by Bob Freudenberger

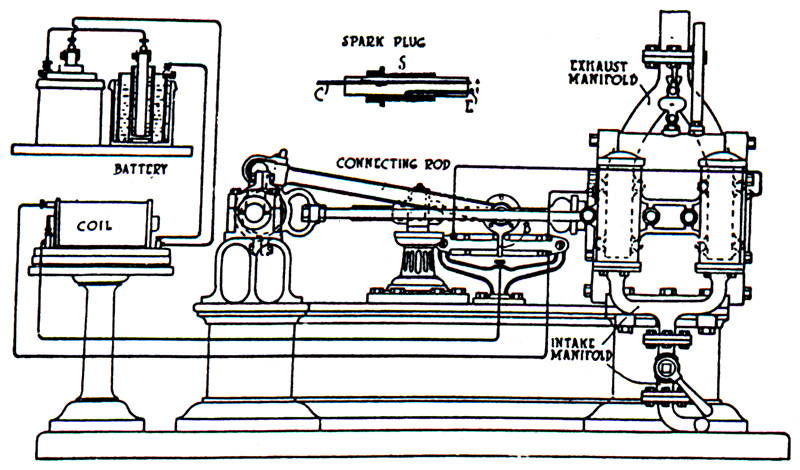

While you may not think much of their cars, the French were very much in the forefront of early automotive developments. This is Lenoir’s strange internal combustion engine.

In 1860, the year before the Confederates fired on Fort Sumter and the Civil War began, a Frenchman named Jean-Joseph-Étienne Lenoir invented the spark plug as a way of igniting the mixture in his coal gas-fueled internal combustion engine. His patent application describes a hollow brass bolt with a porcelain insulator cemented into it. Two platinum wires projected from the combustion chamber end and had a small gap between them. One was connected to the bolt for ground, and the other went through the top of the insulator to a terminal.

While that sounds basically like what we’ve got today, a multitude of important changes have occurred in the spark plug’s long evolution. Take insulator materials, for instance. Porcelain, mica, and glass were tried and eventually discarded, and heat‑formed aluminum oxides are now used. They’re hard enough to cut glass, have plenty of electrical resistance and heat conductivity, and are capable of withstanding considerable thermal and mechanical shocks.

Downsizing

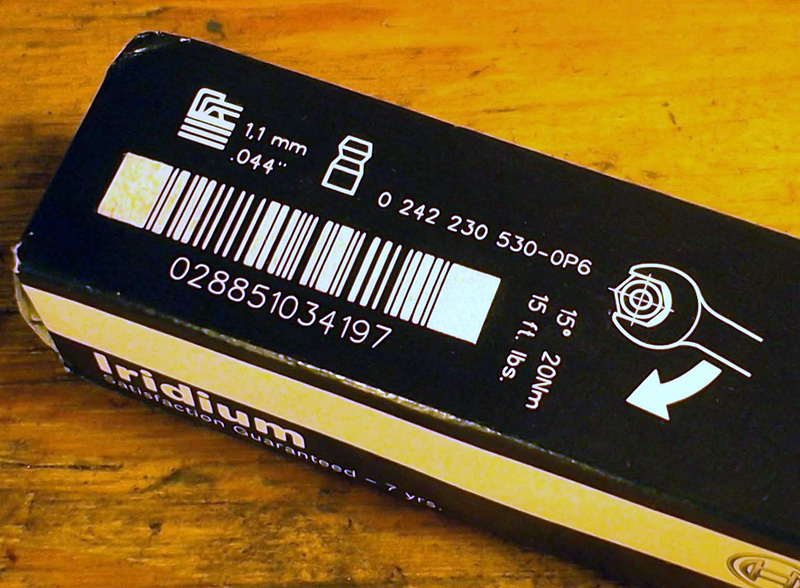

Might as well read the instructions on the box, although this one recommends a .004 in. larger gap than the service manual does.

