by Henry P. Olsen, Manager of Ole’s Carb

The fuel supply system of any vehicle must be designed to deliver an adequate volume of fuel at the correct pressure to the carburetor(s) or fuel injectors during every operating condition at which the engine will be ever operated. This, of course, is especially important if you expect maximum performance from the engine, as in a street rod, or racing application. It is also important to design the system to keep the fuel as cool as possible in order to avoid vapor lock problems. Everything from the fuel tank vent system, the tank itself, the pump and the pressure regulator the lines, connections, and their routing must be selected and combined to work in concert to achieve your volume and pressure goals. If all this isn’t handled properly, the air/fuel mixture will shift lean or rich and cause performance to suffer.

Tank Venting

Here are the parts of a gas cap that permit venting — that is, allowing air at atmospheric pressure to enter the tank to replace the volume of fuel used. A stock cap may not flow enough for extended high-fuel demand conditions causing a vacuum to develop in the tank.

The tank vent system on any high-performance or race vehicle is often in the ½ inch inside diameter range, while the vent hole in the gas cap of a vintage car may have been as small as 1/16th inch. If the vent system is too small, the pump may create a vacuum in the tank, and this vacuum will make it harder for the pump to supply sufficient volume and pressure. A typical vented gas cap on a 1960s-era car has a vent restriction in the 1/16th to 3/32th inch range, small enough so that when the vehicle is driven at high fuel demand conditions for even a short time, supply will be insufficient.

The shiny depression in the cap gasket sealing surface of this fuel tank filler neck from a 1960s Ford is where air enters for venting. The surface sometimes wears flat over the years, thus reducing the vent area. You may need to do some grinding to increase the vent size, but do it with the filler neck off the car and far from the gasoline!

The evaporative emissions control canister system (EVAP) that has been in all cars sold in this country since 1971 is used to both eliminate the release of unburned hydrocarbons from the tank (and from the fuel bowl in the era of carburetors) into the atmosphere, and to allow air into the gas tank to make up for the volume of gasoline the engine is consuming. The charcoal canisters used in a pre-1996 OBD I vehicle have an air inlet filter that should be kept clean or periodically replaced since the EVAP system is continually purging as the vehicle is driven. The OBD II PCM of a ’96 and newer vehicle has a diagnostic routine programmed into it that will turn on the MIL (Malfunction Indicator Lamp, also known as the Check Engine Light) and set a fault code if it detects any problems in the system, such as a restriction or a leak.

Heavy pulling

With this early EVAP canister cut open, you can see the carbon/charcoal that is used to trap and store the fuel vapors from the tank. The canister also provides the venting function.

Many motorhomes and trucks that are used to tow trailers, or any vehicle that has had a high-performance engine transplant, may experience surging or a lack of power when they are driven under high-load conditions for an extended period of time. An example of this would be a heavy vehicle that loses power and begins to surge whenever it is driven up an upgrade that lasts over a mile or two.

The first thing to check in this situation is the tank vent system. An easy way to test for a venting problem is to drive the vehicle with the gas cap loose while duplicating the load conditions under which the problem occurs. If the symptoms disappear when this extra air is allowed into the tank, you will know to investigate the EVAP, or the vent in the cap.

An example of a vehicle we encountered that had serious trouble caused by insufficient venting makes the point. This high-performance kit car not only had power problems, but the customer also mentioned that it had “burned up†two or three electric fuel pumps. When the customer pulled up to the shop, we noted that the engine suddenly shut off on its own, then we heard a gurgling sound coming from the carburetor followed by a thump from the fuel tank area. It turned out that the gas cap, which had a 0.060 in. vent hole, was concealed under a decorative flip-top gas cap that was not vented. The gurgling we heard was caused by the vacuum that had built up in the gas tank sucking the gasoline back out of the fuel lines and the carburetor’s fuel bowl, and the thump was the tank popping back into its original shape once the vacuum dissipated. The electric pump was overheating because it was fighting against the vacuum in the tank and had little to no fuel passing through it to keep it cool. The problem was easily solved by providing a vent in the decorative cap.

