by Henry P. Olsen

Transplanting a modern (OBD II/1996 or later) fuel-injected, feedback engine into a vintage vehicle may be the ideal way to get the power and engine reliability of a modern vehicle into that special car that was built when vehicles were not just practical transportation. If your installation is done correctly, you will have a classic with great performance, driveability, and reliability — just as good as that of the recent vehicle the engine came out of. But such engine swaps can also turn into a mechanic’s nightmare.

Before you take the engine package out of the donor vehicle (if the engine is not from a running vehicle, you can always find a match), it would be a good idea to make some recordings of the PCM’s data with a scan tool that can play back the live engine data throughout the driving range. This can help you immensely if you have problems once the engine is installed and running.

The EFI engine in this 1947 Suburban has a whole lot more power than the original six cylinder, and it even gets better gas mileage.

You can save yourself a lot of time and effort if you select an engine package from a vehicle that falls into approximately the same weight range as the one it is destined for because the PCM was programmed for a specific weight (as well as final drive ratio, considering tire diameter, overdrive, and axle ratio, exhaust system backpressure, and aerodynamic drag — you’d be hard-pressed to find a vintage car that’s not pretty much a barn door). The PCM has limits on how much data it receives from its various sensors can vary from its vehicle-specific programming and still be accommodated. If these limits are exceeded (major changes in vehicle weight or final drive ratio, for example), you may experience engine ping, low power, or other problems.

When you’re tuning a carburetor-equipped engine, you will need tools like a dial-back timing light, an exhaust gas analyzer, and a weather station, but with EFI engines the PCM and its sensors make all the tuning adjustments an experienced tuner can do in less than instantaneously and continuously.

One advantage a modern fuel-injected engine has over a vintage carburetor-equipped motor is that the PCM, in effect, acts as an on-board tuner continually optimizing the air/fuel mixture and ignition spark advance based on the density of the air, gasoline formulation, and driving conditions (engine load). The inputs the PCM references that allow it to perform these necessary tuning adjustments are those for the ECT (Engine Coolant Temperature), MAP (Manifold Absolute Pressure — engine load/vacuum), Mass Air Flow (air density, temperature, and amount),TPS (Throttle Position), VSS (Sehicle Speed), rpm (crankshaft and camshaft position), O2, and knock sensors (this last one allows the PCM to sense engine spark knock and retard the timing timing until it just stops, keeping as much advance as possible without detonation).

Those of us who are still working with vintage carbureted engines use tools such as five-gas exhaust analyzers and dial-back timing lights to determine what jetting and spark advance adjustments are needed. We also use a Race Air Pro weather station from Computech to reference the air density conditions that are present when we are tuning the engine. These readings are valuable to a more advanced tuner because whenever the air density changes, both the jet size and spark advance the engine needs to produce maximum power will change.

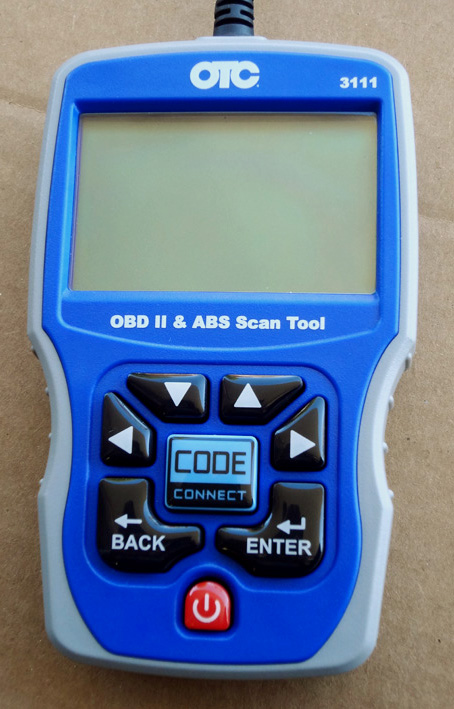

The OTC 3111 Code Connect is an easy-to-use scan tool that will allow you to view and record the datastream to review later for comparison purposes. It will read any DTCs (Diagnostic Trouble Codes) and in many cases will provide you with valuable repair information with one touch of the Code Connect button.

A modern engine management system acts as an on-board, real-time tuner as it adjusts the air/fuel mixture and spark advance hundreds of times per minute with reference to the data it gets from its various sensors. The PCM also is monitoring things such as the engine misfire rate, catalyst efficiency, and watches for incoming data that is out of the range it was programmed to expect. Plus, it has a comprehensive monitor that looks for open or shorted circuits. All of this means that the PCM does more in one second to tune a fuel-injected engine than a good carburetor tuner can do in a lengthy tuning session.

