Here’s an overview of Nissan’s Variable Valve Event and Lift system. We’ll look at which Nissan and Infiniti vehicles are equipped with VVEL, how the system functions, and maintenance considerations.

Variable Valve Event and Lift (VVEL) is a system that allows the driver to control engine air intake by manipulating the accelerator pedal, much like the throttle valve does on typical cars. The amount of intake valve opening (valve lift) can be varied from a tiny crack at idle, to maximum lift at wide open throttle. Because the air flow is being controlled by the valve lift, the throttle can be held open to virtually eliminate intake manifold vacuum, thereby increasing efficiency. VVEL is not just another acronym for a valve timing system; it’s a major shift in the role of the intake valves and a leap forward in internal combustion engine efficiency, response, and power.

Controlling air flow directly at the combustion chamber has always been optimal, but because of technology, cost, and reliability hurdles, it hasn’t been practical until now. We’ll examine the benefits and operation of VVEL in the hope it will provide an appreciation and understanding of the system, so readers will have a leg up when they first encounter a diagnostic challenge on a VVEL-equipped engine.

Which Vehicles Have VVEL?

The following vehicle and engine combinations are equipped with VVEL systems:

2008 Infiniti G37 Coupe: V6 VQ37VHR

2009 Infiniti G37 Sedan: V6 VQ37VHR

2009 Nissan 370Z: V6 VQ37VHR

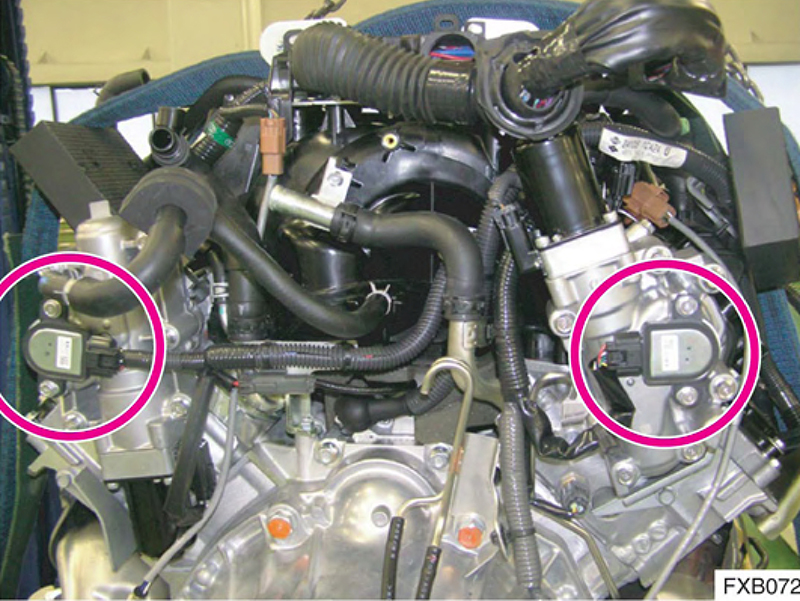

2009 Infiniti FX50: V8 VK50VE

2011 & 2012 Infiniti M37: V6 VQ37VHR

2011 & 2012 Infiniti M56: V8 VK56VD

2011 & 2012 Infiniti QX56: V8 VK56VD

You may notice these are all very nice cars. As usual, new technology is installed on the flagship vehicles first, for people willing to pay for the very best available. As production costs come down and efficiency requirements increase, you’ll likely see this type of technology trickle down to some of the less expensive models.

Benefits of VVEL

The chief benefit of controlling engine air intake at the combustion chamber is the increase in efficiency due to the decrease in throttling losses. These are losses in engine efficiency due to the energy used to create intake manifold vacuum. In other words, creating intake vacuum is work and as such, burns fuel. If fuel is used to create a vacuum, it cannot be used to move the vehicle down the road, thus fuel is wasted on a function that does not aid engine output.

Have you ever blocked the hose on a household vacuum cleaner with your hand? Does the motor sound like it’s working harder when the hose is blocked? It sure does! You may even notice the lights dim because of the extra load. The throttle plate restricts the intake flow just like a hand covering a vacuum cleaner hose. This makes the engine work harder, especially at idle, when the engine is doing no useable work at all. However, this is necessary on a conventional throttle engine, because without the throttle restriction, the engine would race uncontrollably. On a VVEL engine, the throttle is opened to reduce manifold vacuum at idle. The engine does not race because the air flow is being regulated with the intake valve lift. The engine is no longer being strangled to regulate rpm; it’s operating at its own pace and breathing from an abundance of air at atmospheric pressure.

This brings us to cylinder filling. Superchargers and turbochargers increase the pressure in the intake manifold to help force more air into the cylinder. They increase air consumption beyond the engine’s natural volumetric efficiency. So, what do you suppose happens when the intake manifold is at atmospheric pressure instead of a vacuum? Let’s see.