Lines and flow restriction

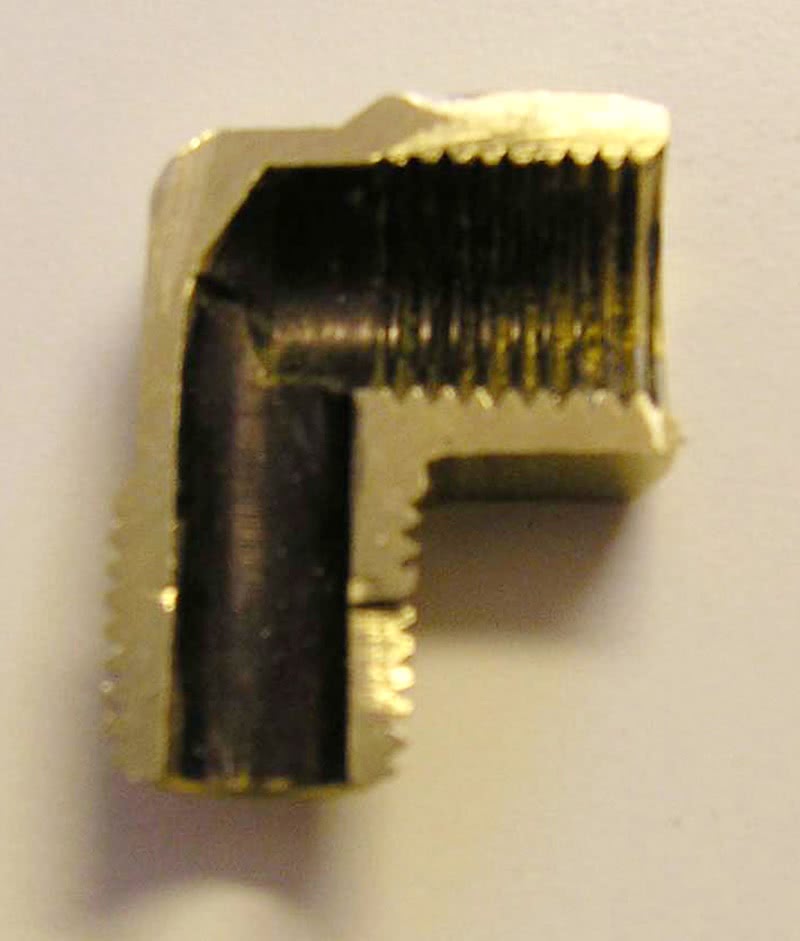

Whenever a liquid flows through a line, whether metal or rubber, the texture of the surface of the inner walls will set up turbulence and drag, resisting flow. In a vehicle, the length of the fuel line, any bends, the design of the fittings, and any in-line filters all add to flow resistance causing a reduction in both fuel volume and pressure under high-demand conditions. A fuel line inside diameter (ID) of 1/4 inch for a four cylinder, 5/16th inch for a six, and 3/8th inch for a V8 are good starting points for stock/mild-performance production engines, but a high-horsepower performance engine may require the use of a larger lines.

