Frame Realignment and Suspension Alignment Pose Unique Challenges

In America, we drive on 55- to 75-mph highways. In certain countries in Europe such as Germany, highway speeds are typically much higher, sometimes with no limit. Mercedes-Benz, a global automaker, therefore insists on adherence to strict frame and suspension alignment specifications, as even small deviations from these specs can compromise vehicle stability and occupant safety, especially when magnified by speed. For those who repair Mercedes-Benz vehicles, there is zero tolerance for anything less than using the best resources that the automaker provides.

In America, we drive on 55- to 75-mph highways. In certain countries in Europe such as Germany, highway speeds are typically much higher, sometimes with no limit. Mercedes-Benz, a global automaker, therefore insists on adherence to strict frame and suspension alignment specifications, as even small deviations from these specs can compromise vehicle stability and occupant safety, especially when magnified by speed. For those who repair Mercedes-Benz vehicles, there is zero tolerance for anything less than using the best resources that the automaker provides.

Effective repair is rooted in accessing and using the most accurate collision service information, which is available at the Mercedes-Benz subscription-based startekinfo.com website. Facilities and technicians must also embrace industry-recognized training that raises technician competency to meet the repair challenges posed by new materials and inbound technology. In addition, the equipment and tools employed to must enable the safe and complete repair of any vehicle.

These three requirements enable a vehicle to be restored to the same safety ratings that the vehicle had pre-collision. Anything less is a disservice to the consumer, demonstrates a lack of professionalism, and puts the shop at risk of a charge of negligence.

Repair from the inside out

Mercedes-Benz requires that its dealer and independent collision repair facilities be certified by the automaker. In addition to Mercedes-Benz service/repair information, these certified facilities are required to employ factory-approved equipment, tools, and procedures. It should be noted that approved companies develop equipment and tools predicated on Mercedes-Benz repair information.

Examples include dedicated “jig and fixture†straightening benches, proprietary diagnostic tools (e.g. factory scan tool, Romess-Rogg inclinometer), based on collision repair procedures described in Mercedes-Benz Workshop Information System (WIS) guidelines at www.startekinfo.com (which provide jigs and mounting instruction, straightening guidance, bodywork repair data, diagrams, and documentation).

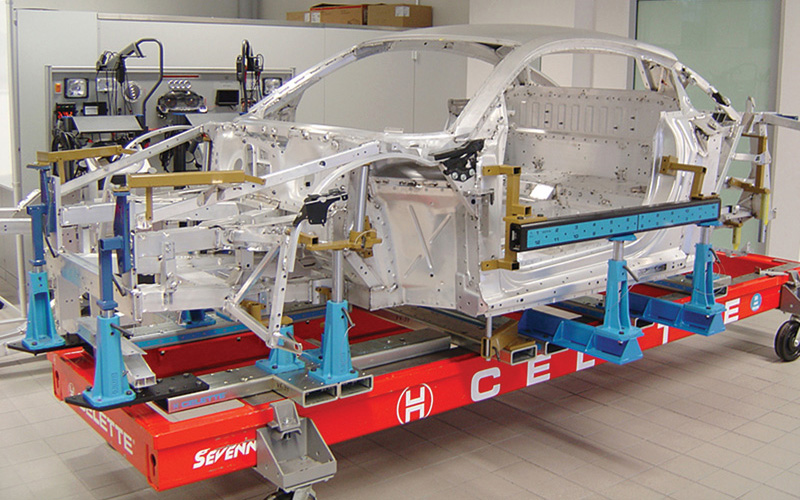

During manufacture, Mercedes-Benz vehicles are built using jig and fixture systems. Jigs are the key mounting points where a vehicle is attached to an automated assembly line, and also to a collision repair bench system, should a collision repair ever be necessary. Fixtures are measuring points that are used to provide a reference for the proper location of those key mounting points throughout a collision repair. In general, fixtures are not a point that is held and pulled against; rather, the fixture serves as a reference point for key location points to be pulled to before initiating further repairs.

Using dedicated bench systems during collision repair, such as those supplied by Celette Inc. (which is now part of the Azimuth Group) or Car Bench, helps Mercedes-Benz certified collision repair facilities precisely measure, control and monitor the repair. The vehicle must be mounted and securely fastened to the bench at points not affected by the collision using the straightening brackets and vehicle-defined mounting points. This allows dimensional variations in deformed or distorted parts to be recognized.

