In order to maintain emissions compliance, Mercedes-Benz engineers have to control the temperature range the engine will operate in and develop engine management parameters within this range. This may sound simple enough, but how do you accomplish this when the car might sit for an hour of traffic on a hot summer day, or cruise at highway speeds in the dead of winter?

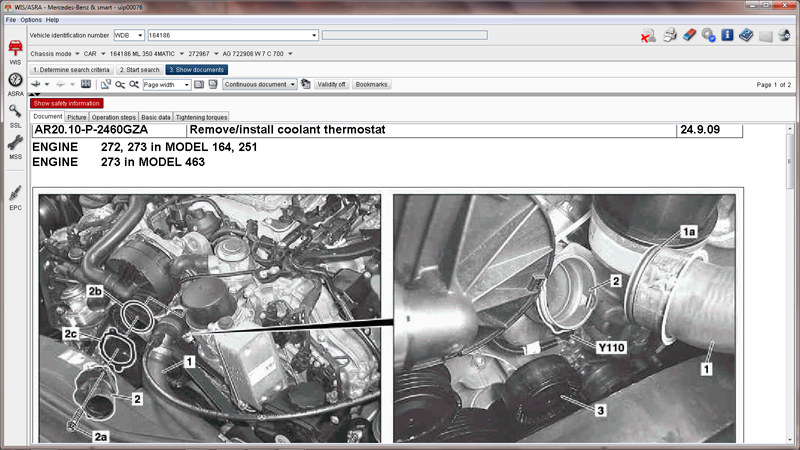

This is the e-thermostat location on a 221 chassis with the V12 engine. It is buried under the Secondary Air Pump motor and behind an idler pulley for the drive belt. WIS can help you with both testing and service procedures.

When most of us think of technological developments, we don’t think about cooling systems. We think about high-speed CAN data buses that allow the traction control system to work with the electronic throttle to rein in a vehicle. We may even think about fiber-optic systems that carry music, movies, and media for entertaining our passengers, and providing navigation. We think about electronically fuel-injected high-horsepower engines that still get 25 to 30 mpg.

Now think about a typical car being driven in a temperate climate that may sit for an hour in an urban traffic jam on a 100 deg. F. day. This same car may need to carry its owner to work in single-digit temperatures on a February morning. A car’s cooling system does more than just prevent the engine from overheating. It keeps it within the temperature range required to promote optimum efficiency and emissions control, and to allow long life for mechanical components.

Engineers design engines to work best within a specific temperature range. The engine management system uses coolant temperature as a reference for controlling fuel delivery and ignition timing. The pistons, rings, valve stems, bearings and other internal engine parts will have expanded to the tolerances that will maximize the life of all components. The cooling system’s job is to keep the engine operating in that temperature window as much as possible. Think of our example of a car being driven in traffic on a hot day. Most of the airflow over the radiator fins would be only what’s available from the cooling fans. So, the thermostat opens all the way to allow the maximum volume of coolant flow. On a cold day at cruising speeds, the heat load is low, and so is the temperature of the coolant in the radiator. The thermostat will close as its element shrinks, coolant flow is decreased. This is how engine temperature was maintained in its “Temperate Zone†for decades.

What’s an E-Thermostat’s Purpose?