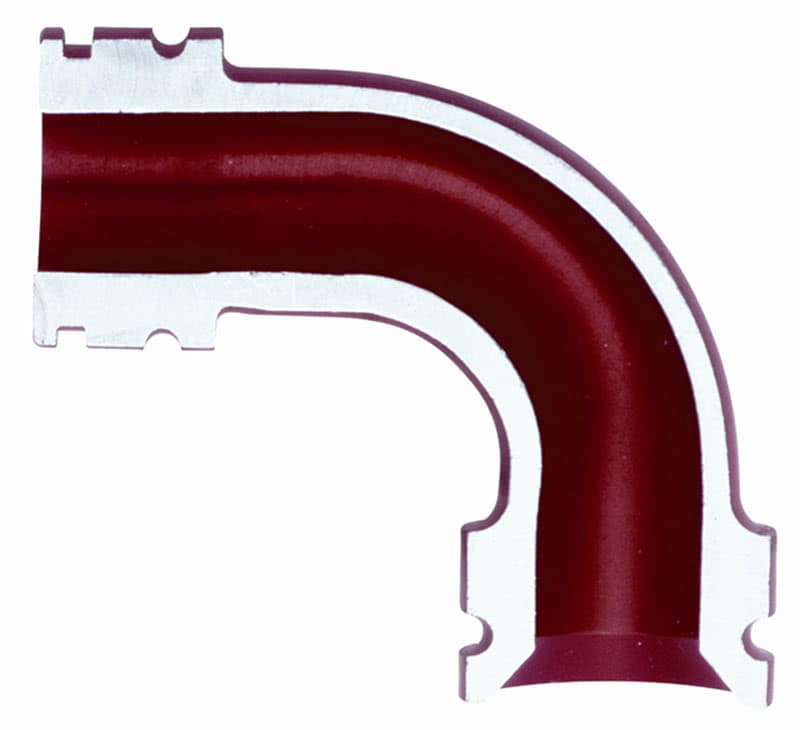

This Aeroquip fitting also bends the flow of gasoline 90 degrees, but is much less restrictive than a typical brass fitting. It’s similar to what plumbers call a “street elbow.â€

The fuel filter(s) must stop any contaminants from getting past without restricting free flow. As the filter gets dirty, it will become a restriction, perhaps causing a lack of power and/or vapor lock. The fuel volume and pressure that is available at the point where injectors are fed from the rail, or at the inlet of the carburetor(s) must be correct under all possible operating conditions.

La Bomba

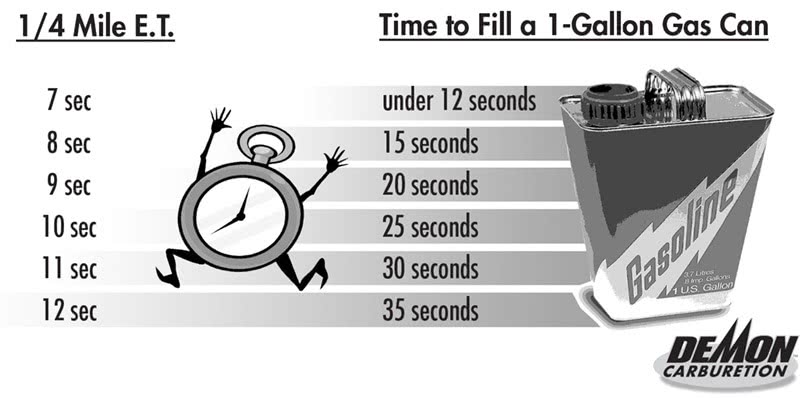

This chart from Demon Fuel Systems shows how fuel demand changes based on a vehicle’s quarter mile time.

The pump that is used in a production vehicle was designed to supply the correct volume of fuel at the proper pressure for most “normal†driving conditions and engine loads. If the vehicle has any performance upgrades, or if it is driven harder than its designers anticipated, you may need to upgrade to a higher-volume pump. The use of a high-performance electric pump mounted near the tank can help solve most of the low-pressure/volume problems that many owners of carbureted RVs/motorhomes/trucks experience while towing a trailer up a long uphill grade.

Most high-performance aftermarket fuel pumps are rated at “X†gallons of flow per hour (free flow), or in some cases the pump is also rated at “X†gallons per hour at “X†psi. The actual volume of fuel flow (when measured at the desired fuel pressure) that is available at the carburetor(s) inlet, or at the injectors, may be 50% lower than the free-flow rating of the fuel pump. This lower flow at actual operating pressure is due to both the operating losses that occur as fuel pump creates the desired fuel pressure and other factors such as the flow restriction of the lines.

Add up the factors that play into how much restriction the pump will be working against — line diameter, the length of the lines, the restriction of the line fittings, tank placement, and the vent system — to get the big picture of fuel supply. Most carburetor-equipped engines have a mechanical, camshaft-driven pump that “sucks” fuel from a tank that is in most cases mounted in the back of the vehicle, then force it a short distance to the bowl. A fuel-injected vehicle in most cases has an electric pump mounted in the tank that pushes the fuel forward to the injector rail.

