BMW has always been a company that leads the way with technological advancements. One important development was the Mechatronic transmission. It’s been installed in many models, so we need to be more familiar with its do’s and don’ts.

![The plastic transmission oil pan should be one of the tips that let you know you are working on a Mechatronic transmission. Do not remove the pan when the transmission is hot as it can become distorted as it cools. Also, use a torque wrench when reinstalling to prevent over-tightening and cracking.] The plastic transmission oil pan should be one of the tips that let you know you are working on a Mechatronic transmission. Do not remove the pan when the transmission is hot as it can become distorted as it cools. Also, use a torque wrench when reinstalling to prevent over-tightening and cracking.]](https://automotivetechinfo.com/wp-content/uploads/2013/08/Mechatronic-ID.jpg)

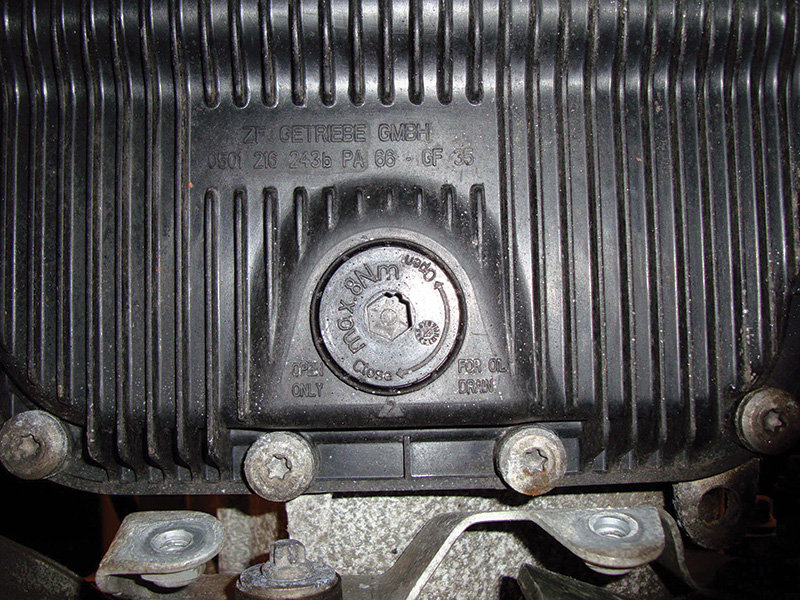

The plastic transmission oil pan should be one of the tips that let you know you are working on a Mechatronic transmission. Do not remove the pan when the transmission is hot as it can become distorted as it cools. Also, use a torque wrench when reinstalling to prevent over-tightening and cracking.]

There are many reasons BMW pushes the envelope of technological development. Sometimes it’s for ease of manufacture, but mostly it’s to improve the driving experience. Increasing government regulations on emissions and fuel mileage also prompt development, and this is nowhere more true than with the automatic transmission. BMW engineers decided that one of the best ways to lower emissions and increase average fuel economy was the redevelopment of the automatic transmission. This blossomed into the implementation of the new Mechatronic transmission BMW co-developed with ZF. It represents some significant innovations such as an internally-mounted EGS control unit, shift-by-wire, and an electronic parking lock, to name only a few. These transmissions have been around since 2002 — over 10 years! — and now require service. We need to become more familiar with what is possible and what is not when attempting to diagnose, repair, and service these units. This information will lead to more cost-effective repairs for the customer and more profitable service work for you. First, let’s go over how this transmission works.

Mechatronic 101

You can drain the fluid by removing this plug. Don’t over-tighten past the marks on the plug as you can crack the housing and cause a leak. If you are changing the fluid, save and measure it so you know how much to put back in. BMW recommends only its own transmission fluid for these units.

