replaced, TCM reprogramming or replacement may be necessary to complete the repair. Check for TSBs that apply to the vehicle you are currently working on, which will include instruction on how to perform the reflash. Refer also to the March 2011 issue of Nissan & Infiniti Tech News for in-depth information about reflash procedures.

Even if the fluid looks okay, if the value of this field is greater than 21000, you should service the transmission. This transmission’s fluid is still within the interval. Use the same window used to clear the fluid deterioration value after service

Sometimes, TCM Initialization is required – which is different from reprogramming – and may be necessary after CVT replacement without replacing the TCM, or when using a TCM from another vehicle. First, park the car, and turn the key to engine OFF. Connect the CONSULT, navigate to transmission control, then to the special functions sub menu. For reference, select the TCM part number and calibration data and print a copy. Start the initialization procedure by doing the following:

- Select Transmission Self-Diagnostic Results.

- Press and hold the brake pedal.

- Shift the selector lever to Reverse.

- Press and hold the accelerator pedal down about one-third, but no more than halfway. The purpose of this step is to get both the wide open throttle and closed throttle position signals to read OFF at the same time.

- Press Erase.

- Shift the selector lever to Park. Observe the shift selector position display. There will be a delay for “P†to illuminate if the Initialization was successful. If there was no delay, perform steps 1-5 again. Turn off the ignition for at least five seconds, then verify success and clear all DTCs.

Heavy Lifting: CVT Replacement and Overhaul

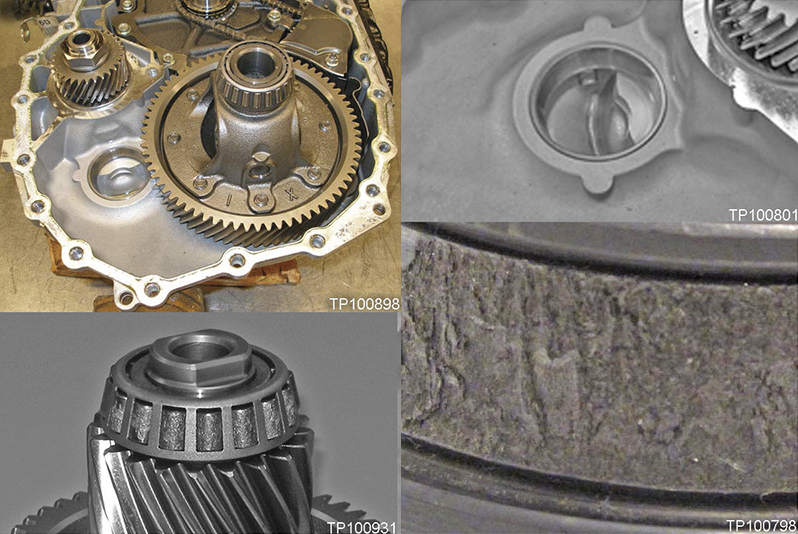

Inspecting the differential reduction gear roller bearing. Be warned! If there is similar damage on both the roller bearings and the inner race, and the outer race can be moved by hand within the CVT case, there is no overhaul possible. You must purchase a new CVT unit.

When does the transaxle have to be replaced? Usually the customer complaint will include a description of sluggishness or slow acceleration. Check for DTCs, even if the MIL is not on. For example, a sluggish Murano may have a bad CVT unit with P0868 stored, but this fault won’t illuminate the MIL. In this particular instance, the valve body can be replaced with upgraded parts. If your shop is equipped to rebuild automatic transmissions, this procedure may be a viable alternative to total CVT replacement.

Some internal failures of the CVT2 found in the Sentra, for example, may result in a whine or grind noise that changes in pitch with acceleration, or persists at highway speeds. This failure is mechanical and won’t set a fault. Again, if your shop is inclined to overhaul transmissions, follow the Nissan published procedures for complete CVT disassembly, inspection, and repair. Bear this in mind, however, that servicing the Nissan CVT requires special service tools in order to pull bearings or races. You will also need to calculate the size of the shims used in the overhaul, and the CONSULT-III includes an application for this. Without the special service tools and the CONSULT, your shop should replace the entire CVT unit instead.

Be certain to perform traditional diagnostic checks first. Access the ECU for faults and check for individual part failure. The customer’s complaint may be caused by a bad wiring harness on that particular circuit, or the part itself. DTCs P0845 and P0840 correspond to the two pressure sensors that the TCM uses to make gear ratio decisions. Many times the TCM is at fault for interpreting the signals incorrectly, but be sure to verify that the sensors are operating within published specifications. It would be wasteful to replace the TCM or perform a recalibration before checking whether or not the sensor works in the first place.

The CVT also uses a torque converter, which can fail to lock up in the same manner as typical automatic transmission systems. If P0744 is stored, the transmission may indeed be slipping; however, there could also be the possibility that the TCM cannot perform the lock-up if the torque converter clutch (TCC) lock solenoid is bad. Perform simple checks to confirm that the solenoid actuates when commanded, and that the clutch locks. Be sure to clear the fault, too, if it’s the first recorded incident of failure. Test drive the vehicle with the CONSULT, and monitor live data PIDs to see if DTC P0744 returns immediately under the right circumstances (accelerator pedal depressed at least one eighth, transmission in “Dâ€, constant speed greater than 25 mph). If the problem is very intermittent, you may be replacing the transmission unit or the lock-up solenoid prematurely on a “hunch.â€

The CVT may start leaking fluid eventually. The independent shop needs to be able to identify and repair possible external fluid leaks. Axle seals, case joints, switches or sensors can all leak the expensive NS-2 fluid. Nissan has actually released a special TSB about leak detection on CVTs, and that fluorescent dye should be used to distinguish between CVT fluid and factory lubricants used at the time of assembly, or corrosion prevention chemicals. The recommended dye is available from Nissan Tech-Mate in a six-pack. Contact Tech-Mate at 1-800-662-2001 and order part number J-28431-6.

CVT operation depends on many inputs from CAN communications, as well as typical on-board control solenoids. Be sure to verify all systems are operational before condemning the transmission itself.

The Future of Transmissions?

Considering the advantages of the CVT, it is an excellent advance in Nissan’s continual efforts to increase the power and efficiency of its vehicles. The CVT contributes to better fuel economy because engine RPM stays fairly constant. Likewise, with lower engine speeds, there are fewer harmful exhaust emissions. Furthermore, a CVT has fewer moving parts than standard gear-driven automatic transmissions. The simplicity means decreased expenses for both manufacture and repair. Nissan has invested heavily in its CVTs, and you should plan to invest time and effort in learning to service them.

0 Comments