These Shelby Cobra fuel pumps show how well-designed these cars were, and one reason why they won so many races.

When an electric pump is used on a drag car with a fuel cell mounted in the rear, the pump has to fight against another factor: the “G†forces created as the car accelerates — gasoline has weight, after all, and that means inertia. A drag car that runs the quarter mile in 10 seconds is accelerating so hard the pump has to force the fuel “uphill†to the tune of twice the force of gravity. Believe it or not, this will require a pump that puts out 25 to 30 psi in order to overcome the “G†forces (not to mention the resistance of the lines) and still be able to provide a minimum of six psi at the carburetor(s) throughout the quarter.

Whenever you’re working an electric pump, remember that it is voltage-sensitive — if you’re not getting full voltage to the pump, it’s not going to perform to capacity. There are also potential fuel inlet restrictions to consider. Think pump pickup screens/socks/filters. While a small amount of clogging here from contaminants such as dirt or rust flakes might not be noticed during normal driving, they might become significant during WOT (Wide Open Throttle) operation.

Needle and seat pressure

These fuel injector D-rails from Wilson Manifolds can be used to solve the problem of unequal fuel distribution on high-horsepower fuel injected race engines.

The pressure at the carburetor(s) should be constant under every operating condition so the float can maintain the proper level in the bowl. When the pressure is too high, the fuel level in the bowl will rise as the float tries unsuccessfully to close the needle against the seat. If the pressure is too low, the fuel level will drop because the float does not have to overcome the expected pressure that the fuel exerts against the needle and seat — flow will be shut off sooner and more easily.

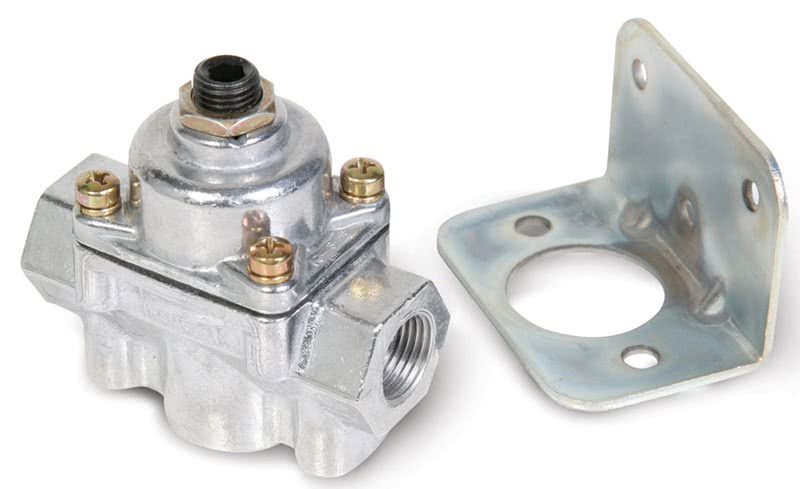

Most modern carburetor-equipped engines work well with fuel pressure in the 6 to 6.5 psi range, but this varies by the application. Many of the vehicles we have checked have had fuel pressure higher than factory specifications even with a new pump. We have also been seen vehicles that have intermittent high fuel pressure problems. So, we’ve been recommending the installation of a high-quality adjustable fuel pressure regulator.

A carbureted 4X4 may experience flooding problems with 6 psi of pressure when driven in bumpy off-road conditions because of a bouncing float. If the fuel pressure is lowered to 3 psi or so while it is beating through rough terrain, the flooding problems will be reduced.

A similar situation occurs on a carbureted street rod with a stiff suspension. We have performed experiments varying fuel pressure while using a portable 5-gas exhaust analyzer to observe air/fuel mixture changes. We were able to observe the mixture shift richer each time we increased the fuel pressure by 1/2 psi starting at about 5 psi. At 5-1/2 psi, the mixture would shift rich whenever the vehicle passed over a speed bump. When the pressure was raised to 7 psi, the slightest irregularity in an otherwise smooth road caused the mixture to go rich.

