Gone are the days when we only replaced water pumps and thermostats when a vehicle was overheating. Now, engine temperature is a critical part of the fuel control and lubrication systems. How do we help keep our customers cool? By controlling heat.

You probably never thought it would come to this. In the ‘70s, we had to learn electronic ignition. In the ‘80s, we had to learn fuel injection and electronic engine management. In the ‘90s, we had to learn powertrain Controller Area Network (CAN) systems. Finally, in the 2000s everything was put on the network. Thankfully, we still need a mechanical engine under it all, and we still need to help keep it at optimal operating temperature. This may seem like basic information to you, but to an engineer this is a tricky proposition. Your customers drive their Volkswagen models through a wide range of operating conditions. A Touareg may take a family and lots of camping gear up steep grades to a mountain campsite. The sporty CC may cruise along at interstate speeds for hours at a time in hot weather. The Routan may function as a short-trip shuttle for soccer moms, and the versatile Jetta may do all that and have to survive hour-long traffic jams during the commute to work. An engineer must produce a cooling system capable of helping keep the engine in its ideal operating range no matter what the type of use.

If you design a cooling system solely to keep an engine from overheating under heavy load, it will run too cool under normal operating conditions. Conversely, if the cooling system is engineered to cool enough in normal driving, the engine may overheat and its life will be shortened when under hard acceleration or heavy loads. With the implementation of OBD II, the cooling system became a monitored component. No, do not look for it as a continuous or non-continuous monitor. To control harmful exhaust emissions, the EPA and SAE want the engine to leave open loop and enter closed loop as soon as possible. The PCM has logic circuits that help monitor coolant and ambient air temperature to verify the vehicle is getting up to operating temperature as soon as possible. If it takes too long to warm up, it will be delayed going into closed loop where the oxygen sensors provide feedback for the optimal mixture. So, the cooling system does more than prolong engine life. It can also have an effect on exhaust emissions and fuel efficiency. What we have learned from these developments is that running too cold can be a problem we have to repair just like we do an engine that’s running too hot.

How does the engine maintain its optimal running temperature? We have a water pump to circulate the coolant, thus taking excess heat from the cylinder head and block and bringing it to the radiator to cool off. We have a thermostat to restrict flow when the engine is cold and allow more flow when the engine is hot. Radiator fans provide additional air flow over the fins. This gives the engine a much wider range of operating conditions without the dangers of under or overheating. When something goes wrong with this system, it is your job to figure out which part has failed. Most of the time this is an easy task, but not always. Subtle problems occur with some frequency. You know this if you’ve ever had a vehicle that had a very hard time running the OBD II monitors, but no codes were set. Or, maybe you had a vehicle that would only overheat at times, or the heater would blow cold air even with the engine running over 15 minutes. You should have a battery of tests that you run to help you isolate the problem. Let’s go over these tests and try to cover every part of the cooling system.

Some of these steps are very basic, but let’s list them for the record. Number One on any list should be a coolant level check. All modern Volkswagen vehicles use a remote reservoir as the place to add and check fluid level. You should see level marks for both a cold engine and a hot engine, and you need to be between these two. Of course, we stress the use of Volkswagen OEM coolant available from your dealer. It meets G12 and G22 specifications and offers superior corrosion resistance for internal engine parts with none of the catastrophic problems associated with some aftermarket antifreezes. The coolant is sold pure so you will have to mix it with water (preferably distilled). A mixture of 50/50 coolant to water will give you the widest temperature range for boiling and freezing protection within typical environmental conditions. If you are unsure of the strength of the mixture, you can check it with a specific gravity tester, either the float type, or a refractometer. Volkswagen recommends changing the G12 coolant every two years as a way to remove corrosion from the system. The later G22 coolant can be used up to five years and should then be replaced.

If the coolant level is low, there is a leak somewhere. A pressure test is the logical next step. Apply pressure to the cooling system and examine the block, cylinder head, hoses, radiator, and water pump for coolant seeping past a gasket or seal. You may have a leak in the heater core, but this should be easily detected because it will be accompanied by the smell of antifreeze in the cabin with the heat on, and possibly dripping from the HVAC condensation drain. You can block off the two heater core lines and repeat your pressure test. There are fluorescent dyes you can add to cooling systems that will stand out brightly under a black light (the same as they do for refrigerant leaks in an A/C system).

If you do not see any external leaks, the problem could be internal. A large concern would be head gasket failure, or perhaps a cracked head or block. Coolant can leak into the engine oil, so check the oil level. A crack in the oil cooler/oil filter housing can also leak coolant into the oil and visa versa. Head gaskets can also leak coolant into the combustion chamber. If severe enough, it can lead to a misfiring cylinder and you should pressure test the system with the engine both cold and hot.

There are several ways to check for a leaky head gasket. The most traditional are the compression and cylinder leak-down tests. Or, you can look for bubbling or pressure build-up at the radiator or reservoir cap. More accurate is the blue solution that turns green in the presence of carbon dioxide, which is a byproduct of combustion. Follow the instructions carefully, but they will probably include draining some of the coolant from the reservoir so as to allow a sufficient amount of cooling system gases to build up.