The PCM of a modern fuel-injected engine is basically just a computer, and like any computer unless it gets the inputs it has been programmed to expect, it will not be able to send the correct output commands. Said more succinctly, garbage in/garbage out. When the inputs the PCM uses to determine how much fuel or spark advance to supply do not match what it was programmed to expect, the PCM may come up with an incorrect air/fuel mixture or ignition spark advance for the engine’s needs, causing performance to suffer.

If you have any driveability problems and you don’t have any pre-engine transplant recordings of the PCM’s data, you can always use the data from a vehicle that matches the donor engine.

The PCM uses a set of “maps†to determine what air/fuel ratio and spark advance it should supply. These “maps†factor in the weight of the vehicle, the final drive ratio, and the aerodynamic drag the PCM was programmed for. The PCM then uses the inputs from the O2 and the knock sensors to fine-tune the mixture and the spark advance.

If you put a fuel-injected engine package from a 6,000 lb. truck into a 2,500 lb. car, or if you make any changes to the final drive ratio from what the PCM was programmed for, the data inputs will not match what the PCM was programmed to expect. This means that the PCM may need to be reprogrammed to match the new application.

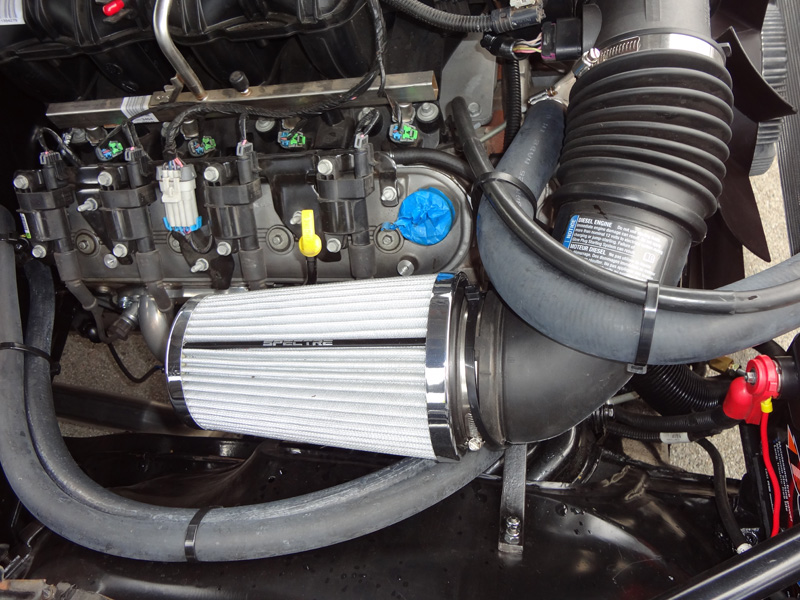

One of the common mistakes many people make when they install an EFI engine in a vintage vehicle is using an air cleaner that picks up hot air from under the hood. The PCM will retard the timing by as much as 10 deg. F. when the inlet air temperature is over 130 deg.

It is also critical that the airflow and temperature of the incoming air supplied to the throttle body match what the PCM was programmed to expect in the vehicle it was designed for now that is in its new home. The PCM was programmed for an inlet air package that breathes cool outside air. If you are using an aftermarket open-element air cleaner, it’s drawing from inside the hot engine compartment. The PCM will see that the incoming temperatures are much hotter than it expects –. the under-hood temperatures can reach 150 deg. F. or more as it is heated from the radiator and the exhaust system. Whenever the inlet air temperature exceeds 130 deg. F., the PCM will retard the spark by as much as 10 deg., which will cause performance to suffer.

The PCM also uses the knock sensor to retard the spark whenever it “hears†ping or detonation as a means to prevent engine damage, as well as to attempt to set optimum timing advance for best performance. We have worked on several vintage vehicles with modern fuel-injected engines with a lack-of-power compliant caused by a knock sensor that was over-retarding the spark advance because the knock sensor was exposed chassis noise that sounded like spark knock. Once we were able to isolate the chassis noise, the knock sensor no longer heard this false signal and performance improved drastically.

Once the open element air cleaner was replaced by a cool air box on this 1947 Suburban, both power and driveability were much improved.

The easiest way to see how much the PCM has to correct the air/fuel mixture and spark advance for the conditions it sees (now that it is in your vintage vehicle) is with the use of a scan tool. This can also be used to see if the PCM has any trouble codes which may or may not turn on the MIL (Malfunction Indicator Lamp, or “Check Engine” light.