On a conventional throttle engine, air will not start to flow into a cylinder until suction generated by the cylinder during the intake stroke exceeds the vacuum in the manifold. If the intake manifold vacuum is 21 in.Hg, the cylinder must generate over 21 in.Hg before it starts to fill. So, if there is no vacuum stored in the manifold, but instead atmospheric pressure, air will be “pushed†into the cylinder sooner in the intake stroke, resulting in more air entering the cylinder, and thus, better cylinder filling.

In addition, the velocity of the air entering the combustion chamber is higher, which results in better fuel atomization and a reduction in partial combustion. When fuel is burned completely, it increases fuel efficiency and decreases hydrocarbon emissions.

Improved throttle response is another benefit of VVEL. When the throttle plate is suddenly opened on a conventional throttle engine, it takes time for the intake manifold to fill with air, and for the vacuum to become equal to atmospheric pressure. This delay results in a lag time between when the accelerator pedal is pressed and when the engine output reaches the desired level. On the other hand, the response on a VVEL engine is near-instant. The power output matches the accelerator input in virtually real-time.

Finally, maximum valve lift can be increased without negatively affecting idle quality. On a conventional throttle engine, valve lift must be balanced between what is optimal for idle and what is optimal for maximum load. Creating a cam profile that has a lot of lift will also increase the duration; the ramps up and the ramps down can only be made so steep. At idle, excessive lift will cause poor air velocity and fuel atomization, and excessive duration will cause blowback into the intake manifold. If a camshaft is created for maximum power, idle quality will suffer. If a cam is created for the best idle quality, maximum output will suffer. With VVEL, the best of both profiles can be used without sacrificing anything, a silky smooth idle and up to over 400 horsepower!

As you may have gathered, the benefits of VVEL are most noticeable at low and medium loads, when the throttle plate would be more closed than open. Therefore, VVEL is most effective on vehicles with high output engines that are more likely to be operated at relatively low to medium loads.

How VVEL Works

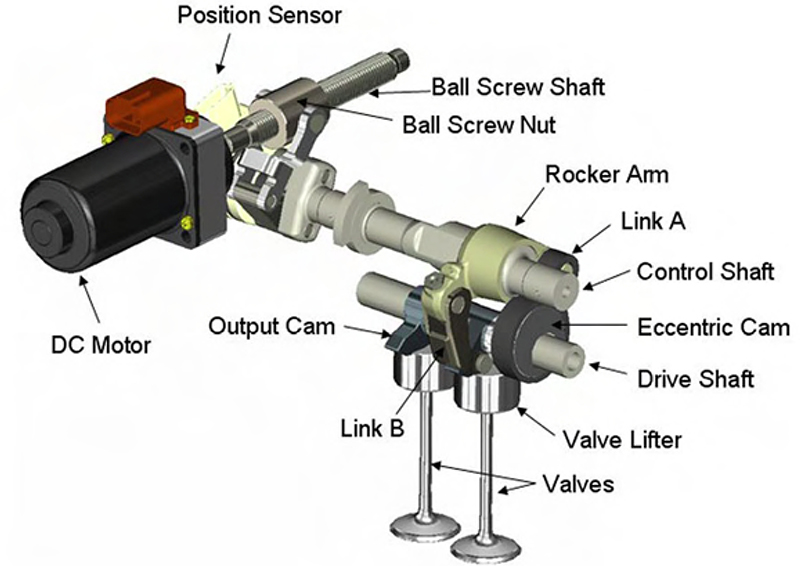

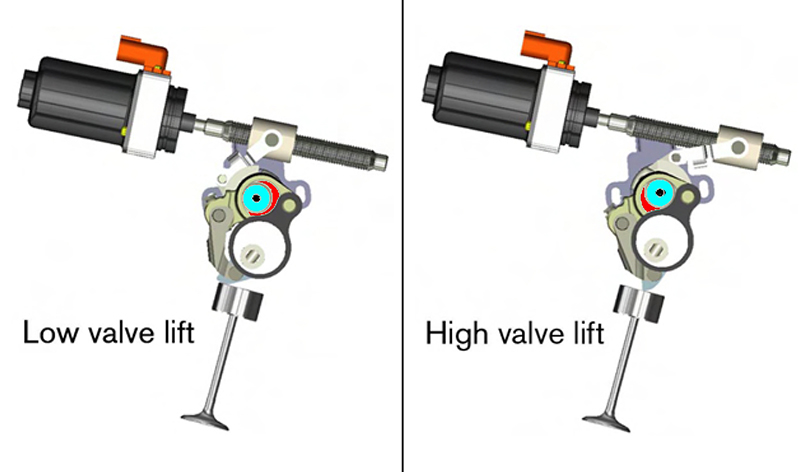

Note the position of the control shaft, colored light blue and red. As the control shaft rotates, the fulcrum is moved and valve lift is modified.

The exhaust cam is a traditional design. Its egg-shaped lobes push on solid lifters mounted atop the exhaust valves. The VQ37VHR engine does not incorporate variable exhaust valve timing. The VK56VD and VK50VE engines use hydraulically actuated duty-cycle-controlled camshaft sprockets to adjust exhaust cam timing to match engine operating conditions, similar to the continuously variable valve timing system found in many previous engine packages. In short, the exhaust valve system on a VVEL engine is the same as on a conventional throttle engine.