Overheating as a result of a coolant leak is a fairly straightforward repair. Find the leak and you have fixed the problem. What can you do if you have an overheating condition, but still have a full cooling system? Clearly, other factors contribute to keeping an engine cool. This is where your job becomes a little more difficult.

In this case, overheating may be due to an inoperative or intermittently failing radiator fan (think the coolant temperature switch, or the fan motor brushes). Another common condition is reduced coolant flow. Since radiator hoses are not transparent, you’ll have to use a different means of judging flow. Coolant circulation can be blocked by a thermostat that stays partially or completely closed, corrosion blocking the radiator tubes, or a restriction in coolant passages of the block or cylinder head. What are some of the tests we can perform to isolate the problem?

Measuring temperature at various locations using a surface probe or a non-contact infrared pyrometer is the most convenient way to check coolant flow. You have to keep in mind that you are measuring the surface temperature of the cooling jacket, not that of the actual coolant itself, so it’s best to compare similar surfaces. Pick several spots around the radiator and you should see the temperature decrease from the inlet toward the outlet. Since you are working near the radiator fan, you must be careful as it can come on at any time even after the engine is shut off. A delay circuit in the fan control module runs those blades for a few minutes to help keep temperatures down during the hot soak-period.

Also, there are cases where the engine may not overheat at idle, but does while being driven. By the same token, an engine can run hot at idle and cool off while driving (which suggests a fan problem). You have to decide if the problem resides with the thermostat, water pump, or fan. Generally, because of their location if you are going to invest the labor to get into the thermostat or pump you may want to do both at the same time. Thermostats can stick closed from corrosion, and water pumps impellers can separate from the shaft and stop spinning. This is why it is so important to use Volkswagen OEM G11, G12, G12+ and G12++ coolants to help increase corrosion protection and save internal cooling system parts. Looking at the normal service maintenance table, Volkswagen does not have recommended intervals for coolant replacement, but at every regular service the level and coolant concentration should be checked, and the system flushed and refilled accordingly. If there is a question of possible mixed coolants read the March 18, 2010 technical service bulletin 19-10-03 for guidance as to which coolants can safely be mixed.

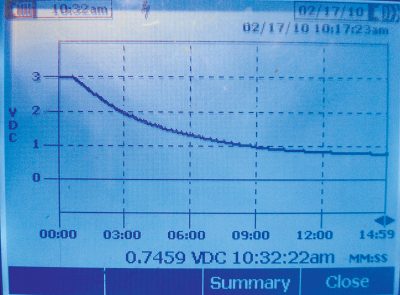

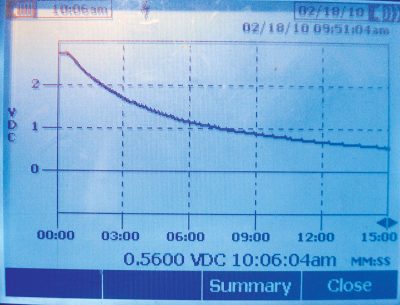

Sticking closed is not the only way a thermostat can fail. If you have ever had a vehicle that had a hard time running the non-continuous monitors for your state inspection program, you know what we mean. Also, if you keep seeing a P0128, it is also an indication of this problem. When a thermostat ages, it can open prematurely, which means at a lower temperature. With coolant flowing when it’s not supposed to, the engine might take a long time to reach full operating temperature. This will prevent the O2 sensor monitor from running, and without this it is very difficult to run the other monitors. There are two tests you can perform to verify the condition of the thermostat. The first is to use your VAG 5052 and evaluate your measuring blocks. Watch the coolant temperature PID for a few minutes after the vehicle is fully warmed up and at idle. If you see the reading fluctuating below the 90 deg. C. mark, you probably need to replace the thermostat. Most Volkswagen engines run at a stable 93 to 94 deg. C. at idle with no load. Another test you can perform is to monitor the signal voltage of the coolant temperature sensor over a 15 minute period. On average you should see the voltage drop to .5 volts after this warm-up at idle.

When servicing the cooling system, there are some important directions you need to follow to help ensure a proper repair. These may seem like small issues, but can have a significant impact once the job is complete. For instance, when replacing a thermostat with a Volkswagen OEM part on a 2005 Passat with the 2.8L ATQ motor, the bleed orifice needs to be at the uppermost position. This makes it much easier to allow the air to escape while filling the system. You can use a vacuum lift tool to fill the system, but Volkswagen has provided methods of bleeding that make it unnecessary. While you are filling the system, open the bleed screws. Visit www.vw.erwin.com [eidt: https://erwin.volkswagen.de/erwin/showHome.do] to look up vehicle-specific service information for the location of the bleed screws. For instance, on the ATQ motor there are two bleed screws, one mounted on a front pipe just inside the driver’s side cylinder head, and a second bleed on the driver’s side on the rear crossover pipe. An air pocket can also get trapped in the heater core, so one of the hoses has a bleed orifice. By loosening the clamp and sliding the hose off slightly, you’ll expose the orifice and allow the air out of the heater core and heater hoses.

With the system properly bled and new parts installed, the cooling system should be able to keep the engine cool even in heavy traffic on a hot summer day. By accomplishing this you are also helping keep your customers’ tempers cool because they’ll know their vehicles have been repaired with the needed Genuine Volkswagen Parts. What more could they want?

Download PDF

0 Comments