When drivers enter a car with a Mechatronic transmission, they insert the ignition key and attempt to crank the engine with the push-to-start button. The DME control unit is in control of the Integrated Supply Module (IVD), which contains the two relays that activate the starter motor. The DME looks at the EWS (for a theft condition), the CAS module for the start request, and the selector lever setting. The DME will only operate the starter relay if it can verify that the vehicle is in Park. This is done through the PT Can bus. The EGS control unit tells the DME control unit that the transmission is in Park or Neutral, and the engine is allowed to be cranked and start. There is also a redundancy feature built into the control units for safety reasons. A signal wire connects the EGS module directly with the CAS. The EGS control unit supplies battery voltage to this wire to allow the engine to crank. Both of these systems need to function if the engine is going to crank and start. Keep in mind the brake switch input needs to show that the brake pedal is applied to allow the engine to crank and to release the park lock as well, but in this article we are more concerned with the transmission gear position. More on this later.

Now that the engine has started, the driver will want to put the vehicle in drive. The driver’s input is the gear selector lever mounted on the right upper side of the steering column. The gear selector lever is directly connected to the steering column module (SZL), therefore the commands are input directly to the SZL. The SZL passes on these messages through the Byteflight CAN protocol to the Safety Information Module (SIM), and then on to the Central Gateway Module (ZGM). The ZGM converts these signals to the PT Can protocol and sends the information to the EGS control unit. Each of these busses must communicate properly to allow these messages to get where they need to go. Once again, there is a redundancy feature built in. There is a direct serial data line from the SZL to the EGS control unit carrying the same information that passes through the various CANs. In an effort to reduce wiring and complexity, the EGS control unit is mounted inside the transmission and attached to the valve body. Only power supply, ground supply and CAN wires need to be connected to the gearbox. This eliminates the power and ground wires required to operate the solenoids and wiring for the various sensors found in the transmission such as those for temperature, shaft speed, and gear position.

Now That We’re Moving . . .

The Mechatronic control unit plug does not need many pins since most of the wiring is internal. Here we have the power supply, ground, and CAN data lines. Make sure the plug is not leaking. If it is, you can replace it.

Like any other EGS system, BMW has developed the Mechatronic control unit to look at the requested gear position, transmission fluid temperature, actual gear position, and input and output shaft speed signals, and calculates which shift and pressure control solenoids to energize and de-energize, as well as when to operate the Torque Converter Lock-Up solenoid. It also evaluates inputs coming into the PT CAN such as engine load and accelerator pedal position. The Mechatronics unit has three shift solenoids and six pressure control solenoids. Of the six pressure control solenoids, three open and three close with current applied. You can monitor the current control and activation of these solenoids even while the vehicle is being driven with your older GT1, or with you new iComm diagnostic tool. Actually servicing these units is another matter. The electrical components mounted in the transmission are not serviceable as of this writing. If you have diagnosed a bad Mechatronics control unit or a bad solenoid or sensor, you need to replace the entire Mechatronics control unit, valve body, and solenoid assembly. You can replace the entire transmission if clutches are worn and slipping.

There are services you can perform other than just replacing the entire transmission. For example, BMW recommends that the transmission fluid be replaced at 100,000 miles. BMW offers a kit for this that includes a pan gasket, filter seal, and transmission fluid that is specific to this application. You should not substitute aftermarket transmission fluid in these units. The correct fluid to use is the Shell M-1375.4, which you can purchase from your BMW dealership parts department. It will take nine to 10 liters to do a complete flush of the system. BMW has not approved any aftermarket transmission fluid, and there is a chance that internal components will be damaged if you make such a substitution. If you need to drain the fluid to perform other service work, there is a convenient drain plug. Be careful not to over tighten it — the pan is plastic and may crack. Also, you tough guys out there should not try to remove the pan while the transmission is hot. The pan is plastic and will warp as it cools without the support of the transmission case. You may want to replace the pan, which has the filter and debris magnets built into it.

Other Service Possibilities

Front transmission oil pump seals and rear output shaft yoke seals are available if you need to replace them to fix a leak. If you are going to pull the transmission to replace the front seals, it might be more cost-effective to replace the entire unit. If the electrical plug socket is leaking, it can be replaced separately. Ditto for the adapter seal between the Mechatronics control unit and the transmission housing. If this seal leaks, it can lead to shifting problems that you may think are in the control unit. It is not particularly labor-intensive to drop the control unit and replace the seal. A leaking seal can also prevent the transmission from going into Drive or back to Park, so it’s worth taking a look at.