If you’re approaching senior citizenhood, you may remember when plug threads were usually 18mm in diameter, and the hex was 13/16ths. That evolved into 14mm and 5/8ths. Real estate in the combustion chamber is at a premium now with multiple valves, direct injection, and precise engineering of the flame front, so it’s not going to stop there. Rich Keller, Champion’s Director of Ignition for Product Engineering, tells us, “There’s going to be a trend over the next three or four years of M14 going to M12.” “Because of direct injection and other factors, I see M10 coming,” Mark Wilkinson, Group Product Manager for Robert Bosch North America, says.

Gap growth is supposed to be minimal with fine-wire-electrode platinums, but this one from an ’08 GM 3.6L was almost .010 in. larger than stock after only 44K miles. So, by 100K the big voltage requirement would be overtaxing the ignition system.

Throughout the automotive age, electrode erosion that widened the gap and rounded the corners, which makes it harder for spark to form, was a challenge. In fact, the main reason ’48 Chryslers got the first resistor plugs was to lessen electrode wear. Slowing down the juice cut out some of the surges that normally occur (the spark may quench and reform several times). Of course, they became more important for reducing radio interference.

Wire fire

A great deal of metallurgical research also went into developing electrode materials, which resulted in hard alloys that resist erosion, and even encapsulated copper on the ground side to carry heat away. That’s pretty much old hat today given the wholesale switch to the premium precious-metal fine-wire type. With a center electrode typically just over a millimeter in diameter, compared to a traditional 2.5mm, they’re supposed to improve starting, reduce fouling, and just generally perform better because they have a lower voltage requirement and reduce quenching.

Fine, but what about the typical 100K-mile replacement interval and gap growth? The Bosch Iridium box states “4X Longer Service Life” (and “Satisfaction Guaranteed for 7 yrs.” — ?). That can’t be referring to 400K miles, can it?

We at Master Technician have two big problems with the nearly-ubiquitous factory-recommended 100K-mile spark plug replacement interval (and with extended service intervals in general, but that’s another story). We just encountered an example of the first problem yesterday. We pulled the plugs out of an ’08 Pontiac Torrent GSX 3.6L V6 with 44K miles on it. The stock gap was supposed to be 0.040 in., but they all measured 0.048 to 0.050 in. At that rate of widening, they’d be up around 0.060 in. by 100K, which would raise the voltage requirement enough to put a substantial extra load on the ignition system. This reminds us of something an engineer said to us years ago: “With DIS, for example, you’re looking at about 27,000 volts as normal. Factory training is really teaching a misconception when it tells technicians the system can generate 100,000. Sure, it can do it, but it’ll blow itself up in the process.”

Screwed

As slow and careful as we tried to be, as much penetrant as we applied, and as many times as we turned it gently in and out, we still wrecked the aluminum head threads in this case. It had just been in there too long.

Problem #2 with the 100K-mile recommendation is the dreaded thread seizure issue, which brings us to thread plating and the use of anti-seize compound. “We use a zinc plating that’s also a thread lubricant, and a plastic acrylic resin that has a slow thermal decomposition,” Keller says. Wilkinson tells us, “There are basically three types of coatings: black oxides, zinc — which is sometimes called trivalent chromate — and nickel. Most OEMs prefer nickel, and it holds up well in salt-spray tests, so that’s what we use.”