Key location mounting points can then be measured and repositioned in accordance with Mercedes-Benz specs and then locked down to prevent movement or damage during further repair. Whether a subframe element, suspension mounting point, safety system sensor, engine cradle, strut tower or some other vehicle element, only accurate positioning during the repair process can replicate the same dynamics obtained during manufacture.

For example, if bench measurement determined that these key location mounting points suffered no damage or displacement in the collision, then the vehicle can be locked down to the bench before any subsequent repair procedures are performed. If any key location point was damaged or displaced during the collision, it can be moved to the proper position on the bench, using the fixture as a reference point. Once positioned properly, the vehicle can then be locked down and further repairs initiated.

If a frame element needs to be straightened and service information indicates that it can be pulled rather than replaced, bench equipment jigs can pull the component to its proper position using fixtures as reference points. Should a part have to be replaced, the fixtures that are located on the bench provide reference points for height, length and width that enable the repair technician to place the new part in its proper position relative to the rest of the vehicle.

Proprietary diagnostic tools are also essential to proper collision repair. The Mercedes-Benz Star Diagnosis System (SDS) tool must be used to fully reset, reinitialize, or reprogram sensors and modules where needed during the collision repair. For instance, recalibration of the steering angle sensor (a key element for electronic stability control) is now a crucial final step in a four-wheel alignment following a collision. Another tool is the Romess-Rogg CM-09606 inclinometer, which unlike other similar tools, is essential to measuring and adjusting ride height for all models.

Is anyone pulling new vehicles right today?

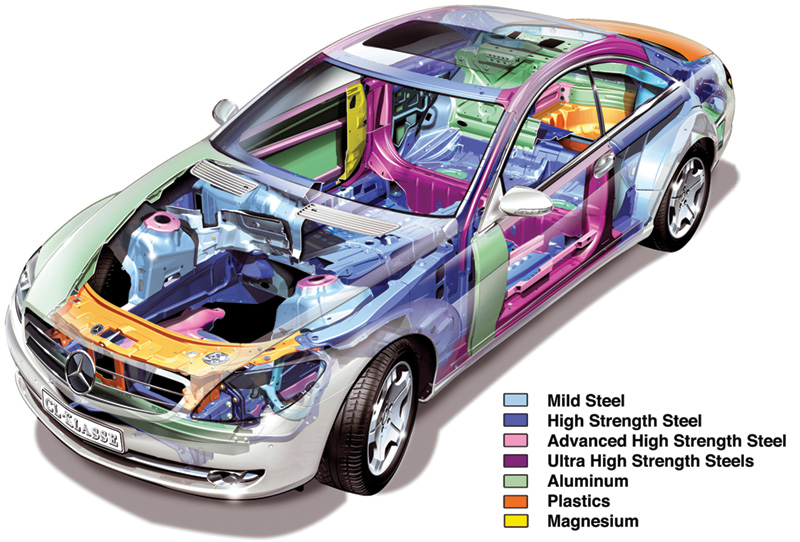

Fixtures have been around for 70 years or so, and were used mostly with mild steels during most of their history. But times are changing. The ramping up of innovations such as high-strength steels, aluminum, plastics, and carbon fiber composites poses numerous challenges to collision repair and to those who make straightening equipment.

Risk management has become an entrenched necessity. The influx of new vehicle technology has forced insurers and repair facilities to confirm repair via documentation, preferably in an automatic electronic form. This documentation provides a record of where that vehicle was before, during and after collision repair to confirm that proper realignment was achieved.

Vehicles are changing dramatically. For example, conventional fixture technology is a mechanical measuring system that locates specific, fixed points. Data cannot be documented and inputted electronically in an efficient manner throughout the repair process. To compensate, facilities may use an electronic measurement tool after repair, but these recording procedures are costly in terms of time.

Realignment equipment manufacturers are retooling in response to inbound materials, associated procedures, and time erosion during repair. Is anybody actually pulling new vehicles correctly?

In the near future, vehicle realignment equipment will see a blending of current and emerging holding and pulling technologies. Some manufacturers suggest that dedicated bench equipment will yield to more universal equipment that will:

- Facilitate the holding and straightening of vehicles made of old or new materials.