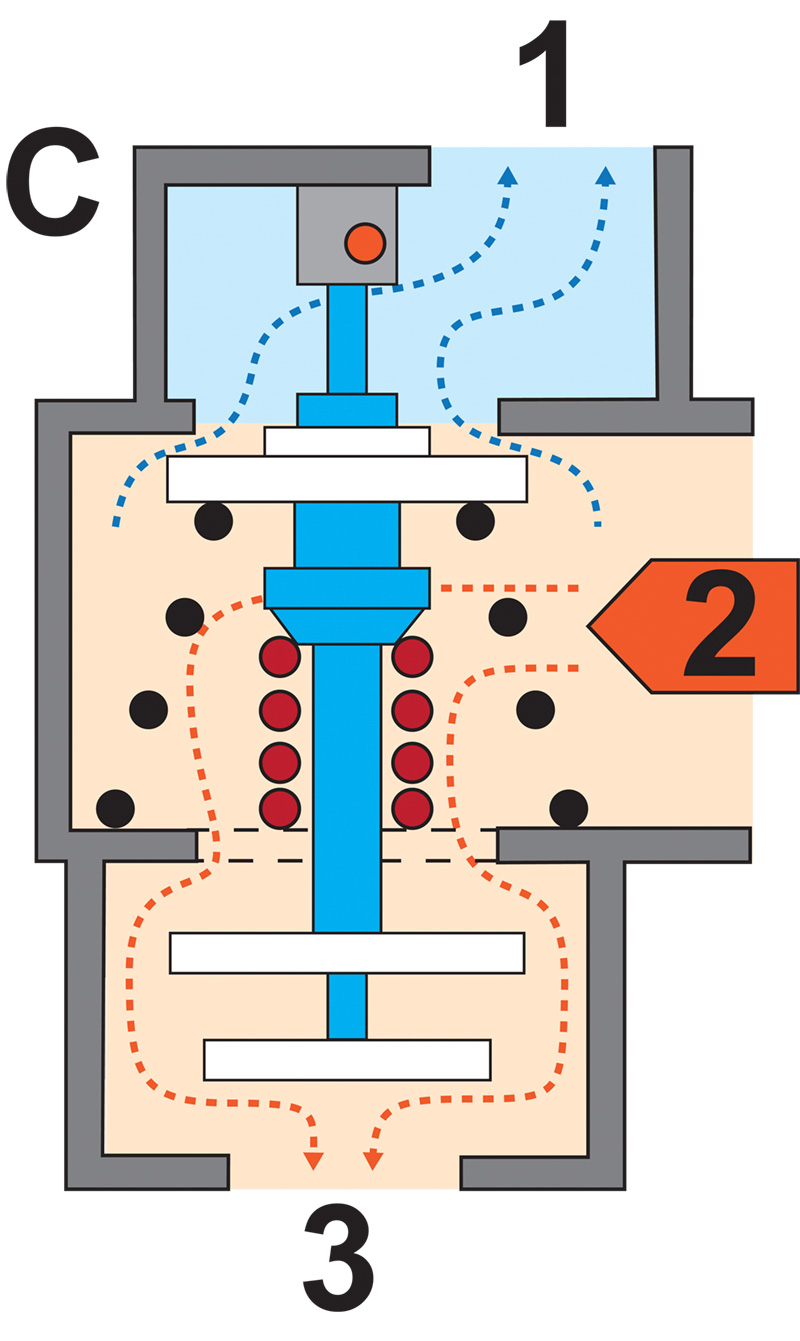

In phase 3, the engine control unit starts to energize the heater coil in the e-’stat and heated coolant from the engine block (passage 2) can either flow through passage 3 (to the water pump), or now to the radiator through passage #1.

To adhere to specific fuel mileage and efficiency standards, engineers needed tighter control of the engine’s temperature. For the M272 engine, Mercedes-Benz developed a more advanced thermostat that can control engine temperature accurately in multiple situations. It still functions like a traditional thermostat with an expanding/contracting element that opens and closes according to coolant temperature, but it has three disks (meaning the thin, round metal plates that alternately cover and uncover coolant passages) instead of the normal single disk to gradually step coolant flow, and a computer-controlled heating element. The three disks provide four different stages in opening the thermostat. Each stage regulates the coolant flow to match the cooling provided by the radiator and the needs of the engine. Any thermostat, even the “e-’stat,†has a fully closed position when the engine is cold to build up coolant heat quickly. Rapidly reaching normal operating temperature allows critical mechanical components to expand to their ideal working shape as soon as possible, and speeds the transition to closed-loop operation.