The intake side is wildly different. The intake cam is replaced by a drive shaft with eccentric cams where the lobes would normally be. It does not have conventional egg-shaped lobes; it’s more like a small circle offset within a large circle. The drive shaft is mounted to an electro-hydraulically adjustable cam sprocket, so intake valve timing is continuously variable. The eccentric cam does not ride on the lifters directly. Its movement is transmitted through a link, to a rocker arm, to another link, and then to an output cam, which presses directly on the lifter. The fulcrum of the rocker arms is a control shaft, which is connected to a DC stepper motor called the VVEL actuator. When the VVEL actuator rotates the control shaft, the rocker fulcrum is shifted due to an eccentric mount, and the valve lift is changed.

Think of a seesaw. If the fulcrum (pivot) is in the center, the amount of movement on each side will be equal. If the fulcrum is moved to the left of center, a smaller amount of travel on the left will cause the movement on the right will be increased. If the fulcrum is moved to the right of center, the opposite will be true. This is how valve lift is controlled with the VVEL system.

The ECM looks at the crankshaft position sensor to determine engine speed and piston position, and the accelerator pedal position sensor to determine desired power output. The ECM then continuously adjusts the control shaft position via a VVEL control module while receiving feedback from a position sensor mounted on the VVEL actuator assembly.

Service Considerations

Replacement VVEL control shaft position sensors require a one-time adjustment when new. The sensors are not variable resistance potentiometers like a TPS. They are resolvers. A permanent magnet is mounted to the end of the control shaft, when the shaft rotates changes in the magnetic field cause sensor output voltage to vary with shaft position. The output signal is interpreted by the VVEL control module, and then sent to the ECM.

As a service technician, valve adjustment may be the first concern that comes to mind when considering VVEL. These engines all have solid lifters and therefore, there is no self-adjusting mechanism. However, special coatings, years of metallurgical development, and top quality engineering have resulted in valve trains that are very durable, and can go hundreds of thousands of miles without needing adjustment. That being said, valve clearance should be checked “whenever you’re in the neighborhood.†If the valve covers are removed for any reason, or there is unusual noise or engine roughness, valve clearance should be inspected.

Both intake and exhaust valve clearance should be measured, but only exhaust valve clearance can be adjusted. If any of the intake valves are out of specification, the cylinder head and VVEL ladder must be replaced as an assembly. If the exhaust valves are out of specification, selective thickness lifters are available to provide up to .020 in. of correction in .0008 in. increments. The exhaust valves, valve seats, guides, and stem seals can all be replaced if need be, provided your shop has the necessary machine equipment, but no individual parts are available for the intake side.

If the VVEL actuator is replaced, an initial adjustment must be performed. The VVEL system must be prepared for adjustment using the CONSULT. Under WORK SUPPORT, select VVEL POS SEN ADJ PREP. Once complete, adjust the VVEL actuator position sensor so that its PID reads 500mV +/- 48mV. This procedure should ONLY be performed when the actuator is replaced, and ONLY on the side that was replaced. Make sure not to get confused and mess with the adjustment on the wrong bank. If you do, you’ll need to replace the VVEL actuator.

Correct Lubrication

Service requirements are pretty typical for VVEL-equipped cars. Motor oil requirements are SM/GF4 or SN/GF5 depending on model, with no requirement for full synthetic or a proprietary certification. The service interval should be 3,750 miles for most drivers, and 7,500 miles for the atypical all-clear-freeway type driver. However, it would be wise to consider the most common cause of failure in variable valve timing systems: oil level and oil quality. Nissan Ester Oil (P/N 999MP-5W30EP) is far less likely to become sludge than conventional oils. It’s also far superior to most “synthetic†motor oils. It’s certainly not the cheapest motor oil, but then again, we’re talking about some pretty high-end vehicles here, which, if poorly maintained, will retaliate with very high repair costs. If you take care of your VVEL equipped vehicle, it will take care of you.

Sources of Additional VVEL Information

For more detailed VVEL information, use the following resources, which are free with a Techinfo subscription:

- Introduction to Engine Mechanical Systems, Variable Valve Timing Module. This document can be found in the E-Learning Modules section of nissan-techinfo.com.

- 2008 Infiniti G37 Coupe New Model Introduction. This document can be found in the E-Learning Modules section of https://www.infiniti-techinfo.com/.

- Service manuals for G37, 370Z, FX, and QX56

These resources are available for purchase on nissan-techinfo.com and/or infiniti-techinfo.com:

- Video (DVD) Training, Volume 145: Variable Valve Event and Lift System ($24.95)

- Classroom training materials (PDF booklets), 2009 Infiniti FX New Technology ($74.95)

- Classroom training materials (PDF booklets), 2011 Infiniti QX56 New Technology ($74.95)

- Classroom training materials (PDF booklets), Engine Mechanical Service Course EMTC9915A ($74.95)

0 Comments