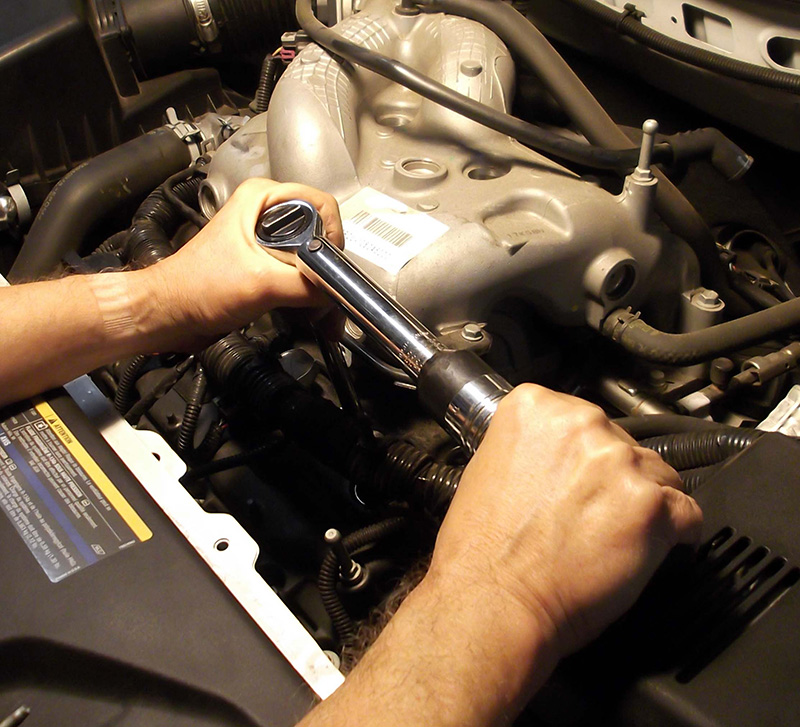

You can tighten tapered-seat plugs 15 degrees after contact if you want, but we prefer to use a torque wrench — 20 Nm in this case.

While neither of those experts thinks much of black oxide, they’re both okay with zinc and nickel, saying that they’re good enough today that you can do without anti-seize. They’re not dead-set against it, though, as long as you apply it very sparingly so that it doesn’t drip down on the business end, and adjust your tightening technique. Keller says, “The torque value is intended for clean, dry threads. If any kind of lubricant is used, tighten to below the low side of the spec or you’ll risk distorting the threads and the shell, perhaps to the point of a seal failure.” “We say in our service literature to reduce torque by 30% if you use anti-seize,” Wilkinson tells us. “Otherwise, you might stretch the housing to the extent that you break the gas seal.”

Why did you wait so long?

Here’s the now-famous Champion one-piece 7989 that addresses the two-piece O.E. plug separation problem in Ford Triton 4.6L, 5.4L, and 6.8L V8s. Meanwhile, get those originals out ASAP (courtesy Federal-Mogul).

Our opinion? Well, we never allow motorists to go over 60K on a set of plugs if we can in any way prevent it, so the point is mostly moot for us. We hate gritting our teeth and putting a pipe on our ratchet handle, spraying penetrant and waiting and hoping, or heating and candle waxing. That combined with the gap growth mentioned above has convinced us that we’ve saved a lot of people serious money by pitching that much more reasonable interval. New plugs are cheap, after all, while engine work and electronics are anything but. Wilkinson adds, “Stressful environments, such as are caused by turbocharging and direct injection, may mean plugs will have to be changed more frequently than every 100,000 miles.”

A related issue is the Ford Triton 4.6L, 5.4L, and 6.8L engines with the high-thread plug. “The original equipment spark plug was a two-piece design with an upper shell and a lower shell,” Keller says. “When there was carbon seizing, the bond would break and the plug would come apart [we saw one break at 35 ft.lbs.] So, we came up with a one-piece shell that won’t do that.” More justification for 60K.

We’ll conclude with a couple of observations:

- Wilkinson tells MT, “Some techs have a tendency to think it’s best to put the same brand back in that the car came with. They might say they only put ACDelco in a GM, for example. Well, ACDelco doesn’t actually manufacture plugs anymore — it closed its plants — but has them made by other big-name companies.

- We well remember platinums for Porsches costing about eight bucks a piece in the mid‑’70s (there’s been a lot of inflation since — that would be almost $32 in today’s dollars!), but now new designs and heavy competition have driven the price of premiums way down.

