Satin Doll: The 650i Gran Coupe in the BMW Individual Frozen Bronze Metallic color shows off with a slightly higher gloss level than typical matt finishes.

Since its 2010 introduction when the full annual production – all 30 units – of the new M3 Frozen Gray Edition sold out within 12 minutes of becoming available, BMW has known it has a hit with its new frozen paint finish. The luxury carmaker has introduced more models featuring the matt (you’re probably used to seeing this word spelled “matte,†but all BMW literature has it without the “eâ€) Frozen finish each year. Now called “Individualâ€, as befits the unique aesthetics of the elegant finish, the matt paint option has been expanded to the BMW M5, 6 Series Gran Coupe, and the 7 Series.

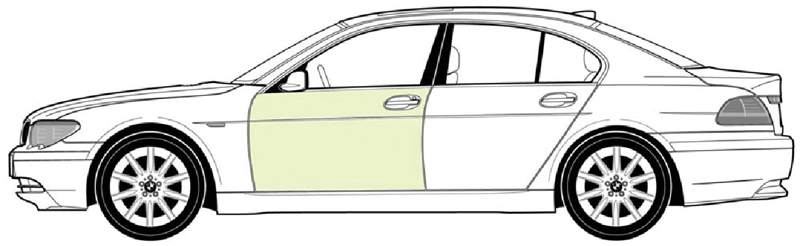

There’s obviously a trend afoot here that will logically result in your seeing this sophisticated BMW matt finish in your collision shop sometime soon. This article will familiarize you with the basics, and perhaps give you the confidence you need to tackle repainting on these striking vehicles.

The BMW Individual Frozen Bronze Metallic matt finish plays with light, reflecting here, absorbing there, to accentuate the 640d Gran Coupe’s fluid lines and understated muscularity.

As a starting point, it’s important to understand that a matt finish such as used on the BMW models mentioned only reflects about 20% of the light that hits it. The rest is diffused to the point that there is no discernible reflection on the surface. You can’t comb your hair or straighten your tie by looking at yourself in a matt-finished panel. While BMW’s Frozen paint isn’t as absorptive as that of a stealth bomber, it’s in that direction. In contrast, traditional gloss paint reflects over 90% of the photons that strike it.

Where it happens

Satin Doll: The BMW Individual 7 Series by Paris-based designer Didit Hediprasetyo in Frozen Diamond Metallic finish shows off a sophisticated, slightly higher gloss level than typical matt finishes. Production was limited to only five of these ultra-luxe models when it was introduced in 2012.

The above might make you think that this phenomenon occurs deep in the finish layers, but the opposite is the case. The effect is achieved in the clearcoat only, so your experience with basecoat application will still be valuable in your work.

The unique look is obtained by the use of different hardeners, reducers, application methods, and drying options. The factors are what make the clearcoat actually absorb more light than traditional paint finishes, but although the finish has a lower sheen, it still meets the same durability standards for protection against stone chipping, corrosion formation, bird droppings, tree sap, and other environmental hazards as non-matt coatings.

After applying the Frozen paint clearcoat, any final coating errors cannot be buffed out. No matter how diligently you might try, you’ll never get a uniform, even level of sheen. Dirt particles, mottling or striping due to improper spray technique, variations in film thickness, and other visible defects require complete repainting of the final topcoat. For this reason, BMW strongly encourages the use of the procedures and materials recommended by matt paint system manufacturers.

Beyond formula into artistic judgment

Three color “Letdown Panels†receive a clearcoat application. They won’t look different until the clear has fully cured. That’s because the basecoat is the same for each panel. The color differences are entirely the result of different clearcoat mix ratios. Letdown Panels are absolutely critical to match both color and gloss level to a matt finish vehicle. Prepare several Letdown Panels, each featuring different mixing ratios of matting agent and clearcoat, and distinct wetter/dryer spraying methods.

Of course, the paint manufacturer’s recommended mixing formula is important. Even minor deviations from the specified ratio of hardener and reducer to the clearcoat paint itself will lead to significant changes in the level of “matting†(gloss reduction).

But matching a matt finish is more than just formula numbers. It requires careful visual inspection. You must pay attention to both color and gloss level. Different areas of the vehicle body may require different gloss levels. Film build can cause a color shift if painting over OE clearcoat.

Additionally, the gloss level for the vehicle being painted may have changed due to its age and cleaning history. This may, for example, necessitate painting the entire side of a vehicle instead of just the damaged panel in order to produce a matched gloss appearance on that side.

Evaluate Letdown Panels while they are attached to the surface to be painted. Compare the color and gloss level of the three test panels to that of the vehicle, all under the same light angle and intensity.

Other factors affecting the degree of gloss in your finished job include whether the hardener and reducer are slow- or fast-acting, whether you use a relatively dry or wet spray method, dry film thickness, ambient temperature, flash-off time, and drying method. Different combinations of these factors can alter gloss level by up to 20%.

This variability makes color/gloss “Letdown Panels†mandatory. After looking up the color formula recommended by the matt paint system manufacturer, spray at least three test cards with different ratios of matting agent (flattener) and clearcoat.