Here is the seal that contains the pressure between the Mechatronic control unit and the transmission pump. If this seal leaks the transmission may have problems moving into and out of gear. It is one of the few serviceable items inside the transmission, so it is a good thing to replace if you need to pull the valve body down.

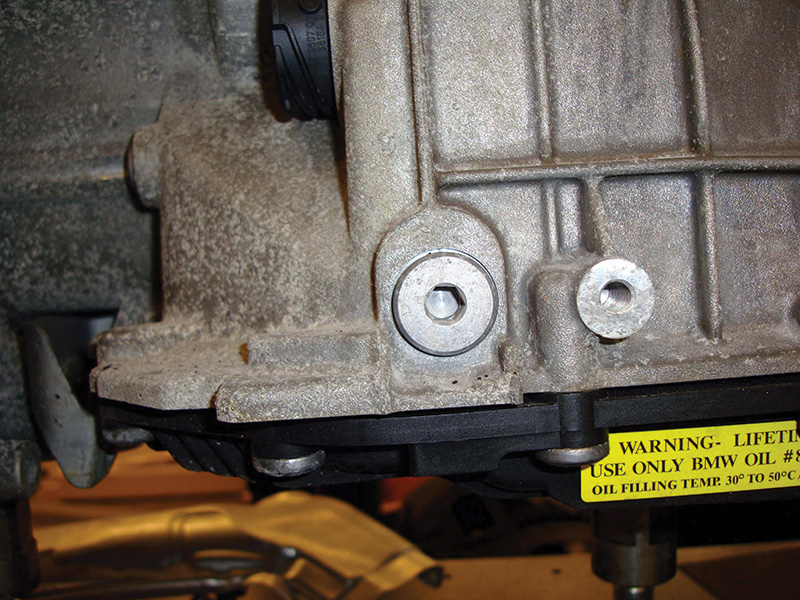

When you refill the transmission, you are going to need to check the fluid level carefully. This is not done with a simple dipstick and a rag anymore. With the engine running, move the selector lever through each gear to make sure all of the passages in the valve body are full of fluid. On the passenger side of the transmission housing toward the rear of the pan there is a fill/fluid level plug. With the transmission between 86 and 122 deg. F. (30 and 50 deg. — closer to the lower number is preferable), remove the plug. A small amount of transmission fluid should drip out of the hole. If not, add fluid through this same hole until it drips out.

This is the fill plug on the Mechatronic transmission. Keep in mind the transmission needs to be in a specific temperature range before you can remove the plug and see if the level is correct. Run the transmission through all gears before you check the fluid level. You will also need to fill the transmission at this hole. It will be near an exhaust pipe, so protect yourself from the heat.

Mechatronics control units have learning ability and will make adaptive adjustments to the pressure and time applied to the clutch packs. These are known as “adaptations” and can be reset with the GT1/iComm, or equivalent. Keep in mind that if you reset the adaptations, the control unit will operate as if the transmission were new and the clutch packs not worn. You may make the shift quality worse until the control unit “learns†the extra pressure and time required for proper shifts. If you need to replace the Mechatronics assembly or the entire transmission, you are going to need to code the unit to the rest of the vehicle. This can only be done with a GT1/iComm, or equivalent. This ‘marries†the control unit to the vehicle and the other control units. You will not be able to reprogram a used control unit to a second vehicle. The flow rates of the solenoids are special to each individual control unit. You should not swap components from one Mechatronics control unit to another for the same reason. You may get lucky, but it may lead to a shifting problem that will damage the transmission. The only option is either to replace the entire transmission depending on the mileage it has on it, or to replace only the Mechatronics control unit/valve body assembly.

When servicing these units, there are only a few bolts that need to be removed. Also, you have to remove the slide lock to separate the control unit from the outer plug. This will allow the assembly to be removed with the transmission in the vehicle.

Summing Up

Knowing what is and isn’t possible when diagnosing a transmission shifting problem will save you time and money. Your customers will appreciate the time you took to investigate the problem and inform them of their repair options. This is why they keep coming back to you.

0 Comments