- In our humble opinion, high‑tech systems make regular spark plug replacement more critical, not less. And in spite of complex electronic engine controls, plugs are still the first things to suspect when you’ve got a hard‑starting, performance, or emissions problem.

Â

The increase in gap over mileage would not necessarily be linear. As the gap increases, the resistance and hence the voltage would increase accelerating gap wear. Gap wear is not the only problem though. Plug contamination of deposits from inferior fuel quality, infrequent oil changes and otherwise poor maintenance or driving habits are other factors that can affect even the most well engineered and perfectly installed spark plug. Every couple of years or 30 to 40K miles would be good. Plus, it gives a good technician an insight to the internal condition of the engine.

good info.. never understand why someone would neglect relatively simple maint. but…..dealer recommendations for service intervals do make us lazy, that’s why our cars run better/faster…… we don’t believe what we read..

I had to chuckle when the fellow said he could forsee M10 plugs coming…. those I have on the shelf. The standard size of the vehicles from the 40’s is M10!

the reason you wrecked the aluminum head with your spark plug is ,you have a head gasket leak the antifreeze peens the threads on the plug so when you try to take it out it takes the thread with it

Great article…It always amazes me how vehicle owners will skimp on maintenance!…over the last 40+ years..I’ve seen a lot of changes..and the biggest is the trend in the last couple of decades, its the move to private vehicle leasing…”Back in the day”, only company leasted vehicles…and maintained them accordingly…but then came private leases…people started “borrowing” their cars…Zero maintance, as they were driving something twice as expensive as they could afford,so how to pay for maintance?..then when it was resold from the used car store..it was advertised as “Fresh off lease” & falsely claimed to have everything as new..so the next guy puts another 2/3 years worth of use on the thing..then when it starts having problems..they come into my shop & I get to tell them that the timing belt broke & bent all the valves,cause it had never been replaced…or the head has to come off,as the plugs are original..It gets worse, because Everyone wants that 2-4 year old luxury car..and can’t afford to put gas in it! let alone do preventive maintenance.If I had a Dollar for every time I’ve heard: I’ve done my maintenance…I took it to fast lube last week! I remember when seeing a BMW or a Benz..was a rare occurrence…now they are in every driveway..with bald tires & dime store brake pads!..

Just my Grumpy old Opinion!

Good info.I’ve ran across a few of the Tritons that needed rethreading.100K plug change,I Agree With ur Analogie,the one seen at 100K plus u could drive a trk thru the gap!I started recommending to the customer change them sooner so. As to save repair,time,and money.

60k… I don’t know on some of this anymore. ive pulled out plugs with 154k and they looked brand new with correct gap very much intact. more shocking, I recently pulled out plugs out of a 2002 2500 with the LQ4 with 275k, it still had the original plugs!!! whoever makes ac delco plugs does a hell of a job!

Thanks for the information! Now please excuse me while I go change my spark plugs!

fyi, NGK makes spark plugs for ACDELCO. Some Delcos are made by Champion [mostly the older ones] AC stands for Albert Champion. He started his own company. Auto lite makes plugs for Ford Motorcraft. Bosch makes plugs for euro cars. [ keep it that way ]. -just some trivial facts that a tech should know……Ernie

>fyi, NGK makes spark plugs for ACDELCO. Some Delcos are made by Champion [mostly the older ones] AC stands for Albert Champion.

UGH.

NGK makes *some* Delco plugs. They’re clearly marked as NGK on one side and DELCO on the other side.

Champion doesn’t make anything for AC Delco. They are entirely different companies and have nothing to do with one another.

https://en.wikipedia.org/wiki/Albert_Champion_(cyclist)

Autolite manufactures Motorcraft spark plugs. Decades of experience have taught me that Autolite plugs are far inferior to Motorcraft plugs.

Bosch makes plugs for all kinds of cars. They’ve been making OEM replacement plugs for American cars for at least 35 years.

Very informative thanks