- Incorporate automatic electronic measurement and documentation throughout the repair process to conserve time.

- Accommodate the safe and complete repair of multiple vehicle platforms, rather than being restricted to just a single platform.

Suspension alignment matters too

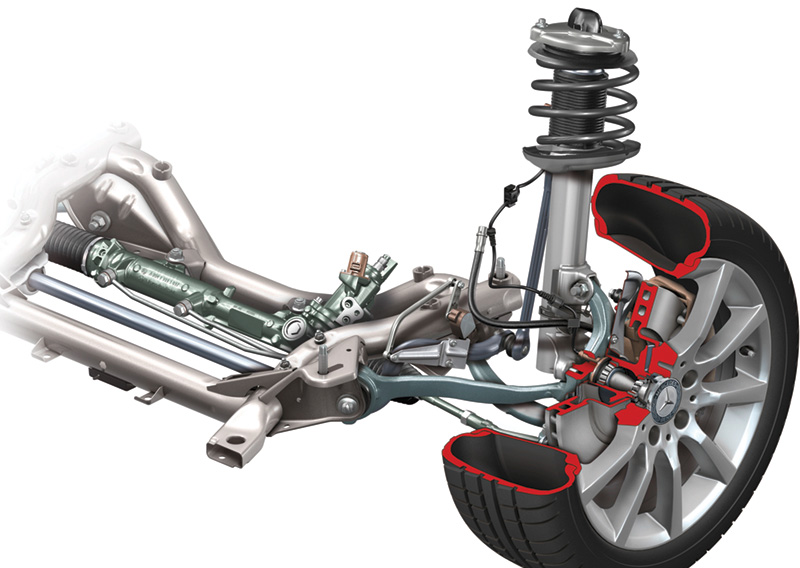

As vehicle suspensions have become complex, proper alignment, ride height, spring position, and wheel/tire condition are now critical to a vehicle’s directional stability, response, cornering adhesion/balance, tire wear, fuel economy, and safety. Vehicles are also equipped with expensive high-quality tires and wheels, which have high replacement costs.

Mercedes-Benz requires four-wheel alignment on all of its models. To properly align a Mercedes-Benz suspension, technicians must use the approved equipment, tools, and procedures for any alignment procedure.

In the mechanical service world, basic maintenance-level wheel alignments resolve most problems. Minor adjustments to camber, caster, or toe are often enough; otherwise, the installation of repair bolts, parts, or kits will generally correct caster, camber, toe or the steering angle sensor angles that are within 0.25 to 0.50 degrees of specs.

Some techs assume that the included angle (IA), caster, and steering axis inclination (SAI) only need to be measured when components have been bent or damaged in a collision, but Mercedes-Benz requires that they be checked during every alignment, even if it is done as maintenance. This is because the latter two are key pivot mounting points that actually hold the suspension to the vehicle.

The ride height for all models — in or out of spec and regardless of suspension type — can be easily measured and adjusted by using the Romess-Rogg CM-09606 inclinometer. Other tools are limited to

in-spec vehicles without air or hydraulic suspensions.

During a suspension alignment, ride height adjustment procedures may require that a specified weight be placed inside the vehicle cabin to simulate a driver being in the vehicle, so that the alignment simulates the vehicle running at a typical curb height. In addition, proper ride height also determines spring position, which can also impact performance, comfort, and safety.

Use the Romess-Rogg electronic inclinometer to measure ride height via the position of the transverse links on front and rear axle drive shafts. Unlike other tools that are sometimes used for vehicles with conventional suspensions, the Romess-Rogg tool can handle models that are out of spec as well as those equipped with either an Airmatic air suspension or ABC hydraulic suspension. For example, Airmatic or ABC suspensions specify different ranges for the Romess inclination values, which allow a technician to then use the Mercedes-Benz SDS tool to raise or lower the car until it is in range and then calibrate the controller to accept that position as right. That’s the difference being properly equipped makes.

Clearly, no customer or facility wants post-collision repair handling problems, premature tire wear, or stability control problems, or the liability risk should another collision occur. So, shop owners must see that the approved service information is easily available to the technicians, and that they keep up to date on procedures, equipment, and suspension designs.

Never Repair a Mercedes-Benz Wheel

|

0 Comments