After drying (colors will appear significantly darker when dry), compare each Letdown Panel to the vehicle, and evaluate both color and gloss level. Check in natural daylight. Hold the card against the vehicle surface to ensure that your viewing angle and light source are the same as for the area being repaired.

Once you determine which Letdown Panel best matches the vehicle, you’ll know which combination of hardener ratio, fluid tip size, and ambient temperature range yielded that match. You’ll know exactly how to refinish this particular vehicle.

Letdown Panels are not new. Professional painters already use them with many tri-coats and pearl finishes. The little extra preparation allows you to paint with confidence.

Spray consistency is key

Matt clearcoats flash off faster than those of traditional gloss paint, so you must maintain a wet edge as you spray. Experiment with the amount of overlap in each spray pass.

“Mottling†describes a finish that looks streaked, spotty, or striped. It is often the result of an unbalanced spray pattern, or not observing the proper flash time between basecoat and clearcoat. For example, if one pass is heavier than the others, that area may appear glossier after curing. Try to spray so that you maintain a wet edge, but that no single pass is heavier than the others.

Tilting the spray gun can place more paint at the top or bottom of the pattern, making film thickness uneven in that area. If you paint while too tired (don’t expect sympathy from the boss), you may inadvertently allow your arm to drop while spraying. This tilts the spray fan up, resulting in more paint being deposited on the bottom portion of the pass than at the top, and, bingo, you’ve created a horizontal stripe in your finish.

Experiment with overlap. If a 50% overlap leaves light streaks between passes, try 75%. Be sure to maintain consistency with each pass.

The BMW ColorSystem refinish manual recommends applying color and matt clearcoat edge-to-edge on a damaged panel. Differences in the age of the factory paint and any spot refinish would make the repaired area reflect light differently. Does the phrase “stick out like a sore thumb†sound like anything you want to hear from your customer?

To further reduce the appearance of striping, spray in two different directions in the same coat. After you’ve completely covered the panel with horizontal passes, cover again in that same wet coat using vertical strokes.

You can also help prevent mottling by using the correct spray gun settings (needle/nozzle/pressure), holding the gun perpendicular to the surface being sprayed, and following the matt paint system’s recommended flash and dry times.

No after-painting corrections allowed

All manufacturers of matt paint systems recommend edge-to-edge application of matt clearcoat on panels being repaired. Differences in film build, original paint aging, cleaning history, and other factors make a spot repair likely to reflect light differently from the way surrounding areas do. The blended section stands out, which is by definition unsatisfactory with matt or flat finishes (or with any paint repair, for that matter).

There can be no de-nibbling or polishing of matt or flat finish topcoats. Any rubbing or polishing to eliminate imperfections will increase the gloss level in the area where mechanical pressure is applied.

Dirt can be removed at the basecoat stage, or after the first coat of clear has flashed off. If inspection reveals any dirt in the final clearcoat, the job must be re-prepared, and the full repair area clearcoated again.

Regular or extra-crispy?

Matt finishes are either baked or air dried. Oven-dried finishes may have slightly more gloss than those that are air-dried, so be sure to follow the paint manufacturer’s drying recommendations. A collision repair instructor with BMW NA tells tbp, “Infrared curing is more complex than traditional spray booth drying. The most consistent, best quality results are achieved with convection drying in a spray booth.â€

Similarly, be careful not to spray your clearcoat too wet. A heavy spray may leave too much solvent remaining during the curing process, which prevents gloss die-back to the proper level for the desired soft matt sheen.

You won’t be able to tell if you have too much gloss until curing is complete. The clearcoat goes on glossy as traditional finishes do, then dries flat. By then, if you notice too much gloss it is too late for anything but a removal and re-spray of the last clearcoat application.

Pay attention to the paint manufacturer’s recommended flash-off and drying times. These companies invest a lot in research and field testing to make sure that their recommended mixing, spraying, and curing techniques produce the best finish.

Adjusting the Degree of Gloss of Matt Clearcoats

(source: Spies Hecker)

Factors Affecting Degree of Gloss |

|

HIGHER GLOSS LEVEL |

LOWER GLOSS LEVEL |

| Hardener with higher solids content | Hardener with lower solids content |

| Slower hardener | Faster hardener |

| Slower reducer | Faster reducer |

| Higher application viscosity | Lower application viscosity |

| Thicker dry film | Thinner dry film |

| More flash-off time | Less flash-off time |

| Force drying | Air drying |

Final exam

The final matt finish should have a uniformly low gloss. The surface may appear on close inspection to have small patterns and a slight texture, but these are normal matt-finish characteristics.

Looking down on the hood and then across the roof from the same standing position, the gloss level of the two different surfaces will appear different even if they are not. Viewing the surface at approximately 60 degrees reveals less gloss than at a flatter angle. To judge gloss level, try to view an entire side of the vehicle at a consistent angle. Do the same for all horizontal surfaces. When you get it right, seeing that classy matt finish you just applied will make you proud.

The plug-in hybrid BMW Concept Active Tourer presented at the 2012 Paris Motor Show features exterior surfaces in high-gloss polish with brushed velvet matt on the undersurface. The subtle shimmering between matt and gloss emphasizes the play of light and shadow created by the new exterior finish.

Photos courtesy of BMW NA and DuPont.

0 Comments