Think of the e-thermostat as having one single upper disk and two staggered lower disks. The upper disk directs coolant flow to the radiator, and the lower disks can either allow coolant to be split between the engine and the radiator, or totally block flow to the engine forcing all of the coolant flow through the radiator. During a cold start, both the upper disk and one of the lower disks totally block coolant flow allowing the engine to build heat rapidly. The heat of the engine coolant opens the first stage supplying the heater core in the cabin. In the third stage, the computer controls the current flowing through a heater element inside the body of the e-’stat. This assistance occurs on both a hot restart where the engine temperature reads over 208 deg. F. (98 deg. C), or after a cold start where the engine temperature is about 82 deg. F. (28 deg. C).

Use www.startekinfo.com to access WIS. This will give you all the steps needed to service the e-thermostat. Here, we have looked up the procedure on a 164 chassis M-Class with the 272 engine.

Â

You can measure the resistance of the heating element in the e-thermostat to see if it’s okay. A good one will have about 14.7 to 15.0 ohms at room temperature. The electrical connection is a little difficult to get to, so you may want to put your test leads across one of the wires that share the power supply and the pin on the ME control unit that grounds it.

When the ME is in Command

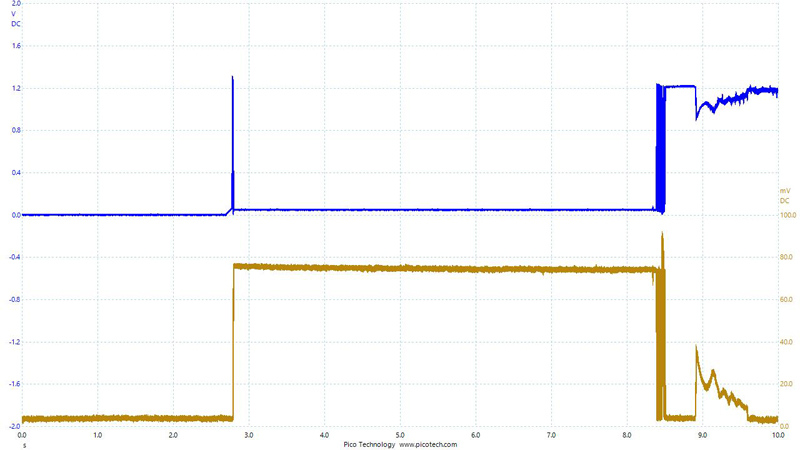

Here we are looking at the electrical control of the e-thermostat. The upper blue trace is the voltage signal. The lower brown trace is the amperage draw. Soon after a hot restart, the ME grounds the element for a few seconds and we can measure the amperage draw. If amperage draw is too low or too high, the e-thermostat has probably failed.

The ME control unit (aka the PCM for Powertrain Control Module, or engine management computer) can regulate the temperature between 185 deg. F. (85 deg. C) to 221 deg. F. (105 deg. C) while the engine is running. Above these temperatures, the ME commands the thermostat to block coolant flow back into the engine, directing all coolant flow to the radiator for maximum cooling. As you can see, with cooling temperatures reaching above 221 deg. F. (105 deg. C), and the boiling point of water being 212 deg. F. (100 deg. C), it is critical that the mixture of Mercedes-Benz extended life coolant and water be in the proper dilution ratio to transport Btus efficiently. The fundamental functions of the cooling system must be working properly for the e-thermostat system to be able to do its job. The water pump must still be capable of providing sufficient flow, and there cannot be any air in the system. When diagnosing and servicing these systems, do not jump to testing this new technology until you have done some basic checks, such as pressure testing.

It makes no sense to use anything but genuine Mercedes-Benz antifreeze for cooling system service. The current blue-dyed formula carries the part number BQ 1 03 0004, which is also designated as G48. It only comes full-strength, not pre-diluted.

The e-thermostat gets its voltage supply from power distribution components such as the front SAM. The ME controls the ground with a pulse-width modulated signal. It determines how much current should flow through the heating element using coolant temperature, engine speed, engine load, and vehicle speed as references. You can monitor the voltage signal and current flow directly, or you can monitor e-thermostat operation through Xentry software. While it is possible to test the element at the thermostat itself, in most instances it is difficult to get to and may require that some components to be removed. What may be easier is to measure the resistance, voltage and current at the ME. Looking at a wiring diagram available on www.startekinfo.com, you can identify the ground pin location at the ME and put your other lead on one of the shared power supply wires.