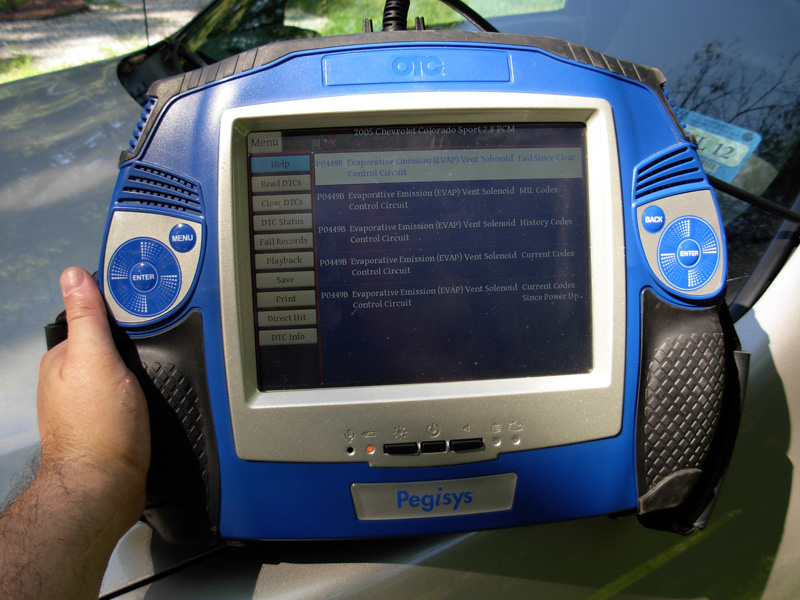

The OTC Genisys is a professional-grade scan tool that can read and record the datastream, plus it provides datastream specifications. It also has the ability to test injectors, EGR solenoids, and transmission shift solenoids. Genisys makes a great deal of repair information available from InfoTech, such as wiring diagrams, and incorporates Repair-Trac, which is a database of suggested repairs for known issues, and Code Assist, which comprises the top three suggested repairs for many DTCs.

There are several companies that offer reprograming software that allows you to turn off the DTC (Diagnostic Trouble Code) routines for off-road applications such as when there are no catalytic convertors, oxygen sensors, or evaporative emissions control systems. If you have advanced computer skills, companies such as HP Tuners and EFILive offer PCM tuning software that can allow you to reference and modify the maps the PCM references to determine what the spark advance and fuel injector on-time should be based on those maps. For any changes in vehicle’s weight, tire size, transmission and final-drive ratios, or exhaust system back pressure, the air/fuel mixture and the ignition spark advance rate can also be altered. Other optional advanced tuning software available from companies such as HP Tuners offers allows the user to modify the air/fuel mixture and the spark advance rate.

The OTC Pegisys is also a professional grade scan tool. It uses a wireless connection to the vehicle, and has the capability of connecting to the Internet for repair information on all systems. It has the same embedded repair information as the Genisys, plus you can use it with a PC to perform J2534 PCM reprogramming.

Before you make any PCM programming changes, you first need to be sure all the inputs the PCM is referencing are correct, then you will need to clear the learned values it stored from the vehicle it came from (you want to start with a PCM that has not learned anything yet). Take the vehicle out for a drive and put some miles on it — both on the freeway and city streets — then take your scan tool and look at the Long-Term fuel trim values (LFT). Readings in the +10% to -10% range would be considered normal. If the LFT are higher or lower than that range, you will need to make some corrections. When you hit values over 25%, or lower than -25%, you will trouble codes, but often if the readings are in the + or – 20% range the PCM may not be triggering codes, but there is still room for improvement. When you are able to get the LFT values of +/-5%, the PCM is working in a range that allows it to make the needed tuning changes without having to over-correct, and performance will be optimal. The PCM does its best work when it only has to make small corrections.

If run into any performance or driveability problems, the first thing to do is get a scan tool and make some recordings of the PCM’s data. Look for things like intake air temperatures or spark timing that are not what you would expect, LFT that is beyond the normal +/- 10% range; values going out of normal range are indicators of where the problem lies. Even a basic scan tool such as the OTC 3111 with Code Connect will help you diagnosis the problem, but an advanced scan tool such as the OTC Genisys and Pegisys we use will supply you with the advanced diagnostic capabilities and manufacturer-specific data that will make the job easier.

There is still clean-up work to do, but the EFI engine has this classic 1947 Suburban running like a modern vehicle.

It is also critical that the air flow data the PCM is getting from the MAF is accurate. Here’s where you can use the rpm and air flow data from a recording made during a wide-open throttle run to compare with the expected readings you would get from a MAF calculator spread sheet. If readings are not within 10%, you should replace the MAF sensor, or reprogram the computer’s volumetric efficiency calculation to match the readings you are getting from the MAF, if it is not defective.

Combining the timeless style that you see when you look at a vintage automobile with the power, driveability, and reliability of a modern fuel-injected, electronically-managed engine is a very good way to bring your vintage vehicle into the 21st century. When you compare a modern engine that can go 60,000 miles or more before it would need a “tune-up†to the 12,000 miles that a vintage carburetor-equipped engine would go before the ignition points needed adjustment or replacement, you can understand why you see so many vintage vehicles with modern engines under the hood. If you take the time to properly transplant and program the PCM of the modern engine package you are installing into your vintage vehicle, you can have it all — the style and look of a vintage ride with the reliability and power of the cars of today.

0 Comments