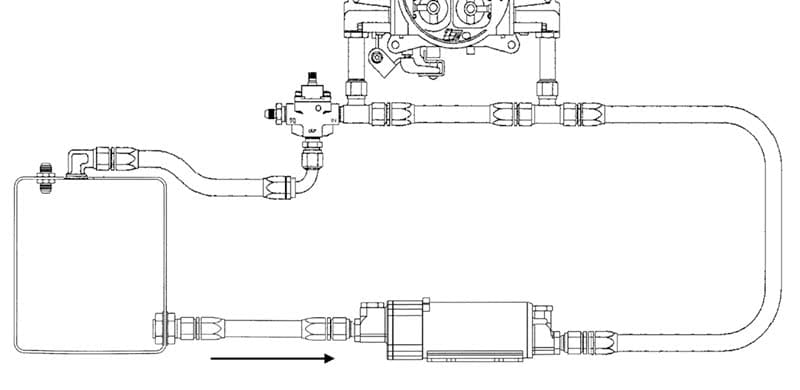

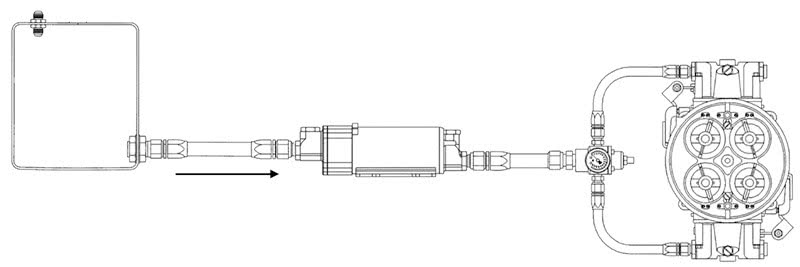

This Demon Fuel Systems drawing shows how a bypass system is plumbed. This can be used to help cure a vehicle with severe vapor lock problems.

EFI psi

This Fuelab unit bypasses excess gasoline back to the tank in order to help keep the fuel from overheating.

The pressure in an injected engine’s fuel rail must also be kept constant or the flow from the injectors will not be accurate. A flow bench such as the ASNU unit we use can show how the volume of fuel flow changes as the pressure is raised or lowered. Surprisingly, disc-style fuel injectors such as General Motors Multec units will actually begin to lose flow volume when the pressure is raised above about 50 psi because the electrical coil has to fight against the pressure in order to open.

Whenever you are building a high-performance EFI engine, the rail must be sized properly for the needs of high-flow injectors. An injector that flows 15 lbs. per hour range does not place the same demands on the system that a 60 lb. per hour injector does. When that big injector opens, it will cause the pressure in the rail to drop below an acceptable level unless the whole fuel supply system is designed properly!

Bubble block

Vapor lock in hot weather is becoming a more common issue with carburetor-equipped engines than it was in the past mainly because the reformulated gasoline of today is blended for use with EFI. Most modern fuel injected engines do not experience vapor lock problems because their fuel pressure is in the 35 to 55 psi range (higher pressure raises the boiling point of gasoline). The gasoline in a carburetor’s bowl is at atmospheric pressure, and the average fuel pressure at the inlet of a carburetor is 6 psi, as we said, thus the same in the line from the fuel pump. So, the fuel in the bowl will boil at a lower temperature (since it is at atmospheric pressure) than the pressurized fuel in the line from the pump. Regardless, boiling of gasoline in either the bowl or the lines must be avoided.

The normal cures of routing the fuel lines as far away as possible from heat sources such as the exhaust system and the radiator hoses will help most of the time, but if you have a problem vehicle you may have to redesign the fuel supply system. When we have a carburetor-equipped vehicle with a severe vapor lock problem, a fix we often use is a high-flow electric fuel pump installed near the tank with a bypass-type fuel pressure regulator mounted at or near the carburetor that returns the bypassed fuel back to the tank. This helps prevent vapor lock because the fuel is always circulating through the fuel system and does not get a chance to heat up as much. We also often recommend the use of an inline heat sink to cool the gasoline that is being returned to the tank.

0 Comments