Stages

The ME controls the e-thermostat in three stages. It can leave the heating element alone by not providing any ground. Without a ground, the circuit is incomplete — there is no current flow and therefore no e-thermostat activity. Or, the ME can pulse the ground thereby heating up the element to a specific temperature and maintaining that temperature. It can also fully ground the element to allow maximum current flow, thus generating the maximum heat the element is capable of. You can monitor this circuit for voltage and amperage. As the wiring diagram shows, you should find battery voltage on the circuit when the ME is not grounding the element. When the ME starts to operate the e-thermostat, you may see your reading go directly to ground, or find a pulse-width modulated signal. Remember, the pulse-width modulated signal holds the e-thermostat in a static position to regulate the coolant flow between 185 deg. F. (85 deg. C) and 221 deg. F. (105 deg. C).

If you measure the current flow while the e-thermostat is being grounded, you should see about 7/10ths of an amp (0.7A). If you measure directly, the meter will probably average the signal over time so you will see less amperage while the signal is pulse-width modulated. You will have to wait for the engine to run long enough to fully ground the e-thermostat to measure the amp draw accurately. If you use a scope with an inductive milliamp probe, you can monitor both the voltage and amperage at the same time. Almost immediately after a hot restart, the ME operates the e-thermostat for approximately six seconds, during which time you can easily read the voltage and amperage. If you are using Xentry software to view the computer’s management actions, it will give you a data PID to evaluate the commands to the e-thermostat.

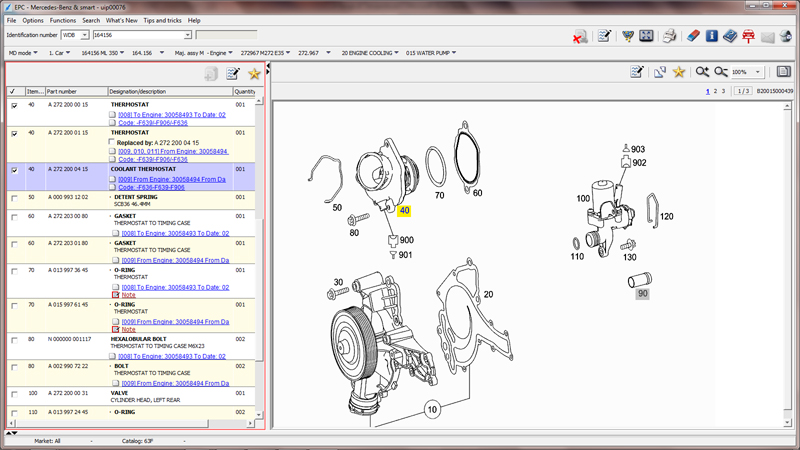

Use Mercedes-Benz EPC to assist you in identifying the proper part. While you should always trust the knowledge of the parts man at your local dealer, EPC will help you identify other parts you may want to replace during the job, such as a new electrical connector if the old one was damaged.

It’s Still a Cooling System

As mentioned earlier, every other aspect of the cooling system must be functioning properly for the e-thermostat to be able to do its important job. If you’re doing a flush and refill as maintenance, or whenever you’ve done any major cooling system work that required draining, it’s recommended that you use coolant exchange equipment. Not only is it a lot faster and neater, it does a much better job of completely flushing the entire system, eliminates trapped air that can cause various troubles, ensures a complete fill, and even helps you find leaks. By the way, the e-thermostat has a check ball to allow air to pass through it during the filling.

Of course, to keep the cars in your care trouble-free, always follow the cooling system maintenance intervals stated in the Owners’ Manual or on WIS to the letter, and use only genuine Mercedes-Benz antifreeze for top-ups and refills.

Knowing how a system functions and what you can do to service it is what keeps your customers coming back. By purchasing genuine Mercedes-Benz parts from your dealer you have a partner in the maintenance of your customers’ vehicles who not only supplies properly-engineered parts, but also offers the best warranty in the industry. Who wouldn’t want a partner like that?

0 Comments